Insimbi engenasici lukhetho oludumileyo lokwenza izixhobo. Ukufunda malunga nentsimbi engenastainless kunokunceda abasebenzisi besixhobo ukuba babe nobuchule ekukhetheni nasekusebenziseni izixhobo ngokufanelekileyo.

Intsimbi engatyiwayo, esoloko ishunqulwa njenge-SS, iyakwazi ukumelana nokuvezwa komoya, umphunga, amanzi, kunye nezinye izinto ezingeyongozi ezonakalisayo. Ngeli xesha, intsimbi ekwaziyo ukuxhathisa iziphumo zokubola kweekhemikhali ezivela kwizinto ezifana neasidi, ialkali, ityuwa, kunye nezinye iikhemikhali ezibizayo, yaziwa ngokuba yintsimbi enganyangekiyo kwiasidi.

Intsimbi estainless, ekwaziwa ngokuba yintsimbi enganyangekiyo enganyangekiyo kwiasidi, inokumelana nomoya, umphunga, amanzi, kunye nezinto ezingathi zinomhlwa. Nangona kunjalo, kubalulekile ukuqaphela ukuba ayizizo zonke insimbi engenasici ekwazi ukumelana nokubola kweekhemikhali. Kwelinye icala, intsimbi enganyangekiyo ngeasidi yenzelwe ukuxhathisa impembelelo yemithombo yeendaba enjenge-asidi, ialkali, netyuwa. Ukuxhatshazwa kwe-corrosion yensimbi engenasici kuchongwa zizinto ezixutywayo ngaphakathi kwentsimbi.

Ukuhlelwa okuqhelekileyo

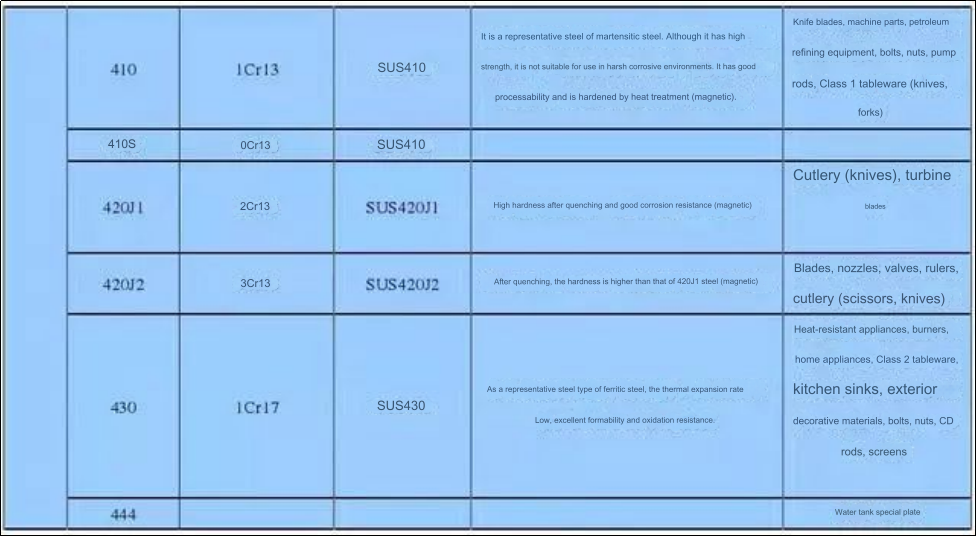

Ngokuqhelekileyo yahlulwe ngombutho we-metallographic:

Kwindawo yombutho we-metallographic, intsimbi eqhelekileyo yentsimbi idla ngokuhlelwa ngokwamaqela amathathu: iAustenitic stainless steel, ferritic stainless steel, kunye ne-martensitic stainless steel. La maqela enza isiseko, kwaye ukusuka apho, intsimbi ye-biphase, i-precipitation-hardened stainless steel stainless, kunye nentsimbi ephezulu ye-alloy equkethe ngaphantsi kwe-50% yesinyithi iye yaphuhliswa ukuhlangabezana neemfuno ezithile kunye nokusebenzela iinjongo ezithile.

