Uyilo lwe-fixture luqhutywa ngokubanzi ngokweemfuno ezithile zenkqubo ethile emva kwenkqubo yomatshinicnc iindawo zomatshinikwayecnc ukuguqula iindawoyenziwe. Xa kuqulunqwa inkqubo, ukuba nokwenzeka kokuphunyezwa kokulungiswa kufuneka kuqwalaselwe ngokupheleleyo, kwaye xa kuyilwa izixhobo, ukuba kuyimfuneko, iingcebiso zokuguqulwa kwenkqubo nazo zinokuphakanyiswa. Umgangatho woyilo lomfanekiso kufuneka ulinganiswe ngokuba unokuqinisekisa ngokuzinzileyo umgangatho wokusetyenzwa kwesixhobo sokusebenza, ukusebenza kakuhle kwemveliso, ixabiso eliphantsi, ukususwa kwetshiphu ezifanelekileyo, ukusebenza ngokukhuselekileyo, ukonga abasebenzi, kunye nokwenza lula kunye nokugcinwa.

1. Imigaqo esisiseko yoyilo lwezixhobo

1. Ukwanelisa uzinzo kunye nokuthembeka kokubeka i-workpiece ngexesha lokusetyenziswa;

2. Kukho amandla okwaneleyo okuthwala okanye ukugoba ukuqinisekisa ukuqhutyelwa komsebenzi kwi-fixture;

3. Dibana nomsebenzi olula kwaye okhawulezayo kwinkqubo yokuqinisa;

4. Iindawo ezisengozini kufuneka zibe nesakhiwo esinokutshintshwa ngokukhawuleza, kwaye kungcono ukuba ungasebenzisi ezinye izixhobo xa iimeko zanele;

5. Ukwanelisa ukuthembeka kokubekwa ngokuphindaphindiweyo kwesigxina ngexesha lohlengahlengiso okanye inkqubo yokutshintshwa;

6. Gwema isakhiwo esiyinkimbinkimbi kunye neendleko eziphezulu kangangoko kunokwenzeka;

7. Khetha amalungu asemgangathweni njengamacandelo ecandelo kangangoko kunokwenzeka;

8. Yenza i-systematization kunye nomgangatho weemveliso zangaphakathi zenkampani.

2. Ulwazi olusisiseko loyilo lwefixture

Isixhobo esigqwesileyo somatshini kufuneka sifezekise ezi mfuno zilandelayo:

1. Ukuqinisekisa ukuchaneka kwe-machining ye-workpiece, isitshixo ekuqinisekiseni ukuchaneka komatshini kukukhetha ngokuchanekileyo i-datum yokubeka, indlela yokubeka kunye namacandelo okumisa. Ukuba kuyimfuneko, kuyimfuneko ukuhlalutya impazamo yokubeka. Kwakhona kuyimfuneko ukunikela ingqalelo kwimpembelelo yesakhiwo sezinye iindawo kwi-fixture ekuchanekeni komatshini. Ukuqinisekisa ukuba ukulungiswa kunokuhlangabezana neemfuno zokuchaneka komatshini we-workpiece.

2. Ukuphucula ukusebenza kakuhle kwemveliso, ubunzima bezinto ezikhethekileyo kufuneka zilungelelaniswe kumthamo wokuvelisa, kwaye iindlela ezahlukeneyo zokubopha ngokukhawuleza kunye nezisebenzayo kufuneka zisetyenziswe kangangoko ukuqinisekisa ukusebenza kakuhle, ukunciphisa ixesha elincedisayo, kunye nokuphucula ukusebenza kakuhle kwemveliso.

3. Ukwakhiwa kwesakhiwo esikhethekileyo kunye nokusebenza kakuhle kwenkqubo kufuneka kube lula kwaye kunengqiqo, ekulungele ukuvelisa, ukudibanisa, ukulungiswa, ukuhlolwa kunye nokugcinwa.

4. Isixhobo sokusebenza esisebenza kakuhle kufuneka sibe namandla okwaneleyo kunye nokuqina, kwaye umsebenzi kufuneka ube lula, ulondoloze umsebenzi, ukhuseleke kwaye uthembekile. Phantsi kwesiseko sokuba iimeko zenjongo zivumela kwaye zinoqoqosho kwaye ziyasebenza, izixhobo zokubambelela koomatshini ezifana noxinzelelo lwe-pneumatic kunye noxinzelelo lwe-hydraulic kufuneka zisetyenziswe kangangoko ukunciphisa amandla omsebenzi womqhubi. Isixhobo kufuneka siququzelele ukususwa kwetshiphu. Ukuba kuyimfuneko, ukususwa kwesakhiwo se-chip kunokusetwa ukukhusela i-chip ekonakalisa indawo yokusebenza kunye nokonakalisa isixhobo, kunye nokuthintela ukuqokelelwa kweetshiphusi ukuzisa ubushushu obuninzi kwaye kubangele ukuguqulwa kwenkqubo yenkqubo.

