1. Umlinganiselo

Amalungu aquka imiphezulu emininzi, nganye inobukhulu obuthile kunye neemfuno zokuma ngokulinganayo. Iimfuno zokuma ezihambelanayo phakathi kwemiphezulu yamacandelo zibandakanya imiba emibini: ukuchaneka komgama phakathi kwemiphezulu kunye nokuchaneka kwendawo ehambelanayo (njenge-coaxiality, i-parallelism, i-perpendicularity kunye ne-circular runout, njl. njl.) iimfuno. Uphononongo lobudlelwane bendawo ehambelanayo phakathi kwemiphezulu yamacandelo ayinakwahlulwa kwi-datum, kwaye indawo yendawo yomhlaba ayinakuqinisekiswa ngaphandle kwedatha ecacileyo. Ngokwengqiqo yayo ngokubanzi, i-datum yingongoma, umgca, kunye nomphezulu kwindawo esetyenziselwa ukumisela indawo yezinye iingongoma, imigca, kunye nomphezulu. Ngokwemisebenzi yabo eyahlukeneyo, iibenchmarks zinokwahlulwa zibe ziindidi ezimbini: iibenchmarks zoyilo kunye nebenchmarks zenkqubo.

1. Isiseko soyilo

Idatha esetyenzisiweyo ukumisela amanye amanqaku, imigca kunye nemiphezulu kwinxalenye yomzobo ibizwa ngokuba yidatum yoyilo. Kwipiston, i-datum yoyilo ibhekisa kumbindi wepiston kunye nomgca osembindini womngxuma wephini.

2. Inkqubo yebenchmark

Idatum esetyenziswa ngamalungu kwinkqubo yomatshini kunye nokudibanisa ibizwa ngokuba yinkqubo datum. Ngokokusetyenziswa okwahlukeneyo, imilinganiselo yenkqubo yahlulwe ngokwemilinganiselo yokubeka, imilinganiselo yokulinganisa kunye nebenchmarks zokuhlanganisa.

I-1) I-datum yokubeka: I-datum esetyenziselwa ukwenza i-workpiece ithathe indawo echanekileyo kwisixhobo somatshini okanye ukulungiswa ngexesha lokucubungula kuthiwa yi-datum yokubeka. Ngokwamacandelo ahlukeneyo okumisa, ezona ziqhelekileyo zisetyenziswa zezi ndidi zimbini zilandelayo:

Uziko oluzenzekelayo kunye nokubeka indawo: njengokubeka i-chuck yemihlathi emithathu.

Ukubeka indawo yomkhono: Indawo yokumisa yenziwe ibe ngumkhono wokumisa, njengokumisa ipleyiti yokumisa.

Ezinye zibandakanya ukubeka kwisakhelo esine-V, ukubekwa kwi-semicircular hole, njl.

2) Idatum yomlinganiselo: Idatum esetyenziselwa ukulinganisa ubungakanani kunye nendawo yomgangatho owenziwe ngoomatshini ngexesha lokuhlolwa kwenxalenye ibizwa ngokuba yidatum yomlinganiselo.

3) I-Datum yeNdibano: I-datum esetyenziselwa ukumisela indawo yenxalenye yecandelo okanye imveliso ngexesha lokudibanisa ibizwa ngokuba yi-asembly datum.

Okwesibini, indlela yokufakela i-workpiece

Ukuze kusetyenzwe umphezulu ohlangabezana neemfuno zobugcisa ezichaziweyo kwindawo ethile yomsebenzi, i-workpiece kufuneka ithathe indawo echanekileyo ngokumalunga nesixhobo kwisixhobo somatshini ngaphambi komatshini. Le nkqubo idla ngokubizwa ngokuba yi "positioning" ye-workpiece. Emva kokuba i-workpiece ibekwe, ngenxa yesenzo samandla okusika, ubunzima, njl. ngexesha lokucubungula, kufuneka kusetyenziswe indlela ethile "i-clamp" i-workpiece ukwenzela ukuba indawo emiselweyo ihlale ingatshintshi. Inkqubo yokufumana i-workpiece kwindawo echanekileyo kumatshini kunye nokudibanisa i-workpiece ibizwa ngokuba "ukusetha".

