Ngaba uyazi kangakanani malunga nokuhlelwa kwezixhobo zoomatshini be-CNC?

Ukuhlelwa kwezixhobo zomatshini we-CNC kusekelwe kumsebenzi, isakhiwo kunye nokusetyenziswa.

Ngoku siza kujonga iindidi ezahlukeneyo:

Ngokusekwe kuMsebenzi

Oomatshini bokujika:Aba matshini benza imisebenzi yokuguqula ubukhulu becala kwi-cylindrical okanye i-conical components.

Aba matshini banokusetyenziselwa ukuguba iindawo ezisicaba okanye ezintsonkothileyo.

Ngokusekelwe kuLwakhiwo

Amaziko Machining axwesileyo:I-spindle kunye ne-workpiece zibekwe ngokuthe tye kwitafile.

Amaziko Machining nkqo:I-spindle kunye ne-workpiece zibekwe ngokuthe nkqo etafileni.

Oomatshini be-Multi-axis:Aba matshini baxhotyiswe ngeezembe ezininzi (ezi-3 okanye ngaphezulu), ezivumela ukuba benze imisebenzi echanekileyo kunye neyinkimbinkimbi.

Ngokusekwe kwiSicelo

Oomatshini boKwemba ngoomatshini abenza imisebenzi yokomba.

Oomatshini bokucola:Aba matshini banokusetyenziselwa ukucola nokupholisha isinyithi.

Oomatshini bokusika iLaser:Itekhnoloji yeLaser isetyenziselwa ukusika izinto ezahlukeneyo.

Oomatshini bokukhupha i-Electro-Discharge (EDM):Aba matshini babumba kwaye bomba izinto ezisebenza ngombane.

Iindlela zokuhlela koomatshini be-CNC zahlukile. Kukho iintlobo ezininzi kunye neenkcukacha. Ingahlelwa kusetyenziswa iindlela zokuhlela ezingentla, kunye nemigaqo emine yokusebenza kunye nesakhiwo.

1. Ukuhlelwa kwezixhobo zoomatshini ngokweendlela zabo zokulawula

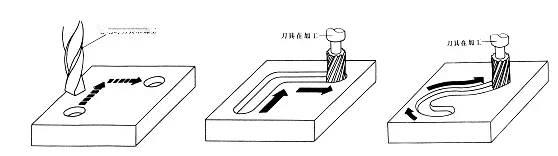

1) Ulawulo lwamanqaku oomatshini be-CNC

Ekuphela kwemfuneko yolawulo lwamanqaku kukubekwa ngokuchanekileyo kweendawo ezihambayo ukusuka kwesinye isixhobo ukuya kwesinye. Iimfuno zomkhondo phakathi kwamanqaku okunyakaza azikho ngqongqo kakhulu. Ngethuba lokuhamba, akukho nkqubo eyenziwa. Akubalulekanga ukuba ukunyakaza kwenzeka njani phakathi kwe-axis yokulungelelanisa nganye. Ukufezekisa ukumisa okuchanekileyo kunye nokukhawuleza, kubalulekile ukuqala ukuhambisa umgama phakathi kwamanqaku amabini ngokukhawuleza, emva koko usondele ngokukhawuleza kwindawo yokuma ukuqinisekisa ukuchaneka. I-motion trajectory iboniswe ngezantsi.

Oomatshini bokugaya be-CNC kunye noomatshini bokubhoboza be-CNC yimizekelo yezixhobo zoomatshini abanamandla okulawula amanqaku. Iinkqubo ze-CNC ezisetyenziselwa kuphela ulawulo lwamanqaku ziye zanqabile ngenxa yokuqhubela phambili kobuchwepheshe be-CNC.

(2) Ulawulo lwelayini izixhobo zomatshini we-CNC

Ulawulo olunxuseneyo koomatshini be-CNC nabo baziwa njengoomatshini bolawulo lwe-CNC. Inophawu lokuba ayilawuli nje kuphela indawo echanekileyo phakathi kwamanqaku kodwa kunye nesantya sokuhamba kunye nendlela (i-trajectory), phakathi kwamanqaku amabini. Ukuhamba kwayo kuhambelana kuphela nesixhobo somatshini silungelelanisa ama-axes ahamba ngokuhambelanayo. Oku kuthetha ukuba ulungelelwaniso olunye kuphela olulawulwa ngexesha. Isixhobo singasetyenziselwa ukusika kwireyithi yokutya echazwe ngexesha lenkqubo yokutshintsha. Ingasetyenziselwa kuphela ukusetyenzwa koxande kunye namalungu anyuliweyo.

