Yintoni iasi yemoto ebhityileyo?

I-asi yemoto ebhityileyo luhlobo olusetyenziswa ezimotweni kwaye luyilelwe ukuba lube lula. Ii-axle ezibhityileyo zikholisa ukusetyenziswa kwizithuthi ezijolise ekusebenzeni kakuhle kwamafutha kunye nokubalula. Banciphisa ubunzima besithuthi xa bephucula ukuphathwa kwayo. Ezi axles zihlala zenziwe ngezinto ezikhaphukhaphu, ezomeleleyo ezifana ne-aluminiyam okanye intsimbi eyomeleleyo. Ezi axles zakhiwe ukuze zikwazi ukuphatha amandla okuqhuba, njengetorque eveliswa yi-injini, kwaye zigcina i-compact, i-designline design. Ii-asi ezibhityileyo zibalulekile ekuhanjisweni kwamandla ukusuka enjini ukuya kumavili.

Kutheni kulula ukugoba kunye nokukhubazeka xa ulungisa shaft ebhityileyo yemoto?

Kuya kuba nzima ukugoba okanye ukuguqula ishafti ebhitye kakhulu. Izinto ezisetyenziselwa ukwenza i-shafts yemoto (eyaziwa ngokuba yi-drive shafts okanye i-axles) idla ngokuba yomelele kwaye ihlala ihlala njalo, njenge-carbon fiber composite okanye intsimbi. Izinto ezisetyenzisiweyo zikhethiweyo ngenxa yamandla abo aphezulu, afunekayo ukuxhathisa i-torque kunye nemikhosi eyenziwa yi-transmission kunye ne-injini yemoto.

Ngexesha lokuvelisa, i-shafts idlula kwiinkqubo ezahlukeneyo, ezifana nokubunjwa kunye nokunyanga ukushisa, ukugcina ukuqina kunye namandla. Ezi zixhobo, kunye neendlela zokuvelisa, zithintela i-shafts ukugoba phantsi kweemeko eziqhelekileyo. Nangona kunjalo, amandla agqithisileyo afana nokungqubana kunye neengozi zinokugoba okanye zikhubaze nayiphi na indawo yemoto, kuquka i-shafts. Kubalulekile ukulungisa okanye ukubuyisela naziphi na iindawo ezonakeleyo ukuqinisekisa ukuba isithuthi sakho sisebenza ngokukhuselekileyo nangempumelelo.

Inkqubo yomatshini:

Amalungu amaninzi e-shaft ane-aspect ratio ye-L / d> 25. I-axis slender ethe tyaba igobile ngokulula okanye inokulahlekelwa nokuzinza kwayo phantsi kwefuthe lomxhuzulane, amandla okusika kunye nemikhosi yokudibanisa ephezulu. Ingxaki yoxinzelelo kwi-shaft slender kufuneka incitshiswe xa uguqula i-shaft.

Indlela yokuqhuba:

Ukuguqula i-reverse-feed turning kusetyenziswa, kunye nenani lamanyathelo asebenzayo, afana nokukhethwa kwezixhobo zejometri parameters, izixa zokusika, izixhobo zokuxininisa, kunye nezixhobo zokuphumla.

Uhlalutyo lwezinto ezibangela ukugoba ukuGuqulwa kokuGuqulwa kwe-Slender Shaft

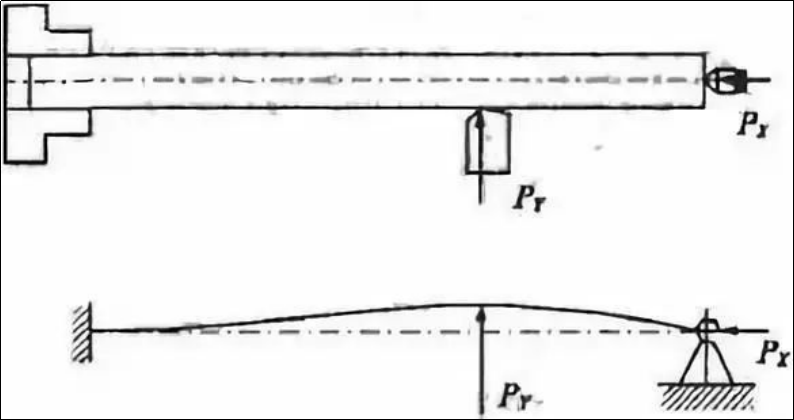

Kusetyenziswa iindlela ezimbini zobuchule bokubamba ukuguqula iishafti ezibhityileyo kwiileyile. Enye indlela isebenzisa i-clamp enye kunye nofakelo oluphezulu, kwaye enye ifakelo ezimbini eziphezulu. Ngokukodwa siza kugxininisa kubuchule bokudibanisa into enye kunye nephezulu. Njengoko kubonisiwe kuMfanekiso 1.