Umgangatho wofakelo lwe-workpiece ngumba obalulekileyo kwi-machining. Ayichaphazeli nje ngokuthe ngqo ukuchaneka komatshini, isantya kunye nokuzinza kofakelo lwe-workpiece, kodwa kuchaphazela umgangatho wokuvelisa. Ukuze kuqinisekiswe ukuchaneka kokuchaneka kokuchaneka phakathi komphezulu owenziwe ngomatshini kunye nedatum yoyilo, i-workpiece kufuneka ifakwe ukuze i-datum yoyilo yomgangatho owenziweyo ithathe indawo echanekileyo ngokumalunga nesixhobo somatshini. Ngokomzekelo, kwinkqubo yokugqiba i-grooves, ukwenzela ukuba kuqinisekiswe iimfuno zokuphuma kwesetyhula kwi-diameter ephantsi ye-groove ye-groove kunye ne-axis ye-skirt, i-workpiece kufuneka ifakwe ukuze i-datum yayo yoyilo ihambelane ne-axis. yesixhobo sokuphotha somatshini.

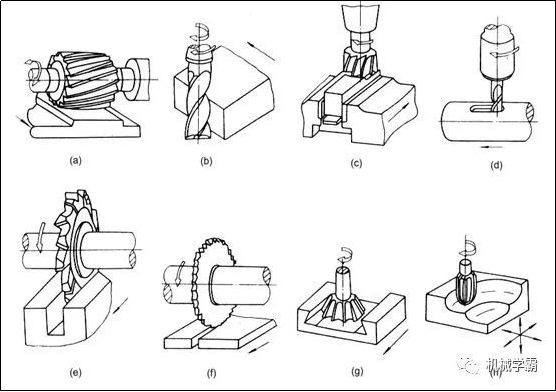

Xa kusenziwa iinxalenye zoomatshini kwiintlobo ngeentlobo zezixhobo zoomatshini, kukho iindlela ezahlukeneyo zokufakela. Iindlela zokufakela zingahlelwa zibe ziintlobo ezintathu: indlela yokulungelelanisa ngokuthe ngqo, indlela yokulungelelanisa ababhali kunye nendlela yokufakela ukulungiswa.

1) Indlela yokulungelelanisa ngokuthe ngqo Xa usebenzisa le ndlela, indawo echanekileyo yokuba i-workpiece kufuneka ihlale kwisixhobo somatshini ifunyenwe ngokulandelelana kwemizamo. Indlela ethile kukusebenzisa isalathisi sokudayela okanye inaliti yokubhala kwi-scribing plate ukulungisa indawo echanekileyo ye-workpiece ngokuhlola okubonakalayo emva kokuba i-workpiece ifakwe ngokuthe ngqo kwisixhobo somatshini, ide ihlangabezane neemfuno.

Ukuchaneka kokubeka kunye nesantya sendlela yokulungelelanisa ngokuthe ngqo kuxhomekeke kwindlela yokulungelelanisa, indlela yokulungelelanisa, izixhobo zokulungelelanisa kunye nenqanaba lobugcisa labasebenzi. Ukungalungi kwayo kukuba kuthatha ixesha elininzi, imveliso ephantsi, kwaye kufuneka iqhutywe ngamava, kwaye idinga izakhono eziphezulu zabasebenzi, ngoko isetyenziselwa kuphela kwimveliso enye kunye ne-batch encinci. Ngokomzekelo, ukuthembela ekulinganiseni ukulungelelaniswa komzimba yindlela yokulungelelanisa ngokuthe ngqo.

2) Indlela yokulungelelanisa yokubhala Le ndlela kukusebenzisa inaliti yokubhala kwisixhobo somatshini ukulungelelanisa i-workpiece ngokomgca owenziweyo kwimveliso engenanto okanye egqityiweyo, ukwenzela ukuba ikwazi ukufumana indawo echanekileyo. Ngokucacileyo, le ndlela ifuna inkqubo enye yokubhala. Umgca ozotyiweyo ngokwawo unobubanzi obuthile, kwaye kukho impazamo yokubhala xa ubhala, kwaye kukho impazamo yokujonga xa kulungiswa indawo yomsebenzi. Ke ngoko, le ndlela isetyenziswa kakhulu kwiibhetshi ezincinci zemveliso, ukuchaneka okungenanto okuncinci, kunye nezixhobo zokusebenza ezinkulu. Akufanelekile ukusebenzisa izixhobo. kumatshini omdaka. Ngokomzekelo, isikhundla somngxuma wepini wemveliso ye-stroke emibini inqunywe ngokusebenzisa indlela yokumakisha yentloko ye-indexing.