CNC lathesngolawulo lomgca ubukhulu becala oomatshini bokusila be-CNC kunye ne-CNC grinders. Inkqubo yeCNC yesi sixhobo somatshini yaziwa ngokuba yinkqubo yolawulo lwe-CNC. Ngendlela efanayo, oomatshini be-CNC abasetyenziswa kuphela kulawulo lomgca abanqabile.

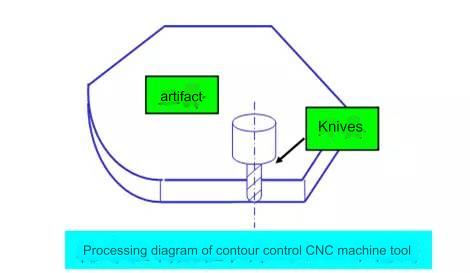

(3) Ulawulo lwe-contour ye-3D izixhobo zomatshini we-CNC

Ulawulo oluqhubekayo oomatshini be-CNC nabo baziwa njengoomatshini bolawulo lwe-contour CNC. Uphawu lolawulo lwalo matshini kukukwazi ukulawula ulungelelwaniso lwentshukumo ezimbini nangaphezulu ngaxeshanye.

Ukuqinisekisa ukuba intshukumo ehambelanayo yesixhobo kwi-contour ye-workpiece ihambelana ne-machining contour ye-workpiece, kuyimfuneko ukulungelelanisa ngokuchanekileyo ukufuduka kunye nesantya sentshukumo nganye elungelelanisiweyo ngokungqinelana nobudlelwane obumiselweyo.

Ukuze usebenzise le ndlela yokulawula, isixhobo se-CNC kufuneka sibe nomsebenzi wokudibanisa. I-Interpolation ichaza imilo yomgca othe ngqo okanye i-arc ngokulungiswa kwemathematika okwenziwa ngabaqhubi be-interpolation kwinkqubo ye-CNC. Oku kusekelwe kwidatha eyisiseko efakwe yiprogram, njengezilungelelaniso zeendawo zokugqibela zomgca othe ngqo, ulungelelaniso lweendawo zokugqibela ze-arc, okanye i-radius okanye i-coordinate coordinate. Ngelixa ubala, yabela iipulses kumlawuli ngamnye we-coordinate axis ngokweziphumo. Oku kulawula ukushenxiswa koqhakamshelwano kumlungelelanisi ngamnye ukuze ahambelane nekhontowuli efunekayo. Ngexesha lokunyakaza, isixhobo sisika ngokuqhubekayo umphezulu womsebenzi, ovumela ukusetyenzwa okuhlukeneyo njengemigca ethe tye, iigophe kunye nee-arcs. Icontour-controlled machineing trajectory.

Ezi zixhobo zoomatshini ziquka i-CNC lathes kunye noomatshini bokugaya kunye noomatshini bokusika i-CNC, amaziko omatshini, njl njl. Izixhobo ze-CNC ezihambelana nazo zibizwa ngokuba yi-contour control systems. Ingahlelwa ngokweendidi ezintathu ngokusekelwe kwinani leezembe elizilawulayo: ifom

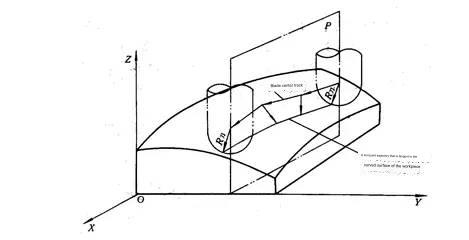

1 Amakhonkco emigca emibini:isetyenziselwa ikakhulu iileyile ze-CNC eziqhuba imiphezulu ejikelezayo, okanye oomatshini bokusila be-CNC abalungisa imiphezulu egobileyo.

