Ngaba uyabuqonda ubudlelwane phakathi kwe-vernier calipers kunye ne-micrometers kunye neshishini le-CNC?

Zombini i-vernier calipers kunye ne-micrometers zizixhobo zokulinganisa ezichanekileyo eziqhele ukusetyenziswa kwishishini le-CNC kwimilinganiselo echanekileyo yokulinganisa.

I-Vernier calipers, ekwaziwa ngokuba zizikali ze-vernier okanye ii-sliding calipers, zizixhobo zokulinganisa eziphathwa ngesandla ezisetyenziselwa ukulinganisa imilinganiselo yangaphandle (ubude, ububanzi, kunye nobukhulu) bezinto. Ziquka isikali esiphambili kunye ne-sliding vernier scale, evumela ukufundwa okuchanekileyo ngaphaya kwesisombululo somlinganiselo oyintloko.

IiMicrometers, kwelinye icala, zikhethekileyo kwaye ziyakwazi ukulinganisa imigama emincinci ngokuchaneka okuphezulu. Zisetyenziselwa ukulinganisa imilinganiselo efana nobukhulu, ubukhulu kunye nobunzulu. IiMikhromitha zibonelela ngemilinganiselo kwiimicrometers (µm) okanye kwiwaka lemillimeter.

Kwishishini le-CNC, ukuchaneka kubalulekile ekuqinisekiseni ukuchaneka komatshini kunye neenkqubo zokuvelisa. I-Vernier calipers kunye ne-micrometers zidlala indima ebalulekileyo kulawulo lomgangatho, ukuhlolwa, kunye nemilinganiselo echanekileyoCNC oomatshini iindawo. Bavumela abaqhubi be-CNC kunye neengcali ukuba baqinisekise ubungakanani, bagcine ukunyamezelana okuqinileyo, kunye nokuqinisekisa ukusebenza kakuhle koomatshini be-CNC.

Ukudibanisa iteknoloji ye-CNC kunye nezixhobo zokulinganisa ezichanekileyo ezifana ne-vernier calipers kunye ne-micrometers zinceda ukulungelelanisa iinkqubo zokuvelisa, ukuphucula ukusebenza kakuhle, kunye nokuhambisa amacandelo aphezulu e-CNC-machine.

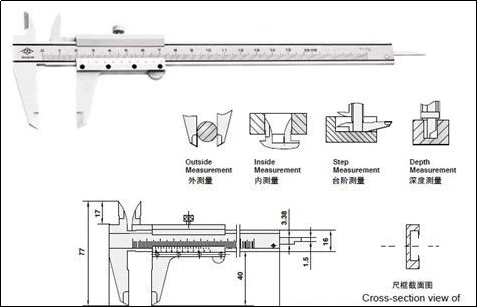

Isishwankathelo seVernier Calipers

Njengesixhobo sokulinganisa esisetyenziswa ngokubanzi esichanekileyo, i-vernier caliper yenziwe ngamacandelo amabini: isikali esiphambili kunye ne-sliding vernier eqhotyoshelwe kwisikali esikhulu. Ukuba yahlulahlulwe ngokwexabiso lesikali se-vernier, i-vernier caliper ihlukaniswe kwiintlobo ezintathu: 0.1, 0.05, kunye ne-0.02mm.

Uzifunda njani ii-vernier calipers

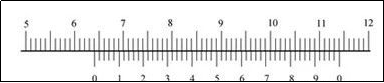

Ukuthatha i-caliper ye-vernier echanekileyo kunye nexabiso le-0.02mm njengomzekelo, indlela yokufunda inokwahlulwa ibe ngamanyathelo amathathu;

1) Funda yonke i-millimeter ngokomlinganiselo okufutshane kwisikali esiphambili ukuya ngasekhohlo kumgca ongu-zero wesikali esincedisayo;

2) Phindaphinda-phinda ngo-0.02 ukufunda idesimali ngokwenani lemigca ekroliweyo elungelelaniswe nesikali kwisikali esiphambili kwicala lasekunene lomgca onguziro wesikali esincedisayo;

3) Dibanisa inani elipheleleyo kunye nedesimali ngasentla ukuze ufumane isayizi iyonke.

