1. Z-direction tool setting yeziko lomatshini

Kukho iindlela ezintathu ngokubanzi zokusetwa kwesixhobo se-Z kumaziko omatshini:

1) Indlela yokumisela isixhobo kumatshini 1

Le ndlela yokuseta isixhobo kukumisela ngokulandelelana ubudlelwane bendawo phakathi kwesixhobo ngasinye kunye nesixhobo sokusebenza kumatshini wokulungelelanisa inkqubo ngokusetwa kwesixhobo ngexesha.CNC Machining iindawokwayeCNC ukuguqula iindawo. Amanyathelo ayo okusebenza athile ngolu hlobo lulandelayo.

(1) Thelekisa ubude besixhobo, fumana esona sixhobo side njengesixhobo sokubhekisela, yenza ucwangciso lwesixhobo se-Z, kwaye usebenzise ixabiso lokumisela isixhobo (C) ngeli xesha njengexabiso le-Z lenkqubo yokulungelelanisa, kunye ne-H03= 0 ngeli xesha.

(2) Faka izixhobo ze-T01 kunye ne-T02 kwi-spindle ngokulandelelana, kwaye unqume ixabiso le-A kunye ne-B njengexabiso lembuyekezo yobude ngokumisela isixhobo. (Le ndlela ayilinganisi ngokuthe ngqo imbuyekezo yesixhobo, kodwa yahlukile kwindlela yesi-3 egqitywe lulungiselelo lwesixhobo olulandelelanayo.)

(3) Gcwalisa ixabiso lembuyekezo lobude obumiselweyo (obona bude besixhobo bude kuthatyathwe ubude besixhobo obuseleyo) kwiphepha lokumisela. Iimpawu ezintle nezimbi zichongwa yi-G43 kunye ne-G44 kwiprogram, kwaye ngeli xesha ngokuqhelekileyo imelwe yi-G44H-. Xa usebenzisa i-G43, ubude bembuyekezo lixabiso elibi.

Le ndlela yokumisela isixhobo inesixhobo esiphezulu sokumisela ukusebenza kakuhle kunye nokuchaneka, kunye notyalo-mali oluncinci, kodwa kungenakulungeleka ukubhala amaxwebhu enkqubo, enempembelelo ethile kwintlangano yokuvelisa.

2) Indlela yokumisela isixhobo kumatshini 2

Amanyathelo okusebenza athile ale ndlela yokuseta isixhobo ngala alandelayo:

(1) Isicwangciso solungelelwaniso lwendlela ye-XY siyafana nangaphambili, faka ixabiso le-offset kwizinto ze-XY kwi-G54, kwaye usete into engu-Z ukuya ku-zero.

(2) Faka esikhundleni i-T1 esetyenziselwa ukuqhutyelwa phambili kunye ne-shaft engundoqo, sebenzisa i-gauge yebhloko ukulungelelanisa ulwalathiso lwe-Z, funda i-Z yexabiso le-Z1 yenkqubo yokulungelelanisa isixhobo somatshini emva kokuqina okufanelekileyo, kwaye ugcwalise ixabiso lembuyekezo yobude H1 emva ukuthoba ubude begeji yebhloko.

(3) Faka i-T2 kwi-shaft ephambili, uyilungelelanise kunye ne-block gauge, funda i-Z2, ukhuphe ubude be-block gauge uze ugcwalise i-H2.

(4) Ngokufanisa, sebenzisa iigeyiji zebhloko ukulungelelanisa zonke izixhobo zesixhobo, kwaye ugcwalise i-Hi emva kokutsala ubude beegeji zebhloko.