I-1, iNtsimbi eNgenaMagnetic engenaMagnetic

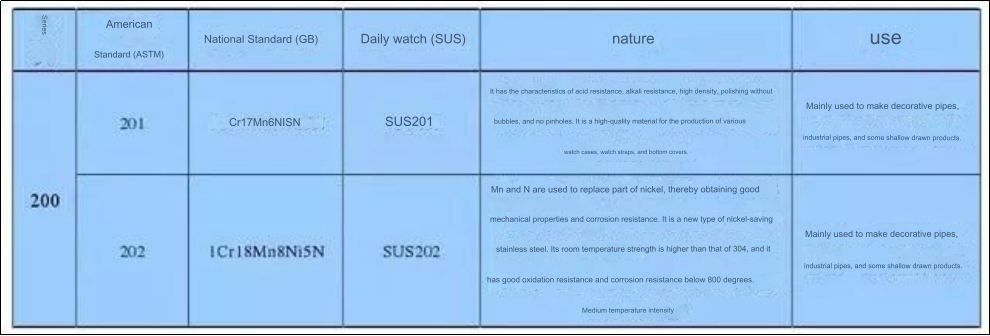

Olu hlobo lwensimbi engenasici lune-crystal structure eyaziwa ngokuba yi-austenitic, eyona nto iqiniswe ngokusebenza okubandayo. Ayisiyo magnetic, kodwa amanani angama-200 kunye nama-300, afana ne-304, aqhele ukusetyenziswa yi-American Iron kunye ne-Steel Institute ukuchonga le ntsimbi.

2, iStainless Steel Yenziwe Ubuninzi bentsimbi

Olu hlobo lwensimbi engenasici lubandakanya i-crystal structure elawulwa yi-ferrite (isigaba A), esinamandla. Ayinakwenziwa lukhuni ngokufudumeza, kodwa ukusebenza okubandayo kunokukhokelela ekonyukeni okuncinci kwamandla. I-American Iron and Steel Institute ichaza i-430 kunye ne-446 njengemizekelo.

3, iNtsimbi eQimileyo

Olu hlobo lwensimbi engenasici lunokwakheka kwekristale ebizwa ngokuba yimartensitic enemagnethi. Iimpawu zayo zomatshini zingatshintshwa ngonyango lobushushu. I-American Iron and Steel Institute ibhekisela kuyo njenge-410, 420, kunye ne-440. I-Martensite iqala ngesakhiwo se-austenitic kumaqondo obushushu aphezulu kwaye inokutshintsha ibe yi-martensite (okt, iba nzima) xa iphola ngesantya esifanelekileyo ukuya kwiqondo lokushisa.

4, Duplex Stainless Steel

Olu hlobo lwensimbi engenasici lunomxube wezakhiwo ze-austenitic kunye ne-ferritic. Umyinge wenqanaba elingaphantsi kwisakhiwo udla ngokuba mkhulu kune-15%, nto leyo eyenza ibe ngumagnethi kwaye ikwazi ukomelezwa ngokusebenza okubandayo. I-329 ngumzekelo owaziwayo wolu hlobo lwensimbi engenasici. Xa kuthelekiswa ne-austenitic stainless steel, i-duplex steel ibonisa amandla amakhulu kunye nokunyuka okuphawulekayo kokuchasana ne-intergranular corrosion, i-chloride stress corrosion, kunye ne-point corrosion.

I-5, iStainless Steel kunye nePrecipitation Hardening Capability

Olu hlobo lwensimbi engenasici lune-matrix mhlawumbi i-austenitic okanye i-martensitic kwaye inokuqina ngokuqina kwemvula. Intsimbi yaseMelika

kwayeI-Steel Institute inika iinombolo ze-600 zezi zinsimbi, ezifana ne-630, eyaziwa ngokuba yi-17-4PH.

