Ulusi ndi helix yomwe imadulidwa kukhala chogwirira ntchito kuchokera kunja kapena mkati ndipo imagwira ntchito zingapo zofunika. Choyamba, ulusi umapanga kulumikizana kwamakina pophatikiza ulusi wamkati ndi ulusi wakunja. Kulumikizana uku kumatsimikizira kuti mbali zosiyanasiyana za workpiece zikhoza kulumikizidwa mwamphamvu wina ndi mzake.

Kuphatikiza apo, ulusi umagwira ntchito yofunika kwambiri pakupatsirana. Amatha kutembenuza mayendedwe a rotary kukhala liniya zoyenda ndi mosemphanitsa. Kuthekera kumeneku kumakhala kothandiza kwambiri pamapulogalamu ambiri, monga pamakina omwe amafunikira kuyenda kwa mzere kuti agwire ntchito zinazake.

Kuphatikiza apo, ulusi umapereka zabwino zamakina. Pogwiritsa ntchito ulusi, magwiridwe antchito apamwamba amatha kuchitika mwanjira iliyonse. Izi zikuphatikizapo kuchulukitsidwa kwa mphamvu yonyamula katundu, kulimbikira kukana kumasuka kapena kugwedezeka, komanso kupititsa patsogolo mphamvu zotumizira mphamvu.

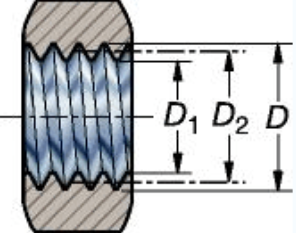

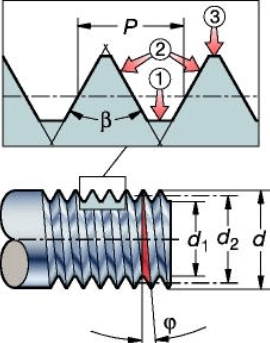

Pali mitundu yosiyanasiyana ya ulusi, iliyonse yomwe imatsimikizira geometry ya ulusi. Chofunikira cha mbiri ya ulusi ndi diameter ya workpiece. Izi zikuphatikizapo m'mimba mwake waukulu (m'mimba mwake waukulu kwambiri wa ulusi) ndi m'mimba mwake (m'mimba mwake pamalo ongoganizira kumene ulusi uli ndi ziro). Miyezo iyi ndi yofunika kwambiri kuti zitsimikizire kuti ulusiwo ukulowa bwino komanso umagwira ntchito bwino.

Kumvetsetsa terminology ya ulusi ndikofunikira kuti mugwiritse ntchito ulusi bwino. Mawu ena ofunikira amaphatikizapo lead (mtunda wa axial ulusi umayenda mukusintha kumodzi kokwanira) ndi phula (mtunda pakati pa mfundo zofananira pa ulusi woyandikana). Kuyeza kolondola kwa lead ndi phula ndikofunikira kuti zitsimikizire kupangidwa kolondola kwa ulusi ndi kugwirizana.

Mwachidule, ulusi umagwira ntchito zingapo zofunika m'mafakitale osiyanasiyana. Amathandizira kulumikizana kwamakina, kutumiza zoyenda ndikupereka zabwino zamakina. Kumvetsetsa mbiri ya ulusi ndi mawu ofananirako ndikofunikira kuti mugwiritse ntchito ulusi bwino ndikuwonetsetsa kuti zikuyenda bwino.

Kuthetsa Chinsinsi cha Pitch: Kufufuza Tanthauzo Lake ndi Njira Yowerengera

Kuthamanga kwa ulusi ndi chinthu chofunikira kwambiri pakupanga ndi kupanga makina. Kumvetsetsa tanthauzo lake ndikuwerengera molondola ndikofunikira kuti mupange zida zamakina apamwamba kwambiri. M'nkhaniyi, tiwona zovuta za ulusi, ma geometry ake, ndi momwe angadziwire molondola. Kuphatikiza apo, tiyambitsa Anebon, kampani yomwe imagwira ntchito zama makina a CNC ndi mphero ya CNC, yopereka mawu othamanga komanso odalirika pa intaneti pamakina a CNC.