(5) Xa ucwangcisa, sebenzisa ezi ndlela zilandelayo ukuhlawula:

T1;

G91 G30 Z0;

M06;

I-G43 H1;

G90 G54 G00 X0 Y0;

I-Z100;

…(Oku kulandelayo yinkqubo yokupasa kwesixhobo seNombolo 1 isixhobo kude kube sekupheleni)

T2;

G91 G30 Z0;

M06;

G43 H2;

G90 G54 G00 X0 Y0;

I-Z100;

…(Yonke imixholo yokuqhuba yeNombolo yesi-2 yemela)

…M5;

M30;

3) Ukusetwa kwesixhobo esingekho kumatshini + ukusetwa kwesixhobo kumatshini

Le ndlela yokumisela isixhobo kukusebenzisa i-presetter yesixhobo ukulinganisa ngokuchanekileyo imilinganiselo ye-axial kunye ne-radial yesixhobo ngasinye ngaphandle kwesixhobo somatshini, ukumisela ixabiso lembuyekezo yobude besixhobo ngasinye, kwaye emva koko usebenzise esona sixhobo side kwisixhobo somatshini ukwenza i-Z To ukusetha isixhobo, misela inkqubo yolungelelwaniso lomsebenzi.

Le ndlela yokumisela isixhobo inesixhobo esiphezulu sokumisela ukuchaneka kunye nokusebenza kakuhle, kwaye ilungele ukulungiswa kwamaxwebhu enkqubo kunye nombutho wokuvelisa, kodwa utyalo-mali lukhulu.

2. Igalelo ledatha yokuseta isixhobo

(1) Idatha yokucwangcisa isixhobo efunyenwe ngokwemisebenzi engentla, oko kukuthi, i-X, Y, kunye ne-Z ixabiso lemvelaphi yenkqubo yokulungelelanisa inkqubo kwinkqubo yokulungelelanisa umatshini, kufuneka ifakwe ngesandla kwi-G54 ~ G59 yokugcina. Amanyathelo okusebenza ngolu hlobo lulandelayo:

①Cofa【IMENU OFFSET】isitshixo.

②Cofa iqhosha lekhesa ukuya kwiCNC milling iinxalenyekwayeCNC ukuguqula iindawoulungelelaniso lwenkqubo G54~G59 ukuba iqhutywe.

③Cofa u【X】 isitshixo ukufaka i-X yokulungelelanisa ixabiso.

④Cofa 【INPUT】isitshixo.

⑤Cofa u【Y】isitshixo ukufaka uY kulungelelanisa ixabiso.

⑥Cofa【INPUT】isitshixo.

⑦Cofa u【Z】isitshixo ukufaka u-Z kulungelelanisa ixabiso.

⑧Cofa【INPUT】isitshixo.

(2) Ixabiso lembuyekezo yesixhobo lifakwa ngokubanzi kwisixhobo somatshini ngaphambi kokulungiswa kwenkqubo yi-MDI (igalelo ledatha ngesandla). Amanyathelo okusebenza ngokubanzi ngala alandelayo:

①Cofa【IMENU OFFSET】isitshixo.

②Cofa iqhosha lentshukumo yekhesa kwinombolo yembuyekezo.

③Ixabiso lembuyekezo yegalelo.

④Cofa 【INPUT】isitshixo.

3. Uvavanyo lokusika indlela yokubeka imela

Indlela yokusika isilingo yindlela elula yokumisela isixhobo, kodwa iya kushiya amanqaku kwi-workpiece, kwaye ukuchaneka kwesixhobo kuphantsi. Ilungele ukusetwa kwesixhobo ngexesha lokwenziwa kwezinto ngokurhabaxa. Indlela yokumisela isixhobo sayo iyafana naleyo ye-edge ye-mechanical finder.

4. Isixhobo sokumisela isixhobo sokucofa i-Lever

Isixhobo sokumisela ukuchaneka kwesalathisi sokudayela i-lever siphezulu, kodwa le ndlela yokusebenza inzima kwaye ukusebenza kakuhle kuphantsi. Kufanelekile ukusetwa kwesixhobo somngxunya wokugqiba (umphezulu), kodwa ayifanelekanga kumngxuma womatshini orhabaxa.