Ngokuqhelekileyo, ngaphandle kwe-alloys, i-austenitic stainless steel inika ukuxhathisa okungaqhelekanga. Kwiindawo ezingaphantsi kwe-corrosion, i-ferritic stainless steel inokusetyenziswa, ngelixa kwiindawo ezinobungozi obuncinci apho kufuneka khona amandla aphezulu okanye ukuqina, i-martensitic stainless steel kunye ne-precipitation hardened steel stainless zikhetho ezifanelekileyo.

Iimpawu kunye neendawo zokusetyenziswa

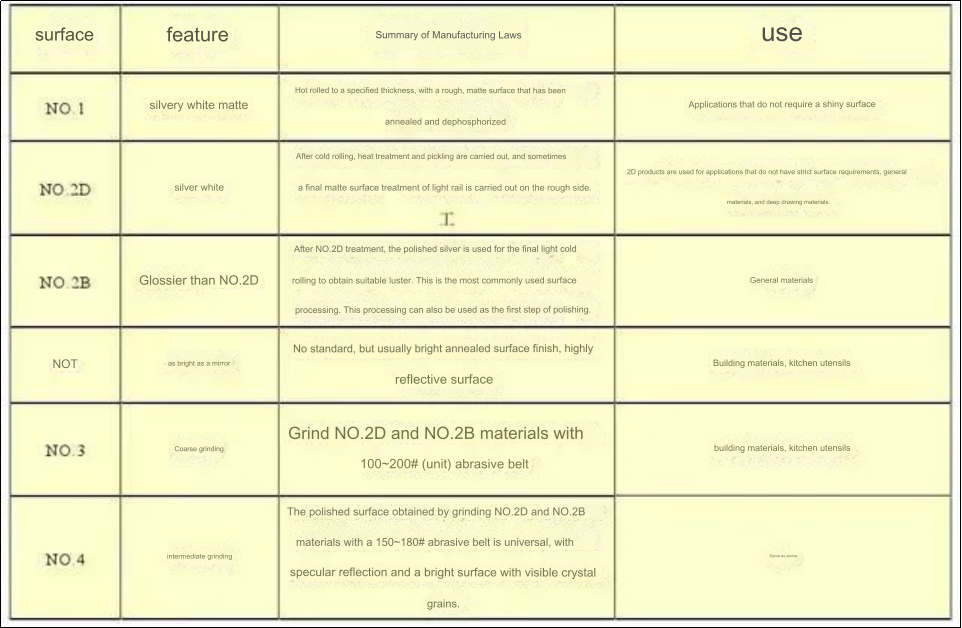

Itekhnoloji yomphezulu

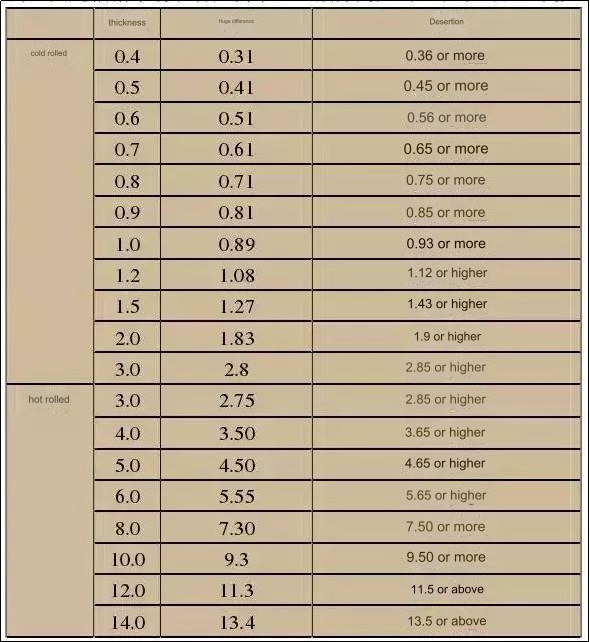

Ukwahlula ukutyeba

1, ngenxa yokuba oomatshini bokusila bentsimbi kwinkqubo yokuqengqeleka, ubushushu bomqulu bubonakala buguquguquka kancinane, obukhokelela kubunzima bokutenxa kwebhodi eqengqelekayo, ngokubanzi kungqindilili kumacala omabini obhityileyo. Xa ulinganisa ubukhulu bebhodi, urhulumente uchaza ukuba inxalenye ephakathi yentloko yebhodi kufuneka ilinganiswe.