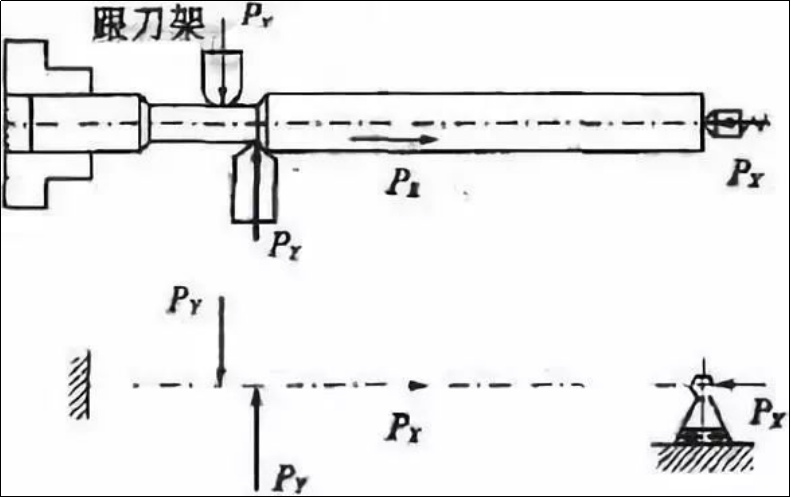

Umzobo 1 I-clamp enye kunye nendlela enye yokudibanisa ephezulu kunye nohlalutyo lwamandla

Ezona zizathu ziphambili zokugoba ukuguquka okubangelwa kukujika ishaft ebhityileyo zezi:

(1) Amandla okusika abangela inguqu

Amandla okusika anokwahlulwa abe ngamacandelo amathathu: i-axial force PX (axial force), i-radial force PY (i-radial force) kunye ne-tangential force PZ. Xa uguqula i-shafts encinci, amandla ahlukeneyo okusika anokuba nemiphumo eyahlukileyo kwi-deformation yokugoba.

I-1) Impembelelo ye-radial cutting forces PY

Amandla eradial anqumla ngokuthe nkqo kwi-axis ye-shaft. I-radial cutting force igoba i-shaft ebhityileyo kwinqwelo-moya ethe tye ngenxa yokungaqini kwayo. Umzobo ubonisa umphumo wamandla okusika ekugobeni kwe-shaft slender. 1.

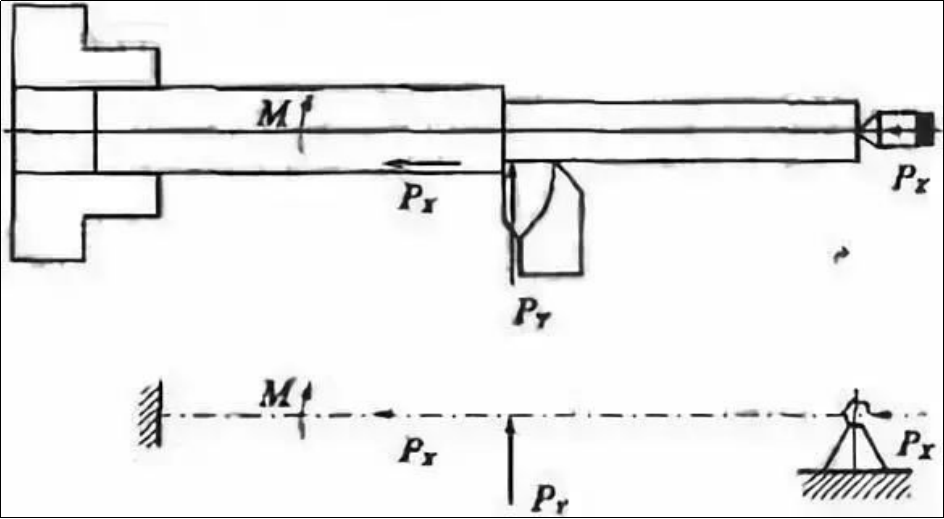

2) Impembelelo ye-axial cutting force (PX)

I-axial force ihambelana ne-axis kwi-shaft encinci kwaye yenza umzuzu wokugoba kwindawo yokusebenza. I-axial force ayibalulekanga ekujikeni ngokubanzi kwaye inokungahoywa. Ngenxa yokungagungqi kwayo kakuhle, i-shaft ayizinzanga ngenxa yokuzinza kwayo. I-shaft ebhityileyo igoba xa i-axial force inkulu kunomlinganiselo othile. Njengoko kubonisiwe kumfanekiso wesi-2.