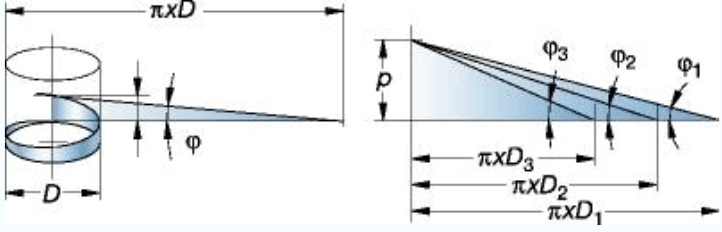

Geometry ya ulusi imachokera ku ulusi phula m'mimba mwake (d, D) ndi phula (P): mtunda wa axial pamodzi ndi ulusi pa workpiece kuchokera pa mfundo imodzi pa mbiri kupita ku mfundo yotsatira. Ganizirani ngati makona atatu omwe amazungulira chogwirira ntchito. Kapangidwe ka katatu kameneka kumatsimikizira mphamvu ndi magwiridwe antchito a zigawo za ulusi. Kuwerengera kolondola kwa phula la ulusi ndikofunikira kuti muwonetsetse kukwanira, kugawa koyenera komanso kugwira ntchito bwino kwa magawo amakina.

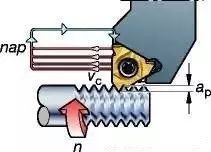

Kuti adziwe bwino phula, wopanga amagwiritsa ntchito luso lamakono la CNC. CNC Machining, kapena makina owongolera manambala apakompyuta, ndi njira yopangira yomwe imagwiritsa ntchito zida zamakina zoyendetsedwa ndi makompyuta kuti zichotse bwino zinthu kuchokera kuzinthu zopangira kupanga zida zamakina. CNC Machining Online Quoting ndi ntchito yoperekedwa ndi makampani ambiri akatswiri omwe amalola makasitomala kupeza mwachangu komanso mosavuta kuyerekezera kwamitengo pamwambo wawo.CNC Machining magawo.

Anebon ndi kampani yotsogola m'makampani opanga zida za Hardware, yomwe imapereka ntchito zopangira makina a CNC ndi mphero za CNC kuyambira pomwe idakhazikitsidwa mu 2010. Ndi gulu la akatswiri ndi zida zamakono, Anebon imapereka zinthu zabwino, zapamwamba kwambiri. . Makina okhazikika omwe amatumizidwa kuchokera ku Japan. CNC mphero ndi lathes komanso pamwamba grinders amawathandiza kupereka mwatsatanetsatane mankhwala ndi khalidwe. Kuphatikiza apo, Anebon ndi ISO 9001:2015 yotsimikizika, kuwonetsa kudzipereka kwawo kusunga miyezo yapamwamba kwambiri yopangira komanso kukhutira kwamakasitomala.

Powerengera mawu, nthawi zambiri amawonetsedwa mu ulusi pa inchi (TPI) kapena mamilimita. Kwa ulusi wa metric, phula limatchulidwa ngati mtunda wa mamilimita pakati pa zingwe ziwiri zoyandikana. Mosiyana, pamakina otengera ulusi, TPI imayimira ulusi pa inchi imodzi. Kuyeza bwino ulusi wa ulusi n'kofunika kwambiri kuti zitsimikizire kuti zimagwirizana pakati pa zingwe zomangika ndikupewa mavuto omwe angakhalepo monga kumasuka, kuphulika kapena kusakwanira kwa katundu.

CNC makinaZimagwira ntchito yofunika kwambiri kuti munthu athe kuyeza mawu molondola. Pogwiritsa ntchito ukadaulo wapamwamba kwambiri komanso zida zolondola, zida zamakina za CNC zimatha kukwaniritsa zofunikira komanso zofunikira. Mapulogalamu apamwamba a mapulogalamu amathandizira makina a CNC kuwerengera ulusi wovuta, kuonetsetsa kuti ulusi wolondola umapezeka pa ntchito iliyonse yapadera.