2, isizathu sokunyamezelana kuhambelana nemarike kunye nemfuno yabathengi, ngokubanzi yahlulwe ibe yinyameko enkulu kunye nokunyamezelana okuncinci: umzekelo,

Loluphi uhlobo lwentsimbi engatyiwayo lula ukurusa?

Kukho izinto ezintathu eziphambili ezichaphazela ukubola kwentsimbi engatyiwayo:

1, umxholo wezinto zokudibanisa.

Impembelelo ye-Alloying Elements Ngokubanzi, intsimbi equkethe ubuncinane i-10.5% yechromium ibonisa ukuchasana nokugqwala. Ngaphaya koko, intsimbi engenastainless enamanqanaba aphezulu echromium kunye nenickel, njengoko ifunyenwe kwintsimbi engama-304 ene-nickel eyi-8-10% kunye ne-18-20% yechromium, ibonisa ukuxhathisa okuthuthukisiweyo kwaye iqhelekile ukumelana nomhlwa kwiimeko eziqhelekileyo.

2. Impembelelo yeNkqubo yokuNyibilika kwi-Corrosion Resistance

Ukuxhatshazwa kwe-corrosion of steel stainless nako kunokuchaphazeleka yinkqubo yokunyibilikisa kwiindawo zokuvelisa. Izityalo ezinkulu zensimbi ezingenasici ezixhotywe ngobuchwepheshe obuphezulu kunye nezixhobo zanamhlanje zinokuqinisekisa umgangatho wemveliso ozinzile kunye nothembekileyo ngokulawulwa ngokuchanekileyo kwezinto ezixutywayo, ukususwa okusebenzayo kokungcola, kunye nokulawulwa ngokuchanekileyo kwamaqondo okushisa okupholisa i-billet. Oku kukhokelela kumgangatho ophezulu wangaphakathi kunye nokuncitshiswa kokungenwa ngumhlwa. Ngakolunye uhlangothi, iintsimbi ezincinci zentsimbi ezinezixhobo eziphelelwe lixesha kunye neteknoloji zinokuba nzima ukususa ukungcola ngexesha lokunyibilikisa, okukhokelela ekuqhumeni okungenakuphepheka kweemveliso zabo.

3. indawo yangaphandle, imozulu yomile kwaye ingena umoya akulula ukurusa.

Imeko yendawo yangaphandle, ngakumbi imozulu eyomileyo nengena umoya, ayikhuthazi ukumila komhlwa. Ngokuchaseneyo, amanqanaba aphezulu okufuma komoya, imozulu yemvula ehlala ixesha elide, okanye iindawo ezisingqongileyo ezinamaqondo aphezulu e-pH zinokukhokelela ekwakhekeni komhlwa. Nokuba i-304 insimbi engenasici iya kuhlwa xa iphantsi kweemeko ezimbi zokusingqongileyo.

Intsimbi engatyiwayo ibonakala inomhlwa indawo yokujongana nayo?

1. Iindlela zemichiza

Sebenzisa iindlela zeekhemikhali ezifana ne-pickling paste okanye isitshizi ukuququzelela ukugqithiswa kwakhona kweendawo eziqhumayo, ukwenza ifilimu ye-chromium oxide ebuyisela ukuxhathisa ukubola. Ukulandela ukukhethwa, ukuhlanjululwa ngokucokisekileyo ngamanzi kubalulekile ukususa zonke izinto ezingcolileyo kunye neentsalela ze-asidi. Gcwalisa inkqubo yokonyango ngokutsha ngezixhobo ezifanelekileyo kunye nokutywinwa nge-wax. Kwiindawo ezincinci ze-rust spots, umxube we-1: 1 we-petroli kunye neoli unokufakwa ngelaphu elicocekileyo ukususa i-rust.

