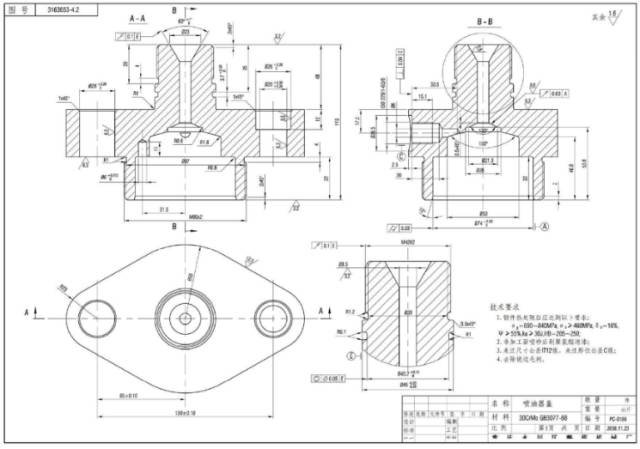

IiMfuno zobuGcisa kwimizobo yoomatshini equlunqwe liqela le-Anebon iquka olu luhlu lweemfuno ezisisiseko zilandelayo:

1. Iimfuno zobugcisa ngokubanzi

2. Imfuneko yonyango lobushushu

3. Imfuneko yokunyamezelana

4. Icandelo leengile

5. Imfuneko yeNdibano

6. Imfuneko yokuphosa

7. Imfuneko yokwambathisa

8. Iimfuno zemibhobho

9. Iimfuno zokulungisa i-solder

10. Ukwenziwa kwemfuneko

11. Iimfuno zokusika i-workpiece

▌ IiMfuno zoBugcisa ngokuBanzi

1. Amalungu asusa ulusu lwe-oxide.

2. Phezulu kwendawo yokucutshungulwa kweengxenye, akufuneki kubekho imikrwelo, imivumbo kunye nezinye iziphene ezonakalisa ubuso bamacandelo.

3. Susa iibhura.

▌ IiMfuno zoNyango loBubushushu

1. Emva konyango lobushushu, HRC50 ~ 55.

2. Amacandelo okucima i-high-frequency, 350 ~ 370℃ tempering, HRC40 ~ 45.

3. Ubunzulu beCarburizing 0.3mm.

4. Unyango lokuguga lobushushu obuphezulu.

▌ Iimfuneko Zokunyamezela

1. Ukunyamezela imilo engaphawulwanga kuya kuhlangabezana neemfuno ze-GB1184-80.

2. Ukutenxa okuvumelekileyo kobukhulu bobude obungachazwanga yi-±0.5mm.

3. Indawo yokunyamezela ukuphosa i-symmetrical kwi-configuration yesayizi esisiseko yokuphosa okungenanto.

▌ Iikona kunye nemiphetho yamalungu

1. I-radius yekona i-R5 ayichazwanga.

2. I-chamfer ngaphandle kwesitofu yi-2 × 45 °.

3. Iikona ezibukhali/iikona ezibukhali/iikona ezibukhali zibuthuntu.

▌ IiMfuneko zeNdibano

1. Ngaphambi kokuhlanganisana, isitywina ngasinye kufuneka sifakwe kwioli.

2. Ukufudumeza kwe-oyile kuvunyelwe ukutshaja okushushu kweebheringi eziqengqelekayo ngexesha lokuhlanganisana, kunye nobushushu be-oyile obungekho ngaphezulu kwe-100℃.

3. Ukulandela i-gear assembly, iindawo zoqhagamshelwano kunye ne-backlash kwindawo yezinyo kufuneka zihambelane nemigangatho echazwe kwi-GB10095 kunye ne-GB11365.

4. Ekudibaneni kwenkqubo ye-hydraulic, ukusetyenziswa kwe-filler yokutywina okanye i-sealant kuvunyelwe, ngaphandle kokuba igcinwe ngaphandle kwenkqubo.

5. Konkeiindawo zomatshinikunye namacandelo angena kwindibano (kubandakanywa nalawo athengiweyo okanye anikezelwe ngaphandle) kufuneka abe nezatifikethi ezivela kwisebe lokuhlola.