Mwachidule, kumvetsetsa zovuta za mamvekedwe ndikuwerengera molondola ndikofunikira kuti mupange zida zamakina apamwamba kwambiri. Pogwiritsa ntchito makina opanga makina a CNC ndikugwiritsa ntchito mwamboKusintha kwa CNC, opanga amatha kukwaniritsa zolondola komanso zabwino kwambiri pazogulitsa zawo. Wodzipereka kuchita bwino komanso ndi zida zamakono, makampani ngati Anebon amatsogolera popereka zodalirika, zogwira mtima za CNC Machining ma quote services. Podziwa bwino za ulusi, opanga amatha kupanga zingwe zomwe zimakwaniritsa miyezo yapamwamba kwambiri ya magwiridwe antchito.

1. Kuwerengera ndi kulolerana kwa phula la phula la 60 ° ulusi wakunja wooneka ngati dzino (muyezo wadziko lonse GB197/196)

a.Kuwerengera kukula kwake koyambira

Kukula koyambira kwa phula lalikulu la ulusi = kukula kwakukulu kwa ulusi - pitch × coefficient value.

Chiwonetsero cha formula: d/DP×0.6495

Chitsanzo: Kuwerengera kuchuluka kwa phula la ulusi wakunja wa M8

8-1.25×0.6495=8-0.8119≈7.188

b. Nthawi zambiri amagwiritsidwa ntchito 6h kunja kwa ulusi phula m'mimba mwake kulolerana (kutengera ulusi phula)

Mtengo wapamwamba ndi "0"

Malire apansi ndi P0.8-0.095P1.00-0.112P1.25-0.118

P1.5-0.132P1.75-0.150P2.0-0.16

P2.5-0.17

Njira yowerengera malire apamwamba ndiye saizi yoyambira, ndipo njira yotsika yowerengera ya d2-hes-Td2 ndiye kuphatikizika koyenera kwa kukula-kupatuka-kololedwa.

Kulekerera kwa 6h giredi phula m'mimba mwake ya M8: malire apamwamba 7.188 mtengo wotsika: 7.188-0.118 = 7.07.

C. Nthawi zambiri amagwiritsidwa ntchito 6g giredi kunja ulusi phula phula m'mimba mwake: (zotengera phula phula)

P0.80-0.024P1.00-0.026P1.25-0.028P1.5-0.032

P1.75-0.034P2-0.038P2.5-0.042

Chiwerengero chapamwamba chowerengera d2-ges ndicho kupatuka koyambira

Njira yocheperako yowerengera d2-ges-Td2 ndiye kulolerana kosiyana koyambira

Mwachitsanzo, 6g giredi phula m'mimba mwake mtengo kulolerana M8: kumtunda malire mtengo 7.188-0.028 = 7.16 otsika malire mtengo: 7.188-0.028-0.118 = 7.042.

Zindikirani:

①Kulekerera kwa ulusi pamwambaku kumatengera ulusi wokulirapo, ndipo kulolerana kwa ulusi wa ulusi wabwino kumasinthidwanso molingana, koma kulolerako kumangokulitsidwa, kotero kuwongolera sikudzadutsa malire, kotero iwo sanalembedwe patebulo. Kumwamba kunatuluka.

②Pakupanga kwenikweni, molingana ndi kulondola komwe kumafunidwa ndi kapangidwe kake ndi mphamvu yotulutsa ulusi wa zida zopangira ulusi, kukula kwa ndodo yopukutidwa kumachulukitsidwa ndi 0.04-0.08 poyerekeza ndi mdulidwe wa ulusi wopangidwa, womwe ndi m'mimba mwake wa ulusi wopukutidwa. ndodo. Mwachitsanzo, m'mimba mwake wa kampani yathu ya M8 yakunja ulusi 6g ulusi wopukutidwa ndi ndodo ndi 7.08-7.13, yomwe ili mkati mwa izi.

③Poganizira zofunikira pakupanga, kuchepetsa kutsika kwa malire a phula la ulusi wakunja popanda chithandizo cha kutentha ndi chithandizo chapamwamba pakupanga kwenikweni chiyenera kusungidwa pamlingo wa 6h momwe zingathere.

2. Kuwerengera ndi kulolerana kwa phula la phula la 60 ° ulusi wamkati (GB197/196)

a.6H mlingo ulusi phula m'mimba mwake kulolerana (kutengera phula phula)

malire apamwamba:

P0.8+0.125P1.00+0.150P1.25+0.16P1.5+0.180

P1.25+0.00P2.0+0.212P2.5+0.224

Mtengo wotsika ndi "0",

Njira yapamwamba yowerengera 2+TD2 ndiye kukula koyambira + kulolerana.