5. Isixhobo esikhethekileyo esinoqoqosho olulungileyo kufuneka sisebenzise amacandelo asemgangathweni kunye nesakhiwo esisemgangathweni kangangoko kunokwenzeka, kwaye sizame ukuba nesakhiwo esilula kunye nokuveliswa okulula ukunciphisa iindleko zokwenziwa kwexabiso. Ngoko ke, uhlalutyo oluyimfuneko lobugcisa kunye noqoqosho lweskimu sokulungisa kufuneka lwenziwe ngokomyalelo kunye nomthamo wemveliso ngexesha loyilo, ukwenzela ukuba kuphuculwe inzuzo yezoqoqosho kwimveliso.

3. Isishwankathelo sokumiselwa komgangatho wezixhobo kunye noyilo lwezixhobo

1. Iindlela ezisisiseko kunye namanyathelo oyilo lwe-fixture

Amalungiselelo phambi koyilo Izinto zoqobo zoyilo loyilo ziquka oku kulandelayo:

a) Ulwazi lobuchwephesha olufana nesaziso soyilo, inxalenye egqityiweyo yokuzoba umzobo, umzobo ongenanto kunye nendlela yenkqubo, ukuqonda ukusetyenzwa kweemfuno zobugcisa benkqubo nganye, ukumisa kunye neskimu sokubambelela, isiqulatho sokusetyenzwa kwenkqubo yangaphambili, imeko engenanto, izixhobo zoomatshini kunye nezixhobo ezisetyenziswa ukusetyenzwa , Ukuhlola izixhobo zokulinganisa, isibonelelo somatshini kunye nesixa sokusika, njl.;

b) Ukuqonda ibhetshi yemveliso kunye nesidingo sokulungiswa;

c) Qonda iiparamitha eziphambili zobugcisa, ukusebenza, ukucaciswa, ukuchaneka kunye nemilinganiselo yoqhagamshelwano yesakhiwo esidityaniswe nesixhobo, njl.njl. isixhobo somatshini esisetyenzisiweyo;

d) Uluhlu lwemathiriyeli esemgangathweni yezilungiso.

2. Iingxaki eziqwalaselwe kuyilo lwezixhobo

Uyilo lwefixture ngokubanzi lunesakhiwo esinye, lunika abantu imvakalelo yokuba ulwakhiwo aluntsonkothanga kakhulu, ngakumbi ngoku ukuba ukuthandwa kwezixhobo zehydraulic zenza lula kakhulu ubume bomatshini boqobo, kodwa ukuba akukho ngqwalasela ichaziweyo ngexesha lenkqubo yoyilo, iingxaki ezingeyomfuneko ziya kuthi. ngokuqinisekileyo kwenzeka:

a) Isibonelelo esingenanto sesixhobo sokusetyenzwa. Ubungakanani besithuba esingenanto bukhulu kakhulu, okubangela ukuphazamiseka. Ngoko ke, kuyimfuneko ukulungiselela umzobo onqabileyo ngaphambi kokuyila. Shiya indawo eyaneleyo.

b) Ukususwa kwetshiphu kubushelelezi besixhobo. Ngenxa yesithuba esilinganiselweyo sokucutshungulwa kwesixhobo somatshini ngexesha loyilo, ukulungiswa kuhlala kuyilwa kwindawo exineneyo. Ngeli xesha, kudla ngokungahoywa ukuba iifayili zentsimbi ezenziwe ngexesha lomatshini ziqokelela kwikona efileyo, kubandakanywa nokuhamba kakubi kwe-cut cut fluid, eya kubangela iingxaki ezizayo. Ukucubungula kuzisa ingxaki enkulu. Ngoko ke, ekuqaleni kwenkqubo yangempela, iingxaki ezivela ngexesha lokucubungula kufuneka ziqwalaselwe. Emva koko, ukulungiswa kusekelwe ekuphuculeni ukusebenza kakuhle kunye nokuququzelela ukusebenza.

