Yintoni isixhobo se-CNC?

Ukudityaniswa kwezixhobo zokusebenza eziphambili kunye nezixhobo eziphezulu zokusika i-CNC zinokunika umdlalo opheleleyo ekusebenzeni kwayo okufanelekileyo kunye nokufezekisa izibonelelo zezoqoqosho ezilungileyo. Ngophuhliso olukhawulezayo lwezixhobo zokusika izixhobo, izixhobo ezahlukeneyo zokusika izixhobo ezitsha ziye zaphucula kakhulu iipropathi zabo zomzimba, oomatshini kunye nokusebenza kokusika, kwaye uluhlu lwabo lwesicelo luye lwaqhubeka nokwandisa.

Ukuqulunqwa kwesakhiwo sezixhobo ze-CNC?

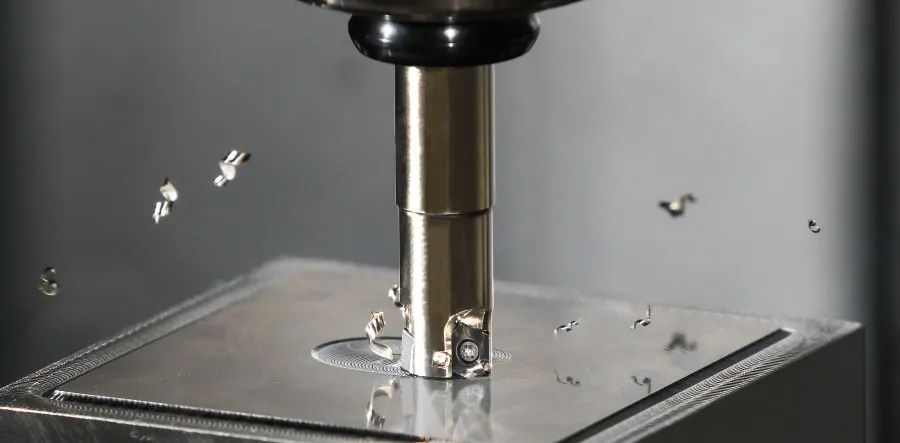

I-CNC (i-Computer Numerical Control) izixhobo zizixhobo zoomatshini ezisetyenziswa yimiyalelo ecwangcisiweyo efakwe kwiikhowudi kwindawo yokugcina, efana nekhompyutha. Ezi zixhobo zisebenzisa inkqubo elawulwa yikhompyutha ukwenza imisebenzi yomatshini echanekileyo, njengokusika, ukugrumba, ukungqusha nokubumba. Izixhobo zisetyenziswa kwiinkqubo zokuvelisa, ngakumbi kumashishini afana ne-aerospace, i-automotive, amayeza, kunye nokusebenza kwesinyithi.

izixhobo CNC ziquka uluhlu koomatshini, ezifanaCNC millingoomatshini, CNCinkqubo lathe, Ii-router ze-CNC, i-CNC plasma cutters, kunye ne-CNC laser cutters. Ezi zixhobo zisebenza ngokuhambisa isixhobo sokusika okanye i-workpiece kwii-axes ezintathu okanye ngaphezulu usebenzisa ulawulo lwamanani ekhompyutheni.

Izixhobo ze-CNC zaziwa ngokuchaneka kwazo, ukuchaneka, kunye nokuphinda-phinda, nto leyo ezenza zilungele ukwenza iinxalenye ezintsonkothileyo kunye namacandelo anokunyamezelana okuqinileyo. Kananjalo bayakwazi ukuvelisa iimveliso ezikumgangatho ophezulu ngesantya esikhawulezayo kunoomatshini bezandla bemveli, nto leyo enceda ukunyusa imveliso kunye nempumelelo kwimveliso.

Ziziphi iimpawu ezisisiseko ekufuneka izixhobo ze-CNC zibe nazo?

1. Ubunzima: Izixhobo zesixhobo se-CNC kufuneka zibe nzima ngokwaneleyo ukuxhathisa ukuguga kunye nokukrazula ngexesha lenkqubo yomatshini.

2. Ukuqina: Izixhobo zesixhobo se-CNC kufuneka zibe nzima ngokwaneleyo ukumelana nempembelelo kunye nemithwalo yothuso.

3. Ukumelana nokushisa: Izixhobo zesixhobo se-CNC kufuneka zikwazi ukumelana nobushushu obuphezulu obuveliswe ngexesha lenkqubo yomatshini ngaphandle kokulahlekelwa amandla okanye ukuqina.