Mwachitsanzo, phula lalikulu la M8-6H ulusi wamkati ndi: 7.188 + 0.160 = 7.348 malire apamwamba: 7.188 ndi malire otsika.

b. Njira yowerengera kukula kwa ulusi wamkati ndi yofanana ndi ya ulusi wakunja

Ndiko kuti, D2 = DP × 0.6495, ndiko kuti, phula lamkati la ulusi wamkati ndilofanana ndi phula diameter × coefficient value.

c.6G kalasi ulusi phula m'mimba mwake zoyambira zopatuka E1 (kutengera ulusi phula)

P0.8+0.024P1.00+0.026P1.25+0.028P1.5+0.032

P1.75+0.034P1.00+0.026P2.5+0.042

Chitsanzo: Malire apamwamba a phula lalikulu la M86G ulusi wamkati: 7.188+0.026+0.16=7.374

Malire apansi: 7.188 + 0.026 = 7.214

Njira yapamwamba yamalire 2+GE1+TD2 ndiye kukula koyambira kwa phula mainchesi + kupatuka + kulolerana.

Njira yotsika yotsika mtengo 2+GE1 ndi kukula kwake kwa phula + kupatuka

3. Kuwerengera ndi kulolerana kwa mainchesi akuluakulu a ulusi wakunja (GB197/196)

a.Upper malire a 6h mainchesi awiri a ulusi wakunja

Ndiye kuti, chitsanzo cha ulusi wamtengo wapatali M8 ndi φ8.00, ndipo kulolerana kwapamwamba ndi "0".

b. Kulekerera kwa malire apansi a mainchesi akuluakulu a kalasi yakunja ya 6h (kutengera phula la ulusi)

P0.8-0.15P1.00-0.18P1.25-0.212P1.5-0.236P1.75-0.265

P2.0-0.28P2.5-0.335

Njira yowerengera ya malire otsika a mainchesi akulu: d-Td ndiye kulolera koyambira kwa mainchesi akulu a ulusi.

Chitsanzo: M8 ulusi wakunja 6h kukula kwake kwakukulu: malire apamwamba ndi φ8, malire otsika ndi φ8-0.212=φ7.788

c.Kuwerengera ndi Kulekerera kwa Diameter Yaikulu 6g ya Ulusi Wakunja

Kupatuka kwa ulusi wakunja kwa 6g (kutengera kukwera kwa ulusi)

P0.8-0.024P1.00-0.026P1.25-0.028P1.5-0.032P1.25-0.024P1.75–0.034

P2.0-0.038P2.5-0.042

Njira yapamwamba yowerengera ma d-ges ndiye gawo loyambira la ulusi waukulu-referensi yopatuka.

Njira yowerengera yocheperako d-ges-Td ndiye gawo loyambira la ulusi waukulu wa diameter-baseline deviation-tolerance.

Chitsanzo: M8 ulusi wakunja 6g kalasi yayikulu m'mimba mwake kumtunda malire φ8-0.028=φ7.972.

Malire otsika φ8-0.028-0.212=φ7.76

Zindikirani: ①Kukula kwakukulu kwa ulusi kumatsimikiziridwa ndi kukula kwa ndodo yopukutidwa ndi kuchuluka kwa ulusi wogudubuza / mbiri ya dzino logudubuza, ndipo mtengo wake umasiyana mosiyana ndi kumtunda ndi pakati pa ulusiwo. Pamaziko a chida chofanana chopanda kanthu ndi cholumikizira, chocheperako m'mimba mwake, chokulirapo chachikulu, ndipo mosinthanitsa, chokulirapo chapakati, chocheperako m'mimba mwake.

② Pazigawo zomwe zimafuna chithandizo cha kutentha ndi chithandizo chapamwamba, poganizira mgwirizano pakati pa teknoloji yokonza ndi kupanga kwenikweni, kukula kwakukulu kwa ulusi kuyenera kuyendetsedwa pamunsi wa kalasi 6h kuphatikiza 0.04mm kapena kupitirira. Mwachitsanzo, kwa ulusi wakunja wa M8, kukula kwakukulu kwa ulusi wopukuta (kugudubuza) kuyenera kutsimikiziridwa kukhala pamwamba pa 7.83 ndi pansi pa 7.95.