2 Isiqingatha sonxulumaniso 2 amazembe:Oku kusetyenziselwa ikakhulu ukulawula izixhobo zoomatshini ezineezembe ezingaphezulu kwe-3. Iizembe ezimbini zinokudityaniswa kwaye i-axis yesithathu inokwenza isondlo sexesha.

3 Unxulumaniso lwee-axis ezintathu:Olu lunxibelelwano olubandakanya amazembe amathathu alungelelanisiweyo, ngokuqhelekileyo i-X/Y/Z, kwaye isetyenziswa ngoomatshini bokugaya i-CNC, amaziko oomatshini, njl. njl. kunye ne-axis yolungelelwaniso olujikelezayo olujikeleza ii-asi zolungelelaniso zomgca.

Kwiziko lomatshini wokujika, umzekelo, unxibelelwano phakathi kwee-axis ezimbini zolungelelwaniso (i-X-axis kunye ne-Z-axis kwicala le-longitudinal) kufuneka ilawulwe ngaxeshanye noqhagamshelwano lwe-spindle's (i-C-axis), ejikeleza kwi-axis engu-Z. .

4 Unxulumano lwe-axis emine:Lawula imigca emithathu yolungelelaniso lwe-X, Y kunye no-Z ngaxeshanye ukuze zidityaniswe ne-axis yolungelelwaniso olujikelezayo.

5 Unxulumaniso lwee-axis ezintlanu:Oku kukuvumela ukuba ulawule ukudityaniswa kwee-asi zolungelelaniso ezintathu ngaxeshanye, X/Y/Z. Isixhobo sikwalawula ngaxeshanye ezimbini ze-AB kunye no-C zilungelelanisa ii-axes ezijikeleza ezi migca zilandelelanayo. Oku kunika itotali yeezembe ezintlanu. Isixhobo ngoku sinokubekwa naphi na esithubeni.

Isixhobo sinokulawulwa ukujikeleza sijikeleze zombini ii-axes zika-x kunye no-y ngaxeshanye, ngoko ke sihlala sisika kwicala elinye nomphezulu wecontour. Oku kuqinisekisa ukugudiswa kunye nokuchaneka komphezulu. Umphezulu owenziwe ngoomatshini ulula, ukwandisa ukusebenza kakuhle.

2. Ukuhlelwa kweenkqubo ezilawulwa yi-servo

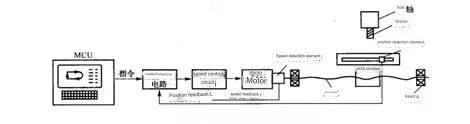

1) Izixhobo zoomatshini ze-CNC ezivulekileyo

Olu hlobo lwesixhobo somatshini lune-servo yokutya evulekileyo, oku kuthetha ukuba akukho sixhobo sokubona impendulo. I-motor yayo yokuqhuba idla ngokuba yi-stepper. Eyona nto iphambili yemoto ye-stepper kukuba ijikeleza inyathelo elipheleleyo ngalo lonke ixesha inkqubo yolawulo itshintsha isiginali ye-pulse. I-motor ine-self-locking feature kwaye ingasetyenziselwa ukulungisa i-engile yomgama.

Umsasazi we-pulse ulawula isekethe ye-drive ngokusebenzisa umqondiso womyalelo wesondlo ukusuka kwinkqubo ye-CNC. Inani lee-pulses kunye ne-pulse frequency inokutshintshwa ukulawula ukulungelelaniswa kokuhamba, isantya sokufuduka, okanye ukufuduswa. ulwalathiso.

Iimpawu eziphambili zale ndlela kukulula kwayo, ukusebenziseka ngokulula, kunye neendleko eziphantsi. Akukho ngxaki yokungazinzi kwinkqubo yolawulo kuba inkqubo ye-CNC ithumela kuphela imiqondiso yendlela enye. Ukuchaneka kokufuduswa kuphantsi, nangona kunjalo, kuba impazamo yokuhanjiswa komatshini ayilungiswanga ngempendulo.

