Inkonzo yeDie Casting

I-Die casting ibe yinto ekhethekileyo ye-Anebon iminyaka engaphezu kwe-10. Iinkonzo zethu zokuphosa i-aluminiyam bezinceda iinjineli, abayili bemveliso kunye nabayili bezakhiwo ukuba bazise uyilo lwabo ebomini kunye noyilo lwenxalenye yobugcisa kunye nomgangatho othembekileyo. Njengoko sinikwe amava ethu kushishino, kunye nezixhobo zethu zanamhlanje, iinjineli zethu zokuvelisa kunye nomgangatho, kunye nabasebenzi bemveliso, uqinisekisiwe umgangatho wokwenziwa kwamacandelo kunye neemveliso zakho ngexabiso loqoqosho nge-Anebon.Siyi-ISO 9001: 2015 umenzi wokuphosa oqinisekisiweyo osebenza ngokukhethekileyo kwiinkonzo zokuphosa kumashishini aphambili kunye neenkampani zehlabathi. Izixhobo zethu zigubungela phantse zonke iinjineli zokufa, ukuyila kunye nophuhliso iimfuno inkampani yakho inokufuna.

Izixhobo zokuphosa kunye nokubumba kuyabiza, ngoko ke inkqubo yokuphosa i-die isetyenziselwa kuphela ukuvelisa inani elikhulu leemveliso. Kulula ukwenza iinxalenye ze-die-cast, ezifuna ngokubanzi amanyathelo amane kuphela, kunye nokonyuswa kwexabiso elinye kuphantsi. I-Die casting ilungele ukwenziwa kwenani elikhulu lezinto ezincinci kunye neziphakathi, ngoko ke ukuphosa kwe-die yeyona nto isetyenziswa kakhulu kwiinkqubo ezahlukeneyo zokuphosa. Xa kuthelekiswa nobunye ubuchule bokuphosa, umphezulu we-die-cast umcaba kwaye unomlinganiselo ophezulu wokuhambelana.

Yintoni iDie Casting?

I-Die casting yinkqubo yokuphosa isinyithi ebonakaliswe ngokusetyenziswa komgodi wokungunda ukufaka uxinzelelo oluphezulu kwintsimbi etyhidiweyo. Ukungunda kuqhele ukwenziwa ngoomatshini ukusuka kwialloyi zamandla aphezulu, ezinye zifana nokubumba inaliti. Uninzi lwe-die castings aluna-iron, njenge-zinc, ubhedu, i-aluminiyam, i-magnesium, ilothe, i-tin, kunye ne-load-tin alloys kunye nezinye i-alloys. Kuxhomekeke kuhlobo lokugalela ukufa, igumbi elibandayo lokufa umatshini wokuphosa okanye igumbi elitshisayo lokufa umatshini liyafuneka.

Iimpawu

I-Die casting yindlela yokuphosa apho i-alloy liquide etyhidiweyo igalelwe kwigumbi loxinzelelo, i-cavity ye-mold yensimbi izaliswe ngesantya esiphezulu, kwaye i-alloy liquid iqiniswe phantsi koxinzelelo ukuze yenze i-casting. Iimpawu eziphambili ze-die casting ezahlula kwezinye iindlela zokuphosa luxinzelelo oluphezulu kunye nesantya esiphezulu.

1. Intsimbi etyhidiweyo igcwalisa i-cavity phantsi koxinzelelo kwaye ikhazimle kuxinzelelo oluphezulu. Uxinzelelo oluqhelekileyo luyi-15-100 MPa.

2 . Ulwelo lwesinyithi luzalisa umngxuma ngesantya esiphezulu, ngokuqhelekileyo kwi-10-50 m / s, kwaye ezinye zinokudlula i-80 m / s, (isantya somgca nge-ingate kwi-cavity - isantya se-ingate), ngoko ke ixesha lokuzaliswa kwesinyithi esinyibilikisiweyo ligqithise kakhulu. mfutshane, kwaye i-cavity ingazaliswa malunga ne-0.01-0.2 imizuzwana (kuxhomekeke kubukhulu bokuphosa).

I-Die-casting yindlela echanekileyo yokuphosa. Amalungu okuphosa ukufa afakwe ngokuphosa, anokunyamezela okuncinci kakhulu kunye nokuchaneka okuphezulu komphezulu. Kwiimeko ezininzi, iinxalenye zokufa zinokudityaniswa ngaphandle kokujika. Amacandelo nawo angaphoswa ngokuthe ngqo.

Ziziphi iingenelo zeenkonzo zokuphosa ukufa?