c) Ukuvuleka ngokubanzi komdlalo. Ukungahoyi ukuvuleka kwenza kube nzima kumqhubi ukuba afake ikhadi, elichitha ixesha kwaye linzima, kwaye uyilo luyi-taboo.

d) Imigaqo yethiyori esisiseko yoyilo lwesakhiwo. Iseti nganye yezilungiso kufuneka idlule kumaxesha angenakubaleka okubamba kunye nokukhulula, ukuze ikwazi ukuhlangabezana neemfuno zomsebenzisi ekuqaleni, kodwa izilungiso ezongeziweyo kufuneka zibe nokugcinwa kokuchaneka, ngoko musa ukuyila into echasene nomgaqo. Nokuba ungayenza ngoku ngethamsanqa, ayizukuhlala ixesha elide. Uyilo olulungileyo kufuneka lume uvavanyo lwexesha.

e) Ukutshintshwa kwezinto ezibekayo. Indawo yokubeka inxitywe kakhulu, ngoko ke ukutshintshwa ngokukhawuleza kunye nokulula kufuneka kuthathelwe ingqalelo. Kungcono ukuyilwa njengenxalenye enkulu.

Ukuqokelelwa kwamava oyilo lwezixhobo kubaluleke kakhulu. Ngamanye amaxesha uyilo luyinto enye, kodwa yenye into kwisicelo esisebenzayo, ngoko uyilo olulungileyo yinkqubo yokuqokelela okuqhubekayo kunye nesishwankathelo.

Izixhobo ezisetyenziswa ngokuqhelekileyo zohlulwe ngokwezi ntlobo zilandelayo ngokwemisebenzi yazo:

01 ukubumba ngundo

02 Ukwemba kunye nezixhobo zokusila

03 CNC, isixhobo chuck

04 Uvavanyo lwegesi, isixhobo sovavanyo lwamanzi

05 Ukucheba kunye nokubetha izixhobo

06 izixhobo zokuwelda

07 Ukulungiswa kokugudiswa

08 Izixhobo zeNdibano

09 pad ukuprinta, laser engraving tooling

01 ukubumba ngundo

Inkcazo: Isixhobo sokubeka kunye nokubambene ngokubunjwa kwemveliso

Amanqaku oyilo:

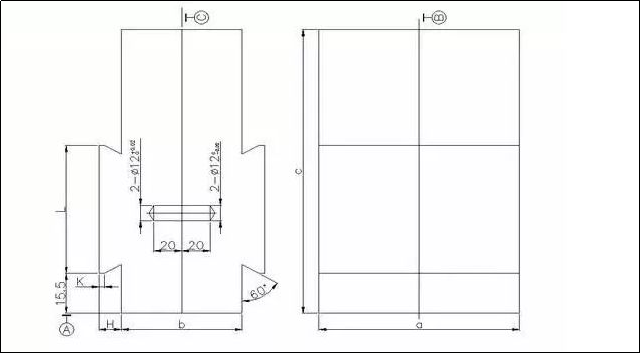

1. Olu hlobo lwe-clamping mold lusetyenziswa kakhulu kwi-vise, kwaye ubude bayo bunokunqunyulwa ngokweemfuno;

2. Ezinye izixhobo ezincedisayo zokumisa zingayilwa kwi-clamping mold, kwaye i-clamping mold ixhunywe ngokubanzi nge-welding;

3. Lo mfanekiso ungentla ngumfanekiso olula, kwaye ubungakanani besakhiwo somgodi wokubumba bunqunywe yimeko ethile;

4. Tshatisa isikhonkwane sokumisa esinobubanzi be-12mm kwindawo efanelekileyo kwisibuko esishukumayo, kunye nomngxuma wokumisa kwindawo ehambelanayo yesilayidi sokungunda esisisigxina ukuze silingane isikhonkwane sokumisa;

5. I-cavity yendibano kufuneka ihlanjululwe kwaye yandiswe nge-0.1mm ngesiseko somphandle womzobo onqabileyo ngaphandle kokunciphisa ngexesha loyilo.