Indlela yokufunda ye-0.02mm vernier caliper

Njengoko kubonisiwe kumzobo ongentla, isikali esiphambi kwesikali esiphambili esijongene nomgca we-0 we-subscale yi-64mm, kwaye umgca we-9 emva komgca we-0 we-subscale uhambelana nomgca oqingqiweyo wesikali esikhulu.

Umgca we-9 emva komgca we-0 we-sub-scale uthetha: 0.02 × 9 = 0.18mm

Ngoko ubungakanani bomsebenzi olinganisiweyo ngu: 64+0.18=64.18mm

Uyisebenzisa njani i-vernier caliper

Hlanganisa imihlathi ukuze ubone ukuba i-vernier ihambelana nophawu lwe-zero kwisikali esikhulu. Ukuba ilungelelanisiwe, inokulinganiswa: ukuba ayilungelelaniswanga, impazamo enguziro kufuneka irekhodwe: umgca wesikali esinguziro wevernier ubizwa ngokuba yimpazamo eyiqanda enguziro kwicala lasekunene lomgca wesikali esingu-zero kumzimba werula, kwaye imposiso embi enguziro ibizwa ngokuba yimposiso embi enguziro kwicala lasekhohlo lomgca wesikali esingu-zero kumzimba werula (le Le ndlela yommiselo ihambelana nommiselo we-axis yenani, imvelaphi ilungile xa imvelaphi isekunene, kwaye ithabatha xa imvelaphi ingasekhohlo).

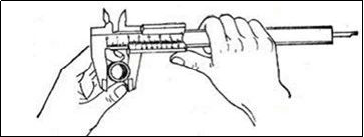

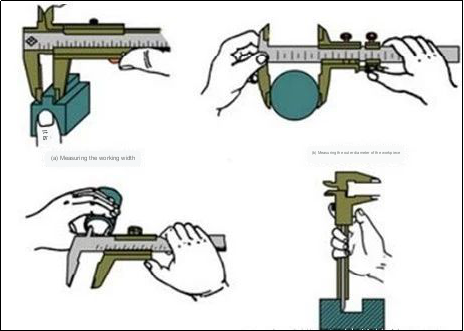

Xa ulinganisa, bamba irula yomzimba ngesandla sakho sasekunene, hambisa ikhesa ngobhontsi wakho, kwaye ubambeiindawo ze-aluminiyam ze-cncngedayamitha yangaphandle (okanye idiameter yangaphakathi) ngesandla sakho sasekhohlo, ukuze into eza kulinganiswa ibekwe phakathi kweenzipho zokulinganisa zangaphandle, kwaye xa ibotshelelwe ngokuqinileyo kwiinzipho zokulinganisa, ungaFunda, njengoko kubonisiwe kulo mfanekiso ungezantsi. :

Ukusetyenziswa kwe-Vernier Calipers kwiiNkonzo ze-CNC Machining

Njengesixhobo sokulinganisa esiqhelekileyo, i-vernier caliper ingasetyenziswa kwezi nkalo zine zilandelayo:

1) Ukulinganisa ububanzi bomsebenzi

2) Ukulinganisa i-diameter yangaphandle ye-workpiece

3) Ukulinganisa ububanzi bangaphakathi bomsebenzi

4) Ukulinganisa ubunzulu bomsebenzi

Iindlela zokulinganisa ezikhethekileyo zale miba mine zibonisiwe kulo mfanekiso ungezantsi:

Ukusetyenziswa kweVernier Calipers kwiIinkonzo zoMatshini ze-CNC

Njengesixhobo sokulinganisa esiqhelekileyo, i-vernier caliper ingasetyenziswa kwezi nkalo zine zilandelayo:

1) Ukulinganisa ububanzi bomsebenzi

2) Ukulinganisa i-diameter yangaphandle ye-workpiece

3) Ukulinganisa ububanzi bangaphakathi bomsebenzi

4) Ukulinganisa ubunzulu bomsebenzi

Iindlela zokulinganisa ezikhethekileyo zale miba mine zibonisiwe kulo mfanekiso ungezantsi:

Imiqathango yokusetyenziswa

I-vernier caliper sisixhobo sokulinganisa esichanekileyo, kwaye ezi zinto zilandelayo kufuneka ziqwalaselwe xa usebenzisa:

1. Phambi kokusetyenziswa, coca umgangatho wokulinganisa weenyawo ezimbini eziqhotyoshwayo, vala iinyawo ezimbini eziqhotyoshwayo, kwaye ukhangele ukuba umgca ongu-0 werula encedisayo ulungelelaniswe nomgca ongu-0 werula eyintloko. Ukuba akunjalo, ufundo lomlinganiselo kufuneka lulungiswe ngokwempazamo yokuqala.

2. Xa ulinganisa i-workpiece, indawo yokulinganisa i-clamp footage kufuneka ihambelane okanye i-perpendicular kumphezulu we-workpiece, kwaye akufanele iguqulwe. Kwaye amandla akufanele abe mkhulu kakhulu, ukwenzela ukuba ungakhubeki okanye unxibe iinyawo zekliphu, eziza kuchaphazela ukuchaneka komlinganiselo. 3. Xa ufunda, umgca wokujonga kufuneka ube yi-perpendicular kumgangatho wesikali, ngaphandle koko ixabiso elilinganisiweyo liya kuba lingachanekanga.

4. Xa ulinganisa i-diameter yangaphakathi, yigubungele kancinci ukuze ufumane ixabiso eliphezulu.

5. Emva kokuba i-vernier caliper isetyenzisiwe, yisule ngokucophelela, sebenzisa ioli ekhuselayo, kwaye uyibeke phantsi kwikhava. ukuba ithe yagqwala okanye igobile.

I-spiral micrometer, ekwabizwa ngokuba yi-micrometer, sisixhobo esichanekileyo sokulinganisa. Umgaqo, ulwakhiwo kunye nokusetyenziswa kwe-spiral micrometer iya kuchazwa ngezantsi.

Yintoni iSpiral Micrometer?

I-Spiral micrometer, eyaziwa ngokuba yi-micrometer, i-spiral micrometer, i-centimeter card, sisixhobo esichaneke ngakumbi sokulinganisa ubude kune-vernier caliper. Inokulinganisa ubude ngokuchanekileyo ukuya kwi-0.01mm, kwaye uluhlu lokulinganisa luziisentimitha ezininzi.

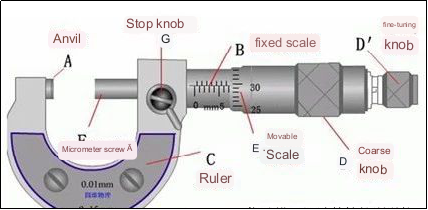

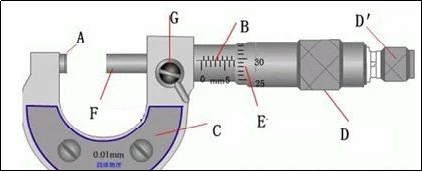

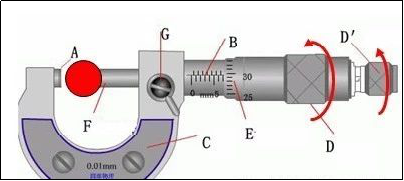

Ubume be-spiral micrometer

Oku kulandelayo ngumzobo weskim sesakhiwo se-spiral micrometer:

Umgaqo osebenzayo we-screw micrometer

I-screw micrometer yenziwe ngokomgaqo we-screw amplification, oko kukuthi, i-screw ijikeleza kanye kwi-nut, kwaye i-screw iqhubela phambili okanye ibuyele ecaleni kwicala le-axis yokujikeleza ngomgama we-pitch enye. Ke ngoko, umgama omncinci ohanjiswe ecaleni kwe-axis unokubonakaliswa ngokufunda kwisangqa.

