1

Impembelelo kwiqondo lokushisa lokusika: isantya sokusika, izinga lokutya, inani lokusika umva.

Impembelelo kumandla okusika: inani lokusika umva, izinga lokutya, isantya sokusika.

Impembelelo ekuzinzeni kwesixhobo: isantya sokusika, isantya sokutya, isixa sokusika umva.

2

Xa isixa sokubandakanya umva siphindwe kabini, amandla okusika aphindwe kabini;

Xa izinga lokutya liphindwe kabini, amandla okusika anyuka malunga ne-70%;

Xa isantya sokusika siphindwe kabini, amandla okusika ayancipha ngokuthe ngcembe;

Ngamanye amazwi, ukuba i-G99 isetyenzisiwe, isantya sokusika siya kunyuka, kodwa amandla okusika akayi kutshintsha kakhulu.

3

Ngokutsho kokukhutshwa kweefayili zetsimbi, kunokugwetywa ukuba amandla okusika kunye nokushisa okusika kuphakathi koluhlu oluqhelekileyo.

Xa ixabiso langempela lika-X lilinganisiwe kunye nobubanzi be-Y bomzobo bungaphezulu kwe-0.8, isixhobo sokuguqula kunye ne-angle yokuphambuka yesibini yama-degrees angama-52 (oko kukuthi, isixhobo esisetyenziswa ngokuqhelekileyo esinencakuba ye-35 degrees kunye ne-angle yokuphambuka ehamba phambili I-93 degrees) I-R ngaphandle kwemoto inokusula imela kwindawo yokuqala.

5

Ubushushu obumelelwe ngumbala weefayili zentsimbi: umhlophe ungaphantsi kwama-degrees angama-200

Yellow 220-240 degrees

Ibhlowu emnyama i-290 degrees

Blue 320-350 degrees

Purple emnyama ngaphezu kwe 500 degrees

Ubomvu bungaphezu kwama-800 degrees

6

FUNAC OI mtc idla ngokungagqibekanga kumyalelo we-G:

G69: andiqinisekanga

G21: Ubungakanani beMetric yokufaka

I-G25: Ukubhaqwa kwesantya sokuguquguquka kweSpindle kuyekiwe

G80: Umjikelo wenkonkxa uyarhoxisa

G54: inkqubo yolungelelaniso olungagqibekanga

G18: Ukukhetha inqwelomoya yeZX

I-G96 (G97): ulawulo lwesantya somgca rhoqo

G99: Isondlo ngokwenguquko nganye

I-G40: Ukurhoxiswa kwembuyekezo yempumlo yesixhobo (G41 G42)

I-G22: ukufunyanwa kwestroke yokugcina IVULIWE

G67: Macro inkqubo modal call ukurhoxiswa

G64: andiqinisekanga

G13.1: Ukurhoxiswa kwemowudi yolungelelwaniso lwepolar

7

Intambo yangaphandle ngokuqhelekileyo i-1.3P, kwaye intambo yangaphakathi yi-1.08P.

8

Isantya somsonto S1200/pitch* ukhuseleko factor (ngokubanzi 0.8).

9

Isixhobo esisetyenziswa ngesandla sempumlo Ifomula yembuyekezo: ukusuka ezantsi ukuya phezulu, chamfering: Z=R*(1-tan(a/2)) X=R(1-tan(a/2))*tan(a) ukusuka phezulu ukuya phezulu Yehla kwi-chamfer kwaye utshintshe uthabatha udibanise.

10

Ngalo lonke ixesha ukondla kunyuka ngo-0.05, isantya siyancipha ngo-50-80 revolutions. Oku kungenxa yokuba ukunciphisa isantya kuthetha ukuba ukunxiba isixhobo siyancipha, kwaye icnc ukusikaamandla anyuka kancinci, ukuze enze ukunyuka kwesondlo esibangela ukuba amandla okusika anyuke kwaye ubushushu bunyuke. Impembelelo.

11

Impembelelo yokusika isantya kunye namandla okusika kwisixhobo ibaluleke kakhulu, kwaye isizathu esona sizathu sokuba isixhobo siwele ngenxa yokunyanzeliswa kwamandla. Ubudlelwane phakathi kwesantya sokusika kunye namandla okusika: xa isantya sokusika sikhawuleza, ukutya kuhlala kungatshintshi, kwaye amandla okusika ayancipha kancane. Eyona nto iphakamileyo, xa amandla okusika kunye noxinzelelo lwangaphakathi lukhulu kakhulu ukuba ukufakwa kufakwe, kuya kubetha (ngokuqinisekileyo, kukho nezizathu ezifana noxinzelelo kunye nokuqina kobunzima obubangelwa utshintsho lweqondo lokushisa).