I-3) Ukusebenzisa indlela yokufakela i-fixture: izixhobo zenkqubo ezisetyenziselwa ukunyanzelisa i-workpiece kwaye iyenze ihlale kwindawo echanekileyo ibizwa ngokuba yisixhobo somatshini. Isixhobo sisixhobo esongezelelweyo sesixhobo somatshini. Isikhundla salo ngokubhekiselele kwisixhobo kwisixhobo somatshini sihlengahlengiswe kwangaphambili ngaphambi kokuba i-workpiece ifakwe, ngoko akuyomfuneko ukulungelelanisa indawo nganye xa kusenziwa i-batch of workpieces, enokuqinisekisa iimfuno zobugcisa zokucubungula. Yindlela esebenzayo yokubeka esindisa abasebenzi kunye neengxaki, kwaye isetyenziswa ngokubanzi kwibhetshi kunye nemveliso yobuninzi. Ukusetyenzwa kwethu kwangoku kwepiston yindlela yofakelo olusetyenziswayo.

①. Emva kokuba i-workpiece ibekwe, ukusebenza kokugcina indawo yokumisa ingatshintshwanga ngexesha lenkqubo yomatshini ibizwa ngokuba yi-clamping. Isixhobo esikwisixhobo esigcina i-workpiece kwindawo enye ngexesha lokusetyenzwa sibizwa ngokuba sisixhobo sokubamba.

②. Isixhobo sokudibanisa kufuneka sihlangabezane nezi mfuno zilandelayo: xa i-clamping, ukubeka indawo yokusebenza akufanele yonakaliswe; emva kokuba i-clamping, isikhundla se-workpiece ngexesha lokucubungula akufanele sitshintshe, kwaye i-clamping kufuneka ichaneke, ikhuselekile kwaye inokwethenjelwa; i-clamping Isenzo siyakhawuleza, umsebenzi ufanelekile kwaye usindisa umsebenzi; isakhiwo silula kwaye ukuveliswa kulula.

③. Izilumkiso xa ubamba: amandla okubamba kufuneka afaneleke. Ukuba inkulu kakhulu, i-workpiece iya konakala. Ukuba incinci kakhulu, i-workpiece iya kususwa ngexesha lokucubungula kwaye iya konakalisa ukubekwa kwendawo yokusebenza.

3. Ulwazi olusisiseko lokusika isinyithi

1. Ukuguqula intshukumo kunye nomhlaba owenziweyo

Ukuguqula ukunyakaza: Kwinkqubo yokusika, ukwenzela ukuba kususwe isinyithi esingaphezulu, kuyimfuneko ukwenza i-workpiece kunye nesixhobo senze intshukumo yokusika isihlobo. Intshukumo yokususa isinyithi esingaphezulu kwisixhobo sokusebenza ngesixhobo sokujika kwilathe ibizwa ngokuba yi-turning motion, enokwahlulwa ibe yintshukumo ephambili kunye nentshukumo yokutya. yenza umthambo.

Intshukumo ephambili: Uluhlu lokusika kwi-workpiece lunqunyulwe ngokuthe ngqo ukuze luguqulelwe kwiichips, ngaloo ndlela lwenza intshukumo yendawo entsha yomsebenzi, ebizwa ngokuba yintshukumo ephambili. Xa usika, ukunyakaza okujikelezayo kwe-workpiece yeyona nto iphambili. Ngokuqhelekileyo, isantya sentshukumo ephambili siphezulu, kwaye amandla okusika asetyenzisiweyo aphezulu.

Ukunyakaza kokutya: intshukumo yokwenza umgca omtsha wokusika ngokuqhubekayo ubeka ukusika, intshukumo yokutya yintshukumo ecaleni kwendawo yokusebenza eya kwenziwa, enokuthi ibe yintshukumo eqhubekayo okanye intshukumo ephakathi. Ngokomzekelo, ukunyakaza kwesixhobo sokuguqula kwi-lathe ethe tyaba kuyaqhubeka, kwaye intshukumo yokutya ye-workpiece kwiplani yintshukumo ephakathi.