Umzobo 2: Isiphumo sokusika amandla kumandla axial

(2) Ukusika ubushushu

I-thermal deformation ye-workpiece iya kwenzeka ngenxa yokushisa okusikiweyo okuveliswa ngokucutshungulwa. Umgama phakathi kwe-chuck, umphezulu we-rearstock kunye ne-workpiece igxininisekile ngenxa yokuba i-chuck ilungisiwe. Oku kunciphisa ukwandiswa kwe-axial ye-shaft, okubangela ukugoba kwe-shaft ngenxa ye-axial extrusion.

Kucacile ukuba ukuphucula ukuchaneka komatshini we-shaft obhityileyo kuyingxaki enkulu yokulawula uxinzelelo kunye ne-thermal deformation kwinkqubo yenkqubo.

Amanyathelo okuphucula ukuchaneka koMatshini we-Slender Shaft

Ukuphucula ukuchaneka kwe-machining shaft slender, kuyimfuneko ukuthatha amanyathelo ahlukeneyo ngokwemiqathango yokuvelisa.

(1) Khetha indlela echanekileyo yokubambelela

I-clamping ephakathi kabini, enye yeendlela ezimbini zokubambelela ngokwesiko ezisetyenziselwa ukujika iishafts ezibhityileyo, zingasetyenziselwa ukubeka ngokuchanekileyo i-workpiece ngelixa uqinisekisa ukubumbana. Le ndlela yokubamba umkhono obhityileyo unokuqina okulambathayo, inguquko enkulu yokugoba, kwaye ichaphazeleka lula kukungcangcazela. Ngoko ke ifanelekile kuphela ukufakwa kunye nobude obuncinci ukuya kwi-diameter ratio, isibonelelo esincinci somatshini kunye neemfuno eziphezulu ze-coaxiality. Mdeamacandelo omatshini achanekileyo.

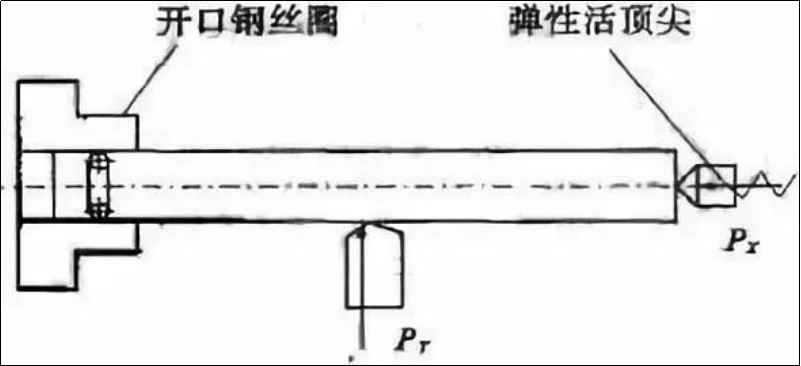

Kwiimeko ezininzi, ukucwangciswa kwee-shafts ezinqabileyo zenziwa ngokusebenzisa inkqubo yokudibanisa equkethe enye phezulu kunye ne-clamp enye. Kobu buchule bokubamba, nangona kunjalo, ukuba unencam eqine kakhulu ayisayi kugoba nje i-shaft kodwa ikwayithintele ukuba inde xa i-shaft ijika. Oku kunokubangela ukuba i-shaft icinezelwe nge-axially kwaye igobe ngaphandle kokuma. I-clamping surface ayinakulungelelaniswa nomngxuma we-tip, enokubangela ukuba i-shaft igobe emva kokuba ibanjwe.

Xa usebenzisa i-clamping technique ye-clamp enye ngomphezulu omnye, umphezulu kufuneka usebenzise amaziko okuhlala a-elastiki. Emva kokufudumeza umkhono obhityileyo, unokwandiswa ngokukhululekileyo ukunciphisa ukugoba kwawo. Ngelo xesha umhambi wentsimbi evulekileyo ufakwe phakathi kwemihlathi kwi-slender sleeve ukunciphisa ukudibanisa kwe-axial phakathi kwemihlathi ukuya kwi-slender sleeve kunye nokuphelisa ukubeka ngaphezulu. Umzobo 3 ubonisa ukufakela.