4. Kuwerengera ndi kulolerana kwazing'onozing'ono za ulusi wamkati

a.Kuwerengetsera kukula kwa kagawo kakang'ono ka ulusi wamkati (D1)

Kukula koyambira kwa ulusi wocheperako = kukula koyambira kwa ulusi wamkati - phula × kokwanira

Chitsanzo: Kukula koyambira kwa mainchesi ang'onoang'ono a ulusi wamkati M8 ndi 8-1.25 × 1.0825 = 6.646875≈6.647

b. Kuwerengera kwa ulusi wamkati 6H kulolerana kwazing'onozing'ono (zotengera ulusi wa phula) ndi mtengo waung'ono

P0.8+0.2P1.0+0.236P1.25+0.265P1.5+0.3P1.75+0.335

P2.0+0.375P2.5+0.48

M'munsi malire apatuka chilinganizo D1 + HE1 wa ulusi wamkati 6H kalasi ndiye kukula kofunikira kwa ulusi wamkati wam'mimba mwake + wopatuka.

Zindikirani: Mtengo wokondera ndi "0" pamlingo wa 6H

Kuwerengera kwa malire apamwamba a 6H mlingo wa ulusi wamkati=D1+HE1+TD1, ndiko kuti, kukula kwazing'ono za ulusi wamkati + kupatuka + kulolerana.

Chitsanzo: Malire apamwamba a ulusi wamkati wa 6H grade M8 ndi 6.647 +0 = 6.647

Malire apansi ang'onoang'ono a 6H kalasi ya M8 mkati ulusi ndi 6.647 + 0 + 0.265 = 6.912

c. Kuwerengera kwapatuka koyambira kwa mainchesi ang'onoang'ono a ulusi wamkati 6G (kutengera phula) ndi mtengo wa mainchesi ang'onoang'ono.

P0.8+0.024P1.0+0.026P1.25+0.028P1.5+0.032P1.75+0.034

P2.0+0.038P2.5+0.042

Njira yowerengera malire apansi ang'onoang'ono a ulusi wamkati 6G = D1 + GE1 ndiye kukula kwakukulu kwa ulusi wamkati + kupatuka.

Chitsanzo: Malire otsika ang'onoang'ono a 6G grade M8 ulusi wamkati ndi 6.647 + 0.028 = 6.675

Chilinganizo cha D1 + GE1 + TD1 cha mtengo wapamwamba wa malire ang'onoang'ono a ulusi wamkati wa 6G kalasi ya M8 ndi kukula kwakukulu kwa ulusi wamkati + kupatuka + kulekerera.

Chitsanzo: Malire apamwamba a ulusi wamkati wa 6G grade M8 ndi 6.647 + 0.028 + 0.265 = 6.94

Zindikirani:

①Kutalika kwa dzino kwa ulusi wamkati kumagwirizana mwachindunji ndi nthawi yobereka ya ulusi wamkati, kotero kuti zopanda kanthu ziyenera kukhala mkati mwa malire apamwamba a kalasi ya 6H momwe zingathere.

②Panthawi yokonza ulusi wamkati, kucheperachepera kwa ulusi wamkati kumachepetsa mphamvu ya chida chopangira - mpopi. Pamalingaliro a ntchito, ang'onoang'ono awiri ang'onoang'ono, ndi bwino, koma kuganizira mozama, m'mimba mwake yaing'ono imagwiritsidwa ntchito pakati pa malire apakati ndi apamwamba, ngati ndi chitsulo kapena aluminiyamu, iyenera kugwiritsidwa ntchito pakati pa malire apansi ndi malire apakati a m'mimba mwake yaying'ono .

③Pamene kukula kwakung'ono kwa ulusi wamkati ndi 6G, kumatha kuzindikirika ngati 6H. Mlingo wolondola makamaka umayang'ana kuphimba kwa phula lalikulu la ulusi. Chifukwa chake, kutalika kwapampopi kokha kumaganiziridwa panthawi yokonza ulusi, ndipo mainchesi ang'onoang'ono samaganiziridwa. The awiri a dzenje kuwala.