02 Ukwemba kunye nezixhobo zokusila

Amanqaku oyilo:

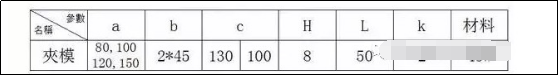

1. Ukuba kuyimfuneko, ezinye izixhobo zokubeka ezincedisayo zinokuthi zenziwe kwi-core fixed kunye neplate yayo ehleliweyo;

2. Lo mfanekiso ungentla ngumzobo wesakhiwo esilula, kwaye imeko yangempela kufuneka iyilwe ngokwesakhiwo semveliso;

3. I-cylinder ixhomekeke kubukhulu bemveliso kunye noxinzelelo ngexesha lokucubungula, kwaye i-SDA50X50 isetyenziswa ngokuqhelekileyo;

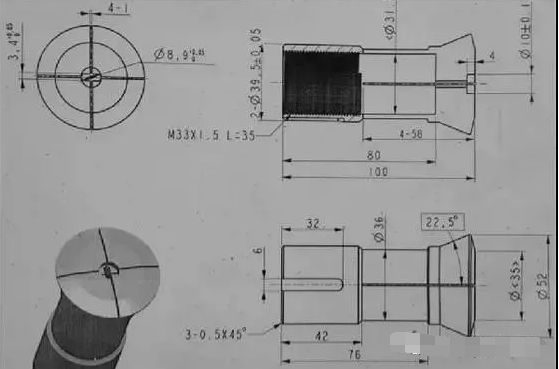

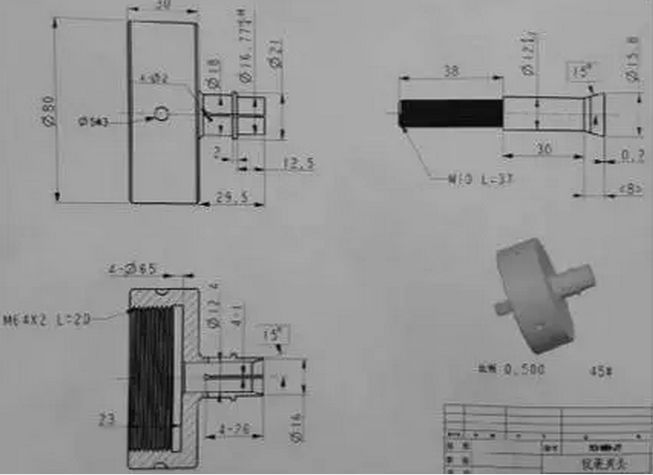

03 CNC, isixhobo chuck

CNC Chuck

Ikholethi yangaphakathi

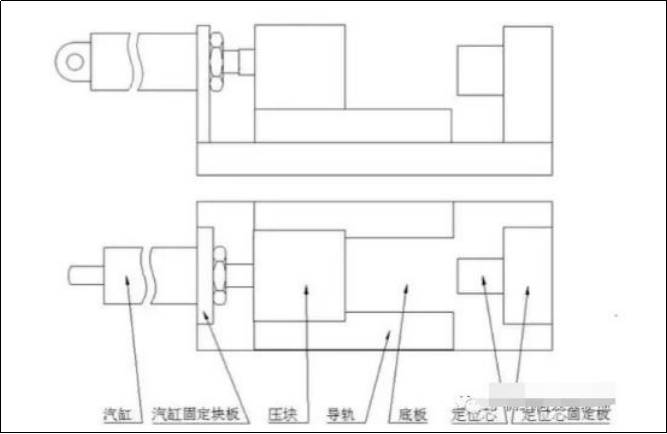

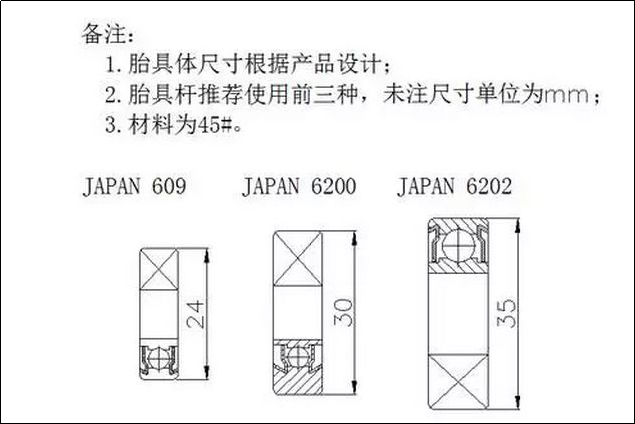

Amanqaku oyilo:

1. Ubungakanani obungaphawulwanga kulo mzobo ungentla bumiselwa ngokwesakhiwo sobungakanani bomngxuma wangaphakathi wemveliso eyiyo;

