I-Aluminiyam yeyona nto isetyenziswa kakhulu kwaye isetyenziswa ngokubanzi kwizinto zetsimbi ezingezizo isinyithi, kwaye uluhlu lwayo lwesicelo lusakhula. Kukho ngaphezu kwe-700,000 yeentlobo zeemveliso ze-aluminiyam eziveliswa ngokusebenzisa izinto ze-aluminiyam. Ngokwezibalo, kukho ngaphezu kwe-700,000 iintlobo zeemveliso ze-aluminium, kwaye amashishini ahlukeneyo afana neshishini lokwakha kunye nokuhombisa, ishishini lezothutho, ishishini le-aerospace, njl. Namhlanje, uXiaobian uya kukwazisa ngetekhnoloji yokusetyenzwa kweemveliso ze-aluminium kunye nendlela yokuphepha ukusetyenzwa kwe-deformation.cnc machining inxalenye

Iinzuzo kunye neempawu ze-aluminiyam zezi zilandelayo:

1. Ubuninzi obuphantsi. Ubuninzi be-aluminium malunga ne-2.7 g / cm3. Ubuninzi bayo yi-1/3 kuphela yentsimbi okanye ubhedu.

2. Iplastiki ephezulu. I-Aluminiyam ine-ductility efanelekileyo kwaye inokwenziwa kwiimveliso ezahlukeneyo ngeendlela zokucutshungulwa koxinzelelo ezifana ne-extrusion kunye nokwelula.

3. Ukumelana nokubola. I-Aluminiyam yintsimbi ehlawuliswa kakubi kakhulu, kwaye ifilimu ye-oxide ekhuselayo iya kwenziwa phezu komhlaba phantsi kweemeko zendalo okanye i-anodizing, kwaye inokumelana nokugqwesa okungcono kakhulu kunentsimbi.

4, kulula ukomeleza. I-aluminium ecocekileyo ayinamandla kakhulu, kodwa inokunyuswa nge-anodizing.

5. Unyango olulula lomphezulu. Unyango olungaphezulu lunokuphucula ngakumbi okanye lutshintshe iipropathi zomphezulu we-aluminiyam. Inkqubo ye-aluminiyam ye-anodizing ikhulile kwaye izinzile ekusebenzeni, kwaye isetyenziswe ngokubanzi kulungiso lweemveliso ze-aluminiyam.

6. I-conductivity elungileyo kwaye kulula ukuyibuyisela kwakhona.

Ukucubungula iteknoloji yeemveliso ze-aluminium

Ukubethelwa kweemveliso ze-aluminium

1. Inqindi elibandayo

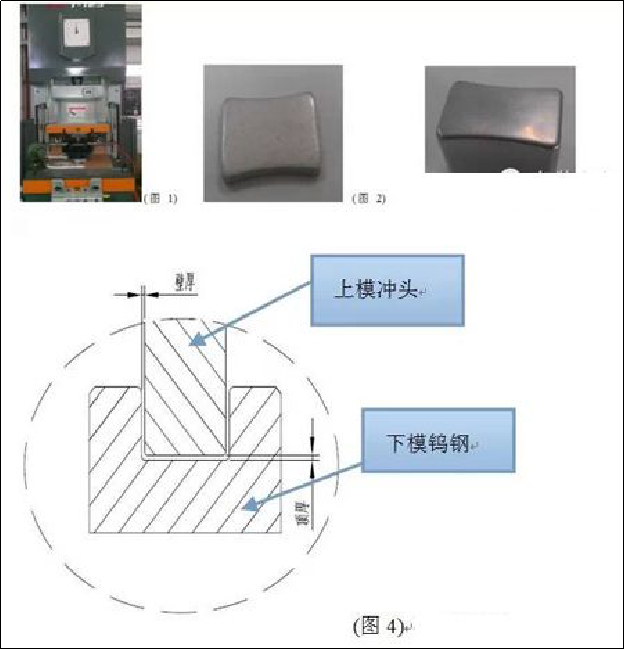

Sebenzisa iipellet ze-aluminiyam eziphathekayo. Umatshini we-extrusion kunye nokufa zisetyenziselwa ukubunjwa kwexesha elilodwa, elilungele imveliso ye-cylindrical okanye imilo yemveliso enzima ukuyifumana ngenkqubo yokwelula, njenge-oval, square, kunye neemveliso ezixande.