4. Ukunxiba ukuxhathisa: Izixhobo zesixhobo se-CNC kufuneka zixhathise ukunxitywa kwe-abrasive okubangelwa ukudibana ne-workpiece.

5. Ukuzinza kweekhemikhali: Izixhobo ze-CNC zesixhobo kufuneka zizinzile kwiikhemikhali ukuphepha ukubola kunye nezinye iindlela zokulimala kweekhemikhali.

6. Ukucutshungulwa: Izixhobo zesixhobo se-CNC kufuneka zibe lula umatshini kunye nokubumba kwifom efunwayo.

7. Ukusebenza kweendleko: Izixhobo ze-CNC zesixhobo kufuneka zifikeleleke kwaye zingabizi, ziqwalasela ukusebenza kwazo kunye nokuphila ixesha elide.

Iintlobo, iipropati, iimpawu kunye nokusetyenziswa kwezixhobo zokusika izixhobo

Uhlobo ngalunye lwemathiriyeli luneempawu zalo, iimpawu, kunye nokusetyenziswa kwalo. Nazi ezinye izixhobo eziqhelekileyo zokusika izixhobo, kunye neepropati kunye nokusetyenziswa kwazo:

1. Isinyithi esinesantya esiphezulu (HSS):

I-HSS sisixhobo sokusika esisetyenziswa ngokuqhelekileyo, esenziwe ngokudityaniswa kwentsimbi, i-tungsten, i-molybdenum, kunye nezinye izinto. Iyaziwa ngobulukhuni bayo obuphezulu, ukuxhathisa ukunxiba, kunye nokuqina, okwenza ukuba ifaneleke ukwenza uluhlu olubanzi lwezinto eziphathekayo, kuquka iintsimbi, i-alloys ye-aluminium, kunye neeplastiki.

2. Carbide:

I-Carbide yinto edibeneyo eyenziwe kumxube we-tungsten carbide particles kunye ne-metallic binder, njenge-cobalt. Iyaziwa ngobunzima bayo obukhethekileyo, ukuxhathisa ukunxiba, kunye nokumelana nobushushu, iyenza ilungele ukwenza izixhobo eziqinileyo, njengentsimbi engatyiwa, intsimbi ekhandiweyo, kunye nobushushu obuphezulu.

3. I-Ceramic:

Izixhobo zokusika i-Ceramic zenziwe kwizinto ezahlukeneyo ze-ceramic, ezifana ne-aluminium oxide, i-silicon nitride, kunye ne-zirconia. Baziwa ngobulukhuni babo obuphezulu, ukuxhathisa ukunxiba, kunye nokuzinza kweekhemikhali, okubenza bafaneleke ukwenza izinto ezinzima kunye ne-abrasive, njenge-ceramics, i-composites, kunye ne-superalloys.

4. Cubic Boron Nitride (CBN):

I-CBN yimathiriyeli eyenziwe nge-cubic boron nitride crystals. Iyaziwa ngobunzima bayo obukhethekileyo, ukumelana nokunxiba, kunye nokuxhathisa ukushisa, okwenza kube yinto efanelekileyo yokwenza iintsimbi ezilukhuni kunye nezinye izinto ezinzima umatshini usebenzisa ezinye izixhobo zokusika.

5. Idayimani:

Izixhobo zokusika idayimani zenziwe kwiidayimani zendalo okanye zokwenziwa. Baziwa ngobulukhuni babo obukhethekileyo, ukuxhathisa ukunxiba, kunye nokumelana nobushushu, kubenza bafaneleke ukwenza iintsimbi ezingenayo i-ferrous, i-composites, kunye nezinye izinto ezinzima kunye ne-abrasive.

Kukwakho nesixhobo esikhethekileyo esibizwa ngokuba sisixhobo esicandisiweyo.

Ngokubanzi, ezi zinto zingasentla zisetyenziswa njengeengubo zokwaleka, kwaye zisetyenziswa ngokubanzi kwizixhobo zoomatshini be-CNC.

Isixhobo esigqunyiweyo sisixhobo esinomgca omncinci wezinto ezisetyenzisiweyo kwindawo yayo ukuphucula ukusebenza kwayo kunye nokwandisa ixesha lokuphila. Izinto zokugquma zikhethwa ngokusekelwe kwinjongo yokusetyenziswa kwesixhobo, kunye nezinto eziqhelekileyo zokugquma zibandakanya i-titanium nitride (TiN), i-titanium carboni (TiCN), kunye ne-diamond-like carbon (DLC).