Le ndlela yokulawula yayisetyenziswa ngabo bonke oomatshini bokuqala be-CNC, kodwa yayinezinga eliphezulu lokungaphumeleli. Ngaphandle kokuphuculwa kweesekethe zokuqhuba, le ndlela yokulawula isasetyenziswa ngokubanzi namhlanje. Le ndlela yokulawula, ngakumbi kwilizwe lethu isetyenziselwa iinkqubo ze-CNC eziqhelekileyo ezinoqoqosho kunye nokuguqula izixhobo ezindala usebenzisa i-CNC. Le ndlela yokulawula ikwavumela ikhompyuter enye yetshiphu okanye ikhompyuter yebhodi enye ukuba iqwalaselwe njengomatshini weCNC, onciphisa iindleko zenkqubo.

Izixhobo zoomatshini ezinolawulo oluvaliweyo

Olu hlobo lwesixhobo somatshini we-CNC lusebenzisa ulawulo oluvaliweyo. I-motor drive inokuba yi-DC okanye i-AC kwaye kufuneka ibe nengxelo yesikhundla kunye nengxelo yesantya eqwalaselwe ukubona nayiphi na intshukumo yokwenyani yenxalenye ehambayo nakweyiphi na indawo ngexesha lokusetyenzwa. Inkqubo ye-CNC iyondla imali emva kwexesha langempela kumthelekisi. Umqondiso womyalelo ufunyanwa ngokufakela kwaye uthelekiswe nesixa. Umahluko ke usetyenziselwa ukulawula i-servodrive, eqhuba icandelo lokufuduka ukuze kupheliswe impazamo.

Ngokuxhomekeke kwindawo kunye nesixhobo sempendulo yesixhobo sokujonga impendulo, kukho iindlela ezimbini: iluphu evaliweyo (igcwele) kunye ne-semi-closed loop (i-semi-closed loop).

1 Ulawulo lwe-loop oluvaliweyo

Isixhobo sempendulo yesikhundla, njengoko kubonisiwe kumzobo sisebenzisa inqaku lokubona umgama womgama. (Okwangoku, umthetho wokugaya usetyenziswa kakhulu) Oku kuxhonywe kwisali yesixhobo somatshini. Ibhaqa ngokuthe ngqo ukufuduswa komgca kulungelelwaniso lwesixhobo somatshini. Umqondiso ovela kwi-motor unokupheliswa ngempendulo. Imposiso yokudlulisa iyancitshiswa kwikhonkco lokuhanjiswa komatshini, okukhokelela ekuchanekeni okuphezulu kokumiswa kwe-static kumatshini.

Impendulo eguquguqukayo yothungelwano lomatshini ngokubanzi lude kakhulu kunempendulo yombane. Yonke inkqubo yolawulo lwe-loop evaliweyo inzima kakhulu ukuzinzisa, kwaye uyilo lwayo kunye nohlengahlengiso lunzima kakhulu. Le ndlela yolawulo evaliweyo isetyenziswa ikakhulu kumatshini wokunxibelelanisa i-CNC, oomatshini bokugaya abachanekileyo be-CNC, njl. Ezifuna ukuchaneka okuphezulu.

2 Ulawulo lwe-loop oluvaliweyo

Ingxelo yendawo isekelwe kumacandelo okubona i-engile, ngoku ikakhulu iikhowudi zeekhowudi. Iinjini ze-servo okanye izikrufu zifakelwe amacandelo okubona i-engile (okwangoku ikakhulu ii-encoders). Iimpawu zolawulo lwenkqubo zizinzile ngakumbi kuba uninzi lweekhonkco zokuhambisa ngoomatshini azikho kwi-loop evaliweyo. Imbuyekezo yexabiso elisisigxina leSoftware inokuphucula ukuchaneka kweempazamo zothumelo lomatshini, njengempazamo yesijiva. Uninzi koomatshini be-CNC basebenzisa imowudi ye-loop evaliweyo.

I-3 Dimensional hybrid control control machine CNC

Ukudala inkqubo yokulawula i-hybrid, iimpawu zendlela yokulawula nganye inokugxininiswa ngokukhethiweyo. Ukuze uhlangabezane neemfuno zezixhobo ezithile zoomatshini kunye nokuhlawulela ukungafani phakathi kweendlela ezimbini, kucetyiswa ukuba kusetyenziswe inkqubo yokulawula i-hybrid. Iindlela ezimbini eziqhelekileyo luhlobo lwembuyekezo lwe-loop evulekileyo kunye nohlobo lwembuyekezo ye-loop evaliweyo.