Itoni yomatshini osetyenzisiweyo inxulumene nendawo enqamlezileyo yemveliso. Umsantsa phakathi upper die punch kunye ezantsi die tungsten steel na ubukhulu bodonga imveliso. Xa upper die punch kunye ezantsi die tungsten steel zicinezelwe kunye, umsantsa nkqo kwiziko esezantsi ofileyo Kuba ubukhulu phezulu imveliso.inxalenye yealuminiyam

Izinto eziluncedo: Umjikelo wokuvula i-mold ufutshane, kwaye iindleko zophuhliso ziphantsi kunomzobo wokubumba.

Ukungalungi: Inkqubo yokuvelisa inde, ubungakanani bemveliso buguquguquka kakhulu kwinkqubo, kwaye iindleko zabasebenzi ziphezulu.

2. Ukuzolula

Sebenzisa ulusu lwe-aluminiyam. Ilungele imizimba non-cylindrical (imveliso aluminiyam kunye neemveliso egobileyo) ukuba zikhubazeke amaxesha amaninzi ngokusebenzisa iimatshini die eqhubekayo kunye nokungunda ukuhlangabezana neemfuno imilo.

Izinto eziluncedo: imveliso entsonkothileyo kunye neninzi yokuguqulwa inolawulo oluzinzileyo lwe-dimensional kwinkqubo yokuvelisa, kwaye umgangatho wemveliso ulula.

Ukungalungi: ixabiso eliphezulu lokungunda, umjikelo wophuhliso olude, kunye neemfuno eziphezulu zokukhetha umatshini kunye nokuchaneka.

Unyango lwangaphezulu lweemveliso ze-aluminium

1. Ukuqhunyiswa kwesanti (ukudubula ukuchama)

Inkqubo yokucoca kunye nokucoca iindawo zetsimbi usebenzisa impembelelo yokuhamba kwesanti ephezulu.

Unyango oluphezulu lwamalungu e-aluminium kule ndlela lunokufumana iqondo elithile lokucoceka kunye noburhabaxa obuhlukeneyo kumphezulu we-workpiece, ukwenzela ukuba iipropati ze-mechanical zomphezulu we-workpiece ziphuculwe, ngaloo ndlela kuphuculwe ukuxhathisa ukukhathala kwe-workpiece kunye nokwandisa. umsantsa phakathi kwayo kunye nokwaleka. Ukunamathela kwengubo kwandisa ukuqina kwefilimu yokugqoka, kwaye kukwalungele ukulinganisa kunye nokuhlobisa kwengubo. Le nkqubo sihlala siyibona kwiimveliso ezahlukeneyo ze-Apple.

2. Ukugudisa

Ukusebenzisa oomatshini, iikhemikhali okanye isenzo se-electrochemical ukunciphisa uburhabaxa bomphezulu we-workpiece ukufumana indlela eqaqambileyo, ethe tyaba yokucubungula umphezulu. Inkqubo yokugudisa yahlulwe ikakhulu ibe: ukugudisa ngoomatshini, ukupholiswa kweekhemikhali, ukupholiswa kwe-electrolytic. Emva kokupholisha ngoomatshini + ukupholishwa kwe-electrolytic, iinxalenye ze-aluminium zinokusondela kwisiphumo sesibuko sentsimbi engenasici. Le nkqubo inika abantu ingqiqo yokulula okuphezulu kunye nekamva elifashiniweyo.