I-pitch yentambo echanekileyo ye-screw micrometer yi-0.5mm, kwaye isikali esishukumayo sinezikali ezihlulwe ngokulinganayo ezingama-50. Xa isikali esishukumayo sijikeleza kube kanye, isikrufu semicrometer singaqhubela phambili okanye sibuye umva nge-0.5mm, ngoko ke ukujikelezisa isahlulo esincinci ngasinye silingana nokulinganisa I-micro screw progresss okanye ihlehle 0.5/50=0.01mm. Inokubonwa ukuba isahlulo ngasinye esincinci sesikali esishukumayo simele i-0.01mm, ngoko ke i-micrometer ye-screw ingachaneka ukuya kwi-0.01mm. Ngenxa yokuba inokuqikelelwa ukuba ifundeka enye, inokufundwa ukuya kutsho kwiwaka leemilimitha, ngoko ikwabizwa ngokuba yi<em>micrometer.

Indlela yokusebenzisa i-spiral micrometer

Xa sihlala sincedisa abathengi ukuba baqhagamshele isixhobo sethu sokufumana idatha kunye ne-spiral micrometer yomlinganiselo ophezulu wokusebenza, sihlala sikhokela abathengi ukuba benze oku kulandelayo xa besenza i-spiral micrometer:

1. Qwalasela inqaku elinguziro phambi kokusetyenziswa: jija kancinane iqhosha lokuguqula kakuhle u-D′ ukwenza intonga yokulinganisa (F) idibane ne-anvil yokumejarisha (A) de iretshi yenza isandi. Ngeli xesha, indawo ye-zero kwirula eshukumayo (umkhono oshukumayo) Umgca okroliweyo kufuneka ulungelelaniswe nomgca wereferensi (umgca omde othe tye) kumkhono osisigxina, kungenjalo kuya kubakho impazamo engu-0.

2. Bamba isakhelo serula (C) esandleni sasekhohlo, jika iqhoshana lohlengahlengiso elirhabaxa D ngesandla sasekunene ukwenza umgama phakathi kwentonga yokulinganisa F kunye ne-anvil A nkulu kancinane kunento elinganisiweyo, faka into elinganisiweyo, jika iqhoshana lokukhusela u-D' ukuze ubambe into elinganisiweyo kude kube i-ratchet yenza isandi, jika iqhosha elisisigxina G ukulungisa intonga yokulinganisa kwaye uthathe ukufunda.

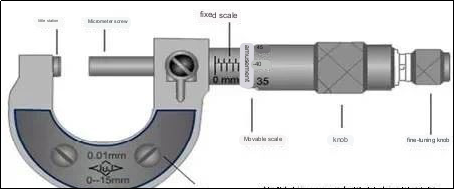

Indlela yokufunda ye-screw micrometer

1. Funda isikali esimiselweyo kuqala

2. Funda isikali sesiqingatha kwakhona, ukuba umgca wesiqingatha sesikali ubonakalisiwe, bhala phantsi njengo-0.5mm; ukuba umgca wesiqingatha sesikali awuvezwanga, bhala phantsi njengo-0.0mm;

3. Funda kwakhona isikali esishukumayo (nikela ingqalelo kuqikelelo), kwaye urekhode njengo-n × 0.01mm;

4. Isiphumo sokugqibela sokufunda sisikali esisisigxina + isikali esisiqingatha + nesikali esishukumayo

Ngenxa yokuba umphumo wokufundwa kwe-spiral micrometer uchanekile ukuya kwiwaka le-mm, i-spiral micrometer ikwabizwa ngokuba yi-micrometer.