6. Ngaphambi kokuhlanganisana, iinxalenye kufuneka zicocwe ngokucokisekileyo ukuze kuqinisekiswe ukungabikho kwee-burrs, flash, oxide, rust, chips, oil, agents coloring, nothuli.

7. Phambi kokudityaniswa, kubalulekile ukuphonononga imilinganiselo ephambili yokulingana yamalungu kunye namalungu, ngakumbi uphazamiseko lwemilinganiselo kunye nokuchaneka okunxulumeneyo.

8. Kuyo yonke indibano, amalungu kufuneka angankqonkqozwa, aphathwe, angakrwelwe, okanye avunyelwe ukuba aruse.

9. Xa ukhusela izikhonkwane, iibholiti, kunye namantongomane, kubalulekile ukuba ungazibethi okanye usebenzise izipani ezingafanelekanga kunye nezitshixo. Izikhonkwane zokubeka izikhonkwane, amandongomane, izikrufu, kunye neentloko zebholithi kufuneka zihlale zingonakali emva kokuqiniswa.

10. Iifasteners ezifuna i-torque ethile yokuqinisa kufuneka zigcinwe kusetyenziswa i-torque wrench kwaye ziqiniswe ngokuhambelana ne-torque echaziweyo.

11. Xa udibanisa inxalenye efanayo kunye ne-screws ezininzi (i-bolts), kufuneka ziqiniswe kwi-cross, i-symmetrical, i-step-by-step, kunye nendlela efanayo.

12. Ukuhlanganiswa kwezikhonkwane zekhoni kufuneka kubandakanye umbala womngxuma, uqinisekise izinga loqhagamshelwano elingekho ngaphantsi kwe-60% yobude obuhambelanayo, ukusabalalisa ngokulinganayo.

13. Amacala amabini esitshixo seflethi kunye nesitshixo kwi-shaft kufuneka agcine uqhagamshelwano olufanayo ngaphandle kwezithuba.

14. Ubuncinci be-2/3 yemigangatho yamazinyo kufuneka idibane ngexesha lokudibanisa i-spline, kunye nesantya soqhagamshelwano esingekho ngaphantsi kwe-50% kubude kunye nobude becala lamazinyo angundoqo.

15. Ekudibaneni kwesitshixo esisicaba (okanye i-spline) yeematshisi zesilayidi, iinxalenye zesigaba kufuneka zihambe ngokukhululekileyo, kungabikho ukuqina okungalinganiyo.

16. Ukugqithisa okugqithisiweyo kufuneka kususwe emva kokudibanisa.

17. Umngxuma ongesiqingatha sesetyhula weringi yangaphandle, isitulo esivulekileyo sokuthwala, kunye nesigqubuthelo sokuthwala akufuneki uxinge.

18. Iringi yangaphandle ephetheyo kufuneka igcine unxibelelwano oluhle kunye nomngxuma ophakathi kwesetyhula yesitulo esivulekileyo sokuthwala kunye nesigqubuthelo sokuthwala, kwaye ibonise ukudibana okufanayo kunye nesitulo sokuthwala ngaphakathi koluhlu oluchaziweyo ngexesha lokuhlolwa kombala.

19. Emva kokuhlanganisana, iringi yangaphandle yebheringi kufuneka igcine ukudibana okufanayo kunye nobuso besiphelo sesigqubuthelo sokubeka isiphelo.

20. Emva kokufakwa kweebheringi ezijikelezayo, ukujikeleza ngesandla kufuneka kube nokuguquguqukayo kwaye kuzinzile.

21. Umphezulu odibeneyo we-bushing ephezulu kunye nesezantsi yokuthwala i-bushing kufuneka ibambelele ngokuqinileyo kwaye ihlolwe nge-0.05mm feeler.

. Isikhonkwane akufunekanga sikhululeke emva kofakelo.

23. Umzimba ophetheyo we-spherical bearing kunye nesihlalo sokuthwala kufuneka ube noqhagamshelwano olufanayo, kunye nesantya soqhagamshelwano esingekho ngaphantsi kwe-70% xa sikhangelwa ngombala.

