Kwa mainjini, zida za shaft monga ma crankshafts, ma camshaft, ndi ma cylinder liners amagwiritsa ntchito chucks pakukonza kulikonse. Pa processing, ndi chucks pakati, achepetsa ndi kuyendetsa workpiece. Malinga ndi kuthekera kwa chuck kugwira chogwirira ntchito ndikusunga pakati, chimagawidwa kukhala chuck yolimba ndi chuck yoyandama. Nkhaniyi ikukamba za mfundo ziwiri zosankhidwa za chucks ndi zosamalira tsiku ndi tsiku.5aixs CNC Machining magawo

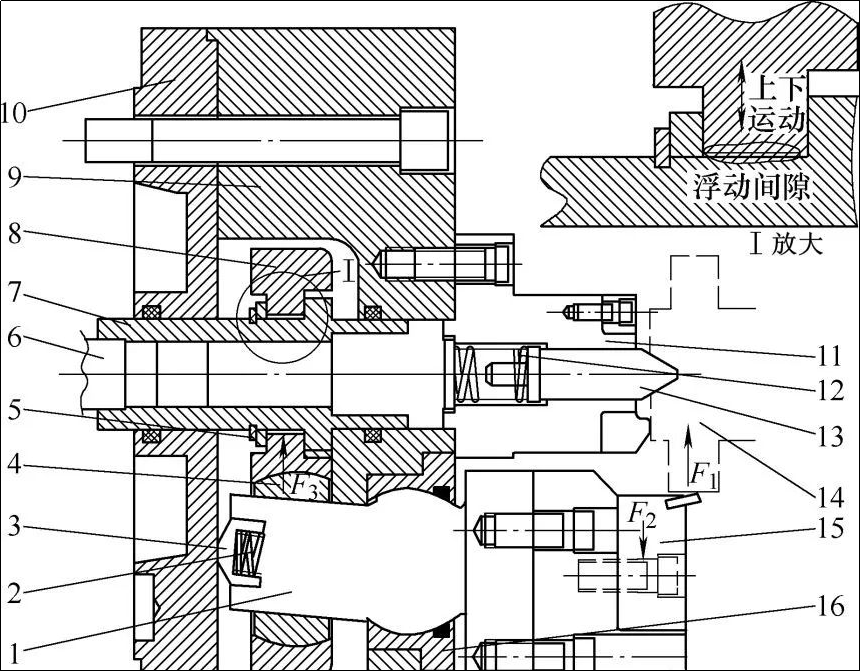

Ma chucks okhwima ndi ma chucks oyandama ndi osiyana kwambiri pamapangidwe ndi njira zosinthira. Kutenga ma chucks angapo a mtundu waku Japan mwachitsanzo, Chithunzi 1 chikuwonetsa momwe chuck yoyandama imagwirira ntchito: chogwiriracho chili pansi pa chotchinga chothandizira ndi pamwamba. Kuyika kwa axial ndi radial ndi clamping kumachitika. Kenako, silinda ya chuck imayendetsa ndodo ya tayi ya chuck, mbale yosinthira gap, mbale yothandizira mkono wa nsagwada, cholumikizira chozungulira, ndi mkono wa nsagwada kupyola ndodo, ndikuzindikira nsagwada ya chuck kuti igwire ntchito.

Pakakhala kupatuka kwakukulu kwa coaxially pakati pa nsagwada zitatu za chuck ndi pakati pa chogwirira ntchito, nsagwada za chuck zomwe zimalumikizana ndi workpiece poyamba zimayikidwa ndi mphamvu F2, yomwe imaperekedwa ku nsagwada. mbale yothandizira mkono kudzera mumkono wa nsagwada ndi malo ozungulira. F3 imagwira pa mbale yothandizira ya claw mkono. Kwa chuck yoyandama, pali kusiyana pakati pa ndodo yapakati ya chuck ndi mbale yothandizira mkono. Pansi pa mphamvu ya F3, mbale yothandizira mkono ya claw imagwiritsa ntchito kusiyana koyandama (mbale yosinthira kusiyana, ndodo yapakati ya chuck, ndi mbale yothandizira ya mkono wa nsagwada palimodzi imapanga makina oyandama a chuck), sunthani mbali ya mphamvuyo mpaka nsagwada zitatu zitseke chogwirira ntchito kwathunthu.

