I-HV, i-HB, kunye ne-HRC zonke ziyimilinganiselo yobunzima obusetyenziswa kuvavanyo lwemathiriyeli. Masiziqhawule:

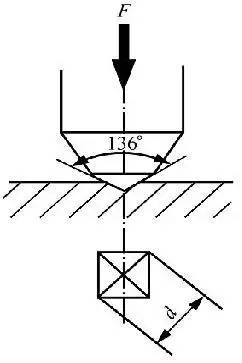

1)HV Ukuqina (Vickers Hardness): Ubulukhuni be-HV ngumlinganiselo wokuxhathisa kwemathiriyeli ekungeneni. Kuchongwa ngokufaka umthwalo owaziwayo kumphezulu wezinto eziphathekayo usebenzisa i-indenter yedayimane kunye nokulinganisa ubungakanani besiphumo esibangelwayo. Ubulukhuni be-HV bubonakaliswa kwiiyunithi zokuqina kwe-Vickers (HV) kwaye ngokuqhelekileyo isetyenziselwa izinto ezibhityileyo, iingubo kunye namalungu amancinci.

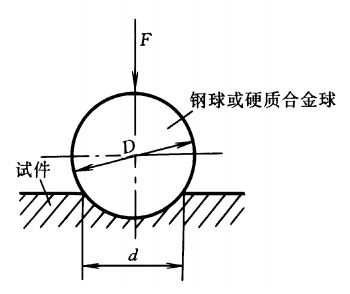

2)HB Ukuqina (Ukuqina kweBrinell): Ubulukhuni be-HB ngomnye umlinganiselo wokuchasana kwesixhobo kwi-indentation. Kubandakanya ukusebenzisa umthwalo owaziwayo kwizinto eziphathekayo usebenzisa i-indenter yebhola yentsimbi eqinile kunye nokulinganisa ububanzi besiphumo esibangelwayo. Ukuqina kwe-HB kubonakaliswa kwiiyunithi zokuqina kweBrinell (HB) kwaye isoloko isetyenziselwa izinto ezinkulu nezinkulu, kubandakanywa isinyithi kunye nealloys.

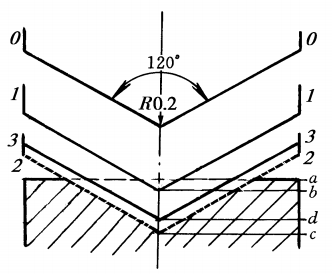

3)HRC Ukuqina (Rockwell Hardness): Ubulukhuni be-HRC ngumlinganiselo wokuchasana kwezinto ekungeneni okanye ukungena. Isebenzisa izikali ezahlukeneyo (A, B, C, njl.) Ngokusekelwe kwindlela ethile yokuvavanya kunye nohlobo lwe-indenter esetyenzisiweyo (i-diamond cone okanye ibhola yensimbi eqinile). Isikali se-HRC siqhele ukusetyenziselwa ukulinganisa ubulukhuni bemathiriyeli yesinyithi. Ixabiso lobulukhuni limelwe njengenani kwisikali se-HRC, njenge-HRC 50.

Iqhele ukusetyenziswa HV-HB-HRC itheyibhile yokuthelekisa ubulukhuni:

| Itheyibhile yokuthelekisa ubulukhuni bentsimbi eqhelekileyo (ingqikelelo yamandla aqikelelwayo) | ||||