2. Isangqa sangaphandle esidibana nomngxuma wangaphakathi wemveliso kufuneka sishiye umda we-0.5mm kwelinye icala ngexesha lokuvelisa, kwaye ekugqibeleni uyifake kwisixhobo somatshini we-CNC kwaye ugqibe ukuyijika kwisayizi ukuze uthintele ukuguqulwa kunye ne-eccentricity. okubangelwa yinkqubo yokucima;

3. Izinto eziphathekayo zenxalenye yendibano zicetyiswa ukuba zisebenzise insimbi yasentwasahlobo, kwaye inxalenye yentonga ye-tie i-45 #;

4. Intambo ye-M20 yentambo yokubopha intambo eqhelekileyo, enokuthi ihlengahlengiswe ngokwemeko yangempela.

Isixhobo Inner Beam Chuck

Amanqaku oyilo:

1. Lo mfanekiso ungentla ngumzekeliso wesalathiso, kwaye ubungakanani bendibano kunye nesakhiwo sichongwa ngokuhambelana nomgangatho wangaphandle wemveliso kunye nesakhiwo;

2. Izinto eziphathekayo ziyi-45 #, zicinywe.

Isixhobo esingaphandle beam chuck

Amanqaku oyilo:

1. Lo mfanekiso ungasentla ngumzekeliso wesalathiso, kwaye ubukhulu bokwenene buxhomekeke kubukhulu kunye nesakhiwo somngxuma wangaphakathi wemveliso;

2. Isangqa sangaphandle esidibene nomngxuma wangaphakathi wemveliso kufuneka sishiye umda we-0.5mm kwelinye icala ngexesha lokuvelisa, kwaye ekugqibeleni sifake kwi-lathe yesixhobo kwaye sigqibe ukuyijika kwisayizi ukuthintela ukuguqulwa kunye ne-eccentricity ebangelwa. ngenkqubo yokucima;

3. Izinto eziphathekayo ziyi-45 #, zicinywe.

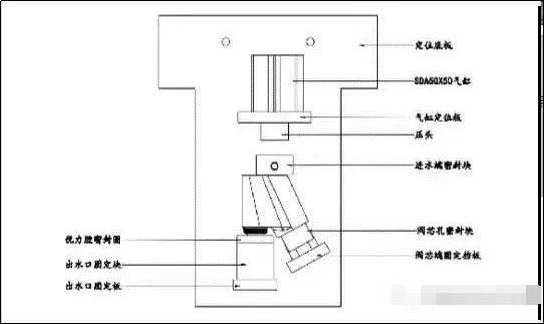

04 Isixhobo sovavanyo lwegesi

Amanqaku oyilo:

1. Lo mfanekiso ungentla ngumfanekiso wesithenjwa wesixhobo sokuvavanya igesi. Ulwakhiwo oluthile kufuneka luyilwe ngokuhambelana nesakhiwo sangempela semveliso. Ingcamango kukutywina imveliso ngendlela elula kakhulu, kwaye uvumele inxalenye efuna ukuvavanywa izaliswe ngegesi ukuqinisekisa ukuqina kwayo;

2. Ubungakanani be-cylinder bunokulungelelaniswa ngokobukhulu bokwenene bemveliso, kwaye kuyafuneka ukuba kuqwalaselwe ukuba i-stroke ye-cylinder inokuhlangabezana nokulula ukukha nokubeka imveliso;

3. Umphezulu wokutywina odibana nemveliso ngokubanzi wenziwe ngerabha egqwesileyo, iringi yerabha ye-NBR kunye nezinye izinto ezinoxinzelelo oluhle. Ngexesha elifanayo, kufuneka kuqatshelwe ukuba kukho ibhloko yokumisa ehambelana nokubonakala kwemveliso, zama ukusebenzisa iibhloko zeplastiki ezimhlophe kwaye uzisebenzise ngexesha lokusetyenziswa. Isigqubuthelo esiphakathi sihlanganiswe ngendwangu yekotoni ukukhusela ukubonakala kwemveliso ukuba yonakaliswe;

4. Isalathiso sokumisa imveliso kufuneka siqwalaselwe kuyilo, ukwenzela ukuba kuthintelwe ukuvuza kwerhasi ekubanjweni ngaphakathi kwendawo yemveliso kwaye kubangele ukufunyanwa kobuxoki.