2. Indlela yomatshini

Ukusetyenziswa kokuqhushumba kwesanti, iglasi okanye ukudutyulwa kwesuntswana leceramic, ukugqabhuka, ukubrasha, kunye nokupholisha kuthetha iindlela ezibonakalayo zokususa ungcoliseko olushiywe yimisebenzi yokupolisha okanye ukugruzuka kwangaphambili. Naluphi na uhlobo longcoliseko, ngakumbi amasuntswana entsimbi angaphandle, angakhokelela ekudlekeni, ngakumbi kwiindawo ezifumileyo. Ngaloo ndlela, kuyacetyiswa ukuba kuqhutywe ukucocwa ngokomzimba kweendawo phantsi kweemeko ezomileyo. Kubalulekile ukuba uqaphele ukuba ukusetyenziswa kweendlela eziphathekayo kunokususa kuphela ukungcola komhlaba kwaye akutshintshi ukuchasana kwe-corrosion yendalo. Ngenxa yoko, kuyacetyiswa ukuba ugqibezele inkqubo ngokuphinda uhlaziywe ngezixhobo ezifanelekileyo kunye nokutywinwa nge-wax yokupolisha.

Isixhobo esisetyenziswa ngokuqhelekileyo kwibakala lensimbi engenasici kunye nokusebenza

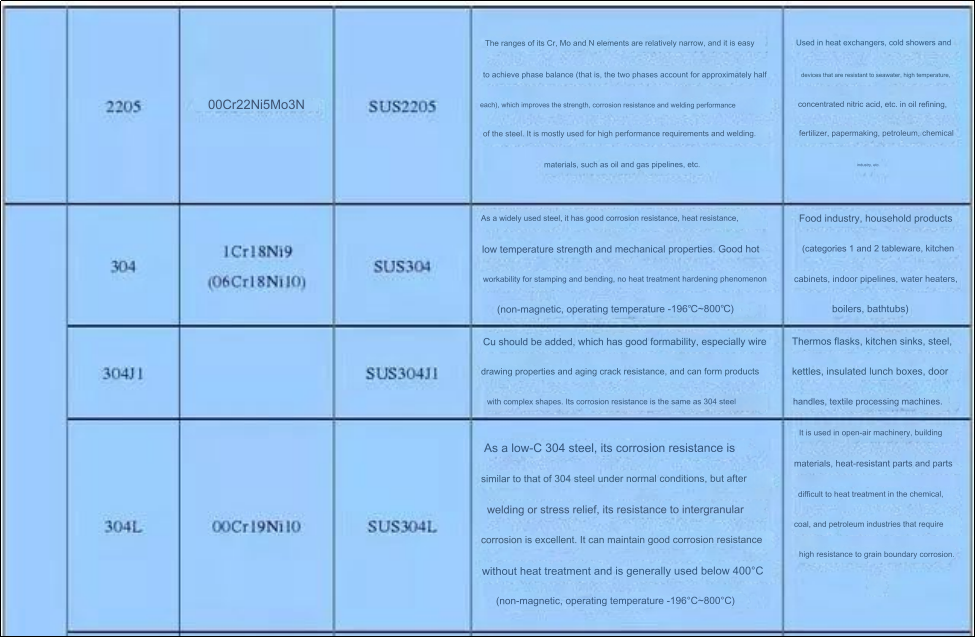

I-1, i-304 yensimbi engenastainless isetyenziswa kakhulu i-austenitic stainless steel, ilungele ukuvelisa ukutsalwa nzulu.cnc amacandelo oomatshini, imibhobho yeasidi, izikhongozeli, iinxalenye zesakhiwo, kunye nemibutho yezixhobo ezahlukeneyo. Ukongeza, iyakwazi ukwenza izixhobo ezingezizo-magnetic kunye nobushushu obuphantsi kunye namalungu.