3. IiNkqubo ze-CNC zihlelwa ngokwenqanaba lazo lokusebenza

Iisistim ze-CNC zihlelwa ngokweendidi ezintathu ngokusekelwe kwinqanaba lokusebenza kwazo: eliphantsi, eliphakathi, neliphezulu. Le ndlela yokwahlula isetyenziswa kakhulu kwilizwe lethu. Imigangatho yokuhlela yahlukile ukusuka kwixesha elithile ukuya kwelinye. Ngokutsho kwinqanaba lophuhliso lwangoku, iintlobo ezahlukeneyo zeenkqubo ze-CNC zihlulwe zibe ngamacandelo amathathu ngokusekelwe kwimisebenzi ethile kunye nezalathi. Iinkqubo ze-CNC eziPhakathi neziphakamileyo zidla ngokubizwa ngokuba zisebenza ngokupheleleyo okanye njenge-CNC eqhelekileyo.

(1) Ukusika isinyithi

Ibhekisela koomatshini be-CNC abenza imisebenzi eyahlukeneyo yokusika njengecnc ukujika & milling. Oku kunokohlulwa kube ziindidi ezimbini eziphambili.

Oomatshini be-CNC abanje ngeelathe kunye noomatshini bokungqusha.

Olona phawu luphambili lweziko lomatshini lithala leencwadi lesixhobo, elinesixhobo sokutshintsha isixhobo esizenzekelayo. Idlula kuphela i-workpiece kumatshini kube kanye. Emva kokubamba i-workpiece, izixhobo zokusika zitshintshwa ngokuzenzekelayo. Iinkqubo ezahlukeneyo, kubandakanywa ukugaya (ukuguqula), izitshixo, ukuphinda (ukugaya), kunye nokubetha intambo zenziwa ngokuqhubekayo kwindawo nganye yesiqwenga kumatshini ofanayo, umzekelo, (isakhiwo / ukugaya). Iziko, indawo yokujika, indawo yokugaya, njl.

(2) I-Metal Forming

Kubhekiselwa koomatshini be-CNC abasetyenziselwa ukukhupha, ukubethelwa kunye nokucofa, kunye nokuzoba, kunye neminye imisebenzi yokwenza. Ezinye zezona matshini zixhaphakileyo zisetyenziswa CNC ziquka CNC ocinezela kunye CNC umbhobho benders.

(3) ICandelo loLungiselelo oluKhethekileyo

I-CNC wire EDM oomatshini zezona ziqhelekileyo, zilandelwacnc ukusika isinyithioomatshini kunye noomatshini bokucwangcisa i-CNC laser.

(4) Ukulinganisa nokuzoba

Okubandakanyiweyo kolu didi ikakhulu zizixhobo zokulinganisa ezintathu-dimensional, iiseti zezixhobo ze-CNC, iiplani ze-CNC, njl.

Eyona njongo iphambili ye-Anebon iya kuba kukukunika abathengi bethu ubudlelwane obunzulu noboxanduva lweshishini, ukubonelela ngengqwalasela yobuqu kubo bonke kuYilo olutsha lweFashoni ye-OEM Shenzhen Precision Hardware Factory Custom Fabrication.CNC millinginkqubo, ukuphosa ngokuchanekileyo, inkonzo yeprototyping. Ungafumana elona xabiso lisezantsi apha. Kwakhona uya kufumana iimveliso ezisemgangathweni kunye nezisombululo kunye nenkonzo emangalisayo apha! Akufanele ube madolw' anzima ukubamba iAnebon!

Uyilo olutsha lweFashoni ye-CNC yeNkonzo yokuMachining yaseTshayina kunye neNkonzo yokuLungisa i-CNC yesiNtu, i-Anebon inamanani amaqonga orhwebo angaphandle, ayi-Alibaba, i-Globalsources, i-Global Market, i-Made-in-china. "XinGuangYang" Imveliso ye-HID brand kunye nezisombululo zithengisa kakuhle kakhulu eYurophu, eMelika, kuMbindi Mpuma nakweminye imimandla kumazwe angaphezu kwama-30.

Ixesha lokuposa: Oct-06-2023