1. Zochitika zakuthupi za makina a titaniyamu

Mphamvu yodula ya titaniyamu alloy processing ndi yokwera pang'ono kuposa yachitsulo cholimba chomwecho. Komabe, zochitika zakuthupi za kukonza titaniyamu aloyi ndizovuta kwambiri kuposa kukonza zitsulo, zomwe zimapangitsa kuti titaniyamu alloy processing ikumane ndi zovuta zazikulu.

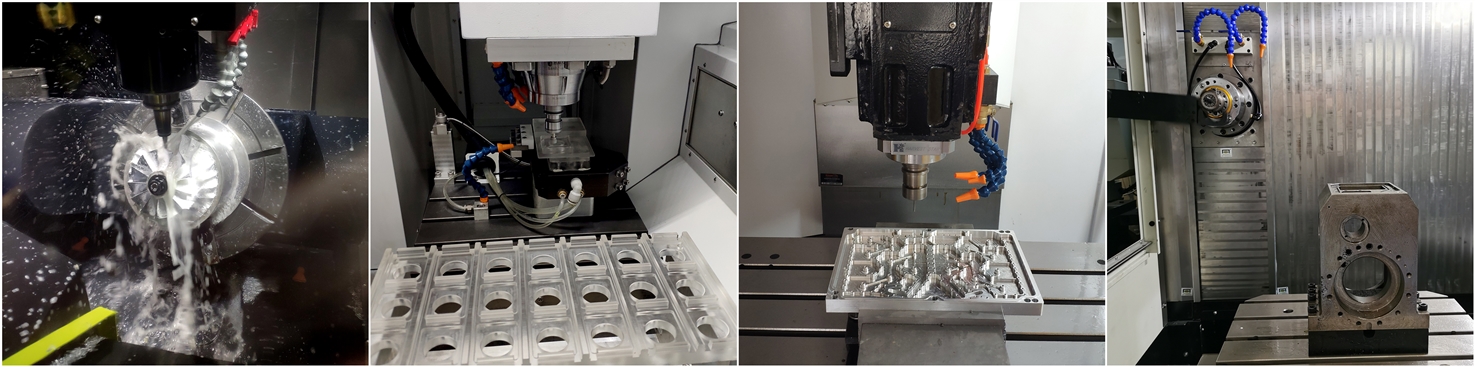

Kutentha kwa ma alloys ambiri a titaniyamu ndi otsika kwambiri, 1/7 yokha yachitsulo ndi 1/16 ya aluminium. Choncho, kutentha kwaiye pamene kudula titaniyamu aloyi sangafulumire anasamutsidwa workpiece kapena kuchotsedwa ndi tchipisi. Komabe, idzaunjikana pamalo odulirapo, ndipo kutentha komwe kumapangidwa kumatha kufika pa 1,000 °C kapena kupitilira apo, zomwe zingapangitse kuti chidacho chiwonongeke, kuphwanya, ndi kusweka mwachangu. Mapangidwe a m'mphepete mwake ndi maonekedwe ofulumira a m'mphepete mwawo amatha kutentha kwambiri kumalo odulidwa, kufupikitsa moyo wa chida.makina a titaniyamu

Kutentha kwakukulu komwe kumapangidwa panthawi yodula kumawononganso kukhulupirika kwa titaniyamu aloyi mbali, zomwe zimapangitsa kuchepa kwa geometric kulondola kwa magawo ndi ntchito zolimba zomwe zimachepetsa kwambiri kutopa kwawo.

Kutanuka kwa titaniyamu aloyi kungakhale kopindulitsa pakuchita pang'ono, koma panthawi yodula, kusinthika kwa zotanuka ndizomwe zimayambitsa kugwedezeka. Kupanikizika kodula kumapangitsa kuti "elastic" workpiece ichoke pa chida ndikudumpha, kotero kukangana pakati pa chida ndi workpiece ndikokulirapo kuposa kudula. Kukanganako kumapangitsanso kutentha, kumakulitsa vuto la kusayenda bwino kwa matenthedwe a titaniyamu.

Vutoli ndi lalikulu kwambiri pokonza mbali zopyapyala zooneka ngati mphete, zopunduka mosavuta. Sikophweka kupanga makina a titaniyamu okhala ndi mipanda yopyapyala kuti akhale olondola kwambiri. Pamene chida kukankhira workpiece zinthu kutali, woonda khoma mapindikidwe m'deralo kuposa zotanuka osiyanasiyana; kupindika kwa pulasitiki kumachitika, ndipo mphamvu zakuthupi ndi kuuma kwa malo odulira kumawonjezeka kwambiri. Kucheka pa liwiro lomwe lakhazikitsidwa kale limakhala lokwera kwambiri, zomwe zimapangitsa kuti pakhale zida zakuthwa.