Umzobo 3: Indlela yokuphucula usebenzisa ibamba enye kunye ne-top clamp

Ukunciphisa amandla okuguqula ngokunciphisa ubude be-shaft.

1) Sebenzisa i-heelrest kunye nesakhelo seziko

I-clamp enye kunye nomphezulu omnye zisetyenziselwa ukujika ishaft ebhityileyo. Ukunciphisa impembelelo ye-radial force kwi-deformation ebangelwa i-shaft e-slender, i-toolrest yendabuko kunye nesakhelo seziko lisetyenziswa. Oku kufana nokongeza inkxaso. Oku kwandisa ukuqina kwaye kunokunciphisa impembelelo ye-radial force kwi-shaft.

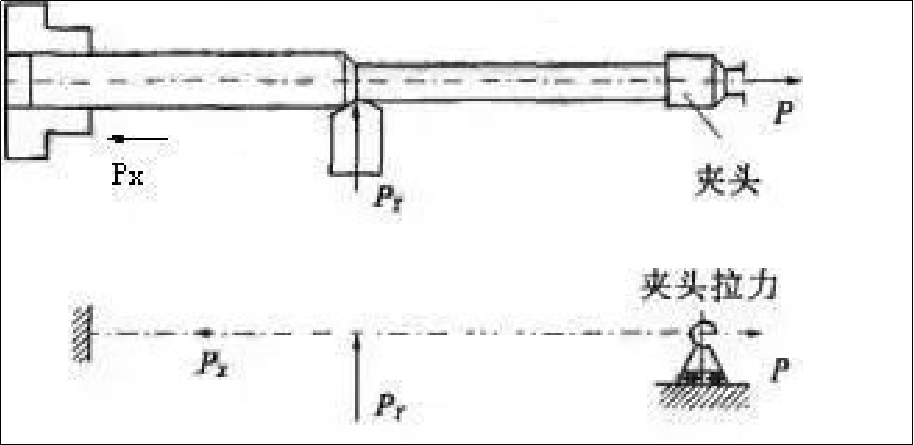

I-2) Umkhono obhityileyo ujikelezwa yi-axial clamping technique

Kunokwenzeka ukunyusa ukuqina kunye nokuphelisa umphumo we-radial force kwi-workpiece ngokusebenzisa ukuphumla kwesixhobo okanye isakhelo seziko. Ayinakukwazi ukusombulula ingxaki ye-axial force egoba i-workpiece. Oku kuyinyani ngakumbi kwishaft ebhityileyo enobubanzi obude. I-shaft ebhityileyo ke ngoko iyakwazi ukujikwa kusetyenziswa ubuchule be-axial clamping. I-axial clamping ithetha ukuba, ukuze ujike i-shaft ebhityileyo, enye isiphelo se-shaft ibotshelelwe nge-chuck kunye nesinye isiphelo sayo ngentloko eyilwe ngokukodwa. Intloko ebambezelayo isebenzisa i-axial force kwi-shaft. Umzobo 4 ubonisa intloko ebambayo.

Umfanekiso we-4 Axial clamping kunye neemeko zoxinzelelo

Umkhono obhityileyo uphantsi koxinzelelo lwe-axial rhoqo ngexesha lenkqubo yokujika. Oku kuphelisa ingxaki ye-axial cutting force egoba i-shaft. Amandla e-axial anciphisa ukuguqulwa kokugoba okubangelwa yimikhosi yokusika i-radial. Iphinde ihlawule i-axial ye-axial ngenxa yokushisa okusika. ukuchaneka.