Imigqaliselo ye-spiral micrometer

1. Xa ulinganisa, qaphela ukuyeka ukusebenzisa iqhosha xa i-screw micrometer isondela kwinto eya kulinganiswa, kwaye usebenzise iqhosha lokulungisa kakuhle endaweni yoko ukuphepha uxinzelelo olugqithisileyo, olungenakwenza kuphela umphumo wokulinganisa ichanekile, kodwa nokukhusela. i-screw micrometer.

2. Xa ufunda, qaphela ukuba umgca okroliweyo obonisa isiqingatha se-millimeter kwisikali esisisigxina ubonakalisiwe.

3. Xa kufundwa, kukho inani eliqikelelwayo kwindawo yewaka, elingenakulahlwa nje ngokungaqhelekanga. Nokuba indawo enguziro yesikali esimiselweyo ilungelelaniswe nje nomgca wesikali esithile somlinganiselo oshukumayo, indawo yewaka nayo kufuneka ifundwe njengo “0”.

4. Xa i-anvil encinci kunye ne-screw micrometer zisondelene kunye, indawo ye-zero yesikali esishukumayo ayihambelani nendawo ye-zero yesikali esisisigxina, kwaye kuya kubakho impazamo ye-zero, ekufuneka ilungiswe, oko kukuthi, ixabiso lempazamo enguziro kufuneka lisuswe kufundo lomlinganiselo wokugqibela wobude.

Ukusetyenziswa ngokufanelekileyo kunye noLondolozo lweSpiral Micrometer

• Jonga ukuba ingaba umgca onguziro uchanekile kusini na;

• Xa ulinganisa, umgangatho olinganisiweyo we-workpiece kufuneka ucinywe;

• Xa i-workpiece inkulu, kufuneka ilinganiswe kwintsimbi efana ne-V okanye i-flat plate;

• Sula intonga yokulinganisa kunye ne-anvil phambi kokuba wenze imilinganiselo;

• Isixhobo se-ratchet siyafuneka xa ukrwela umkhono oshukumayo;

• Musa ukukhulula ikhava yangasemva, ukwenzela ukuba ungatshintshi umgca we-zero;

• Musa ukongeza i-oyile ye-injini eqhelekileyo phakathi komkhono osisigxina kunye nomkhono oshukumayo;

• Emva kokusetyenziswa, sula ioli kwaye uyibeke kwibhokisi ekhethekileyo kwindawo eyomileyo.

Usukelo lwe-Anebon kunye nenjongo yeshishini ku "Soloko usanelisa iimfuno zabathengi bethu". I-Anebon qhubeka nokuseka kunye nesimbo kunye noyilo olubalaseleyo lweempahla ezikumgangatho ophezulu kuzo zombini eziphelelwe lixesha kunye namathemba amatsha kwaye siqonde ithemba lokuphumelela kubathengi bethu kanye njengokuba silungiselela iiprofayili ezichanekileyo ezichanekileyo, i-cnc eguqula iinxalenye ze-aluminium kunye neendawo zokusila ze-aluminium kubathengi. . I-Anebon ngeengalo ezivulekileyo, imema bonke abathengi abanomdla ukuba batyelele iwebhusayithi yethu okanye baqhagamshelane nathi ngokuthe ngqo ngolwazi oluthe kratya.

IFactory Customized China CNC Machine kunye neCNC Engraving Machine, imveliso ye-Anebon iyaziwa ngokubanzi kwaye ithenjwa ngabasebenzisi kwaye inokudibana ngokuqhubekayo nokuphuhlisa iimfuno zoqoqosho nezentlalo. I-Anebon yamkele abathengi abatsha nabadala abavela kuzo zonke iindlela zobomi ukuze baqhagamshelane nathi kubudlelwane beshishini elizayo kunye nokuzuza impumelelo efanayo!

Ixesha lokuposa: Jul-03-2023