"Kutentha" ndiye "wolakwa" zomwe zimapangitsa kuti zikhale zovuta kukonza ma aloyi a titaniyamu!

2. Ukadaulo wodziwa momwe titaniyamu CNC Machining

Kutengera kumvetsetsa momwe ma aloyi a titaniyamu amagwirira ntchito ndikuwonjezera zinachitikira, njira yayikulu yodziwira ma aloyi a titaniyamu ndi motere:

(1) Zoyikapo zokhala ndi geometry zabwino zimagwiritsidwa ntchito kuchepetsa mphamvu yodulira, kudula kutentha, ndi kupindika.

(2) Sungani chakudya chokhazikika kuti mupewe kuuma kwa workpiece. Chidacho chiyenera kukhala nthawi zonse m'malo odyetserako panthawi yodula, ndipo kuchuluka kwa ma radial kudula kuyenera kukhala 30% ya radius panthawi ya mphero.

(3) Kuthamanga kwambiri komanso kuthamanga kwakukulu kwamadzimadzi kumagwiritsidwa ntchito pofuna kuonetsetsa kukhazikika kwa kutentha kwa makina opangira makina komanso kupewa kuwonongeka kwa workpiece ndi kuwonongeka kwa zida chifukwa cha kutentha kwambiri.

(4) Khalani akuthwa m’mphepete; zida zosamveka zimayambitsa kutentha ndi kutha, zomwe zimayambitsa kulephera kwa zida.

(5) Machining mu chikhalidwe chofewa kwambiri cha titaniyamu aloyi mmene ndingathere chifukwa zinthu zimakhala zovuta makina pambuyo kuumitsa, ndi kutentha mankhwala kumawonjezera mphamvu zakuthupi ndi kuvala kuika.

(6) Gwiritsani ntchito mphuno yaikulu yozungulira kapena chamfer kuti mudule momwe mungathere m'mphepete. Izi zimachepetsa mphamvu yodulira ndi kutentha pamalo aliwonse ndikuletsa kusweka kwanuko. Pamene mphero titaniyamu aloyi, pakati pa magawo kudula, liwiro kudula ali ndi chikoka kwambiri pa moyo chida vc, kutsatiridwa ndi chinkhoswe radial (mphero kuya) ae.

3. Yambani ndi tsamba kuti muthetse vuto la titaniyamu

Kuvala kwa groove popanga ma aloyi a titaniyamu ndiko kuvala kwapambuyo kumbuyo ndi kutsogolo molunjika kukuya kwa kudula, komwe nthawi zambiri kumachitika chifukwa cha kusanjikiza kowumitsidwa komwe kumasiyidwa ndi kukonzanso koyambirira. Zomwe zimapangidwira komanso kufalikira kwa chida ndi zida zogwirira ntchito pakutentha kopitilira 800 ° C ndizifukwa zopangira kuvala kwa groove. Chifukwa pakupanga makina, mamolekyu a titaniyamu a workpiece amadziunjikira kutsogolo kwa tsamba ndipo "amawotcherera" pamphepete mwa tsamba pansi pa kuthamanga kwambiri ndi kutentha kwakukulu, kupanga m'mphepete mwake. Mphepete mwamanga ikachoka pamphepete, imachotsa zokutira za carbide, kotero kuti makina a titaniyamu amafunikira zida zapadera ndi ma geometries.cCustomprecision Machining

4. Kapangidwe kachipangizo koyenera kupanga titaniyamu

Cholinga cha titaniyamu alloy processing ndi kutentha, ndipo kuchuluka kwamadzimadzi odula kwambiri ayenera kupopera pamphepete mwachangu komanso molondola kuti achotse kutentha mwachangu. Pali masanjidwe apadera a odula mphero makamaka opangira titaniyamu.

Anebon Metal Products Limited ikhoza kupereka CNC Machining, Die Casting, Sheet Metal Fabrication service, chonde omasuka kulankhula nafe.

Tel: +86-769-89802722 E-mail: info@anebon.com URL: www.anebon.com

Nthawi yotumiza: Jan-18-2022