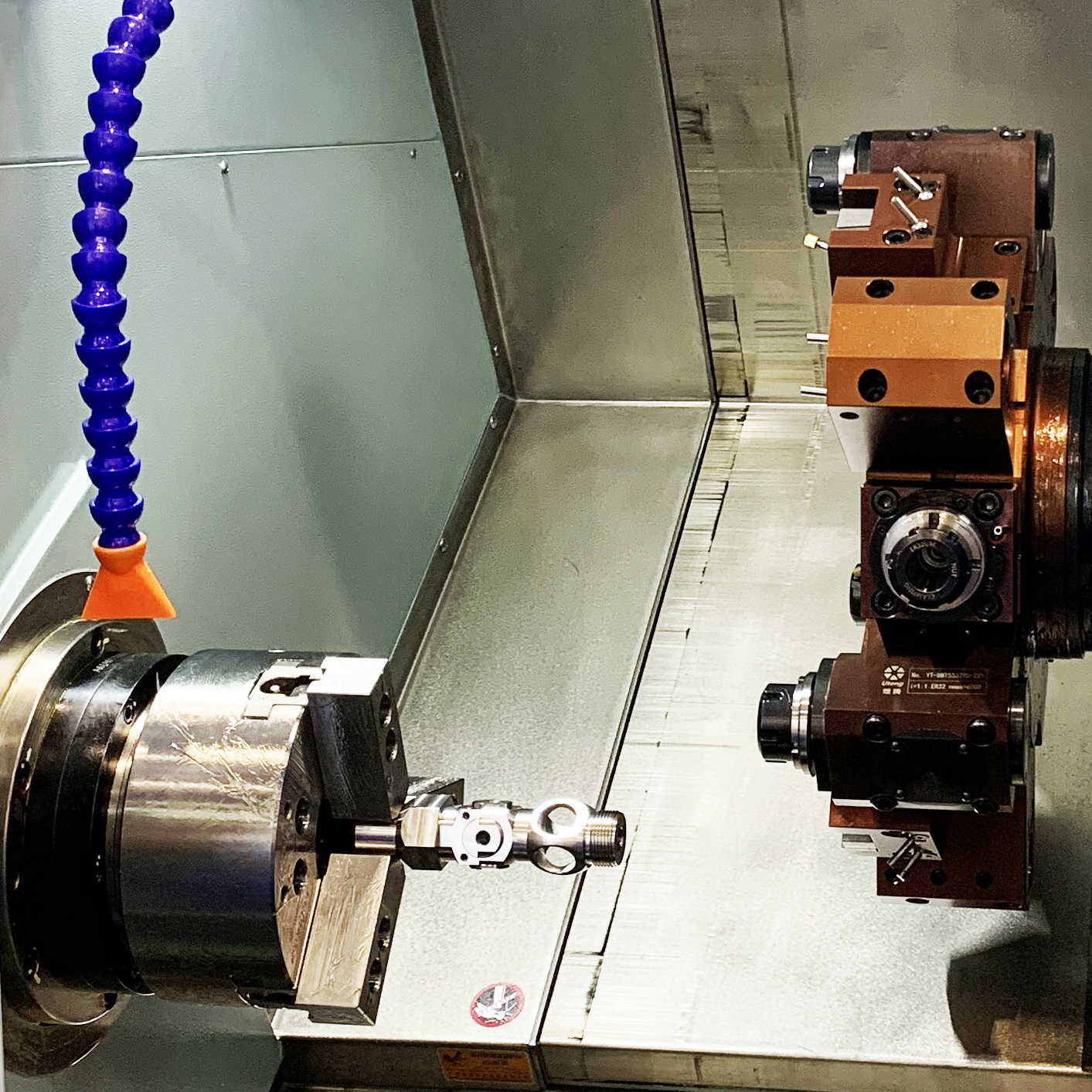

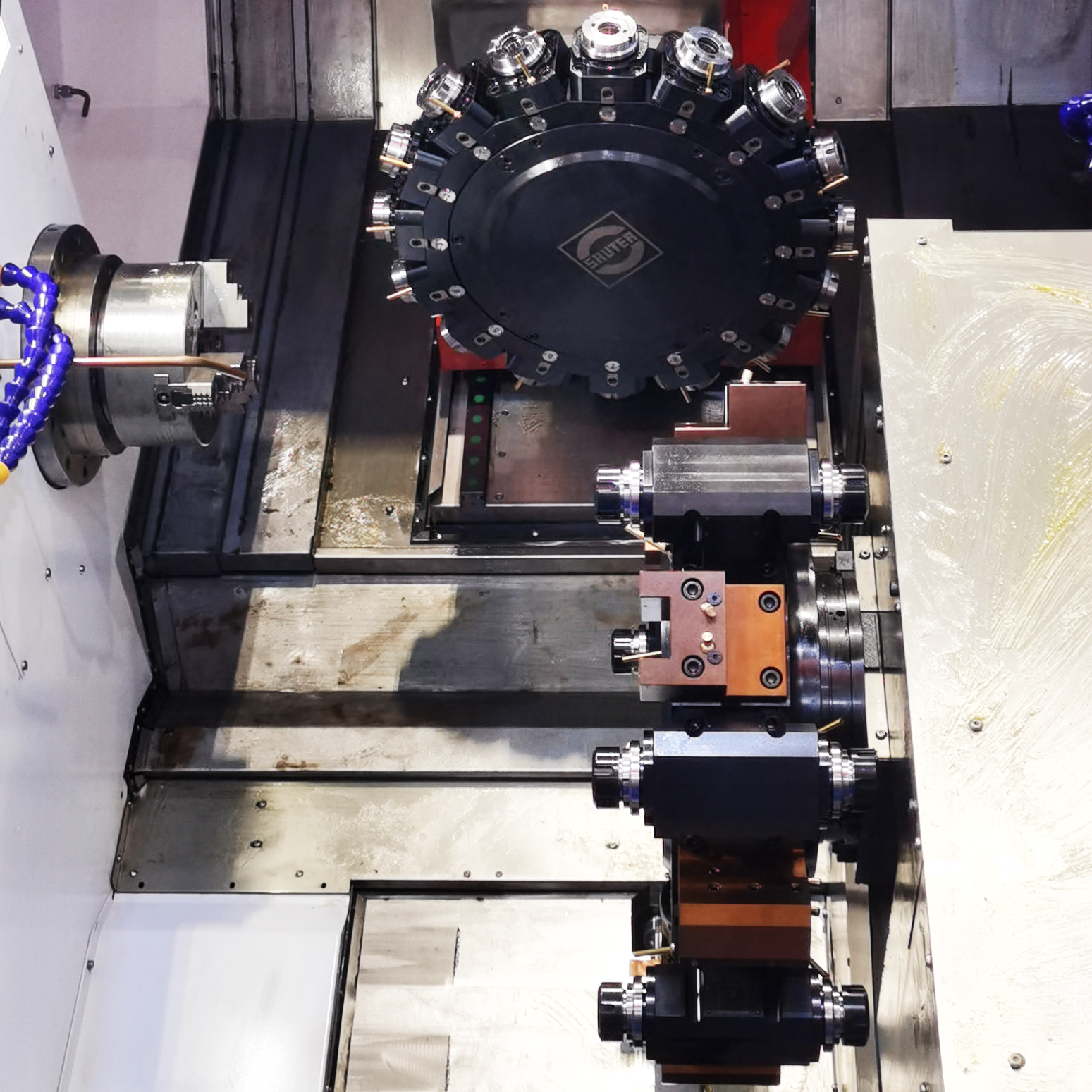

12

Niningokuchanekileyo machiningI-CNC lathes, la manqaku alandelayo kufuneka anikwe ingqwalasela eyodwa:

(1) Kwiintambo zoqoqosho zangoku ze-CNC kwilizwe lam, iinjini eziqhelekileyo ezinenqanaba le-asynchronous eziqhelekileyo zisetyenziselwa ukuqonda utshintsho lwesantya esingenanyathelo ngokuguqulela amaza. Ukuba akukho kuncitshiswa komatshini, i-torque yemveliso ye-spindle ihlala ingonelanga kwizantya eziphantsi. Ukuba umthwalo wokusika mkhulu kakhulu, kulula ukuba udikwe Iimoto, kodwa ezinye izixhobo zoomatshini zineendawo zokulungisa le ngxaki kakuhle kakhulu.

(2) Kangangoko kunokwenzeka, isixhobo sinokugqiba ukusetyenzwa kwenxalenye enye okanye ishifti enye yomsebenzi. Ekugqityweni kwamacandelo amakhulu, ingqalelo ekhethekileyo kufuneka ihlawulwe ukuze ugweme ukutshintsha isixhobo phakathi ukuze kuqinisekiswe ukuba isixhobo sinokucutshungulwa ngexesha elinye.

(3) Niniukujikaintambo ene-lathe ye-CNC, sebenzisa isantya esiphezulu kangangoko ukuphumeza umgangatho ophezulu kunye nemveliso esebenzayo.

(4) Sebenzisa i-G96 kangangoko kunokwenzeka.

(5) Ingcamango esisiseko ye-high-speed machining kukwenza ukutya kudlule isantya sokuqhuba ukushisa, ukwenzela ukuba ubushushu bokusika bukhutshwe kunye neefayili zentsimbi ukuhlukanisa ubushushu bokusika kwi-workpiece, ukwenzela ukuba kuqinisekiswe ukuba i-workpiece yenza. ungatshisi okanye ushushu kancinci. Ke ngoko, i-high-speed machining lukhetho oluphezulu kakhulu. Isantya sokusika sihambelana nezinga eliphezulu lokutya ngelixa ukhetha inani elincinci lokubandakanya umva.