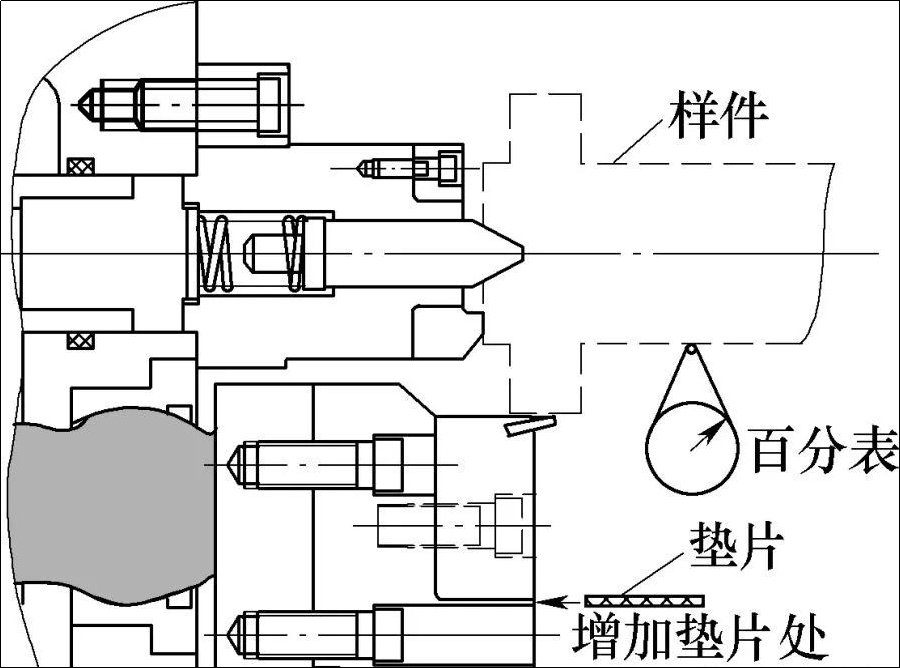

Chithunzi 1 Kapangidwe ka chuck yoyandama

1. Dzanja la mkono

2. Rectangular kasupe

3. Chivundikiro chapamwamba chozungulira

4. Cholumikizira chozungulira

5. Chilolezo chosinthira mbale

6. Ndodo ya Cylinder kukoka

7. Chuck pakati kukoka ndodo

8. Mbale yothandizira mkono wa claw

9. Thupi la Chuck 10. Chophimba chomaliza cha Chuck

10. Kuyimilira chipika chothandizira

12. Zogwirira ntchito ziyenera kukonzedwa

13. Chuck Jaws 16. Thandizo la mpira

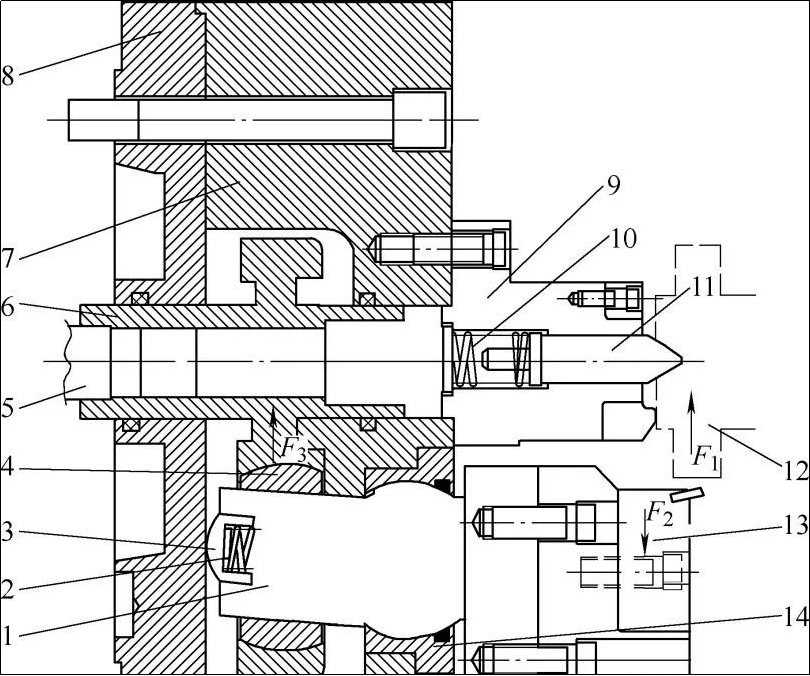

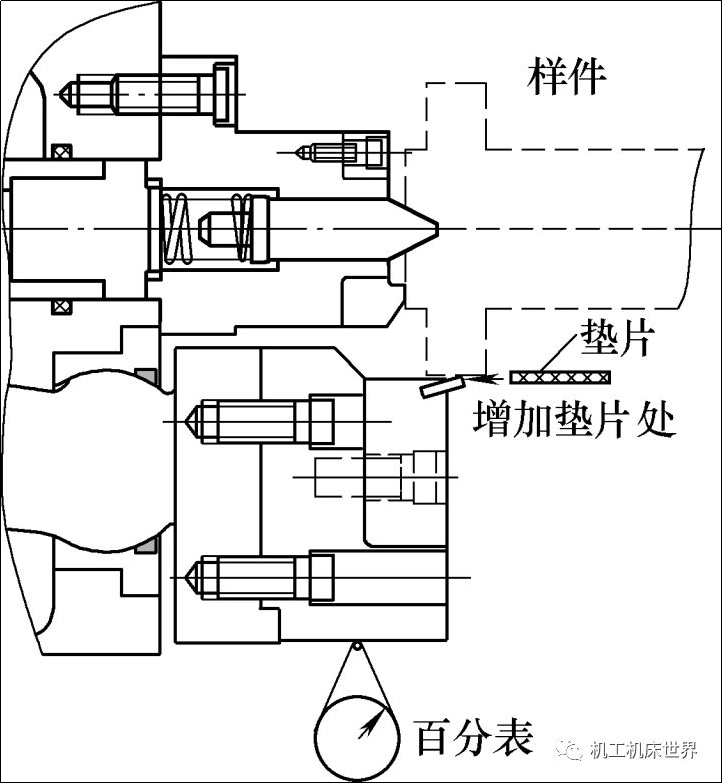

Chithunzi 2 chikuwonetsa machitidwe a chuck okhwima

Pansi pa chipika chothandizira choyikirapo komanso pamwamba, chogwiriracho chimayikidwa ndikumangika mwamphamvu komanso mozungulira, kenako silinda yamafuta a chuck imayendetsa ndodo yapakati, yozungulira ndi nsagwada za chuck kudzera pa ndodo yokoka. Dzanja limayenda, ndipo pamapeto pake, nsagwada za chuck zimagwira ntchito. Popeza kuti pakati kukoka ndodo ya chuck imalumikizidwa mwamphamvu ndi cholumikizira chozungulira ndi mkono wa nsagwada, pambuyo poti nsagwada za chuck (nsagwada zitatu) zatsekeredwa, malo opumira adzapangidwa. The clamping center opangidwa ndi pamwamba sichimadutsana, ndipo workpiece adzakhala ndi zoonekeratu clamping deformation pambuyo chuck ndi clamped. Chuck isanayambe kugwiritsidwa ntchito, m'pofunika kusintha kusinthana pakati pa chuck ndi pakati pakatikati kuti zitsimikizire kuti chuck sichidzawonekera pambuyo pa clamping. Clamped chikhalidwe.