24. I-alloy bearing surface ayifanele isetyenziswe xa ijika ibe tyheli, kwaye i-nucleation phenomenon ayivumelekanga ngaphakathi kwe-engile yoqhagamshelwano ekhankanyiweyo, kunye nommandla we-nucleation ngaphandle kwe-engile yoqhagamshelwano elinganiselwe ukuba ingabi ngaphezu kwe-10% ye-non- indawo yoqhagamshelwano.

25. Isiphelo sesalathiso sobuso begiya (isixhobo sobuxhakaxhaka) kunye negxalaba leshaft (okanye isiphelo sobuso bomkhono wokumisa) kufuneka zilingane ngaphandle kokuvumela i-0.05mm feeler ukuba idlule, iqinisekisa i-perpendicularity kunye ne-perpendicularity end with the gear reference end face and axis.

26. Umphezulu odityanisiweyo webhokisi yegiya kunye nesigqubuthelo kufuneka ugcine unxibelelwano oluhle.

27. Ngaphambi kokuhlanganisana, kubalulekile ukuhlola ngokucokisekileyo kunye nokususa ii-angles ezibukhali, ii-burrs, kunye namasuntswana angaphandle asele kwiindawo zokucutshungulwa, ukuqinisekisa ukuba isitywina sihlala singakrwelwanga ngexesha lokulayisha.

▌ IiMfuneko zokuphosa

1. Umphezulu wokuphosa kufuneka ungabonisi ukugquma okuphantsi, iifractures, contractions, okanye ukungafezeki okufana nokungaphumeleli ekujuleni (umz., izinto ezinganelanga ezizaliswe, ukwenzakala komatshini, njl. njl.).

2. I-castings kufuneka ihlanjululwe ukuphelisa nayiphi na i-protrusions, i-edges ebukhali, kunye nezibonakaliso zeenkqubo ezingagqitywanga, kwaye isango lokugalela kufuneka lihlambuluke kwinqanaba kunye ne-casting surface.

3. Umphezulu ongeyena umatshini wokuphosa kufuneka ubonise ngokucacileyo uhlobo lwe-casting kunye nokumakishwa, ukuhlangabezana neenkcukacha zomzobo ngokubhekiselele kwisikhundla kunye nefonti.

4. Ubunzima bomhlaba ongeyena umatshini wokuphosa, kwimeko ye-sand casting R, akufanele idlule i-50μm.

5. Iicastings kufuneka zisuswe i-sprue, iingqikelelo, kunye nasiphi na i-sprue esiseleyo kumphezulu ongengomatshini mawenziwe umgangatho kwaye ukhazimliswe ukuhlangabezana nemigangatho yomgangatho womphezulu.

6. Ukugaywa kufuneka kungabi nantlabathi ebumbayo, isanti engundoqo, kunye neentsalela ezingundoqo.

7. Amacandelo athambekileyo kunye nommandla wokunyamezela kwe-dimensional of casting kufuneka acwangciswe ngokulinganayo kunye nenqwelo-moya.

8. Nayiphi na isanti ebumbayo, isanti engundoqo, iintsalela eziphambili, kunye nayo nayiphi na isanti ethambileyo okanye encamathelayo ekubumbeni, kufuneka igudiswe kwaye icocwe.

9. Uhlobo lokulungileyo nokungalunganga kunye nakuphi na ukunxaxha kweconvex casting kufuneka kulungiswe ukuze kuqinisekiswe utshintsho olugudileyo kunye nokuqinisekisa umgangatho wenkangeleko.

10. I-creases kwi-non-machine surface of the casting akufanele idlule ubunzulu be-2mm, kunye nesithuba esincinci se-100mm.

11. Umphezulu ongengoomatshini wokwenziwa kwemveliso yomatshini kufuneka udutyulwe ukuchama okanye unyango lwe-roller ukuhlangabezana neemfuno zokucoceka kwe-Sa2 1/2.

12 Makuqiniswe amaqonga ngamanzi.

13. Umphezulu wokuphosa kufuneka ube lula, kwaye nawaphi na amasango, i-protrusions, isanti enamathelayo, njl., kufuneka isuswe.

14. Ukufakwa kwecasting akufuneki kube ne-insulation ephantsi, iintanda, i-void, okanye ezinye iziphene zokuphosa ezinokubeka esichengeni ukusetyenziswa.