I-2, i-304L insimbi engenasici isetyenziselwa ukujongana ne-intergranular corrosion susceptibility ye-304 insimbi engenasici ngenxa ye-Cr23C6 yemvula phantsi kweemeko ezithile. Imeko yokuqonda le ultra-low carbon austenitic stainless steel ibonelela ngokuphawulekayo ukuphucula intergranular ukuxhathisa umhlwa xa kuthelekiswa 304 stainless steel. Ukongeza, ngelixa ibonisa amandla asezantsi kancinci, yabelana ngeempawu ezifanayo kunye nentsimbi engama-321 kwaye isetyenziselwa ukuwelda. Ilungele ukwenziwa kwezixhobo ezahlukeneyo zezixhobo kunye nezixhobo ezikwaziyo ukumelana nomhlwa kunye namalungu angenako ukunyangwa isisombululo esiluqilima.

I-3, i-304H yensimbi engenasici. Isebe langaphakathi le-304 yensimbi engenasici, i-carbon mass fraction ye-0.04% -0.10%, ukusebenza kweqondo lokushisa eliphezulu kungcono kune-304 yensimbi engenasici.

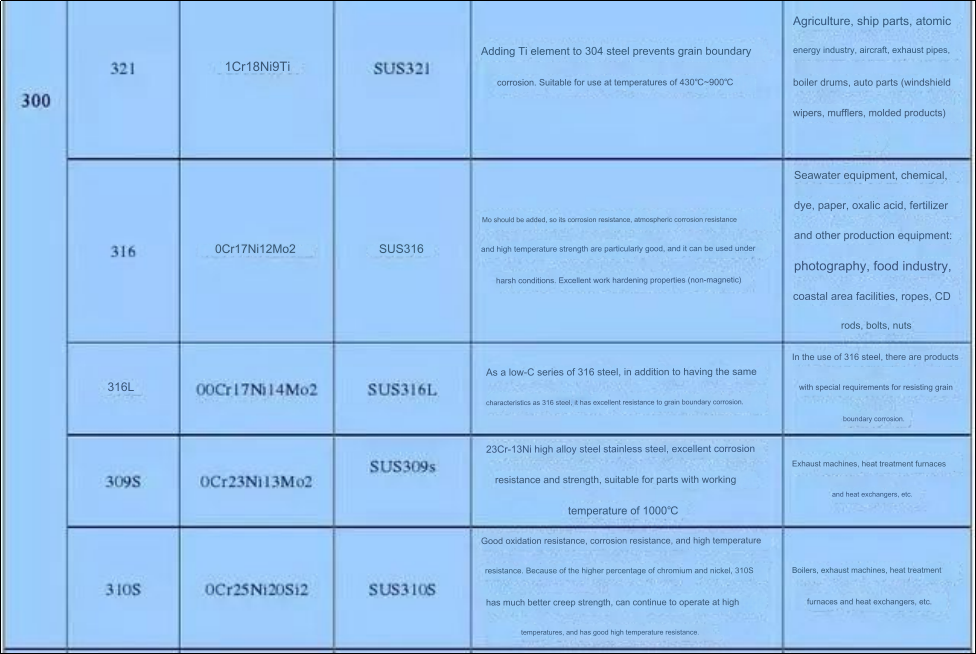

4, 316 intsimbi engenasici. Ukongezwa kwe-molybdenum ngesiseko sentsimbi ye-10Cr18Ni12 yenza ukuba intsimbi ibe nokuchasana kakuhle nokunciphisa imidiya kunye ne-corrosion point. Emanzini olwandle nakwamanye amajelo eendaba, ukuxhathisa ukubola kubhetele kunentsimbi engatyiwayo engama-304, eyona nto isetyenziselwa ukugoba izinto zokuchasa.

5, 316L intsimbi engenasici. Intsimbi yekhabhoni ephantsi kakhulu, ekwazi ukumelana nokunyangwa kwe-intergranular corrosion, ilungele ukwenziwa kwamalungu adityanisiweyo kunye nezixhobo ezinobukhulu obunqamlezileyo obunqamlezayo, njengezinto ezikwaziyo ukumelana nomhlwa kwizixhobo zepetrochemical.