Imihlaba eyenziweyo kwi-workpiece: Ngexesha lenkqubo yokusika, iindawo ezinomatshini, iindawo ezisetyenzisiweyo, kunye neendawo eziza kusetyenziswa zenziwe kwi-workpiece. Umphezulu ogqityiweyo ubhekisa kumphezulu omtsha osuswe kwintsimbi engaphezulu. Umphezulu oza kwenziwa ngoomatshini ubhekisa kumphezulu ekuza kusikwa kuwo umaleko wesinyithi. Umphezulu owenziwe ngomatshini ubhekiselele kwindawo apho umgca wokusika wesixhobo sokuguqula ujika.

2. Izinto ezintathu zexabiso lokusika zibhekisela kubunzulu bokusika, izinga lokutya kunye nesantya sokusika.

1) Ukusika ubunzulu: ap=(dw-dm)/2(mm) dw=idiameter ye-workpiece engasebenziyo dm=i-diameter ye-workpiece yomatshini, ubunzulu bokusika yinto esiyibiza ngokuba yimali yokusika.

Ukukhethwa kobunzulu bokusika: Ubunzulu bokusika i-αp kufuneka bumiselwe ngokwesibonelelo somatshini. Xa urhabaxa, ngaphezu kokushiya isibonelelo sokugqiba, zonke izibonelelo ezirhabaxa kufuneka zisuswe kwipasi enye kangangoko kunokwenzeka. Oku akunakwenza kuphela imveliso yokusika ubunzulu, izinga lokutya ƒ kunye nokusika isantya V enkulu phantsi kwesiseko sokuqinisekisa iqondo elithile lokuqina, kodwa nokunciphisa inani lokudlula. Xa isibonelelo somatshini sikhulu kakhulu okanye ukuqina kwenkqubo yenkqubo akwanelanga okanye amandla e-blade ayanelanga, kufuneka ahlulwe abe ngamapasi amabini. Ngeli xesha, ubunzulu bokusika bokupasa kokuqala kufuneka bube bukhulu, obunokuthi bube ne-2/3 ukuya kwi-3/4 yesibonelelo esipheleleyo; kunye nobunzulu bokusika ukupasa kwesibini kufuneka bube buncinci, ukwenzela ukuba inkqubo yokugqiba ifumaneke. Uburhabaxa obuncinci bomgangatho wexabiso leparamitha kunye nokuchaneka okuphezulu komatshini.

Xa umphezulu weendawo zokusika ziyi-castings ekhuniweyo, i-forgings okanye i-stainless steel kunye nezinye izinto ezinzima ezibandayo, ubunzulu bokunqunyulwa kufuneka budlule ubunzima okanye umaleko obandayo ukuze ugweme ukusika imiphetho yokusika kwi-hard or chilled layer.

2) Ukhetho lwemali yokutya: ukufuduka okuhlobene kwendawo yokusebenza kunye nesixhobo kwicala lentshukumo yokutya rhoqo xa i-workpiece okanye isixhobo sijikeleza okanye sibuyisela kanye, iyunithi mm. Emva kokuba ubunzulu bokusika bukhethiwe, isondlo esikhulu kufuneka sikhethwe ngokusemandleni. Ukukhethwa kwexabiso elifanelekileyo lokutya kufuneka kuqinisekise ukuba isixhobo somatshini kunye nesixhobo asiyi konakaliswa ngenxa yamandla amaninzi okusika, ukuphambuka komsebenzi obangelwa yi-cutting force akuyi kudlula ixabiso elivumelekileyo lokuchaneka kwe-workpiece, kwaye umgangatho orhabaxa wexabiso leparameter ayizukuba nkulu kakhulu. Xa urhabaxa, owona mda uphambili wokuxheshiswa kukusika amandla, kwaye kwisiqingatha sokugqiba kunye nokugqiba, umda oyintloko wokutya buburhabaxa bomphezulu.

