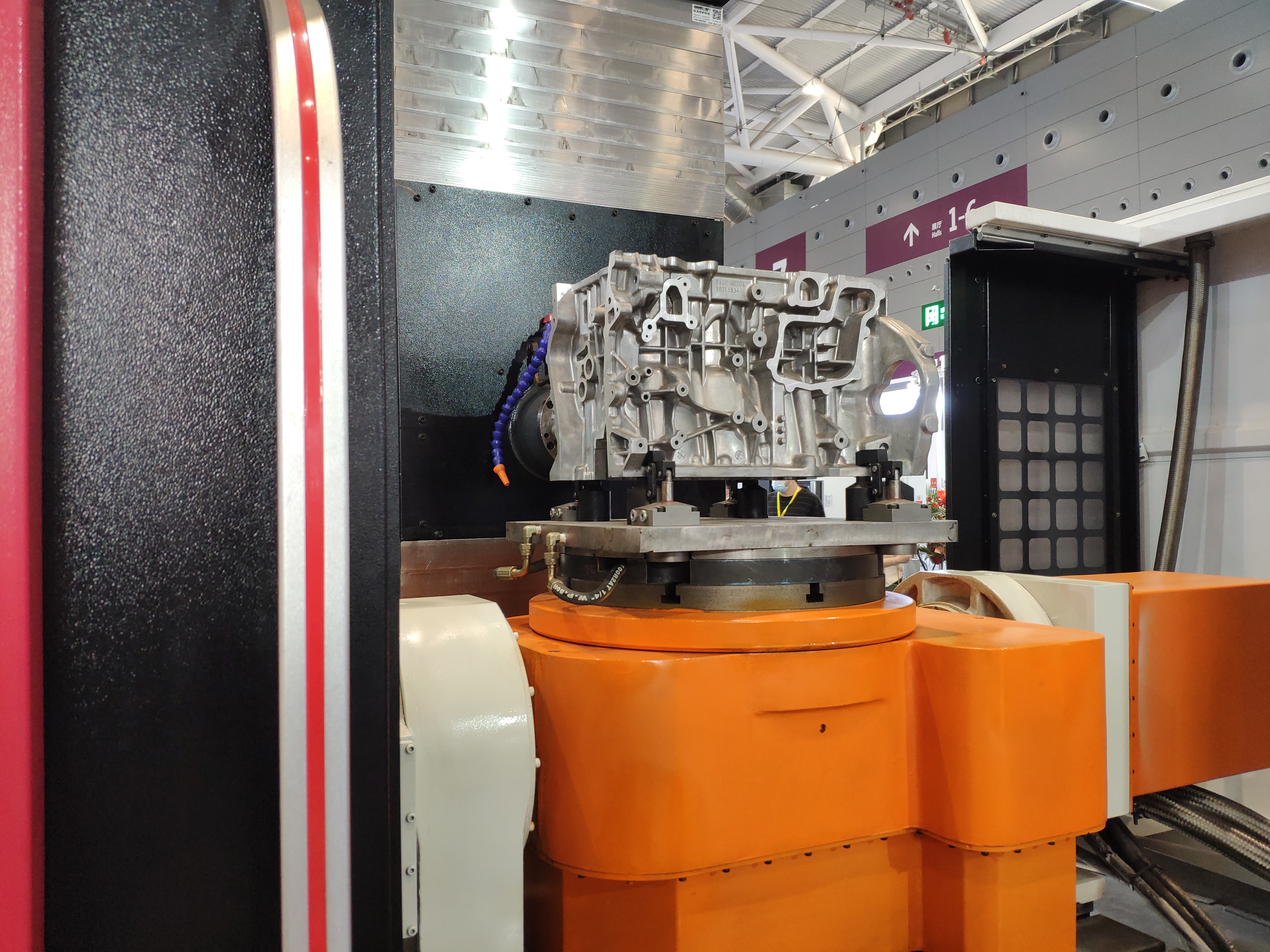

Unyango lobushushu besinyithi kukufudumeza intsimbi okanye i-alloy workpiece kwiqondo lobushushu elifanelekileyo kwindawo ethile, kwaye emva kokugcina ubushushu kangangexesha elithile, lupholile kwimidiya eyahlukeneyo ngezantya ezahlukeneyo, ngokuguqula umphezulu okanye ngaphakathi. izinto zentsimbi. Inkqubo yesakhiwo se-microstructural ukulawula ukusebenza kwayo.cnc machining inxalenye

Udidi oluphambili

Iinkqubo zokunyanga ubushushu besinyithi zinokwahlulahlulwa zibe ziindidi ezintathu: unyango lobushushu ngokubanzi, unyango lobushushu bomhlaba kunye nonyango lobushushu bekhemikhali. Ngokuxhomekeke kwindawo yokufudumeza, ubushushu bokufudumala kunye nendlela yokupholisa, udidi ngalunye lunokwahlulwa lube ziinkqubo ezininzi ezahlukeneyo zonyango lobushushu. Isinyithi esifanayo sisebenzisa iinkqubo ezahlukeneyo zokunyanga ukushisa ukufumana i-microstructures ezahlukeneyo kwaye ngoko ke iipropati ezahlukeneyo. Isinyithi sesona sixhobo sisetyenziswa kakhulu kwishishini, kwaye i-microstructure yensimbi nayo inzima kakhulu, ngoko kukho iintlobo ezininzi zeenkqubo zokunyanga ubushushu bentsimbi.inxalenye yomatshini wobhedu cnc