6, 316H intsimbi engatyiwa. I-316 ye-stainless steel yesebe yangaphakathi, i-carbon mass fraction ye-0.04% -0.10%, ukusebenza kweqondo lokushisa eliphezulu kungcono kune-316 insimbi engenasici.

7, 317 intsimbi engenasici. Ukugonywa kunye nokuxhathisa ukukhasa kungcono kune-316L yentsimbi engatyiwayo, esetyenziswa ekwenzeni i-petrochemical kunye ne-organic acid ekwazi ukumelana nomhlwa.

I-8, i-321 insimbi engenasici yintsimbi ye-austenitic ene-titanium stabilization. Ukongezwa kwe-titanium kujolise ekwandiseni ukuxhathisa kwi-corrosion ye-intergranular, kwaye ikwabonisa iimpawu ezifanelekileyo zomatshini kumaqondo aphezulu. Phantsi kweemeko ezininzi, ayicetyiswa ukuba isetyenziswe, ngaphandle kweemeko ezithile ezifana nokujongana namaqondo obushushu aphezulu okanye umhlwa owenziwe yi-hydrogen.

I-9, i-347 insimbi engenasici yi-alloy ye-austenitic stainless steel ezinziswe nge-niobium. Ukongezwa kwe-niobium kunceda ukomeleza ukuxhathisa kwayo kwi-intergranular corrosion kunye nokukwazi kwayo ukumelana nokubola kwi-asidi, i-alkaline, ityuwa, kunye nezinye iindawo ezinobungozi beekhemikhali. Ikwabonisa neempawu zokuwelda ezigqwesileyo, ziyenza ilungele ukusetyenziswa njengento enganyangekiyo kwi-corrosion kunye nentsimbi ekwaziyo ukumelana nobushushu. Le ngxubevange yentsimbi isetyenziswa ikakhulu kumandla obushushu kunye namashishini epetrochemical kwizicelo ezahlukeneyo ezifana nezikhongozeli zokwenza, imibhobho, utshintshiselwano lobushushu, iishafti, kunye neetyhubhu zomlilo kwiziko lemizi-mveliso, kunye neethemomitha zetyhubhu yomlilo.

I-10, i-904L insimbi engenasici yintsimbi ye-austenitic ephezulu kakhulu ephuhliswe yi-OUTOKUMPU (eFinland) enomxholo we-nickel ukusuka kwi-24% ukuya kwi-26% kunye nomxholo wekhabhoni ongaphantsi kwe-0.02%. Iqhayisa ngokuxhathisa okugqwesileyo kokutya kwaye iqhuba kakuhle kwiiasidi ezingenayo i-oxidizing ezifana ne-asidi ye-sulfuric, i-acetic acid, i-fomic acid, kunye ne-asidi ye-phosphoric. Ukongeza, ibonisa ukuxhathisa okuqinileyo kwi-corrosion ye-crevice kunye noxinzelelo lwe-corrosion. Ilungele ukusetyenziswa kunye ne-asidi ye-sulfuric kwiindawo ezahlukeneyo ezingaphantsi kwe-70 ℃ kwaye inikezela ukuxhathisa okuphezulu kwe-corrosion kwi-acetic acid kunye ne-acids exubeneyo ye-asidi ye-formic kunye ne-acetic acid kuyo nayiphi na ingxinano kunye nobushushu phantsi koxinzelelo oluqhelekileyo. Ekuqaleni ihlelwe njenge-alloy esekelwe kwi-nickel phantsi komgangatho we-ASMESB-625, ngoku iphinde yahlelwa njengensimbi engenasici. Ngelixa i-China's 015Cr19Ni26Mo5Cu2 izabelo zentsimbi ezifanayo kunye ne-904L, abavelisi bezixhobo ezininzi zaseYurophu basebenzisa i-904L yensimbi engenasici njengeyona nto iphambili kwizinto zabo.iindawo zecnc, njenge-E + H mass flow meter measurement tube kunye ne-Rolex watch case.

