1. Kugwiritsa ntchito ma calipers

Caliper amatha kuyeza m'mimba mwake, m'mimba mwake, kutalika, m'lifupi, makulidwe, kusiyana kwa masitepe, kutalika, ndi kuya kwa chinthu; caliper ndiye chida choyezera chomwe chimagwiritsidwa ntchito kwambiri komanso chosavuta komanso chogwiritsidwa ntchito pafupipafupi pamalo opangira.

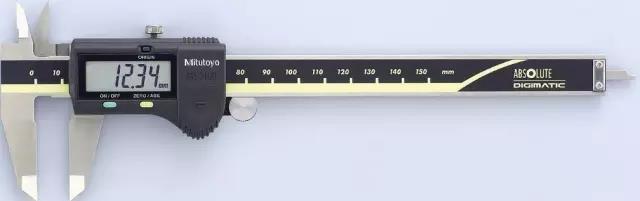

Digital Caliper: Resolution 0.01mm, yogwiritsidwa ntchito poyeza kukula ndi kulolerana kwakung'ono (kulondola kwakukulu).

Khadi tebulo: kusamvana 0.02mm, ntchito ochiritsira kukula muyeso.

Vernier caliper: 0.02mm kusamvana, komwe kumagwiritsidwa ntchito poyesa muyeso.

Musanagwiritse ntchito caliper, chotsani fumbi ndi dothi ndi pepala loyera loyera (gwiritsani ntchito kunja kwa caliper kuti mugwire pepala loyera ndikuchikoka mwachibadwa; bwerezani maulendo 2-3)

Poyezera ndi caliper, malo oyezera a caliper ayenera kukhala ofanana kapena perpendicular pamwamba pa kuyeza kwa chinthu choyezera momwe mungathere;

Mukamagwiritsa ntchito kuyeza kwakuya, ngati chinthu choyezedwa chili ndi ngodya ya R, m'pofunika kupewa R angle koma pafupi ndi R, ndipo wolamulira wakuya ayenera kukhala wolunjika momwe angathere mpaka kutalika kwake;

Caliper ikayesa silinda, imayenera kuzunguliridwa, ndipo kuchuluka kwake kumayesedwa m'magawo:CNC Machining gawo.

Chifukwa cha kuchuluka kwa ma calipers, ntchito yokonza iyenera kukhala yabwino kwambiri. Pambuyo pa tsiku lililonse logwiritsa ntchito, liyenera kupukutidwa ndikuyikidwa m'bokosi. Musanagwiritse ntchito, chipika chimafunika kuti muwone kulondola kwa caliper.

2. Kugwiritsa ntchito micrometer

Musanagwiritse ntchito micrometer, chotsani fumbi ndi dothi ndi pepala loyera loyera (gwiritsani ntchito micrometer kuyeza kukhudzana pamwamba ndi wononga pamwamba ndi pepala loyera linakanidwa ndiyeno kukoka mwachibadwa, kubwereza 2-3 nthawi), ndiye kupotoza. mphira yoyezera kukhudzana Pamene pamwamba ikugwirizana mwamsanga ndi wononga pamwamba, kusintha kwabwino kumagwiritsidwa ntchito, ndipo pamene malo awiriwa akhudzana kwathunthu, kusintha kwa zero kungathe kuchitidwa kuti muyese.gawo lopangidwa ndi makina

Poyezera zida ndi micrometer, sunthani knob, ndipo ikakhudzana ndi chogwirira ntchito, gwiritsani ntchito knob yokonza bwino kuti mulowemo. Imani ndikuwerenga deta kuchokera pachiwonetsero kapena sikelo mukamva kudina katatu.

Mukayeza zinthu zapulasitiki, malo olumikizirana ndi muyeso ndi wononga zimakhudza chinthucho.

Poyezera kukula kwa ma shafts ndi micrometer, yezani mayendedwe osachepera awiri ndikuyesa micrometer muyeso yayikulu m'zigawo. Zolumikizana ziwirizi ziyenera kukhala zoyera nthawi zonse kuti muchepetse zolakwika.

3. Kugwiritsa ntchito wolamulira wamtali

Kuyeza kwautali kumagwiritsidwa ntchito kwambiri poyeza kutalika, kuya, kusalala, verticality, concentricity, coaxiality, kugwedezeka kwa pamwamba, kugwedezeka kwa dzino, kuya, ndi kutalika. Poyezera, yang'anani kaye kafukufukuyo ndi magawo olumikizirana kuti atayike.

4. Chida choyezera molondola: chinthu chachiwiri

Chinthu chachiwiri ndi chida choyezera chosalumikizana ndikuchita bwino komanso kulondola. Chidziwitso cha chida choyezera sichimalumikizana mwachindunji ndi pamwamba pa gawo loyezera, kotero palibe mphamvu yoyezera makina; chinthu chachiwiri chimatumiza chithunzi chojambulidwa kudzera mu mzere wa data kupita ku khadi yopezera deta ya kompyuta kudzera mu njira yowonetsera. Kujambula pakompyuta yowunikira ndi pulogalamuyo: zinthu zosiyanasiyana za geometric (mfundo, mizere, zozungulira, ma arcs, ellipses, rectangles), mtunda, ngodya, mphambano, kulolerana kwa geometric (kuzungulira, kuwongoka, kufanana, vertical) Digiri, kutengera, malo, kukhazikika. , symmetry), ndi kutulutsa kwa CAD kwa chithunzi cha 2D. Mzere wa workpiece ukhoza kuwonedwa, ndipo mawonekedwe a opaque workpiece amatha kuyeza.CNC

5. Zida zoyezera molondola: zitatu-dimensional

Makhalidwe a zinthu zitatu-dimensional ndizolondola kwambiri (mpaka mulingo wa μm), chilengedwe chonse (chingathe kusintha zida zosiyanasiyana zoyezera utali), zitha kugwiritsidwa ntchito kuyeza mawonekedwe a geometric (kuphatikiza ndi zinthu zomwe gawo lachiwiri limatha kuyeza; imathanso kuyeza masilindala ndi ma cones), Kulekerera kwa mawonekedwe ndi malo (kuphatikiza mawonekedwe ndi kulolerana kwa malo komwe kungayesedwe ndi chinthu chachiwiri, kuphatikiza cylindricity, flatness, line profile, surface mbiri, coaxial, zovuta pamwamba, malinga ngati kafukufuku wamagulu atatu Kumene angakhudzidwe, kukula kwake kwa geometric, malo ogwirizana, mawonekedwe apamwamba amatha kuyesedwa pogwiritsa ntchito kompyuta; kusinthasintha, ndi luso lapamwamba kwambiri la digito, lakhala gawo lofunika kwambiri pakukonzekera nkhungu zamakono ndi kupanga ndi kutsimikizira khalidwe Njira, zida zothandiza.

We are a reliable supplier and professional in CNC service. If you need our assistance, please get in touch with me at info@anebon.com.

Anebon Metal Products Limited ikhoza kupereka makina a CNC, kuponyera kufa, ntchito zopangira zitsulo, chonde omasuka kutilankhula nafe.

Tel: +86-769-89802722 Email: info@anebon.com Website : www.anebon.com

Nthawi yotumiza: Apr-13-2020