3. Umzobo

Umzobo wocingo lwesinyithi yinkqubo yokwenziwa kokuphinda kukhuhlwe iphepha lealuminiyam ngaphandle kwemigca ngesanti. Umzobo unokwahlulwa ube ngumzobo othe ngqo, umzobo ongacwangciswanga, umzobo ojikelezayo, umzobo womsonto. Inkqubo yokudweba ucingo lwesinyithi ingabonisa ngokucacileyo yonke into encinci ye-silk, ukwenzela ukuba ukukhanya kweenwele ezintle kubonakale kwi-metal matte, kwaye imveliso inengqiqo yefashoni kunye neteknoloji.

4. Ukusika iglosi ephezulu

Ukusebenzisa umatshini wokukrola, ummese wedayimane uqiniswa kwi-shaft ephambili yomatshini wokukrola ojikelezayo kwisantya esiphezulu (ngokuqhelekileyo i-20,000 rpm) ukusika iindawo, kunye nommandla obalaseleyo wendawo uveliswa phezu komgangatho wemveliso. Ukukhanya kwezinto eziphambili zokusika kuchaphazeleka ngesantya sokugaya i-drill. Ukukhawuleza kwesantya se-drill, ukugqamisa ukugqamisa ukusika, kwaye ngokuphambene noko, kumnyama kwaye kulula ukuvelisa imigca yokusika. I-high-gloss kunye ne-high-gloss cutting isetyenziswe ngokukodwa kwiifowuni eziphathwayo, ezifana ne-iphone5. Kwiminyaka yakutshanje, ezinye iifreyimu zetsimbi zeTV eziphakamileyo ziye zamkela inkqubo yokugaya i-high-gloss. Ukongeza, i-anodizing kunye neenkqubo zokudweba ucingo zenza i-TV igcwele imfashini kunye neteknoloji.

5. Anodizing

I-Anodic oxidation ibhekisela kwi-electrochemical oxidation yesinyithi okanye i-alloys. Ngaphantsi kwe-electrolyte ehambelanayo kunye neemeko zenkqubo ethile, i-aluminium kunye ne-alloys yayo yenza ifilimu ye-oxide kwimveliso ye-aluminium (anode) ngenxa yesenzo sombhobho osetyenzisiweyo. I-Anodizing ayinakucombulula kuphela iziphene zokuqina komphezulu we-aluminium kunye nokumelana nokunxiba, kodwa nokwandisa ubomi benkonzo ye-aluminium kunye nokuphucula ubuhle. Iye yaba yinxalenye eyimfuneko yonyango lomphezulu we-aluminiyam kwaye ngoku yeyona isetyenziswa kakhulu kwaye iphumelele kakhulu. umsebenzi wezandla.

6. I-anode yemibala emibini

I-anodizing yemibala emibini ibhekisa kwi-anodizing kwimveliso enye kunye nokunika imibala eyahlukileyo kwiindawo ezithile. Inkqubo ye-anodizing yemibala emibini ayifane isetyenziswe kwishishini leTV, kuba inkqubo inzima kwaye ixabiso liphezulu; kodwa ukungafani phakathi kwemibala emibini kunokubonakalisa ngcono imbonakalo ephezulu kunye neyodwa yemveliso.

Imilinganiselo yenkqubo kunye nezakhono zokusebenza ukunciphisa ukuguqulwa kokulungiswa kwe-aluminium

Kukho izizathu ezininzi zokuguqulwa kwamacandelo e-aluminium, ehambelana nezinto eziphathekayo, ukumila kwenxalenye, kunye neemeko zemveliso. Kukho ubukhulu becala le miba ilandelayo: i-deformation ebangelwa uxinzelelo lwangaphakathi lwe-blank, i-deformation ebangelwa amandla okusika kunye nokusika ukushisa, kunye ne-deformation ebangelwa yi-clamping force.