Indlela yokumisela isixhobo yile ndlela ilandelayo: sebenzisa isiseko sokulinda samagnetic ukutsala isalathisi sokudayela i-lever kwi-spindle yeziko lomatshini, kwaye wenze intloko ye-gauge kufuphi nodonga lomngxuma (okanye i-cylindrical surface). Ngaphakathi kwempazamo, njenge-0.02, kunokuqwalaselwa ukuba iziko lokujikeleza le-spindle lihambelana nombindi womngxuma olinganisiweyo ngeli xesha, kunye negalelo le-X kunye ne-Y yokulungelelanisa amaxabiso kwinkqubo yokulungelelanisa umatshini ngeli xesha kwi-G54.

5. Ukusetha isixhobo kwicala lika-Z

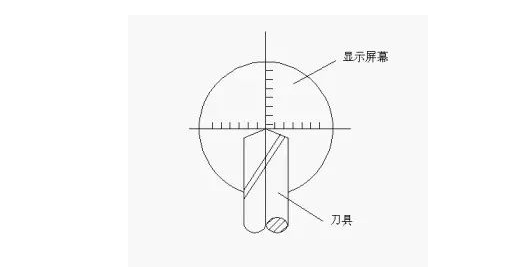

Ukuqwalasela ukwenziwa kokwenziwa kwesixhobo, umgangatho ophezulu wesixhobo sokusebenza udla ngokuthathwa njengemvelaphi yendlela ye-Z yenkqubo yokulungelelanisa i-workpiece. Xa umphezulu wecandelo urhabaxa kwaye awunakusetyenziswa njengesixhobo sokubeka isalathiso, i-vise okanye ibhentshi yokusebenzela nayo ingasetyenziswa njengemvelaphi yolwalathiso lweZ lwenkqubo yolungelelwaniso lweworkpiece, kwaye ke ukuphakama kwendawo yokusebenza kuyalungiswa. phezulu kwi-G54 okanye inkqubo yokulungelelanisa eyandisiweyo yokuzalisa. Ukusetwa kwesixhobo se-Z-direction machine ikakhulu kubandakanya i-Z-direction measuring tool setting, i-block setting tool setting kunye ne-trial cutting tool setting kunye nezinye iindlela.

6. Ukusetwa kwesixhobo ngesixhobo sokulinganisa ulwalathiso lwe-Z

Isixhobo sokumisela ukuchaneka kwesixhobo sokulinganisa i-Z siphezulu, ngakumbi xa izixhobo ezininzi zibekwe kumatshini kwiziko lokugaya, ukusetyenzwa kwesixhobo kuphezulu, utyalo-mali luncinci, kwaye lufanelekile kwinxalenye enye. ukuqhubekeka.

1) Z-direction isixhobo setting ngexesha elinye-isixhobo machining kwiziko machining

Umatshini onesixhobo esinye kwiziko lomatshini uyafana nengxaki yokuba akukho mbuyiselo yobude bokusetwa kwesixhobo kumatshini wokugaya we-CNC. La manyathelo alandelayo:

(1) Indawo yesixhobo esiza kusetyenziselwa ukusetyenzwa;

(2) Hambisa isixhobo phezulu kwendawo yokusebenza, ulinganise umgama phakathi kwendawo yokusebenza kunye nesixhobo kunye nesixhobo sokulinganisa i-Z, kwaye urekhode i-Z-axis yokufunda u-Z yesixhobo somatshini wangoku (oomatshini) inkqubo yokulungelelanisa;

(3) Thabatha ixabiso elingu-Z kumphakamo wesixhobo sokulinganisa u-Z ngeli xesha (elifana ne-50.03mm), uze ugcwalise ixabiso elilinganisiweyo kwinto engu-Z ye-OFFSETSETTING–>coordinate system–>G54;

(4) Qhuba G90 G54G0 X0 Y0 Z100; khangela ukuba ulungelelwaniso luchanekile

Ixesha lokuposa: Jan-09-2023