Inkqubo yethu yokuguqula ukufa ibonelela ngeenzuzo ezininzi ezibalulekileyo, kubandakanya:

l Ukwenziwa ngokwezifiso: Kuyanceda ukufezekisa uyilo oluntsonkothileyo kunye neefom ezenza kube lula ukwenza ngokwezifiso ukuhanjiswa kweenkqubo ezithile zokwenziwa.

ll Iindleko eziphantsi

l Ukusebenza okuphezulu

llll Isebenza ngezinto ezininzi kwaye ikwazi ukumelana nomhlwa

Njengomvelisi ophosa ukufa, i-Anebon Die Casting inikezela ngokudibeneyo, indibano ebanzi kunye novavanyo lwazo zonke iindawo kunye neemveliso. Nokuba unomdla kumacandelo akhethekileyo anje nge-aluminiyam yokufa okanye ukuphosa i-vacuum, okanye ufuna nje ukuba ngumzekelo wenxalenye entsha, unokufumana amava enkonzo epheleleyo kumzi-mveliso wethu.

Mi-aterial

Isinyithi ebesisetyenziselwa ukuphosa ukufa ikakhulu ziquka i-zinc, ubhedu, i-aluminiyam, i-magnesium, ilothe, i-tin, kunye ne-alloys ye-lothe-tin, njl. Iimpawu zetsimbi ezahlukeneyo ngexesha lokufa zimi ngolu hlobo lulandelayo:

•Zinc: Esona sinyithi sokufa ngokulula, sinoqoqosho xa sisenza iindawo ezincinci, kulula ukunxiba, amandla acinezelayo aphezulu, iplastiki ephezulu, kunye nobomi obude bokuphosa.

•Aluminiyam: Umgangatho ophezulu, ukuveliswa okunzima kunye nokuxhonywa kweendonga ezinqabileyo ezinozinzo oluphezulu, ukuxhathisa okuphezulu kwe-corrosion, iipropathi ezilungileyo ze-mechanical, conductivity ephezulu ye-thermal kunye ne-conductivity yombane, kunye namandla aphezulu kumaqondo okushisa aphezulu.

•Magnesium: Kulula ukwenza umatshini, amandla aphezulu kumlinganiselo wobunzima, eyona ilula kwiintsimbi ezisetyenziswa ngokuqhelekileyo.

•Ubhedu: Ubulukhuni obuphezulu kunye nokumelana nokugqwala okuqinileyo. Eyona isetyenziswa ngokuqhelekileyo i-die-cast metal ineempawu ezingcono kakhulu zemishini, i-anti-wear kunye namandla asondele kwintsimbi.

•Ilothe kunye netoti: Uxinaniso oluphezulu kunye nokuchaneka okuphezulu kwe-dimensional yeendawo ezikhethekileyo zokukhusela i-corrosion. Ngenxa yezizathu zempilo yoluntu, le ngxubevange ayinakusetyenziswa njengendawo yokulungisa nokutya. Ingxubevange ye-lead-tin-bismuth (ngamanye amaxesha ikwaqulathe ubhedu oluncinci) ingasetyenziselwa ukwenza amagama agqitywe ngesandla kunye nesitampu esishushu kushicilelo lweletterpress.

Ukuphoswa kweAluminiyam

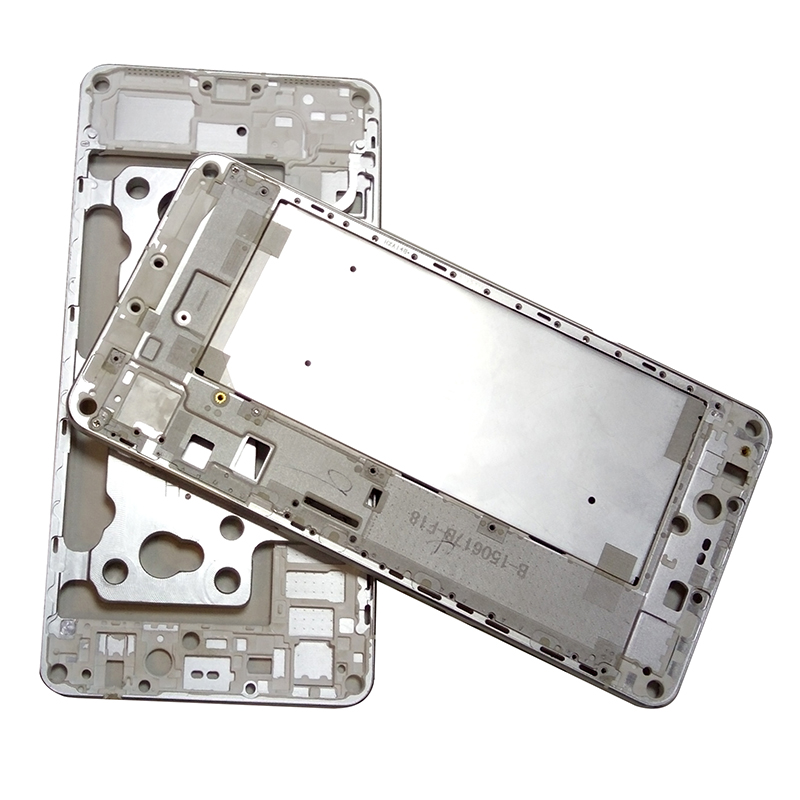

Ukuphosa iZincedisi zeFowuni

I-Aluminium Die Cast