| Ukuhlelwa kobunzima | Tensile strength N/mm2 | |||

| Rockwell | Vickers | Brinell | ||

| HRC | HRA | HV | HB | |

| 17 | - | 211 | 211 | 710 |

| 17.5 | - | 214 | 214 | 715 |

| 18 | - | 216 | 216 | 725 |

| 18.5 | - | 218 | 218 | 730 |

| 19 | - | 221 | 220 | 735 |

| 19.5 | - | 223 | 222 | 745 |

| 20 | - | 226 | 225 | 750 |

| 20.5 | - | 229 | 227 | 760 |

| 21 | - | 231 | 229 | 765 |

| 21.5 | - | 234 | 232 | 775 |

| 22 | - | 237 | 234 | 785 |

| 22.5 | - | 240 | 237 | 790 |

| 23 | - | 243 | 240 | 800 |

| 23.5 | - | 246 | 242 | 810 |

| 24 | - | 249 | 245 | 820 |

| 24.5 | - | 252 | 248 | 830 |

| 25 | - | 255 | 251 | 835 |

| 25.5 | - | 258 | 254 | 850 |

| 26 | - | 261 | 257 | 860 |

| 26.5 | - | 264 | 260 | 870 |

| 27 | - | 268 | 263 | 880 |

| 27.5 | - | 271 | 266 | 890 |

| 28 | - | 274 | 269 | 900 |

| 28.5 | - | 278 | 273 | 910 |

| 29 | - | 281 | 276 | 920 |

| 29.5 | - | 285 | 280 | 935 |

| 30 | - | 289 | 283 | 950 |

| 30.5 | - | 292 | 287 | 960 |

| 31 | - | 296 | 291 | 970 |

| 31.5 | - | 300 | 294 | 980 |

| 32 | - | 304 | 298 | 995 |

| 32.5 | - | 308 | 302 | 1010 |

| 33 | - | 312 | 306 | 1020 |

| 33.5 | - | 316 | 310 | 1035 |

| 34 | - | 320 | 314 | 1050 |

| 34.5 | - | 324 | 318 | 1065 |

| 35 | - | 329 | 323 | 1080 |

| 35.5 | - | 333 | 327 | 1095 |

| 36 | - | 338 | 332 | 1110 |

| 36.5 | - | 342 | 336 | 1125 |

| 37 | - | 347 | 341 | 1140 |

| 37.5 | - | 352 | 345 | 1160 |

| 38 | - | 357 | 350 | 1175 |

| 38.5 | - | 362 | 355 | 1190 |

| 39 | 70 | 367 | 360 | 1210 |

| 39.5 | 70.3 | 372 | 365 | 1225 |

| 40 | 70.8 | 382 | 375 | 1260 |

| 40.5 | 70.5 | 377 | 370 | 1245 |

| 41 | 71.1 | 388 | 380 | 1280 |

| 41.5 | 71.3 | 393 | 385 | 1300 |

| 42 | 71.6 | 399 | 391 | 1320 |

| 42.5 | 71.8 | 405 | 396 | 1340 |

| 43 | 72.1 | 411 | 401 | 1360 |

| 43.5 | 72.4 | 417 | 407 | 1385 |

| 44 | 72.6 | 423 | 413 | 1405 |

| 44.5 | 72.9 | 429 | 418 | 1430 |

| 45 | 73.2 | 436 | 424 | 1450 |

| 45.5 | 73.4 | 443 | 430 | 1475 |

| 46 | 73.7 | 449 | 436 | 1500 |

| 46.5 | 73.9 | 456 | 442 | 1525 |

| 47 | 74.2 | 463 | 449 | 1550 |

| 47.5 | 74.5 | 470 | 455 | 1575 |

| 48 | 74.7 | 478 | 461 | 1605 |

| 48.5 | 75 | 485 | 468 | 1630 |

| 49 | 75.3 | 493 | 474 | 1660 |

| 49.5 | 75.5 | 501 | 481 | 1690 |

| 50 | 75.8 | 509 | 488 | 1720 |

| 50.5 | 76.1 | 517 | 494 | 1750 |

| 51 | 76.3 | 525 | 501 | 1780 |

| 51.5 | 76.6 | 534 | - | 1815 |

| 52 | 76.9 | 543 | - | 1850 |

| 52.5 | 77.1 | 551 | - | 1885 |

| 53 | 77.4 | 561 | - | 1920 |

| 53.5 | 77.7 | 570 | - | 1955 |

| 54 | 77.9 | 579 | - | 1995 |

| 54.5 | 78.2 | 589 | - | 2035 |

| 55 | 78.5 | 599 | - | 2075 |

| 55.5 | 78.7 | 609 | - | 2115 |

| 56 | 79 | 620 | - | 2160 |

| 56.5 | 79.3 | 631 | - | 2205 |

| 57 | 79.5 | 642 | - | 2250 |

| 57.5 | 79.8 | 653 | - | 2295 |

| 58 | 80.1 | 664 | - | 2345 |

| 58.5 | 80.3 | 676 | - | 2395 |

| 59 | 80.6 | 688 | - | 2450 |

| 59.5 | 80.9 | 700 | - | 2500 |

| 60 | 81.2 | 713 | - | 2555 |

| 60.5 | 81.4 | 726 | - | - |

| 61 | 81.7 | 739 | - | - |

| 61.5 | 82 | 752 | - | - |

| 62 | 82.2 | 766 | - | - |

| 62.5 | 82.5 | 780 | - | - |

| 63 | 82.8 | 795 | - | - |

| 63.5 | 83.1 | 810 | - | - |

| 64 | 83.3 | 825 | - | - |

| 64.5 | 83.6 | 840 | - | - |

| 65 | 83.9 | 856 | - | - |

| 65.5 | 84.1 | 872 | - | - |

| 66 | 84.4 | 889 | - | - |

| 66.5 | 84.7 | 906 | - | - |

| 67 | 85 | 923 | - | - |

| 67.5 | 85.2 | 941 | - | - |

| 68 | 85.5 | 959 | - | - |

| 68.5 | 85.8 | 978 | - | - |

| 69 | 86.1 | 997 | - | - |

| 69.5 | 86.3 | 1017 | - | - |

| 70 | 86.6 | 1037 | - | - |

I-HRC/HB IiNgcebiso zoGuquko eziXhelekileyo

Ubunzima buphezulu kune-20HRC, 1HRC≈10HB,

Ubunzima bungaphantsi kwe-20HRC, 1HRC≈11.5HB.