Chithunzi 2 Kapangidwe ka chuck kolimba

1. Dzanja la mkono

2. 10. Kasupe wamakona anayi

3. Chivundikiro chapamwamba chozungulira

4. Cholumikizira chozungulira

5. Ndodo yomangira ya Cylinder

6. Chuck pakati tayi ndodo

7. Thupi la Chuck

8. Chivundikiro chakumbuyo cha Chuck

9. Positioning thandizo chipika

10. Pamwamba

11. Zogwirira ntchito ziyenera kukonzedwa

12. Nsagwada za Chuck

13. Thandizo lozungulira

Kuchokera pakuwunika kwa makina a chuck mu Chithunzi 1 ndi Chithunzi 2, chuck yoyandama ndi chuck yolimba imakhala ndi zosiyana zotsatirazi.

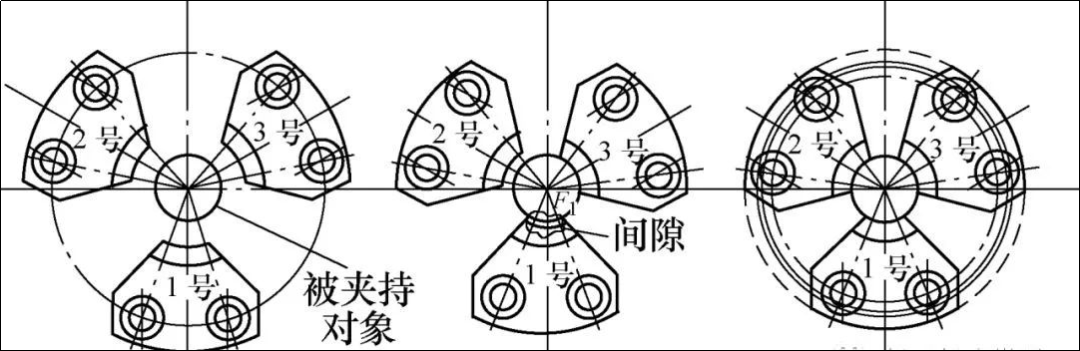

Kuyandama chuck: Monga momwe chithunzi 3, m'kati clamping workpiece, chifukwa cha kutalika osiyana workpiece akusowekapo pamwamba kapena lalikulu roundness kulolerana opanda kanthu, ndi No. 3 nsagwada adzakumana ndi workpiece pamwamba ndi nsagwada za nambala 1 ndi nambala 2 zidzawonekera. Ngati workpiece sichinakhudzidwebe, panthawiyi, njira yoyandama ya chuck yoyandama imagwira ntchito, pogwiritsa ntchito pamwamba pa workpiece monga chithandizo choyandama nsagwada No. Malingana ngati kuchuluka koyandama kuli kokwanira, nsagwada za nambala 1 ndi nambala 2 pamapeto pake zidzatsekedwa. Chogwirira ntchito chimakhala ndi zotsatira zochepa pakatikati pa workpiece.