5. Kuwerengera njira yogawa mutu umodzi wogawa

Njira yowerengera gawo limodzi: n=40/Z

n: chiwerengero cha mabwalo omwe mutu wogawa uyenera kutembenuka

Z: gawo lofanana la workpiece

40: Nambala yamutu yokhazikika

Chitsanzo: Kuwerengetsera mphero ya hexagon

Lowetsani mu fomula: n=40/6

Kuwerengera: ① Sambani tizigawo ting'onoting'ono: pezani chogawa chaching'ono 2 ndikugawanitsa, ndiko kuti, gawani nambala ndi denominator ndi 2 nthawi yomweyo kuti mupeze 20/3. Ngakhale kuchepetsa chiwerengerocho, kugawanika kwake kofanana kumakhalabe komweko.

② Kuwerengera kwa tizigawo ting'onoting'ono: Pakadali pano, zimatengera mikhalidwe ya manambala ndi denominator; ngati manambala ndi denominator ndi zazikulu, ndiye kuti kuwerengera kumachitika.

20÷3=6(2/3) ndi mtengo wa n, ndiye kuti mutu wogawa uyenera kutembenuza 6(2/3) mozungulira. Panthawiyi, kagawo kakang'ono kamakhala kakang'ono; gawo lalikulu la decimal 6 ndiye mutu wagawo uyenera kutembenuza mozungulira 6. Gawo la 2/3 lokhala ndi kachigawo kakang'ono likhoza kukhala 2/3 la bwalo ndipo liyenera kuwerengedwanso panthawiyi.

③Kusankha ndi kuwerengera mbale yolozera: kuwerengera kwa bwalo lochepera limodzi kuyenera kuzindikirika mothandizidwa ndi mbale yolozera pamutu wolozera. Gawo loyamba pakuwerengera ndikukulitsa nthawi yomweyo gawolo ndi 2/3. Mwachitsanzo: ngati mphambuyo ikukulitsidwa ka 14 nthawi imodzi, ndi 28/42; ngati ikulitsidwa ka 10 nthawi imodzi, mphambu ndi 20/30; ngati itakulitsidwa ka 13 nthawi imodzi, mphambu ndi 26/39…Sikelo yokulitsidwa ikhale molingana ndi kuyimba Sankhani kuchuluka kwa mabowo pamenepo.

Panthawi imeneyi, ziyenera kukumbukiridwa:

①Nambala ya mabowo a indexing plate yosankhidwa iyenera kugawikana ndi denominator 3. Mwachitsanzo, mu chitsanzo pamwambapa, mabowo 42 ndi 14 nthawi za 3, mabowo 30 ndi 10 nthawi 3, ndipo mabowo 39 ndi 13 nthawi za 3. .

②Kukula kwa tizigawo ting'onoting'ono kuyenera kukhala kuti nambala ndi denominator zikukulitsidwa nthawi imodzi, ndipo magawo ofanana amakhalabe osasinthika, mwachitsanzo.

28/42=2/3×14=(2×14)/(3×14); 20/30=2/3×10=(2×10)/(3×10);

26/39=2/3×13=(2×13)/(3×13)

28/42 Denominator 42 ndiyo kugwiritsa ntchito mabowo 42 a index index; Nambala 28 imasunthira patsogolo pa dzenje la gudumu lakumtunda, kenako ndikutembenuza dzenje la 28, ndiye kuti, dzenje la 29 ndiye bowo la gudumu lamakono, 20/30 ndi mabowo 10 patsogolo pa malo ozungulira. 30-hole index mbale, ndipo dzenje la 11 ndiye ndendende dzenje la gudumuli. 26/39 ndiye bowo la gudumu lomwe lili pa mbale ya 39-hole index, ndipo mabowo 26 a mabowo 27 amazungulira kutsogolo.

Pamene mphero ya hexagon (yachisanu ndi chimodzi), mabowo monga 42 mabowo, mabowo 30, ndi mabowo 39 omwe angathe kugawikana ndi 3 amagwiritsidwa ntchito ngati masikelo: ntchitoyo ndi kuzungulira chogwirira ka 6, ndiyeno kupita patsogolo pa dzenje loyikirapo. kukhala gudumu chapamwamba motero. Sinthani 28+1/10+1/26+ kachiwiri! Bowo lomwe lili pamwamba pa dzenje la 29/11/27 limagwiritsidwa ntchito ngati dzenje loyikira gudumu.