Iingubo zokwaleka zinokuphucula ukusebenza kwesixhobo ngeendlela ezahlukeneyo, ezifana nokunciphisa ukungqubana kunye nokuguga, ukwandisa ubulukhuni kunye nokuqina, kunye nokuphucula ukuxhathisa kwi-corrosion kunye nokulimala kweekhemikhali. Ngokomzekelo, i-TiN-coated drill bit ingahlala ukuya kuthi ga kathathu ixesha elide kune-One engafakwanga, kunye ne-TiCN-coated end mill inokunqumla izinto ezinzima ngokunxiba okuncinci.

Izixhobo ezigqunyiweyo ziqhele ukusetyenziswa kumashishini afana nelemveliso, i-aerospace, izithuthi, kunye nokwenziwa kwezixhobo zonyango. Zingasetyenziselwa ukusika, ukugrumba, ukungqusha, ukugaya, kunye neminye imisebenzi yomatshini.

Imigaqo yokukhetha izixhobo zesixhobo se-CNC

Ukukhethwa kwezixhobo zesixhobo se-CNC kuyingqwalasela ebalulekileyo xa kuyilwa kunye nokuveliswa ngokuchanekileyoiindawo eziguqukayo. Ukukhethwa kwesixhobo sesixhobo kusekelwe kwizinto ezininzi, kuquka uhlobo lwemathiriyeli eyenziwa ngoomatshini, ukusebenza komatshini, kunye nokugqiba okufunwayo.

Nantsi eminye yemigaqo yokukhetha izixhobo zesixhobo se-CNC:

1. Ukuqina:Isixhobo sesixhobo kufuneka sibe nzima ngokwaneleyo ukumelana nemikhosi kunye namaqondo obushushu avelisiweyo ngexesha lomatshini. Ubunzima buqhele ukulinganiswa kwisikali seRockwell C okanye isikali seVickers.

2. Ukuqina:Isixhobo sesixhobo kufuneka siqine ngokwaneleyo ukumelana nokuqhekeka kunye nokuqhekeka. Ukuqina ngokuqhelekileyo kulinganiswa ngamandla empembelelo okanye ukuqina kokwaphuka.

3. Ukumelana nokunxiba:Isixhobo sesixhobo kufuneka sibe nokumelana nokunxiba kakuhle ukuze kugcinwe umda wayo wokusika kwaye ugweme ukungaphumeleli kwesixhobo. Ukuxhatshazwa kokugqoka kwempahla kudla ngokulinganiswa nomthamo wezinto ezikhutshwayo kwisixhobo ngexesha elithile lomatshini.

4. I-Thermal conductivity: Isixhobo sesixhobo kufuneka sibe ne-conductivity efanelekileyo ye-thermal yokuchitha ubushushu obuveliswa ngexesha lomatshini. Oku kunceda ukuphepha ukusilela kwesixhobo kunye nokugcina ukuchaneka komda.

5. Ukuzinza kweekhemikhali:Isixhobo sesixhobo kufuneka sizinzile ngokwekhemikhali ukuphepha ukuphendulwa kweekhemikhali kunye nezinto zokusebenza.

6. Iindleko:Iindleko zesixhobo sesixhobo nazo ziqwalaselwe okubalulekileyo, ngakumbi kwimiba yemveliso ephezulu.

Izinto eziqhelekileyo ezisetyenziselwa izixhobo ze-CNC ziquka i-carbide, isinyithi esinesantya esiphezulu, i-ceramic, kunye nedayimane. Ukukhethwa kwesixhobo sesixhobo kuxhomekeke ekusebenzeni komatshini othile kunye nokugqiba okufunwayo, kunye nezinto ezisetyenziswayo kunye nezixhobo ezikhoyo.

1) Isixhobo sokusika sihambelana neempawu zomatshini wento eyenziwe ngoomatshini

Ukuhambelana nesixhobo sokusika izixhobo kunye neempawu zomatshini wento esetyenzisiweyo yinto ebalulekileyo yokuqwalaselwa kwi-CNC machining. Iipropati zomatshini zento eyenziwe ngoomatshini ziquka ubunzima bayo, ukuqina, kunye ne-ductility, phakathi kwabanye. Ukukhetha isixhobo sokusika esihambelanayo okanye ukuzalisekisa iipropathi zoomatshini zento eyenziwe ngoomatshini kunokuphucula ukusebenza komatshini kunye nokusebenza kakuhle, ukunciphisa ukunxiba kwesixhobo, kunye nokuphucula umgangatho wenxalenye egqityiweyo.