Chithunzi 3 Kutsekereza nsagwada zoyandama za chuck

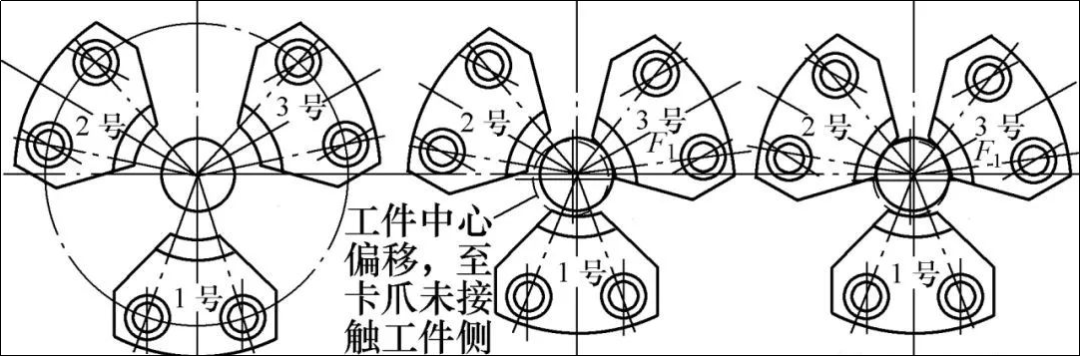

Olimba chuck: Monga momwe chithunzi 4, pa ndondomeko clamping, ngati concentricity pakati chuck ndi workpiece si kusintha bwino, nsagwada No. 3 adzalumikizana workpiece, ndi No. 1 ndi No. 2 nsagwada sadzatero. kukumana ndi workpiece. , ndiye chuck clamping mphamvu F1 idzachitapo kanthu pa workpiece. Ngati mphamvuyo ndi yayikulu mokwanira, chogwiriracho chidzachotsedwa ku malo okonzedweratu, kukakamiza workpiece kupita pakati pa chuck; pamene clamping mphamvu ya chuck ndi yaing'ono, zina zidzachitika. Pamene nsagwada sangathe mokwanira kukhudzana workpiece, kugwedezeka kumachitika pa Machining.cnc mphero cholumikizira

Chithunzi 4 Kumanga kwa nsagwada zolimba za chuck

Zofunikira zosintha chuck isanayambe kugwiritsidwa ntchito: Chuck yolimba ipanga malo otsekera a chuck yokhayo pambuyo pomenya. Mukamagwiritsa ntchito chuck yolimba, ndikofunikira kusintha malo otsekera a chuck kuti agwirizane ndi malo omangira ndi malo ogwirira ntchito, monga momwe tawonetsera pachithunzi 5.cnc Machining aluminiyamu gawo

Chithunzi 5 Kusintha kwa malo okhwima a chuck

Malinga ndi kusanthula kwamapangidwe omwe ali pamwambapa, tikulimbikitsidwa kutsatira mfundo zotsatirazi pakuwongolera ndi kukonza chuck: Mafuta ndi mafuta azinthu zosunthika mkati mwa chuck amasinthidwa pafupipafupi. Kuyenda pakati pa magawo omwe akuyenda mkati mwa chuck kwenikweni ndikugwedezeka. Ndikofunikira kuwonjezera ndikusintha nthawi zonse kalasi yamafuta opaka mafuta / mafuta molingana ndi zofunikira pakukonza chuck. Mukawonjezera mafuta, ndikofunikira kufinya mafuta onse omwe adagwiritsidwa ntchito m'mbuyomu, kenako ndikutsekereza khomo lotulutsa mafuta mukamamanga chuck kuti mutseke mkati mwa chuck kuti asabwerere.

Kuyang'ana nthawi zonse ndikusintha malo okhomerera a chuck olimba komanso pakatikati pa chogwirira ntchito: Chuck yolimba imayenera kuyeza nthawi ndi nthawi ngati pakati pa chuck ndi pakati pa chopondera chogwirira ntchito ndizofanana. Yezerani kuthamanga kwa disc. Ngati ipitilira mulingo wofunikira, onjezani ma spacers moyenera pansagwada imodzi kapena ziwiri zomwe zikugwirizana ndi malo okwera, ndikubwereza masitepe omwe ali pamwambawa mpaka zofunikira zitakwaniritsidwa.