Amagqabantshintshi: Ukulungiswa kokusika, kunokuguqulwa ngokufanayo 1HRC≈10HB (ubulukhuni besixhobo sokusebenza bunoluhlu lokuguquguquka)

Ubunzima bezinto zetsimbi

Ukuqina kubhekisa kwisakhono semathiriyeli ukuxhathisa inguquko yendawo, ngakumbi ukuguqulwa kweplastiki, ukuhlenga okanye ukukrwela. Isalathiso sokulinganisa ukuthamba kunye nobunzima bezinto eziphathekayo.

Ngokweendlela ezahlukeneyo zokuvavanya, ubulukhuni buhlulwe kwiintlobo ezintathu.

①Ukuqina komkrwelo. Isetyenziselwa ikakhulu ukuthelekisa ukuthamba kunye nobunzima beeminerali ezahlukeneyo. Indlela yokukhetha intonga enesiphelo esinye esinzima kunye nesinye isiphelo esithambileyo, udlulise izinto eziza kuvavanywa kunye nentonga, kwaye unqume ubulukhuni bezinto eziza kuvavanywa ngokwendawo yokukrala. Xa sithetha ngokomgangatho, izinto eziqinileyo zenza imikrwelo emide kwaye izinto ezithambileyo zenza imikrwelo emifutshane.

②Ukuqina kokungena. Ikakhulu isetyenziselwa izinto zetsimbi, indlela kukusebenzisa umthwalo othile ukucinezela i-indenter echaziweyo kwizinto eziza kuvavanywa, kwaye uthelekise ukuthamba kunye nokuqina kwezinto eziza kuvavanywa ngobungakanani bokuguqulwa kweplastiki yendawo kumphezulu we izinto eziphathekayo. Ngenxa yomahluko we-indenter, umthwalo kunye nobude bexesha lomthwalo, kukho iintlobo ezininzi zobunzima bokungena, ngakumbi kubandakanywa ukuqina kwe-Brinell, ukuqina kwe-Rockwell, ubulukhuni beVickers kunye nobunzima obuncinci.

③Phinda ubophe ubunzima. Ikakhulu isetyenziselwa izinto zetsimbi, indlela kukwenza isando esikhethekileyo esincinci siwe ngokukhululekileyo ukusuka kumphakamo othile ukuchaphazela isampuli yezinto eziza kuvavanywa, kwaye usebenzise isixa samandla oxinzelelo agcinwe (kwaye akhululwe) kwisampulu ngexesha lovavanyo. impembelelo (ngokubuyiswa kwehamile encinci) umlinganiselo wobude bomtsiba) ukumisela ukuqina kwezinto.

Obona bunzima buxhaphakileyo beBrinell, ukuqina kweRockwell kunye nobulukhuni beVickers bezinto zentsimbi bobobunzima bokungena. Ixabiso lobunzima libonisa amandla omhlaba wezinto eziphathekayo ukuxhathisa i-deformation yeplastiki ebangelwa enye into ecinezelweyo; C) ukulinganisa ubunzima, kwaye ixabiso lobunzima limele ubungakanani bomsebenzi we-elastic deformation wesinyithi.

Ukuqina kweBrinell

Sebenzisa ibhola yensimbi ecinyiweyo okanye ibhola ye-alloy enzima kunye nobubanzi be-D njenge-indenter, yicinezele ebusweni beqhekeza lovavanyo kunye novavanyo oluhambelanayo lwe-F, kwaye emva kwexesha lokubamba elichaziweyo, susa amandla okuvavanya ukufumana i-indentation kunye Idayamitha ye-d. Ukwahlula amandla okuvavanya ngommandla we-indentation, kwaye ixabiso elibangelwayo lixabiso lobunzima beBrinell, kwaye isimboli simelwe yi-HBS okanye i-HBW.