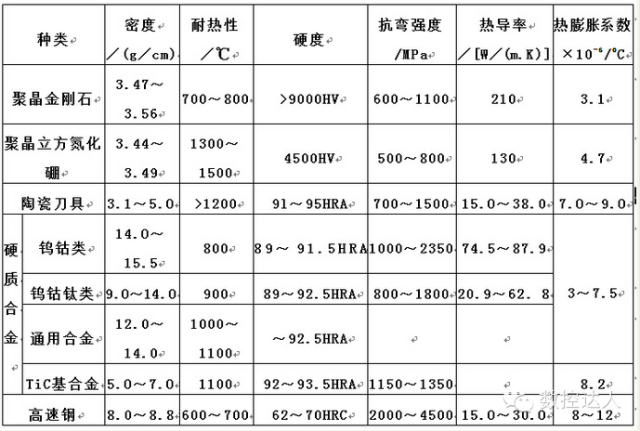

① Umyalelo wobulukhuni besixhobo sesixhobo si: isixhobo sedayimane>isixhobo se-cubic boron nitride> isixhobo se-ceramic>i-tungsten carbide>intsimbi enesantya esiphezulu.

② Umyalelo wamandla okugoba wezixhobo zesixhobo kukuba: intsimbi enesantya esiphezulu > i-carbide enesamente > izixhobo ze-ceramic > idayimane kunye nezixhobo ze-cubic boron nitride.

③ Umyalelo wokuqina kwezixhobo zesixhobo yile: intsimbi enesantya esiphezulu > i-carbide enesamente > cubic boron nitride, idayimani kunye nezixhobo zeceramic.

Umzekelo, ukuba into eyenziwe ngoomatshini yenziwe ngezinto ezilukhuni kunye ne-brittle njengentsimbi eqinile okanye intsimbi etyhidiweyo, isixhobo sokusika esenziwe ngesixhobo esinzima kunye nesinxibo esinqabileyo njenge-carbide okanye i-ceramic sinokukhetha okulungileyo. Ezi zixhobo ziyakwazi ukumelana namandla aphezulu okusika kunye namaqondo okushisa awenziwe ngexesha lomatshini kunye nokugcina imiphetho ebukhali yokusika ixesha elide.

Ngakolunye uhlangothi, ukuba into eyenziwe ngomatshini yenziwe nge-softer and more ductile material efana ne-aluminium okanye ubhedu, isixhobo sokusika esenziwe ngesixhobo esinamandla njengentsimbi ephezulu sinokufaneleka ngakumbi. Isinyithi esinesantya esiphezulu sinokufunxa ngcono ukothuka kunye nokungcangcazela ngexesha lomatshini, ukunciphisa umngcipheko wokuqhekeka kwesixhobo kunye nokuphucula ubomi besixhobo.

2) Ukutshatisa izixhobo zesixhobo sokusika kwiipropathi ezibonakalayo zento eyenziwe ngoomatshini

Ukufanisa isixhobo sokusika izixhobo kunye neempawu ezibonakalayo zento esetyenzisiweyo nayo yinto ebalulekileyo yokuqwalaselwa kwi-CNC machining. Iimpawu ezibonakalayo zento eyenziwe ngoomatshini ziquka ukuqhutyelwa kwayo kwe-thermal, i-coefficient yokwandiswa kwe-thermal, kunye neemfuno zokugqiba umphezulu, phakathi kwabanye. Ukukhetha isixhobo sokusika esihambelanayo okanye esihambelana neempawu ezibonakalayo zento eyenziwe ngoomatshini kunokuphucula ukusebenza komatshini, ukunciphisa ukunxiba kwesixhobo, kunye nokuphucula umgangatho wenxalenye egqityiweyo.

① Ubushushu bokumelana nobushushu bezixhobo ezahlukeneyo zezixhobo: 700-8000C yezixhobo zedayimani, 13000-15000C izixhobo zePCBN, 1100-12000C izixhobo zeceramic, 900-11000C yeTiC(N)-based cemented carbide, kunye ne-WC11000C -esekelwe kwiinkozo ze-ultrafine I-carbide enesamente yi-800~9000C, i-HSS yi-600 ~ 7000C.