3) Buyela umva ukusika i-shaft ukuyijika

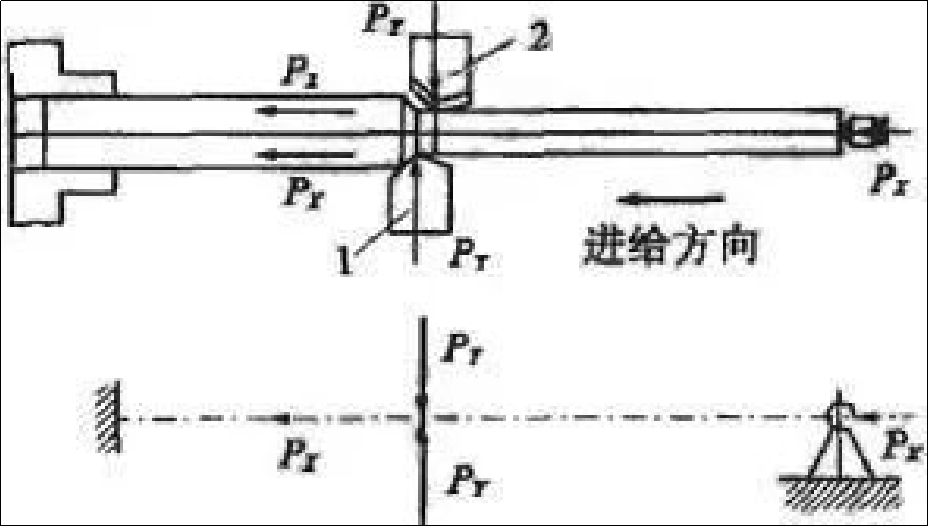

Njengoko kubonisiwe kwi-Figure 5, indlela yokuqhawula umva xa isixhobo sisondliwa nge-spindle ukuya kwi-tailstock ngexesha lenkqubo yokuguqula i-shaft encinci.

Umzobo we-5 Uhlalutyo lweMicimbi yeMicimbi kunye noMachining ngeNdlela yokuReverse Cutting

Amandla e-axial eveliswa ngexesha lokucutshungulwa aya kuxinzelela i-shaft, ukuthintela ukugoba ukugoba. I-tailstock e-elastic inokubuyisela i-elongation ye-thermal kunye ne-compression deformation ebangelwa yi-workpiece njengoko isuka kwisixhobo ukuya kwi-tailstock. Oku kuthintela deformation.

Njengoko kubonisiwe kuMzobo 6, ipleyiti yesilayidi ephakathi iguqulwa ngokongeza umnini wesixhobo sangemva kunye nokuguqula izixhobo zangaphambili nasemva ngaxeshanye.

Umzobo 6 Nyanzelisa uhlalutyo kunye nomatshini weemela ezimbini

Isixhobo sangaphambili sifakwe ngokuthe tye, ngelixa isixhobo sangemva sifakwe umva. Imikhosi yokusika eyenziwa zizixhobo ezimbini zirhoxisa enye kwenye ngexesha lokujika. I-workpiece ayikhubeki okanye ishukunyiswa, kwaye ukuchaneka kokulungiswa kuphezulu kakhulu. Oku kulungele imveliso yobuninzi.

4) Indlela yokusika imagnethi yokuguqula i-shaft encinci

Umgaqo osemva kokusikwa kwamagnetic ufana nokusika umva. Amandla omagnetic asetyenziselwa ukolula i-shaft, ukunciphisa i-deformation ngexesha lokucubungula.

(3) Ukunciphisa inani lokusika

Ubungakanani bokushisa obuveliswa yinkqubo yokusika kuya kugqiba ukufaneleka kwexabiso lokusika. I-deformation ebangelwa ukujikeleza i-shaft encinci iya kuba yinto eyahlukileyo.

1) Ubunzulu bokusika (t)

Ngokutsho kwengcinga yokuba ukuqina kunqunywe yinkqubo yenkqubo, njengoko ubunzulu bokunqunyulwa bukhula, ngokunjalo namandla okusika, kunye nobushushu obuveliswayo xa ujika. Oku kubangela ukuba uxinzelelo kunye nokuphazamiseka kwe-thermal ye-shaft encinci ukunyuka. Xa uguqula i-shafts encinci, kubalulekile ukunciphisa ubunzulu bokusika.

2) Imali yokutya (f).

Ukunyuka kwesantya sokutya kwandisa amandla okusika kunye nobukhulu. Amandla okusika ayanda, kodwa hayi ngokulinganayo. Ngenxa yoko, i-coefficient deformation yamandla kwi-shaft encinci iyancitshiswa. Ngokubhekiselele ekunyuseni ukusebenza kakuhle kokusika, kungcono ukunyusa izinga lokutya kunokunyusa ubunzulu bokusika.

3) Ukusika isantya (v).

Kuyinzuzo ukunyusa isantya sokusika ukwenzela ukunciphisa amandla. Njengoko isantya sokusika sandisa ukushisa kwesixhobo sokusika, ukungqubuzana phakathi kwesixhobo, i-workpiece, kunye ne-shaft iya kuncipha. Ukuba isantya sokusika siphezulu kakhulu, ke i-shaft inokugoba ngokulula ngenxa yamandla e-centrifugal. Oku kuya konakalisa uzinzo lwenkqubo. Isantya sokusika sezixhobo zokusebenza ezinobude obukhulu kunye nobubanzi kufuneka sincitshiswe.