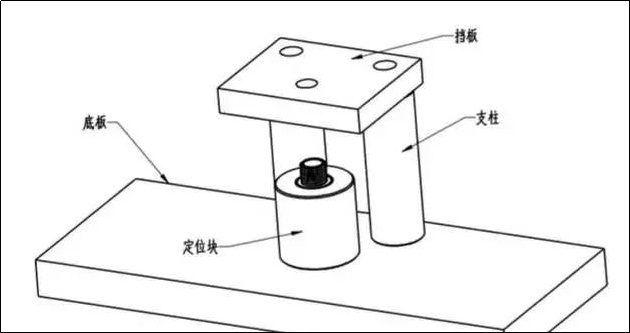

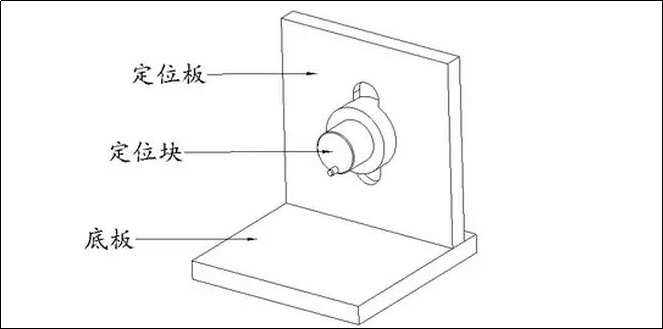

05 izixhobo zokubethelela

Amanqaku oyilo: Lo mfanekiso ungentla ubonisa ubume obuqhelekileyo besixhobo sokubhoboza. Umsebenzi weplate ephantsi kukuququzelela ukulungiswa kwi-workbench yomatshini wokubhoboza; umsebenzi webhloko yokumisa kukulungisa imveliso, isakhiwo esithile siqulunqwe ngokwemeko yangempela yemveliso, kwaye indawo ephakathi ijikeleze ukuququzelela kunye nokuthatha ngokukhuselekileyo nokubeka imveliso; umsebenzi we-baffle kukuququzelela imveliso ukuba ihlulwe kwi-punching knife; Intsika isebenza njengentsika esisigxina. Izikhundla zendibano kunye nobukhulu beendawo ezikhankanywe ngasentla zinokuthi ziyilwe ngokwemeko yangempela yemveliso.

06 izixhobo zokuwelda

I-welding tooling isetyenziselwa ukulungisa indawo yecandelo ngalinye kwindibano ye-welding kunye nokulawula ubungakanani obunxulumene necandelo ngalinye kwindibano ye-welding. Isakhiwo salo ngokuyinhloko ibhloko yokumisa, efuna ukuyilwa ngokuhambelana nesakhiwo sangempelaiinxalenye ze-aluminium machiningkwayeiindawo machining ngobhedu. Kuyafaneleka ukuba uqaphele ukuba xa imveliso ibekwe kwisixhobo sokutshisa i-welding, ayivumelekanga ukuba idale indawo etywiniweyo phakathi kwezixhobo zokuthintela uxinzelelo olugqithiseleyo lwendawo etywiniweyo ngexesha lokufudumala kwenkqubo yokutshisa ekuchaphazela ubungakanani bamacandelo emva kwe-welding. .

07 Ukulungiswa kokugudiswa

08 Izixhobo zeNdibano

Izixhobo zeNdibano zisetyenziswa ikakhulu njengesixhobo sokubeka ukuncedisa ngexesha lenkqubo yokuhlanganisa amacandelo. Ingcamango yayo yoyilo kukuba imveliso inokuthathwa ngokulula kwaye ibekwe ngokuhambelana nesakhiwo sendibano yamacandelo, imbonakalo yobuso bemveliso ayinakonakala ngexesha lenkqubo yokuhlanganisa, kwaye umkhiqizo unokugqunywa ngelaphu lomqhaphu ukukhusela umkhiqizo ngexesha. sebenzisa. Ekukhetheni izinto eziphathekayo, zama ukusebenzisa izinto ezingezona zetsimbi ezifana neglue emhlophe.

09 pad ukuprinta, laser engraving tooling

Amanqaku oyilo: Yila ubume bokumisa isixhobo ngokweemfuno zonobumba zeyona meko yemveliso. Ingqalelo kufuneka ihlawulwe kuncedo lokuthatha kunye nokubeka imveliso kunye nokukhuselwa kwembonakalo yemveliso. Ibhloko yokubeka kunye nesixhobo sokuncedisa i-axiliary positioning edibanisa nemveliso kufuneka yenziwe ngezinto ezingezona zetsimbi ezifana neglue emhlophe. .

Ixesha lokuposa: Dec-26-2022