▌ Iimfuno zokupeyinta

1. Ngaphambi kokupeyinta iindawo zetsimbi, kubalulekile ukuphelisa nayiphi na i-rust, i-oxide, i-grime, uthuli, umhlaba, ityuwa, kunye nezinye izinto ezingcolileyo ukusuka phezulu.

2. Ukulungiselela iindawo zentsimbi zokususa i-rust, sebenzisa i-solvents yendalo, i-caustic soda, i-emulsifying agents, i-steam, okanye ezinye iindlela ezifanelekileyo zokuphelisa igrisi kunye nokungcola ebusweni.

3. Ukulandela i-shot peening okanye ukususwa kwe-rust manual, ixesha elimiselweyo phakathi kokulungisa umphezulu kunye nokusebenzisa i-primer akufanele kudlule iiyure ezi-6.

4. Ngaphambi kokuba udibanise, sebenzisa i-30 ukuya kwi-40μm isambatho esinzima sepeyinti ye-anti-corrosion kwiindawo ezidibeneyo ezidibeneyo. Vala umphetho welap joint ngepeyinti, isigcwalisi, okanye incamathelisa. Ukuba i-primer yonakaliswe ngexesha lomatshini okanye i-welding, phinda usebenzise isambatho esitsha.

▌ Iimfuno zemibhobho

1. Susa nayiphi na i-flash, i-burrs, okanye i-bevels ukusuka ekupheleni kombhobho ngaphambi kokuhlanganisa. Sebenzisa umoya oxinzelelweyo okanye indlela efanelekileyo yokucoca ukungcola kunye ne-rust eseleyo kudonga lwangaphakathi lwemibhobho.

2. Ngaphambi kokuhlanganisana, qiniseka ukuba yonke imibhobho yensimbi, kubandakanywa ne-preformed, iphathwa nge-degreasing, pickling, neutralization, ukuhlamba kunye nokukhuselwa kwe-corrosion.

3. Ngexesha lokudityaniswa, qinisa ngokukhuselekileyo imidibaniso enemisonto efana neeclamps zemibhobho, izixhaso, iiflange, kunye namalungu ukuthintela ukukhulula.

4. Yenza uvavanyo loxinzelelo kumacandelo adibeneyo emibhobho eyenziwe ngaphambili.

5. Xa uhambisa okanye uhambisa umbhobho, tywina indawo yokuhlukanisa umbhobho nge-adhesive tape okanye i-cap yeplastiki ukukhusela i-debris ukuba ingangeni, kwaye uqinisekise ukuba ibhalwe ngokufanelekileyo.

▌ Iimfuno zokulungisa iinxalenye ze-welding

1. Ngaphambi kwe-welding, kubalulekile ukuphelisa nakuphi na ukungafezeki kunye nokuqinisekisa ukuba umphezulu we-groove ulungelelene kwaye ungenayo imiphetho ebukhali.

2. Ngokuxhomekeke kwiimpazamo ezifunyenwe kwintsimbi etyhidiweyo, indawo ye-welding ingalungiswa ngokusebenzisa ukumba, ukuxubha, i-carbon arc gouging, ukusika igesi, okanye iinkqubo zemishini.

3. Coca yonke indawo ejikelezileyo ngaphakathi kwe-20mm radius ye-welding groove, uqinisekise ukususwa kwesanti, i-oyile, amanzi, irusi, kunye nezinye izinto ezingcolileyo.

4. Kuyo yonke inkqubo ye-welding, indawo yokutshisa i-preheating ye-casting yensimbi kufuneka igcine ubushushu obungekho ngaphantsi kwe-350 ° C.

5. Ukuba iimeko ziyavuma, zama ukwenza iwelding kwindawo ethe tyaba kakhulu.

6. Xa uqhuba ukulungiswa kwe-welding, nciphisa ukunyakaza okugqithisileyo kwe-lateral ye-electrode.

7. Ukulungelelanisa ngokufanelekileyo ukugqithiswa kwe-welding nganye, ukuqinisekisa ukuba ukugqithiswa ubuncinane ubuncinane be-1/3 yobubanzi bokupasa. I-weld kufuneka ibe yomelele, ingabikho ukutsha, iintanda, kunye nezitenxo ezibonakalayo. Ukubonakala kwe-weld kufuneka kube mnandi, ngaphandle kokunciphisa, i-slag engaphezulu, i-porosity, i-cracks, i-spatter, okanye ezinye iimpazamo. I-welding bead kufuneka ihambelane.