Amanyathelo enkqubo yokunciphisa ukuguqulwa kokulungiswa

1. Ukunciphisa uxinzelelo lwangaphakathi lwenkcubeko yeenwele

Ukuguga kwendalo okanye okwenziweyo kunye nonyango lokungcangcazela kunokuphelisa ngokuyinxenye uxinzelelo lwangaphakathi olungenanto. Ukulungiswa kwangaphambili kuyindlela esebenzayo yenkqubo. Kwi-blank enentloko enamafutha kunye neendlebe ezinkulu, ngenxa yesibonelelo esikhulu, i-deformation emva kokucubungula nayo inkulu. Ukuba inxalenye engaphezulu yesithuba esingenanto iqhutywe kwangaphambili kwaye isibonelelo secandelo ngalinye sincitshisiwe, asikwazi ukunciphisa kuphela ukuguqulwa kokulungiswa kwenkqubo elandelayo, kodwa kwakhona ukukhulula inxalenye yoxinzelelo lwangaphakathi emva kokulungiswa kwangaphambili kwexesha elithile. ixesha.

2. Ukuphucula ukukwazi ukusika isixhobo

Izinto eziphathekayo kunye neeparitha zejometri zesixhobo zinempembelelo ebalulekileyo kumandla okusika kunye nokusika ukushisa. Ukhetho oluchanekileyo lwesixhobo lubaluleke kakhulu ukunciphisa ukuguqulwa komatshini wenxalenye.

1) Ukhetho olufanelekileyo lwesixhobo seeparamitha zejometri.

① I-angle yeRake: Ngaphantsi kwemeko yokugcina amandla e-blade, i-angle yerake ikhethwe ngokufanelekileyo ukuba ibe nkulu, kwelinye icala, inokugaya i-edge ebukhali, kwaye kwelinye icala, inokunciphisa i-deformation yokusika. ukususwa kwetshiphu kugudileyo, kwaye emva koko unciphise amandla okusika kunye nobushushu bokusika. Ungaze usebenzise izixhobo ezine-engile yerake engalunganga.

②I-angle yokukhulula: Ubungakanani be-angle yokukhulula bunefuthe elithe ngqo ekugqokeni kwe-flank kunye nomgangatho womgangatho owenziwe ngomatshini. Ubunzima bokusika yimeko ebalulekileyo yokukhetha i-angle yokucoca. Ngexesha lokugaya, ngenxa yesantya esikhulu sokutya, umthwalo onzima wokusika, kunye nesizukulwana esikhulu sokushisa, isixhobo sidinga iimeko ezilungileyo zokulahla ubushushu. Ngoko ke, i-angle yokucoca kufuneka ikhethwe ibe yincinci. Xa ukugaya okulungileyo, umgca wokusika kufuneka ube bukhali, ukungqubuzana phakathi kobuso be-flank kunye nomgangatho owenziwe ngomatshini kuncitshiswe, kwaye i-elastic deformation iyancitshiswa. Ngoko ke, i-angle yokucoca kufuneka ibe nkulu.

③ I-angle ye-Helix: Ukuze wenze ukugaya kube lula kunye nokunciphisa amandla okugaya, i-angle ye-helix kufuneka ibe nkulu ngokusemandleni.

④I-angle yokunciphisa ngokufanelekileyo: Ukunciphisa ngokufanelekileyo i-angle yokunciphisa i-angle kunokuphucula iimeko zokutshatyalaliswa kobushushu kunye nokunciphisa ubushushu obuphakathi kwendawo yokucubungula.

2) Ukuphucula isakhiwo sesixhobo.

① Nciphisa inani lamazinyo esixhobo sokusika kwaye wandise indawo yetshiphu. Ngenxa yeplastiki enkulu yezinto ze-aluminium kunye ne-deformation enkulu yokusika ngexesha lokucubungula, indawo enkulu ye-chip iyafuneka, ngoko ke i-radius ephantsi ye-chip groove kufuneka ibe nkulu kwaye inani lamazinyo okugaya kufuneka libe lincinci.