Iimpawu

Ukunyangwa kobushushu besinyithi yenye yeenkqubo ezibalulekileyo kwimveliso yomatshini. Xa kuthelekiswa nezinye iindlela zokusetyenzwa, unyango lobushushu ngokuqhelekileyo aluyitshintshi imilo kunye nokwakheka kweekhemikhali ngokubanzi kwendawo yokusebenza, kodwa itshintsha i-microstructure ngaphakathi kwendawo yokusebenza okanye itshintshe i-chemical composition of the surface of workpiece. , ukunika okanye ukuphucula ukusebenza kwe-workpiece. Ibonakaliswe ngomgangatho ophuculweyo wangaphakathi we-workpiece, ngokuqhelekileyo ingabonakali ngeso lenyama. Ngoko ke, yinkqubo ekhethekileyo yokuvelisa oomatshini kunye nenxalenye ebalulekileyo yolawulo lomgangatho.

Ukuze wenze i-workpiece yensimbi ibe nezixhobo ezifunekayo zomatshini, iipropati zomzimba kunye neekhemikhali, ngaphezu kokukhethwa kwengqiqo yezinto eziphathekayo kunye neenkqubo ezahlukeneyo zokubumba, iinkqubo zokunyanga ukushisa zihlala ziyimfuneko. Intsimbi yeyona nto isetyenziswa kakhulu kwishishini loomatshini. I-microstructure yensimbi iyinkimbinkimbi kwaye inokulawulwa ngonyango lokushisa. Ngoko ke, unyango olushushu lwetsimbi lunomxholo oyintloko wonyango lwentsimbi. Ukongeza, i-aluminiyamu, ubhedu, i-magnesium, i-titanium, kunye nokunye okunjalo kunokuguqulwa ngonyango lobushushu ukuze kufumaneke iipropathi ezahlukeneyo zomatshini, iipropathi zomzimba kunye neekhemikhali.

Inkqubo esisiseko

Unyango lulonke lobushushu yinkqubo yonyango lwesinyithi olutshisa i-workpiece iyonke kwaye emva koko ipholise ngesantya esifanelekileyo ukutshintsha iimpawu zayo zoomatshini. Unyango olushushu olupheleleyo lwentsimbi luneenkqubo ezine ezisisiseko: i-annealing, normalizing, quenching and tempering.inxalenye yeplastiki

I-Anealing kukufudumeza i-workpiece kwiqondo lobushushu elifanelekileyo, usebenzisa amaxesha ahlukeneyo okubamba ngokwezinto eziphathekayo kunye nobukhulu be-workpiece, kwaye emva koko ukupholisa ngokucothayo, ukuzisa ulwakhiwo lwangaphakathi lwentsimbi ukuya okanye kufutshane ne-equilibrium, okanye ukukhulula intsimbi. uxinzelelo lwangaphakathi olwenziwe yinkqubo yangaphambili. Fumana ukusebenza kakuhle kwenkqubo kunye nokusebenza, okanye ulungiselele ukucima ngakumbi.

I-normalizing okanye i-normalizing kukupholisa i-workpiece kwiqondo lokushisa elifanelekileyo kwaye emva koko uyipholise emoyeni. Umphumo we-normalizing ufana no-annealing, kodwa isakhiwo esibangelwayo siphucukile, esihlala sisetyenziselwa ukuphucula ukusebenza kokusika kwezixhobo, kwaye ngamanye amaxesha zisetyenziselwa iimfuno ezithile. Amalungu angekho phezulu asetyenziswa njengonyango lokugqibela lobushushu.

Ukucima kukupholisa ngokukhawuleza i-workpiece emva kokufudumeza kwaye uyibambe kwindawo yokucima njengamanzi, i-oyile okanye enye isisombululo setyuwa ye-inorganic okanye isisombululo se-organic aqueous. Emva kokucima, intsimbi iba nzima kodwa ibe brittle kwangaxeshanye.

Ukuze kuncitshiswe i-brittleness yentsimbi, intsimbi ecinyiweyo ifakwe i-insulated ixesha elide kwiqondo lokushisa elifanelekileyo ngaphezu kweqondo lokushisa elingaphantsi kwe-650 ° C, kwaye lipholile. Le nkqubo ibizwa ngokuba kukuthoba. I-Anealing, i-normalization, ukucima kunye nokuvutha "yimililo emine" kunyango lobushushu ngokubanzi. Phakathi kwazo, ukucima kunye nokutshisa kuhambelana ngokusondeleyo, kwaye zihlala zisetyenziswa kunye, ziyimfuneko.

I-Anebon Metal Products Limited inokubonelela nge-CNC Machining, Die Casting, inkonzo ye-Sheet Metal Fabrication, nceda uzive ukhululekile ukuqhagamshelana nathi.

Tel: +86-769-89802722 E-mail: info@anebon.com URL: www.anebon.com

Ixesha lokuposa: Aug-31-2019