②Umyalelo we-thermal conductivity yezixhobo ezahlukeneyo zesixhobo: I-PCD>PCBN>I-WC-based cemented carbide>TiC(N)-based cemented carbide>HSS>Si3N4-based ceramics>A1203-based based ceramics.

③ Umyalelo wokwandiswa kwe-thermal coefficient yezixhobo ezahlukeneyo zesixhobo yile: HSS>WC-based cemented carbide>TiC(N)>A1203-based ceramics>PCBN>Si3N4-based ceramics>PCD.

④Umyalelo wokuxhathisa ukothuka kwe-thermal kwezixhobo ezahlukeneyo zesixhobo yile: HSS>WC-based cemented carbide>Si3N4-based ceramics>PCBN>PCD>TiC(N)-based cemented carbide>A1203-based ceramics.

Ngokomzekelo, ukuba into eyenziwe ngomatshini ine-conductivity ephezulu ye-thermal, njengobhedu okanye i-aluminium, isixhobo sokusika esine-conductivity ephezulu ye-thermal kunye ne-coefficient ephantsi yokwandiswa kwe-thermal ingaba yinto ekhethekileyo. Oku kuvumela isixhobo ukuba sichithe ubushushu ngokufanelekileyo ngexesha lomatshini kunye nokunciphisa umngcipheko wokulimala kwe-thermal kuzo zombini isixhobo kunye nento eyenziwe ngomatshini.

Ngokufanayo, ukuba into eyenziwe ngoomatshini ineemfuno ezingqongqo zokugqiba umphezulu, isixhobo sokusika esinokumelana nokunxiba okuphezulu kunye ne-coefficient ephantsi ye-friction inokuba lolona khetho lungcono. Oku kunokunceda ukufezekisa umphezulu ofunwayo ngaphandle kokunxitywa kwesixhobo esigqithisileyo okanye umonakalo kwinto eyenziwe ngoomatshini.

3) Ukuthelekisa isixhobo sokusika izixhobo kwiikhemikhali zento eyenziwe ngoomatshini

Ukuhambelana nesixhobo sokusika kwiimpawu zekhemikhali zento esetyenzisiweyo nayo yinto ebalulekileyo yokuqwalaselwa kwi-CNC machining. Iipropathi zekhemikhali zento eyenziwe ngoomatshini zibandakanya ukusebenza kwakhona, ukumelana nokubola, kunye nokwakheka kweekhemikhali, phakathi kwabanye. Ukukhetha isixhobo sokusika esihambelanayo okanye esihambelana neempawu zeekhemikhali zento eyenziwe ngomatshini kunokuphucula ukusebenza komatshini, ukunciphisa ukunxiba kwesixhobo, kunye nokuphucula umgangatho wenxalenye egqityiweyo.

Umzekelo, ukuba into eyenziwe ngoomatshini yenziwe ngezinto ezisebenzayo okanye ezivuthayo ezifana ne-titanium okanye insimbi engenasici, isixhobo sokusika esenziwe ngezinto ezinganyangekiyo kwi-corrosion njengedayimane okanye i-PCD (i-polycrystalline diamond) inokuba lolona khetho lungcono. Ezi zixhobo ziyakwazi ukumelana neendawo ezinobungozi okanye ezisebenzayo kwaye zigcine imiphetho yazo ebukhali ixesha elide.

Ngokufanayo, ukuba into eyenziwe ngomatshini inokwakheka kweekhemikhali eziyinkimbinkimbi, isixhobo sokusika esenziwe ngezinto ezizinzile ngokwekhemikhali kunye ne-inert, njengedayimane okanye i-cubic boron nitride (CBN), inokuba lolona khetho lungcono. Ezi zixhobo zinokuphepha ukuphendulwa kweekhemikhali kunye nezixhobo zokusebenza kunye nokugcina ukusebenza kwazo kokusika ngexesha.

① Ubushushu obuchasayo besixhobo sezixhobo ezahlukeneyo (ngentsimbi) yile: PCBN>i-ceramic>i-alloy eqinile>HSS.

② Ubushushu bokumelana ne-oxidation yezixhobo ezahlukeneyo zesixhobo bunje: ceramic>PCBN>tungsten carbide>diamond>HSS.