② Gxila kakuhle amazinyo. Ixabiso loburhabaxa bomgca wokusika wamazinyo amazinyo kufuneka libe ngaphantsi kwe-Ra = 0.4um. Ngaphambi kokusebenzisa imela entsha, kufuneka usebenzise ilitye elicikizekileyo le-oyile ukulola kancinane ngaphambili nangasemva kwamazinyo emela kancinane ukuphelisa i-burrs kunye ne-serration encinci eshiyekileyo xa ulola amazinyo. Ngale ndlela, kungekhona nje ukusika ukushisa kuya kuncitshiswa, kodwa kunye ne-deformation yokusika incinci.

③ Lawula ngokungqongqo umgangatho wokunxiba wesixhobo. Emva kokuba isixhobo sigqitywe, ixabiso le-roughness ye-workpiece liyanda, ukushisa kweqondo lokushisa kuyenyuka, kwaye i-workpiece deformation iyanda. Ngoko ke, ngaphezu kokukhethwa kwezixhobo zokusebenza kunye nokuchasana kakuhle, umgangatho wokugqoka isixhobo akufanele ube mkhulu kune-0.2mm, ngaphandle koko kulula ukuvelisa i-edge eyakhelwe-up. Xa usika, ubushushu besixhobo sokusebenza kufuneka bungagqithi kwi-100 ℃ ukuthintela ukonakala.

3. Phucula indlela yokubamba ye-workpiece

Kwizixhobo zokusebenza ze-aluminiyam ezinodonga olucekethekileyo ezinokuqina okubuthathaka, ezi ndlela zilandelayo zokubambelela zingasetyenziselwa ukunciphisa ukonakala:

①Amalungu abhityileyo anodonga olucekethekileyo, ukuba i-chuck enemihlathi emithathu ehlala ngaphakathi okanye i-spring chuck isetyenziselwa ukugoba iradial, yakube ikhutshiwe emva kokucocwa, i-workpiece iyakonakala. Ngeli xesha, indlela yokucinezela ubuso be-axial ekupheleni kobunzima obungcono kufuneka isetyenziswe. Misa umngxuma wangaphakathi wenxalenye, yenza i-mandrel ene-threaded, uyifake kumngxuma ongaphakathi wenxalenye, cinezela isiphelo sobuso kunye nepleyiti yokugubungela kuyo, uze uyiqinise nge nut. Xa usenza isangqa sangaphandle, i-clamping deformation inokuthintelwa, ukuze ufumane ukuchaneka okwanelisayo komatshini.

② Xa kusetyenzwa ngodonga olubhityileyo kunye necwecwe elicwecwe, kungcono ukusebenzisa iikomityi zokufunxa ivacuum ukufumana amandla okubamba asasazwe ngokulinganayo, kwaye emva koko usebenze ngexabiso elincinci lokusika, elinokuthi lithintele ukonakala kwesixhobo sokusebenza.

Ukongeza, indlela yokupakisha nayo ingasetyenziswa. Ukuze kwandiswe ukuqina kwenkqubo yee-workpieces ezinodonga olucekethekileyo, i-medium ingazaliswa ngaphakathi kwendawo yokusebenza ukuze kuncitshiswe i-deformation ye-workpiece ngexesha lokudibanisa kunye nokusika. Ngokomzekelo, i-urea enyibilikayo equkethe i-3% ukuya kwi-6% ye-nitrate ye-potassium igalelwa kwi-workpiece. Emva kokucutshungulwa, i-workpiece inokucwiliswa emanzini okanye utywala, kwaye i-filler inokuchithwa kwaye igalelwe.