Umahluko phakathi kwe-HBS kunye ne-HBW ngumahluko kwi-indenter. I-HBS ithetha ukuba i-indenter yibhola yentsimbi eqinile, esetyenziselwa ukulinganisa izinto ezinobunzima beBrinell obungaphantsi kwe-450, njengentsimbi epholileyo, intsimbi engwevu kunye neentsimbi ezingenayo i-ferrous. I-HBW ithetha ukuba i-indenter yi-carbide ene-cemented, esetyenziselwa ukulinganisa izinto ezinobunzima be-Brinell obungaphantsi kwe-650.

Kwibhloko yovavanyo olufanayo, xa ezinye iimeko zovavanyo zifana ncakasana, iziphumo zeemvavanyo ezimbini ziyahluka, kwaye ixabiso le-HBW lidla ngokuba likhulu kunexabiso le-HBS, kwaye akukho mgaqo wobungakanani wokulandela.

Emva kowama-2003, ilizwe lam lamkele ngokulinganayo imigangatho yezizwe ngezizwe, ii-identers zentsimbi ezicinyiweyo, kunye nazo zonke iintloko zeebhola ze-carbide ezisetyenzisiweyo. Ke ngoko, i-HBS iyekisiwe, kwaye i-HBW isetyenziselwa ukumela isimboli yobulukhuni beBrinell. Kwiimeko ezininzi, ubulukhuni beBrinell bubonakaliswa kuphela kwi-HB, kubhekiswa kwi-HBW. Nangona kunjalo, i-HBS isabonwa ngamaxesha ngamaxesha kumaphepha oncwadi.

Indlela yokulinganisa ubulukhuni be-Brinell ifanelekile kwintsimbi etyhidiweyo, i-alloys engeyiyo i-ferrous, i-alloys eyahlukeneyo edibeneyo kunye ne-quinched kunye ne- tempered steels, kwaye ayifanelekanga ukuvavanya iisampuli okanyecnc ukuguqula iindawoeziqine kakhulu, ezincinci kakhulu, ezibhityileyo kakhulu, okanye ezingakuvumeli ukujongwa okukhulu kumphezulu.

Ubunzima beRockwell

Sebenzisa i-cone ye-diamond ene-cone angle ye-120 ° okanye i-Ø1.588mm kunye ne-Ø3.176mm iibhola zentsimbi ezicinyiweyo njenge-indenter kunye nomthwalo ukusebenzisana nayo. Umthwalo wokuqala yi-10kgf kunye nomthwalo opheleleyo ngama-60, i-100 okanye i-150kgf (oko kukuthi, umthwalo wokuqala kunye nomthwalo omkhulu). Ubunzima bubonakaliswa ngumahluko phakathi kobunzulu be-indentation xa umthwalo oyintloko ususiwe kunye nobunzulu be-indentation xa umthwalo oyintloko ugcinwa kunye nobunzulu bokungena phantsi komthwalo wokuqala emva kokusetyenziswa komthwalo opheleleyo.

Uvavanyo lobulukhuni beRockwell lusebenzisa amandla amathathu ovavanyo kunye ne-identers ezintathu. Kukho i-9 indibaniselwano yazo, ehambelana nezikali ze-9 zobunzima be-Rockwell. Ukusetyenziswa kwaba balawuli be-9 kugubungela phantse zonke izinto ezisetyenziswa ngokuqhelekileyo zetsimbi. Kukho ezintathu eziqhele ukusetyenziswa HRA, HRB kunye HRC, phakathi HRC yeyona isetyenziswa kakhulu.

Itheyibhile esetyenziswa ngokuqhelekileyo yovavanyo lobunzima beRockwell:

| Ukuqina | | | Ukuqina | |

| | | | | Carbide, carbide, |

| | | | | I-Annealed, intsimbi eqhelekileyo, i-aluminium alloy |

| | | | | intsimbi eqinile, ecinyiweyo kunye nentsimbi epholileyo, enzulu |

Uluhlu lokusetyenziswa kwesikali se-HRC yi-20 ~ 70HRC. Xa ixabiso lobunzima lingaphantsi kwe-20HRC, kuba i-conicalaluminium cnc machining inxalenyeye-indenter icinezelwe kakhulu, uvakalelo luyancipha, kwaye isikali se-HRB kufuneka sisetyenziswe endaweni yoko; xa ukuqina kwesampulu kungaphezulu kwe-67HRC, uxinzelelo kwincam ye-indenter inkulu kakhulu, kwaye idayimani yonakaliswa lula. Ubomi be-indenter buya kucuthwa kakhulu, ngoko ke isikali se-HRA kufuneka sisetyenziswe ngokubanzi endaweni yoko.