(6) Nika ingqalelo kwimbuyekezo yesixhobo sempumlo R.

13

Itheyibhile yoHlelo lokuHlengahlengiso lweMathiriyeli yokuSebenza (iP79 encinci)

Amaxesha aqhelekileyo okusika intambo kunye nesikali sokubandakanya umva (iP587 enkulu)

Iifomula zokubala zamanani ejometri asetyenziswa ngokuqhelekileyo (iP42 enkulu)

I-intshi ukuya kwiMillimeters Conversion Chart (Enkulu P27)

14

Ukungcangcazela kunye nokuqhekeka kwesixhobo kuhlala kwenzeka ngexesha lokugoba. Ingcambu yazo zonke ezi zinto kukuba amandla okusika abe mkhulu kwaye ukuqina kwesixhobo akwanele. Ubude obufutshane besixhobo sokwandiswa kwesixhobo, i-angle encinci yokunceda, kwaye inkulu indawo ye-blade, ngcono ukuqina. Ngamandla amakhulu okusika, kodwa ububanzi obukhulu be-groove cutter, amandla okusika anokumelana nawo aya kwanda ngokufanelekileyo, kodwa amandla ayo okusika nawo aya kwanda. Ngokuchasene noko, incinci i-groove cutter, incinci amandla anokumelana nayo, kodwa yayo Amandla okusika nawo amancinci.

15

Izizathu zokungcangcazela ngexesha lokubeka:

(1) Ubude bokwandiswa kwesixhobo bude kakhulu, okubangela ukuhla kokuqina.

(2) Izinga lokutya licotha kakhulu, eliya kubangela ukuba iyunithi yokusika amandla inyuke kwaye ibangele ukungcangcazela okukhulu. Ifomula yile: P = F / umva wokusika inani * f P yiyunithi yokusika amandla F amandla okusika, kwaye isantya sikhawuleza kakhulu Iya kungcangcazela imela.

(3) Ukuqina kwesixhobo somatshini akwanele, oko kukuthi, isixhobo sinokuthwala amandla okusika, kodwa isixhobo somatshini asikwazi ukuthwala. Ukuyibeka ngokucacileyo, isixhobo somatshini asishukumi. Ngokuqhelekileyo, iibhedi ezintsha azinalo olu hlobo lwengxaki. Ibhedi enolu hlobo lwengxaki inoba indala okanye indala. Okanye uhlala udibana nababulali bezixhobo zoomatshini.

16

Xa ndiqhuba i-cargo, ndafumanisa ukuba ubungakanani bulungile ekuqaleni, kodwa emva kweeyure ezimbalwa zokusebenza, ndafumanisa ukuba ubungakanani butshintshile kwaye ubungakanani abuzinzile. Isizathu sisenokuba amandla okusika ayengenamandla kakhulu kuba iimela zazintsha zonke ekuqaleni. Enkulu, kodwa emva kwexesha elithile, isixhobo siguga kwaye amandla okusika abe mkhulu, obangela ukuba i-workpiece itshintshe kwi-chuck, ngoko ubungakanani budala kwaye bungazinzanga.

I-Anebon inezona zixhobo ziphambili zemveliso, iinjineli ezinamava nabaqeqeshiweyo kunye nabasebenzi, iinkqubo zolawulo lomgangatho ezivunyiweyo kunye neqela lokuthengisa elinobuhlobo ngaphambili / emva kokuthengisa inkxaso ye-OEM yePlastiki ye-OEM yePlastiki ye-ABS/PA/POM CNC ye-CNC Milling 4 Axis/5 Axis CNC machining iinxalenye, CNC ukuguqula iindawo. Okwangoku, i-Anebon ijonge phambili kwintsebenziswano enkulu ngakumbi nabathengi baphesheya ngokweenzuzo ezifanayo. Nceda ufumane amava simahla ukuze uqhagamshelane nathi ukuze ufumane iinkcukacha ezithe vetshe.

2022 Umgangatho ophakamileyo waseTshayina we-CNC kunye noMatshini, Kunye neqela labasebenzi abanamava nabanolwazi, imarike ye-Anebon igubungela uMzantsi Merika, i-USA, iMid East, kunye noMntla Afrika. Abathengi abaninzi baye baba ngabahlobo be-Anebon emva kwentsebenziswano elungileyo kunye ne-Anebon. Ukuba unayo imfuneko kuyo nayiphi na imveliso yethu, khumbula ukudibana nathi ngoku. I-Anebon ijonge phambili ukuva kuwe kungekudala.

Ixesha lokuposa: Feb-09-2023