③ Amandla okusasazwa kwesixhobo semathiriyeli (yentsimbi) yile: idayimane>I-Si3N4-based ceramics>PCBN>A1203-based based ceramics. Uxinzelelo lokusasaza (kwi-titanium) yi: A1203-based ceramics>PCBN>SiC>Si3N4>diamond.

4) Ukukhetha okunengqiqo kwezixhobo ze-CNC zokusika izixhobo

Ukukhethwa kwezixhobo zeCNC zokusika kuxhomekeke kwizinto ezahlukeneyo ezifana nesixhobo sokusebenza, ukusebenza komatshini, kunye nejiyometri yesixhobo. Nangona kunjalo, ezinye izikhokelo ngokubanzi zokukhetha izixhobo zokusika izixhobo zomatshini we-CNC ziquka:

1. Iimpawu zezinto eziphathekayo ze-workpiece: Qwalasela i-mechanical, physical, kunye ne-chemical properties of the workpiece material xa ukhetha isixhobo sokusika isixhobo. Tshatisa isixhobo sokusika kwisixhobo sokusebenza ukuze ufezekise ukusebenza kakuhle kunye nomgangatho ophezulu.

2. Umsebenzi womatshini: Qwalasela uhlobo lomsebenzi womatshini owenziwayo, njengokujika, ukugaya, ukugrumba, okanye ukucola. Imisebenzi yomatshini eyahlukeneyo ifuna izixhobo ezahlukeneyo zejometri kunye nezixhobo.

3. Ijiyometri yesixhobo: Qwalasela isixhobo sokusika ijometri xa ukhetha imathiriyeli yesixhobo. Khetha izinto ezinokugcina umgca wokusika obukhali kwaye umelane nemikhosi yokusika eyenziwa ngexesha lokusebenza komatshini.

4. Ukunxitywa kwesixhobo: Qwalasela isantya sokunxitywa kwesixhobo xa ukhetha imathiriyeli yesixhobo sokusika. Khetha izinto ezinokumelana nemikhosi yokusika kwaye ugcine umgca wokusika obukhali ixesha elide ukuze unciphise utshintsho lwesixhobo kunye nokuphucula ukusebenza kakuhle komatshini.

5. Iindleko: Qwalasela iindleko zesixhobo sokusika xa ukhetha isixhobo. Khetha into enika ibhalansi engcono kakhulu yokusika ukusebenza kunye neendleko.

Ezinye izixhobo zokusika eziqhelekileyo ezisetyenziswa kwiCNC machiningzibandakanya intsimbi enesantya esiphezulu, carbide, ceramic, diamond, kunye CBN. Isixhobo ngasinye sineenzuzo kunye nokungonakali, kwaye ukukhethwa kwezixhobo zesixhobo kufuneka kusekelwe ekuqondeni ngokucokisekileyo ukusebenza komatshini kunye nezinto zokusebenza.

Usukelo lukanaphakade lwe-Anebon sisimo sengqondo “sokujonga imarike, sijonge isiko, sithathele ingqalelo inzululwazi” kunye nethiyori “yomgangatho osisiseko, themba owokuqala nolawulo oluphambili” kwintengiso eshushu Factory OEM Service High Precision CNC Machining parts for automation. industrial, Anebon quote kumbuzo wakho. Ngolwazi oluthe kratya, nceda uqhagamshelane nathi, i-Anebon iya kukuphendula ngokukhawuleza!

Intengiso eshushu Factory China 5 axis cnc machining iinxalenye, CNC wajika iinxalenye kunye nenxalenye yobhedu lokusila. Wamkelekile ukuba undwendwele inkampani yethu, umzi-mveliso kunye negumbi lethu lokubonisa apho libonisa iimpahla ezahlukeneyo zeenwele eziza kuhlangabezana nolindelo lwakho. Okwangoku, kulungele ukutyelela iwebhusayithi ye-Anebon, kwaye abasebenzi be-Anebon abathengisayo baya kuzama konke okusemandleni abo ukukuzisa eyona nkonzo ilungileyo. Nceda uqhagamshelane ne-Anebon ukuba kufuneka ube nolwazi oluthe kratya. Injongo yeAnebon kukunceda abathengi baqonde iinjongo zabo. I-Anebon iye yenza iinzame ezinkulu zokuphumeza le meko yokuphumelela.

Ixesha lokuposa: Mar-08-2023