I-3) Ukukhethwa kwesantya sokusika: Ngexesha lokusika, isantya esikhawulezayo sendawo ethile kwinqanaba lokusika isixhobo esinxulumene nomphezulu oza kusetyenziswa kwindlela ehamba phambili yokuhamba, iyunithi i-m / min. Xa ubunzulu be-cut αp kunye nereyithi yokutya ƒ ikhethiwe, isantya esiphezulu sokusika sikhethwa kule siseko, kwaye ulwalathiso lophuhliso lwe-cutting processing luyi-high-speed cutting.isitampu inxalenye

Okwesine, ingqikelelo yomatshini yoburhabaxa

Kumatshini, uburhabaxa bubhekiselele kwiipropati zejiyometri ezincinci ezibandakanya izithuba ezincinci kunye neencopho kunye neentlambo kumphezulu womatshini. Yenye yeengxaki zophando lokutshintshelana. Uburhabaxa bomphezulu ngokuqhelekileyo bubunjwa yindlela yokucubungula esetyenziswayo kunye nezinye izinto, ezinjengokungquzulana phakathi kwesixhobo kunye nomphezulu wenxalenye ngexesha lokucutshungulwa, ukuguqulwa kweplastiki yentsimbi engaphezulu xa iitshiphusi zahluliwe, kunye nokungcangcazela kwe-high-frequency vibration. inkqubo yenkqubo. Ngenxa yeendlela ezahlukeneyo zokusetyenzwa kunye nezixhobo zokusebenza, ubunzulu, ukuxinana, ukumila kunye nokuthungwa kwamanqaku ashiywe kumphezulu owenziwe ngomatshini kuyahluka. Uburhabaxa bomphezulu bunxulumene ngokusondeleyo neempawu ezihambelanayo, ukumelana nokunxiba, amandla okudinwa, ukuqina koqhagamshelwano, ukungcangcazela kunye nengxolo yamalungu omatshini, kwaye kunempembelelo ebalulekileyo kubomi benkonzo kunye nokuthembeka kweemveliso zoomatshini.inxalenye yokuphosa i-aluminium

Ukubonakaliswa koburhalarhume

Emva kokuba ubuso benxalenye bucutshungulwe, bubukeka bugudileyo, kodwa alilingani emva kokwandiswa. Uburhabaxa bomphezulu bubhekiselele kwiimpawu zejiyometri ezincinci eziqulunqwe yimigama emincinci kunye neencopho ezincinci kunye neentlambo kumphezulu wenxalenye ecutshungulweyo, eziye zenziwe ngokubanzi ngendlela yokucubungula kunye (okanye) nezinye izinto. Umsebenzi womphezulu wenxalenye uhlukile, kwaye ixabiso leparameter yobunzima obufunekayo bukwahluke. Ikhowudi yobunzima bomphezulu (uphawu) kufuneka imakishwe kwinxalenye yomzobo ukuchaza iimpawu zomphezulu ekufuneka ziphunyezwe emva kokuba umphezulu ugqityiwe. Kukho iintlobo ezi-3 zobude oburhabaxa bomgangatho:

1. Contour arithmetic ithetha ukutenxa Ra

I-arithmetic intsingiselo yexabiso elipheleleyo lomgama phakathi kwamanqaku kumgca wekhonto kwindlela yokulinganisa (Y direction) kunye nomgca wereferensi ngaphakathi kobude besampulu.

2. Ubude obunamanqaku alishumi e-Rz yokungalingani kwe-microscopic

Ibhekisa kumyinge we-avareji ye-5 enkulu yeprofayile yokuphakama kwencopho kunye ne-5 yeprofayile enkulu yentlambo yobunzulu ngaphakathi kobude besampulu.

3. Ubude obuphezulu be-contour Ry

Umgama phakathi komgca weyona ndawo iphakamileyo kunye nomgca wentlambo ephantsi yeprofayili ngaphakathi kobude besampuli.