4. Ulungiselelo olufanelekileyo lweenkqubo

Ngexesha lokusikwa kwesantya esiphezulu, ngenxa yesibonelelo esikhulu somatshini kunye nokuphazamiseka kokusika, inkqubo yokugaya idla ngokuvelisa ukungcangcazela, okuchaphazela ukuchaneka komatshini kunye noburhabaxa bomhlaba. Ngoko ke, inkqubo yokusika isantya esiphezulu se-CNC ingahlulwa ngokubanzi ibe: i-roughing-semi-finishing-corner-clearing-finishing kunye nezinye iinkqubo. Kwiindawo ezineemfuno ezichanekileyo ezichanekileyo, ngamanye amaxesha kuyimfuneko ukwenza ukugqiba isiqingatha sesibini kunye nokugqiba. Emva komatshini orhabaxa, amalungu anokupholiswa ngokwemvelo, aphelise uxinzelelo lwangaphakathi olubangelwa kukusebenza ngokurhabaxa kunye nokunciphisa ukonakala. Isibonelelo esishiywe emva komatshini olukhuni kufuneka sibe sikhulu kunokuguqulwa, ngokubanzi kwi-1 ukuya kwi-2 mm. Ngexesha lokugqiba, indawo yokugqiba yamacandelo kufuneka igcine isibonelelo somatshini ofanayo, ngokubanzi i-0.2 ~ 0.5mm, ukwenzela ukuba isixhobo sikwimeko ezinzileyo ngexesha lenkqubo yomatshini, enokunciphisa kakhulu ukusika ukuchithwa, ukufumana umgangatho womatshini womhlaba omhle, kunye ukuqinisekisa ukuchaneka kweMveliso.

Izakhono zokusebenza ukunciphisa ukugqwethwa komatshini

Ukongeza kwezi zizathu zingasentla, iindawo ze-aluminium zikhubazekile ngexesha lokucubungula. Kumsebenzi wokwenene, indlela yokusebenza nayo ibaluleke kakhulu.

1. Kwiingxenye ezinesibonelelo esikhulu somatshini, ukwenzela ukuba zibe neemeko ezingcono zokutshatyalaliswa kobushushu ngexesha lenkqubo ye-machining kwaye ugweme ukugxilwa kobushushu, umatshini we-symmetrical kufuneka wamkelwe ngexesha lokucoca. Ukuba ishidi le-90mm elinzima lifuna ukucutshungulwa kwi-60mm, ukuba elinye icala ligayiwe kwaye elinye icala lihlanjululwe ngokukhawuleza, kwaye ubungakanani bokugqibela bucutshungulwa ngexesha elinye, ukunyanzeliswa kuya kufikelela kwi-5mm; ukuba icutshungulwa ngokulinganayo ngokutya okuphindaphindiweyo, icala ngalinye licutshungulwa kabini ukuya kwi-Dimension yokugqibela inokuqinisekisa ukucaca kwe-0.3mm.isitampu inxalenye

2. Ukuba kukho i-cavities ezininzi kwiindawo zeplate, akufanelekanga ukusebenzisa indlela yokulandelelana ngokulandelelana kwendawo enye kunye ne-cavity enye ngexesha lokucubungula, okuya kubangela lula ukuba iindawo zikhubazeke ngenxa yoxinzelelo olungalinganiyo. I-multi-layer processing iyamkelwa, kwaye uluhlu ngalunye luqhutyelwa kuyo yonke imingxuma ngexesha elifanayo, kwaye emva koko uluhlu olulandelayo lucutshungulwa ukwenza iinxalenye zigxininiswe ngokulinganayo kunye nokunciphisa i-deformation.

3. Nciphisa amandla okusika kunye nokusika ukushisa ngokutshintsha inani lokusika. Phakathi kwezinto ezintathu zexabiso lokusika, inani le-back-enagement linempembelelo enkulu kumandla okusika. Ukuba isibonelelo somatshini sikhulu kakhulu, amandla okusika ipasi enye likhulu kakhulu, elingayi kuphazamisa kuphela iindawo, kodwa lichaphazela ukuqina kwesixhobo sokuphotha somatshini kunye nokunciphisa ukuqina kwesixhobo. Ukuba inani leemela eziza kudliwa ngasemva liyancipha, ukusebenza kakuhle kwemveliso kuya kuncitshiswa kakhulu. Nangona kunjalo, ukugaya ngesantya esiphezulu kusetyenziswa kwi-CNC machining, enokoyisa le ngxaki. Ngelixa ukunciphisa inani lokusika umva, nje ukuba ukondla kunyuswe ngokufanelekileyo kwaye isantya sesixhobo somatshini sandiswa, amandla okusika angancitshiswa kwaye ukusebenza kakuhle kunokuqinisekiswa ngexesha elifanayo.