Chitsanzo 2: Mawerengedwe a mphero giya 15.

Lowetsani mu fomula: n=40/15

Weretsani n=2(2/3)

Ndiko kutembenuza mabwalo awiri athunthu, ndikusankha mabowo olozera omwe amatha kugawidwa ndi 3, monga 24, 30, 39, 42.51. Onjezani bowo limodzi, 17, 21, 27, 29, 35, 37, 39, 45 mabowo, ngati dzenje loyika gudumuli.

Chitsanzo 3: Kuwerengetsera mphero 82 mano.

Lowetsani mu fomula: n=40/82

Weretsani n=20/41

Izi ndizo: bola ngati mbale yolondolera yokhala ndi mabowo 41 yasankhidwa, tembenuzirani 20 + 1 pa dzenje la gudumu lakumtunda, ndiye kuti mabowo 21 amagwiritsidwa ntchito ngati dzenje la gudumu lapano.

Chitsanzo 4: Kuwerengera kalozera pamphero 51 mano

M'malo chilinganizo n = 40/51, popeza mphambu sangathe kuwerengedwa pa nthawi ino, mukhoza kusankha mwachindunji dzenje, ndiye kusankha index mbale ndi mabowo 51, ndiyeno kutembenuza 51+1 gudumu chapamwamba pa udindo. dzenje, ndiye 52 mabowo, monga gudumu panopa. Kuyika mabowo mwachitsanzo.

Chitsanzo 5: Kuwerengera kalozera pamphero 100 mano.

Lowetsani mu formula n=40/100

Weretsani n=4/10=12/30

Sankhani mbale yolozera mabowo 30 munthawi yake, kenaka ikani mabowo 12+1 kapena 13 pabowo lakumtunda kwa gudumu ngati dzenje loyikapo magudumu.

Ngati ma disks onse owonetserako sakufika ku chiwerengero cha mabowo ofunikira kuti awerengere, njira yowonetsera pawiri iyenera kugwiritsidwa ntchito powerengera, zomwe sizikuphatikizidwa mu njira yowerengera iyi. Pakupanga kwenikweni, kupha magiya nthawi zambiri kumagwiritsidwa ntchito, chifukwa ntchito yeniyeniyo pambuyo powerengera ma index ndizovuta kwambiri.

6. Njira yowerengera ya hexagon yolembedwa mozungulira

① Pezani mbali ina ya hexagon (S pamwamba) ya bwalo D

S=0.866D ndi m'mimba mwake×0.866 (koyeyefiyenti)

② Werengetsani kukula (D) kwa bwalo kuchokera mbali ina ya hexagon (S pamwamba)

D=1.1547S moyang'anizana ndi 1.1547

7. Njira yowerengera ya mbali zotsutsana ndi mzere wozungulira wa hexagon mumayendedwe ozizira

① Pezani mbali ina ya e ya mbali ina (S) ya hexagon yakunja

e=1.13s Mbali yotsutsana×1.13

② Pezani ngodya ina (e) kuchokera mbali ina (ma) yamkati mwa hexagon

e=1.14s Mbali yotsutsana×1.14 (koyefiyenti)

③ Pezani kukula kwa mutu wozungulira (D) kuchokera mbali zina (s) za hexagon yakunja

M'mimba mwake (D) wa bwalo liyenera kuwerengedwa molingana ndi mbali inayo (ndege) ya hexagon (chilinganizo chachiwiri mu 6), ndipo mtengo wapakati wa offset uyenera kukulitsidwa moyenerera, ndiye kuti, D≥1.1547s. Kuchuluka kwa kuchotsera kuchokera pakati kungayerekezedwe.