(4) Khetha i-engile efanelekileyo yesixhobo

Ukunciphisa i-deformation yokugoba ebangelwa ukuguqula i-shaft encinci, amandla okusika ngexesha lokujika kufuneka abe phantsi ngokusemandleni. I-rake, i-engile ehamba phambili kunye ne-edge inclination angles inefuthe elikhulu kumandla okusika phakathi kwee-engile zejometri zezixhobo.

1) Iengile yangaphambili (g)

Ubungakanani beharika (g) i-engile ichaphazela ngokuthe ngqo amandla okusika, ubushushu kunye namandla. Amandla okusika angancitshiswa kakhulu ngokunyusa ii-angles zerake. Oku kunciphisa i-deformation yeplastiki kwaye kunokunciphisa inani lesinyithi esisikwayo. Ukuze kuncitshiswe imikhosi yokusika, ukwandisa i-rake angles kunokwenziwa. Ii-engile zeraki ziphakathi kwe-13deg kunye ne-17deg.

2) I-engile ehamba phambili (kr)

I-deflection ephambili (kr), eyona i-angle enkulu, ichaphazela ukulingana kunye nobukhulu bamacandelo amathathu okusika amandla. Amandla e-radial ayancipha njengoko i-angle yokungena inyuka, ngelixa i-tangential force inyuka phakathi kwe-60deg kunye ne-90deg. Ubudlelwane obulinganayo phakathi kwamacandelo amathathu okusika amandla angcono kuluhlu lwe-60deg75deg. I-engile ehamba phambili enkulu ye-60deg idla ngokusetyenziswa xa ujika iishafts ezibhityileyo.

3) Ukutyekela kweblade

Ukuthambekela kwencakuba (ls), kuchaphazela ukuhamba kweetshiphusi kunye namandla encam yesixhobo, kunye nobudlelwane obulinganayo phakathi kwezi zintathu.amacandelo ajikiweyoyokusika ngexesha lokujika. I-radial force yokusika iyancipha njengoko i-inclination isanda. Nangona kunjalo, amandla e-axial kunye ne-tangential ayanda. Ubudlelwane obulinganayo phakathi kwamacandelo amathathu obunzima bokusika bunengqiqo xa ukuthambekela kwe-blade kuphakathi koluhlu lwe -10deg + 10deg. Ukuze ufumane iitshiphusi ukuba zihambe ukuya kumphezulu we-shaft xa ujika i-shaft encinci, kuqhelekile ukusebenzisa i-angle edge ephakathi kwe-0deg kunye ne-10deg.

Kunzima ukuhlangabezana nemigangatho yomgangatho we-shaft ebhityileyo ngenxa yokuqina kwayo. Umgangatho wokucubungula we-shaft ebhityileyo unokuqinisekiswa ngokwamkela iindlela zokuqhubela phambili kunye neendlela zokubopha, kunye nokukhetha ii-engile zesixhobo ezifanelekileyo kunye neeparamitha.

Injongo ye-Anebon kukubona ukungafezeki kwemveliso egqwesileyo kunye nokubonelela ngeyona nkonzo ilungileyo kubathengi bethu basekhaya nabaphesheya ngokupheleleyo ngo-2022 Umgangatho oPhezulu weAluminiyam yeAluminiyam ePhakamileyo eChanekileyo yeCNC yokuGuqulela uMshini wokuSila inxalenye yeAerospace ukuze kwandiswe imarike yethu kumazwe ngamazwe, iAnebon ikakhulu ibonelela abathengi bethu baphesheya. ngoomatshini abakumgangatho ophezulu, iziqwenga ezigayiweyo kunyeIinkonzo zokuguqula i-CNC.

China wholesale China Machinery Parts kunye CNC Machining Service, Anebon igcina umoya "yokutsha kunye nokumanyana, ukusebenzisana, ukwabelana, umzila, inkqubela ebonakalayo". Ukuba usinika ithuba, siyakubonisa amandla ethu. Ngenkxaso yakho, i-Anebon ikholelwa ukuba siya kukwazi ukukwakhela ikamva eliqaqambileyo wena nosapho lwakho.

Ixesha lokuposa: Aug-28-2023