I-11, i-440C insimbi engenasici. I-Martensitic steel stainless, ubunzima obuphezulu kwintsimbi eqinile, insimbi engenasici, i-HRC57. Ikakhulu isetyenziselwa ukwenza imilomo, iibheringi, ivalve spool, isihlalo, umkhono, isiqu njalo njalo.

I-12, i-17-4PH insimbi engenasici ihlelwa njenge-martensitic precipitation-hardened steel stainless steel kunye ne-Rockwell hardness ye-44. Inika amandla akhethekileyo, ukuqina, kunye nokuxhathisa ukubola, nangona ingafanelekanga ukusetyenziswa kumaqondo okushisa angaphezu kwe-300 ° C. Le ntsimbi ibonisa ukuxhathisa okulungileyo kwiimeko ze-atmospheric, kunye ne-acids diluted okanye ityuwa. Ukuxhatshazwa kwayo kwe-corrosion kuthelekiswa ne-304 yensimbi engenasici kunye ne-430 yensimbi engenasici. Izicelo zale ntsimbi zibandakanya ukusetyenziswa kwayo kwimveliso yamaqonga angaphesheya konxweme, iiblade zeinjini yomoya, iivalve spools, izihlalo, imikhono, iziqu zevalve, nokunye.

Kwintsimi ye-instrumentation yobuchwephesha, ukukhethwa kwentsimbi ye-austenitic ye-stainless yesiqhelo kuchongwa yizinto ezifana nokuguquguquka kunye neendleko. Ulandelelwano olucetyiswayo oluqhelekileyo lokukhethwa kwensimbi engenasici yi-304-304L-316-316L-317-321-347-904L. Ngokucacileyo, i-317 ayisetyenziswanga ngokuqhelekiyo, i-321 ayithandwa, i-347 ikhethwa ngokuxhathisa ubushushu obuphezulu be-corrosion, kwaye i-904L yinto engagqibekanga kumacandelo athile awenziwe ziinkampani ezithile. I-904L yensimbi engenasici ngokuqhelekileyo ayilona khetho oluqhelekileyo kwizicelo zoyilo.

Kwi-design yesixhobo kunye nokukhethwa, ngokuphindaphindiweyo udibana neenkqubo ezahlukeneyo, uchungechunge, amabakala ensimbi engenasici, ukhetho kufuneka lusekelwe kwinkqubo ethile yemidiya, ubushushu, uxinzelelo, iinxalenye zoxinzelelo, ukubola, iindleko kunye nezinye iinkalo zokuqwalasela.

Usukelo lwe-Anebon kunye nenjongo yeshishini ku "Soloko usanelisa iimfuno zabathengi bethu". I-Anebon qhubeka nokuseka kunye nesimbo kunye noyilo lweempahla ezikumgangatho ophezulu kuzo zombini eziphelelwe lixesha kunye namathemba amatsha kwaye siqonde ithemba lokuphumelela kubathengi bethu njengoko sisenza ngokwezifiso iiprofayili ezichanekileyo ezichanekileyo,cnc ukuguqula iinxalenye ze-aluminiyamkwayeiindawo zokugaya i-aluminiumkubathengi. I-Anebon ngeengalo ezivulekileyo, imema bonke abathengi abanomdla ukuba batyelele iwebhusayithi yethu okanye baqhagamshelane nathi ngokuthe ngqo ngolwazi oluthe kratya.

IFactory Customized China CNC Machine kunye neCNC Engraving Machine, imveliso ye-Anebon iyaziwa ngokubanzi kwaye ithenjwa ngabasebenzisi kwaye inokudibana ngokuqhubekayo nokuphuhlisa iimfuno zoqoqosho nezentlalo. I-Anebon yamkele abathengi abatsha kunye nabadala abavela kuzo zonke iindlela zobomi ukuba baqhagamshelane nathi kubudlelwane beshishini elizayo kunye nokuzuza impumelelo efanayo!

Ixesha lokuposa: Jan-23-2024