8. Chiwerengero cha mawerengedwe a square olembedwa mozungulira

① Jambulani bwalo (D) kuti mupeze mbali ina ya lalikulu (S pamwamba)

S=0.7071D ndi m'mimba mwake×0.7071

② Pezani bwalo (D) kuchokera mbali ina ya bwalo (S pamwamba)

D=1.414S moyang'anizana ndi 1.414

9. Mawerengedwe mafomula masikweya mbali zopingasa ndi ngodya zosiyana mu ndondomeko yozizira mitu

① Pezani ngodya ina (e) mbali ina (S) ya bwalo lakunja

e=1.4s ndi mbali ina (s)×1.4 parameter

② Pezani mbali ina (e) ya mbali ina (ma) yapakati

e=1.45s ndi mbali ina (s)×1.45 coefficient

10. Njira yowerengera voliyumu ya hexagon

s20.866×H/m/k amatanthauza mbali yopingasa×mbali yotsutsana×0.866×utali kapena makulidwe.

11. Fomula yowerengera ya voliyumu yocheperako (cone).

0.262H (D2+d2+D×d) ndi 0.262×utali×(mutu waukulu m'mimba mwake×mutu waukulu m'mimba mwake+mutu wawung'ono wang'ono×mutu waung'ono wamutu+wamkulu wamutu wawung'ono×mutu wawung'ono).

12. Kuwerengera kuchuluka kwa gawo (monga mutu wa semicircular)

3.1416h2(Rh/3) ndi 3.1416×utali×utali×(radius-utali÷3).

13. Fomula yowerengera ya miyeso ya makina a matepi amkati amkati

1. Kuwerengera kwa tap main diameter D0

D0=D+(0.866025P/8)×(0.5~1.3) ndiye kukula kwake kwa ulusi waukulu wa mpopi + 0.866025 pitch÷8×0.5~1.3.

Zindikirani: Kusankhidwa kwa 0.5 ~ 1.3 kuyenera kutsimikiziridwa molingana ndi kukula kwake. Kukula kwa mtengo wa phula, kocheperako ndikoyenera kugwiritsidwa ntchito. Mosiyana ndi zimenezi, kukwera kwake kumakhala kocheperako, ndiye kuti coefficient yofananayo iyenera kukulirakulira.

2. Kuwerengera kuchuluka kwa phula (D2)

D2=(3×0.866025P)/8, ndiye kuti, tap diameter=3×0.866025×pitch÷8

3. Kuwerengera kuchuluka kwa mpopi (D1)

D1=(5×0.866025P)/8 ndi m'mimba mwake = 5×0.866025×pitch÷8

Khumi ndi zinayi,

Mawerengedwe a chilinganizo cha kutalika kwa zinthu za mutu ozizira kupanga mawonekedwe osiyanasiyana

Voliyumu ya bwalo lodziwika bwino ndi m'mimba mwake × m'mimba mwake × 0.7854 × kutalika kapena utali wozungulira × 3.1416 × kutalika. Ndiko kuti, d2×0.7854×L kapena R2×3.1416×L

Powerengera, voliyumu ya X÷diameter÷diameter÷0.7854 kapena X÷radius÷radius÷3.1416 yazinthu zofunikira ndi kutalika kwa zinthuzo.

Mzerewu = X/(3.1416R2) kapena X/0.7854d2

Mu formula, X imayimira kuchuluka kwa zinthu zofunika;

L amaimira kutalika kwa mtengo wa chakudya chenicheni;

R/d imayimira ma radius enieni kapena m'mimba mwake.

Cholinga cha Anebon ndikumvetsetsa kuwonongeka kwabwino kwamakampani opanga ndikupereka chithandizo chapamwamba kwa makasitomala akunyumba ndi akunja ndi mtima wonse kwa 2022 Aluminiyamu Aluminiyamu Apamwamba Apamwamba Osapanga dzimbiri Akuluakulu Opangidwa Ndi CNC Kutembenuza Makina Opangira Zamlengalenga, Kuti tikulitse msika wathu wapadziko lonse, Anebon. makamaka kupereka makasitomala oversea Top khalidwe ntchito mbali makina, mbali milled ndi cnc kutembenukira utumiki.

China yogulitsa China Machinery Parts ndi CNC Machining Service, Anebon imachirikiza mzimu wa "zatsopano, mgwirizano, ntchito yamagulu ndi kugawana, mayendedwe, kupita patsogolo kwanzeru". Tipatseni mwayi ndipo tikhala tikuwonetsa kuthekera kwathu. Ndi chithandizo chanu chokoma mtima, Anebon amakhulupirira kuti titha kupanga tsogolo labwino ndi inu limodzi.

Nthawi yotumiza: Jul-10-2023