4. Umyalelo wokuhamba kwemela nawo kufuneka unikwe ingqwalasela. Umatshini orhabaxa ugxininisa ekuphuculeni ukusebenza kakuhle komatshini kunye nokulandela izinga lokususa ngexesha leyunithi nganye. Ngokuqhelekileyo, i-up-cut-cut milling ingasetyenziswa. Okokuthi, izinto ezingaphezulu kwendawo engenanto zisuswa ngokukhawuleza kunye nexesha elifutshane, kwaye i-contour yejometri efunekayo yokugqiba yenziwe ngokusisiseko. Ngelixa ukugqiba kugxininisa ukuchaneka okuphezulu kunye nomgangatho ophezulu, kuyacetyiswa ukuba kusetyenziswe ukugaya. Ngenxa yokuba ukusika amazinyo amazinyo ancipha ngokuthe ngcembe ukusuka kwinqanaba eliphezulu ukuya kwi-zero ngexesha lokugaya, iqondo lomsebenzi wokuqina liyancipha kakhulu, kwaye iqondo lokuguqulwa kwenxalenye nalo liyancitshiswa.

5. Izixhobo zokusebenza ezinodonga olubhityileyo zigqwethekile ngenxa yokucinezelwa ngexesha lokusetyenzwa, kwaye nokugqiba akunakuphepheka. Ukuze kuncitshiswe i-deformation ye-workpiece ibe yincinci, unokukhulula isiqwenga esicinezelayo ngaphambi kokugqiba ubungakanani bokugqibela, ukwenzela ukuba i-workpiece ibuyele ngokukhululekileyo kwimeko yayo yangaphambili, kwaye uyicinezele kancinane, nje ukuba i-workpiece ingaba. ibambekile (ngokupheleleyo). Ngokutsho kokuvakalelwa kwesandla), umphumo ofanelekileyo wokucubungula unokufumaneka ngale ndlela. Ngelizwi, indawo yesenzo samandla okudibanisa ikhethwa kwindawo exhasayo, kwaye i-clamping force kufuneka isetyenziswe kwicala lokuqina okulungileyo kwendawo yokusebenza. Kwisiseko sokuqinisekisa ukuba i-workpiece ayikhululekile, encinci i-clamping force, ingcono.

6. Xa usenza iindawo ezinomgodi, zama ukuba umsiki wokusila angatshoni ngqo kwindawo efana ne-drill xa ucutha umngxuma, nto leyo ebangela ukuba indawo yokusila ingonelanga ukuze ikwazi ukumelana neechips kunye nokususwa kwetshiphu engalunganga, nto leyo ekhokelela ekufudumaleni, ukwanda. kunye nokuwa kwamalungu. Iimela, iimela ezaphukileyo kunye nezinye izinto ezingathandekiyo. Qala ugrumbe umngxuma nge-drill elingana neyokusika okanye enye isayizi enkulu, uze uyigalele ngomsiki wokusila. Kungenjalo, isoftware yeCAM ingasetyenziselwa ukuvelisa iinkqubo ze-helical rundown.

I-Anebon Metal Products Limited inokubonelela nge-CNC Machining, Die Casting, inkonzo ye-Sheet Metal Fabrication, nceda uzive ukhululekile ukuqhagamshelana nathi.

Tel: +86-769-89802722 E-mail: info@anebon.com URL: www.anebon.com

Ixesha lokuposa: Jun-16-2022