Kuwunika kwanthawi ndi nthawi kuchuluka kwa chuck yoyandama (onani Chithunzi 6). Pokonza chuck tsiku lililonse, ndikofunikira kuyeza kuchuluka koyandama komanso kuyandama kwa chuck yoyandama, ndikupereka chitsogozo pakukonza mkati mwa chuck pambuyo pake. Njira yoyezera yoyandama mwatsatanetsatane: chuck ikamangirira chitsanzo, ikani chuck kuti ayezedwe. Tembenuzani chikhadabocho pamalo oyenera kuyeza, yesani chizindikiro choyimba (chofunika kumangitsa maginito mita pansi pa shaft yomwe ikuyenda), ndipo chongani poyezera ngati zero point. Kenako lamulirani nsonga ya servo kuti musunthe chizindikiro choyimba, tsegulani chuck, ikani gasket yokhala ndi makulidwe a Amm pakati pa nsagwada kuti muyesedwe ndi chitsanzo, ikani chitsanzo pa chuck, sunthani chizindikiro choyimba pamalo a zero, ndi kutsimikizira ngati deta mbamuikha ndi oyimba chizindikiro ndi za Amm. Ngati ndi choncho, ndiye kuti kulondola koyandama ndikwabwino. Ngati deta imasiyana kwambiri, zikutanthauza kuti pali vuto ndi makina oyandama a chuck. Muyeso wa nsagwada zina ndi wofanana ndi pamwambapa.

Chithunzi 6 Kuyang'ana kuchuluka koyandama kwa chuck yoyandama

Kusinthidwa pafupipafupi kwa zigawo monga zisindikizo, ma gaskets, ndi akasupe mkati mwa chuck: akasupe amakona anayi, thupi la chuck, chivundikiro chakumbuyo chakumbuyo, akasupe amakona anayi, ndi zisindikizo ndi akasupe pazothandizira zozungulira ziyenera kuchitidwa molingana ndi kuchuluka kwa ntchito ndi pamwambapa. zotsatira za mayeso. M'malo mokhazikika. Kupanda kutero, kutopa kumawononga, kumabweretsa kuchuluka koyandama komanso kutha kwa chuck.

Kupyolera mu kusanthula kwapamwamba kwa mfundo zowonongeka za kusintha kwa chuck ndi kukonza, tcherani khutu ku mfundo zotsatirazi posankha ma chuck: ngati chuck clamping gawo la gawo lokonzedwa ndi lopanda kanthu, chuck yoyandama imakonda, ndipo chuck yolimba. imagwiritsidwa ntchito pamutu. Pamwamba pa chuck clamping ya gawo lopangidwa ndi makina ndi pamwamba pambuyo pa roughing, semi-finishing/finishing. Pambuyo potsatira malamulo ofunikira omwe ali pamwambawa, kusankha kolondola molingana ndi mikhalidwe yosiyanasiyana yogwirira ntchito ndikofunikira.

Kusankhidwa kwa chuck yolimba:

①Makina opangira makina amafunikira kudula kwakukulu komanso mphamvu yayikulu yodulira. Pambuyo clamped ndi workpiece kuti kukonzedwa ndi kuthandizidwa ndi chimango chapakati, ndi minofu workpiece rigidity, ndi lalikulu workpiece rotational galimoto amafunikira.

②Pakakhala palibe njira imodzi yokhazikika, monga pamwamba, mapangidwe a chuck centering amafunikira.

Kusankha chuck yoyandama:

①Zofunikira zazikulu pakuyika pakati pa spindle yogwirira ntchito. Chuck ikamangika, kuyandama kwake sikungasokoneze malo oyambira a spindle.

②Kuchuluka kwa kudula sikuli kwakukulu, ndipo kumangofunika kuyendetsa spindle ya workpiece kuti izungulire ndikuwonjezera kulimba kwa workpiece.

Zomwe zili pamwambazi zikufotokozera kusiyana kwapangidwe ndi kukonza ndi kusankha zofunikira za chuck zoyandama ndi zolimba, zomwe zimathandiza kuti zigwiritsidwe ntchito ndi kukonza. Muyenera kumvetsetsa mozama ndikugwiritsa ntchito mosinthika; muyenera kufotokozera mwachidule zomwe mwakumana nazo pakugwiritsa ntchito ndi kukonza pamasamba.

Anebon Metal Products Limited ikhoza kupereka CNC Machining, Die Casting, Sheet Metal Fabrication service, chonde omasuka kulankhula nafe.

Tel: +86-769-89802722 E-mail: info@anebon.com URL: www.anebon.com

Nthawi yotumiza: Mar-31-2022