▌ Ukwenza Iimfuneko

1. Umlomo wamanzi kunye nokunyuka kwe-ingot kufuneka ulungiswe ngokufanelekileyo ukukhusela i-shrinkage voids kunye nokuphambuka okubalulekileyo ngexesha lokukhwabanisa.

2. I-forgings kufuneka ifakwe kwi-shaping kumatshini wokushicilela kunye nomthamo owaneleyo wokuqinisekisa ukuhlanganiswa okupheleleyo kwangaphakathi.

3. Ubukho beentanda eziphawulekayo, ii-creases, okanye ezinye iziphene ezibonakalayo eziphazamisa ukusebenza akuvumelekanga kwi-forgings. Iziphene zendawo zinokulungiswa, kodwa ubunzulu bokulungiswa akufanele budlule i-75% yesibonelelo somatshini. Iziphene kumphezulu ongasetyenziswanga kufuneka zipheliswe kwaye ziguqulwe ngokungenamthungo.

4. I-Forgings ayivumelekanga ekuboniseni amabala afana namabala amhlophe, i-fissures yangaphakathi, kunye ne-residual shrinkage voids.

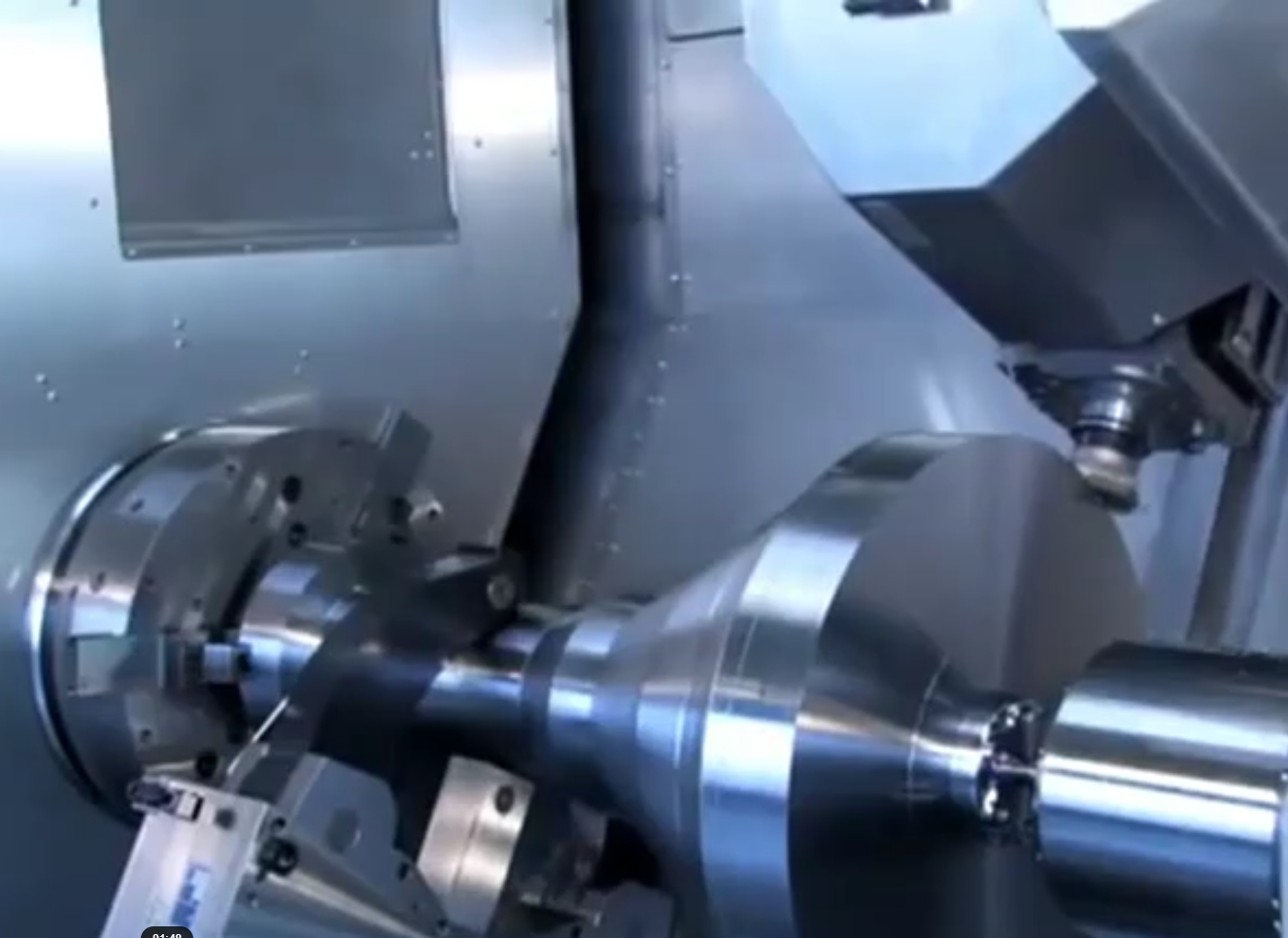

▌ Iimfuno zokusika i-workpiece

1. Amalungu ajike ngokuchanekakufuneka zihlolwe kwaye zivunywe ngokuhambelana neenkqubo zemveliso, ziqinisekise ukuqhubela phambili kwinqanaba elilandelayo kuphela emva kokuqinisekiswa kokuhlolwa kwangaphambili.

2. Abavoti abagqityiweyo mabangabonakalisi naziphi na izitenxo ngendlela yeeprotrusions.

3. Iziqwenga ezigqityiweyo akufanele zibekwe ngokuthe ngqo emgangathweni, kwaye zifuna inkxaso efunekayo kunye nemilinganiselo yokukhusela kufuneka iphunyezwe. Ukuqinisekisa ukungabikho komhlwa, ukubola, kunye nayo nayiphi na impembelelo enobungozi ekusebenzeni, ixesha elide, okanye ukubonakala, kubandakanywa nezibonda, imikrwelo, okanye ezinye iziphene, kubalulekile kumphezulu ogqityiweyo.