Okwangoku, uRa. isetyenziswa ikakhulu kushishino lokwenziwa koomatshini ngokubanzi.

umfanekiso

4. Indlela Yokumela Uburhabaxa

5. Isiphumo soburhabaxa ekusebenzeni kwamalungu

Umgangatho womphezulu we-workpiece emva kokucubungula uchaphazela ngokuthe ngqo umzimba, iikhemikhali, kunye neempawu zoomatshini. Ukusebenza okusebenzayo, ukuthembeka kunye nobomi bemveliso kuxhomekeke kumlinganiselo omkhulu kumgangatho ophezulu weendawo eziphambili. Ngokubanzi, iimfuno zomgangatho womphezulu wamacandelo abalulekileyo okanye abalulekileyo ziphezulu kuneendawo eziqhelekileyo kuba iindawo ezinomgangatho olungileyo womphezulu ziya kuphucula kakhulu ukuxhathisa ukunxiba, ukuxhathisa ukubola, kunye nokumelana nomonakalo wokudinwa.CNC machining aluminiyam inxalenye

6. Ukusika ulwelo

1) Indima yokusika ulwelo

Isiphumo sokupholisa: Ubushushu bokusika bunokuthatha ubungakanani obukhulu bokusika ubushushu, buphucule iimeko zokulahla ubushushu, ukunciphisa ubushushu besixhobo kunye nesixhobo sokusebenza, ngaloo ndlela sandise ubomi benkonzo yesixhobo kunye nokuthintela impazamo yobungakanani bomsebenzi obangelwa deformation thermal.

Ukuthambisa: Ulwelo lokusika lunokungena phakathi kwendawo yokusebenza kunye nesixhobo, ukwenzela ukuba umaleko omncinci wefilimu ye-adsorption yenziwe kwisithuba esincinci phakathi kwe-chip kunye nesixhobo, esinciphisa i-coefficient ye-friction, ngoko inokunciphisa ukungqubuzana phakathi kwesixhobo. i-chip kunye ne-workpiece , ukunciphisa amandla okusika kunye nokusika ukushisa, ukunciphisa ukunxiba kwesixhobo kunye nokuphucula umgangatho wendawo yokusebenza. Ukugqiba, i-lubrication ibaluleke kakhulu.

Isiphumo sokucoca: Iichips ezincinci ezenziwe ngexesha lokucoca zilula ukunamathela kwisixhobo kunye nesixhobo, ngakumbi xa kubholwa imingxuma enzulu kunye nemingxuma yokuvuselela, iichips zivaliwe ngokulula kwiflute ye-chip, echaphazela uburhabaxa bomphezulu wesixhobo sokusebenza kunye. ubomi benkonzo yesixhobo. . Ukusetyenziswa kwamanzi okusika kunokuhlamba ngokukhawuleza ii-chips, ukwenzela ukuba ukusika kuqhutywe kakuhle.

2) Uhlobo: Kukho iintlobo ezimbini zeendlela eziqhelekileyo ezisetyenziselwa ukusika

I-Emulsion: Idlala indima enkulu yokupholisa. I-emulsion yenziwe ngokuhlambulula ioli e-emulsified kunye namaxesha angama-15 ~ 20 amanzi. Olu hlobo lolwelo lokusika lunobushushu obukhulu obuthile, i-viscosity ephantsi kunye nolwelo olulungileyo, kwaye lunokufunxa ubushushu obuninzi. Ukusika ulwelo lusetyenziswa ikakhulu ukupholisa isixhobo kunye nomsebenzi, ukuphucula ubomi besixhobo kunye nokunciphisa deformation thermal. I-emulsion iqulethe amanzi amaninzi, kwaye i-lubrication kunye nemisebenzi yokukhusela i-rust impofu.

Ioli yokusika: Inxalenye ephambili yeoli yokusika ioli yamaminerali. Olu hlobo lolwelo lokusika lunobushushu obuthile obuncinci, i-viscosity ephezulu kunye nolwelo olubi. Ubukhulu becala idlala indima yokuthambisa. Amafutha amaminerali ane-viscosity ephantsi asetyenziswa ngokuqhelekileyo, njengeoli yemoto, ioli ye-diesel elula, i-Kerosene njl.

I-Anebon Metal Products Limited inokubonelela nge-CNC Machining, Die Casting, inkonzo ye-Sheet Metal Fabrication, nceda uzive ukhululekile ukuqhagamshelana nathi.

Tel: +86-769-89802722 E-mail: info@anebon.com URL: www.anebon.com

Ixesha lokuposa: Jun-24-2022