Uvavanyo lobulukhuni beRockwell lulula, lukhawuleza, kwaye luncinci, kwaye lunokuvavanya umphezulu weemveliso ezigqityiweyo kunye nezixhobo zokusebenza ezinzima nezibhityileyo. Ngenxa ye-indentation encinci, kwizinto ezinokwakheka okungalinganiyo kunye nobunzima, ixabiso lobunzima liguquguquka kakhulu, kwaye ukuchaneka akukona phezulu njengobunzima beBrinell. Ukuqina kwe-Rockwell kusetyenziselwa ukumisela ubulukhuni bentsimbi, isinyithi esingenawo i-ferrous, i-alloys enzima, njl.

Vickers Ubulukhuni Vickers Ubulukhuni

Umgaqo wokulinganisa ubulukhuni beVickers ufana nokuqina kweBrinell. Sebenzisa i-diamond square pyramid indenter ene-angle efakiweyo ye-136 ° ukuze ucinezele kumphezulu wezinto eziphathekayo kunye novavanyo oluthile lwe-F, kwaye ususe amandla okuvavanya emva kokugcina ixesha elichaziweyo. Ubunzima bubonakaliswa ngumyinge woxinzelelo kwindawo yeyunithi yendawo yephiramidi yesikwere. Ixabiso, isimboli yamanqaku yi-HV.

Uluhlu lokulinganisa ubulukhuni beVickers lukhulu, kwaye lunokulinganisa izinto ezinobunzima obusuka kwi-10 ukuya kwi-1000HV. I-indentation incinci, kwaye isetyenziswa ngokubanzi ukulinganisa imathiriyeli ebhityileyo kunye neeleya eziqinileyo zomphezulu ezifana ne-carburizing kunye ne-nitriding.

Ubunzima bukaLeeb Ubunzima bukaLeeb

Sebenzisa umzimba wempembelelo kunye nobunzima obuthile bentloko yebhola ye-tungsten carbide ukuchaphazela umphezulu wesiqwenga sovavanyo phantsi kwesenzo samandla athile, kwaye emva koko ubuyele. Ngenxa yobunzima obahlukeneyo bezinto, isantya sokubuyela emva kwempembelelo sikwahlukile. Imagnethi esisigxina ifakwe kwisixhobo sempembelelo. Xa umzimba wempembelelo unyuka usihla, icoil yayo yeperipheral iya kubangela isignali ye-electromagnetic ehambelana nesantya, kwaye emva koko iyiguqule ibe bubulukhuni beLeeb ngesekethe ye-elektroniki. Isimboli iphawulwe njenge-HL.

Umhloli we-Leeb hardness ayifuni i-worktable, kwaye inzwa yobunzima bayo buncinci njengepeni, enokuthi iqhutywe ngokuthe ngqo ngesandla, kwaye inokubonwa ngokulula ukuba yinto enkulu, i-workpiece enzima okanye i-workpiece enemilinganiselo yejometri enzima.

Enye inzuzo yobunzima beLeeb kukuba inomonakalo omncinci kakhulu kumphezulu wemveliso, kwaye ngamanye amaxesha ingasetyenziselwa uvavanyo olungonakalisi; iyingqayizivele kwiimvavanyo zobunzima kuzo zonke iindlela, iindawo ezimxinwa kunye nezikhethekileyoamalungu aluminiyam.

I-Anebon ibambelela kumgaqo othi “Inyanisekile, ikhuthele, ingenisa izinto ezintsha” ukufumana izisombululo ezitsha ngokuqhubekayo. I-Anebon ijonga amathemba, impumelelo njengempumelelo yobuqu. Vumela i-Anebon yakhe ikamva elinempumelelo kwisandla somatshini wobhedu kunye neengxenye ze-CNC ze-titanium / izincedisi zesitampu. I-Anebon ngoku inobonelelo lwempahla olubanzi kunye nexabiso lokuthengisa lilungelo lethu. Wamkelekile ukubuza malunga neemveliso ze-Anebon.

IiMveliso ezihamba phambili eTshayina iCNC yokuMaching iNdawo kunye neNqanaba eliChanekile, ngokwenene kufuneka nayiphi na kwezi zinto ibe nomdla kuwe, nceda usazise. I-Anebon iya kukuvuyela ukukunika ikowuti yakuba ifumene iinkcukacha zomntu. I-Anebon ineenjineli zethu zobuqu ze-R&D ukuhlangabezana nazo naziphi na iimfuno. I-Anebon ijonge phambili ekufumaneni imibuzo yakho kungekudala kwaye ndiyathemba ukuba nethuba lokusebenza kunye nawe kwixesha elizayo. Wamkelekile ukujonga umbutho we-Anebon.

Ixesha lokuposa: May-18-2023