4. Umphezulu olandela inkqubo yokugqiba ukuqengqeleka akufuneki ubonakalise naziphi na iziganeko zokuxobuka emva kokuqengqeleka.

5. Amacandelo alandelayo kunyango lokugqibela lokushisa kufuneka angabonakali nayiphi na i-oxidation yomhlaba. Ukongeza, ukukhwelana kunye nomphezulu wamazinyo emva kokugqitywa kufuneka uhlale ukhululekile kuyo nayiphi na i-annealing.

6. Umphezulu wentambo esetyenzisiweyo akufanele ubonise naziphi na iziphene ezinjengamabala amnyama, ama-protrusions, ama-bulges angaqhelekanga, okanye ama-protrusions.

Ukudala inzuzo ethe chatha kubathengi yintanda-bulumko yeshishini le-Anebon; Ukukhula kwe-shopper ngamandla okusebenza e-Anebon. KwiiMveliso eziNtsha eziTshayo zeAluminiyam eZimeleyocnc iindawo zomatshinikwayeiindawo zokusila ubhedukunye neendawo zesitampu zesiko, ngaba usajonge imveliso esemgangathweni ehambelana kunye nomfanekiso wakho wombutho olungileyo ngelixa usandisa uluhlu lwentengiso yezinto zakho? Cinga ngorhwebo olulungileyo lwe-Anebon. Ukhetho lwakho luya kubonakala lunengqondo!

Iimveliso eziNtsha ezishushu zaseChina zeglasi kunye ne-Acrylic Glass, i-Anebon ixhomekeke kwizinto ezikumgangatho ophezulu, uyilo olugqibeleleyo, inkonzo ebalaseleyo yabathengi kunye nexabiso elikhuphisanayo lokuphumelela ukuthembela kwabathengi abaninzi ekhaya nakwamanye amazwe. Iimveliso ezingama-95% zithunyelwa kumazwe angaphandle kwiimarike zaphesheya.

Ukuba ufuna ukwazi ngakumbi okanye ufuna ukubuza, nceda uqhagamshelaneinfo@anebon.com.

Ixesha lokuposa: Jan-30-2024