Kodi mukuganiza kuti pali ubale wotani pakati pa kudula liwiro, kugwiritsa ntchito zida, ndi liwiro la chakudya mu makina a CNC?

Kuti mugwire bwino ntchito, ndikofunikira kumvetsetsa ubale womwe ulipo pakati pa liwiro la chakudya, kuthamanga kwachangu ndi kukhudzidwa kwa zida mu makina a CNC.

Kuthamanga Liwiro:

Liwiro lodula ndilo kuchuluka kwa kasinthasintha kapena kuyenda muzinthu. Liwiro limayezedwa pamapazi apansi pamphindi (SFM) kapena mita/mphindi (m/min). Kuthamanga kwachangu kumatsimikiziridwa ndi zinthu zomwe ziyenera kupangidwa, chida chodulira, ndi kumaliza komwe kumafunidwa.

Kugwirizana kwa Zida

Chida chothandizira ndikuzama komwe chida chodulira chimalowera pagawo lantchito panthawi yokonza. Kugwiritsa ntchito zida kumakhudzidwa ndi zinthu monga kudulira zida za geometry ndi ma feed ndi kuthamanga komanso kufunidwa kwapamwamba komanso kuchuluka kwa zinthu zochotsa. Posankha kukula kwa chida choyenera, kuya kwa kudula ndi ma radial, mutha kusintha zida.

Feed Speed

Kuthamanga kwa chakudya kumatchedwanso mlingo wa chakudya kapena chakudya pa dzino. Ndi mlingo umene kudula chida patsogolo pa kusintha kwa zinthu za workpiece. Liwiro limayesedwa ndi mamilimita kapena mainchesi pa mphindi. Kuchuluka kwa chakudya kumakhudza mwachindunji moyo wa zida, mawonekedwe apamwamba, komanso magwiridwe antchito onse.

Kawirikawiri, kuthamanga kwapamwamba kumapangitsa kuti zinthu zichotsedwe kwambiri. Komabe, zimatulutsanso kutentha kwambiri. Kuthekera kwa chida chodulira kuti chizitha kuthamanga kwambiri, komanso mphamvu ya chozizirirapo pakuchotsa kutentha ndi zinthu zofunika.

Kugwirizana kwa zida kuyenera kusinthidwa molingana ndi zomwe zidagwiritsidwa ntchito, geometry ya zida zodulira, komanso kumaliza komwe mukufuna. Kugwiritsa ntchito bwino zida kumathandizira kuthamangitsidwa kwa chip ndikuchepetsa kupatuka kwa zida. Zidzakhalanso bwino kudula ntchito.

Kuthamanga kwa chakudya kuyenera kusankhidwa kuti mukwaniritse zomwe mukufuna kuchotsa ndikumaliza, popanda kudzaza chida. Kuchuluka kwa chakudya kungayambitse kugwiritsa ntchito zida zambiri. Komabe, kuthamanga kwapang'onopang'ono kumapangitsa kuti pakhale kusamalitsa bwino komanso kusagwira bwino ntchito.

Wopanga mapulogalamu ayenera kulemba malangizo mu pulogalamu ya CNC kuti adziwe kuchuluka kwa kudula panjira iliyonse. Kudula liwiro, kuchuluka-kudula kumbuyo, kuthamanga kwa chakudya ndi zina zotero zonse ndi gawo la ntchito yodula. Zosiyanasiyana zodula zimafunikira panjira zosiyanasiyana zopangira.

1. Mfundo yosankha kudula ndalama

Zikafika povuta, cholinga chachikulu chimakhala pakukweza zokolola, koma ndalama zoyendetsera chuma ndi kukonza ziyenera kuganiziridwanso; pamene theka-kumaliza ndi kumaliza, kudula bwino, chuma, ndi processing ndalama ayenera kuganiziridwa pamene kuonetsetsa processing khalidwe. Zomwe zimafunikira ziyenera kutsimikiziridwa molingana ndi buku la zida zamakina, buku logwiritsira ntchito, komanso chidziwitso.

Kuyambira kulimba kwa chida, dongosolo la kusankha kudula ndalama ndi: choyamba kudziwa kuchuluka kwa kumbuyo kudula, ndiye kudziwa kuchuluka kwa chakudya, ndipo potsiriza kudziwa kudula liwiro.

2. Kutsimikiza kwa kuchuluka kwa mpeni kumbuyo

Kuchuluka kwa kudula kumbuyo kumatsimikiziridwa ndi kuuma kwa chida cha makina, workpiece ndi chida. Ngati kuuma kumalola, kuchuluka kwa kudula kumbuyo kuyenera kukhala kofanana ndi gawo la machining a workpiece momwe ndingathere. Izi zitha kuchepetsa kuchuluka kwa zida zodutsa ndikuwongolera kupanga bwino.

Mfundo zodziwira kuchuluka kwa mpeni kumbuyo:

1)

Pamene pamwamba roughness mtengo wa workpiece ayenera kukhala Ra12.5μm ~ 25μm, ngati Machining chilolezo chaCNC makinandi zosakwana 5mm ~ 6mm, chakudya chimodzi cha Machining akhakula akhoza kukwaniritsa zofunika. Komabe, pamene malirewo ndi aakulu, kukhazikika kwa dongosolo la ndondomeko kumakhala kosauka, kapena mphamvu ya chida cha makina sichikwanira, imatha kumalizidwa muzakudya zambiri.

2)

Pamene pamwamba roughness kufunika workpiece chofunika kukhala Ra3.2μm ~ 12.5μm, zikhoza kugawidwa mu masitepe awiri: roughing ndi theka-kumaliza. Kusankhidwa kwa kuchuluka kwa m'mbuyo pamakina ovuta ndi chimodzimodzi monga kale. Siyani malire a 0.5mm mpaka 1.0mm mutatha kupanga movutikira ndikuchotsani pakumaliza.

3)

Pamene pamwamba roughness kufunika workpiece chofunika kukhala Ra0.8μm ~ 3.2μm, zikhoza kugawidwa mu masitepe atatu: roughing, theka-kumaliza ndi kumaliza. Kuchuluka kwa kudula kumbuyo panthawi yomaliza ndi 1.5mm ~ 2mm. Pomaliza, kuchuluka kwa kudula kumbuyo kuyenera kukhala 0.3mm ~ 0.5mm.

3. Kuwerengera kuchuluka kwa chakudya

Kuchuluka kwa chakudya kumatsimikiziridwa ndi kulondola kwa gawolo ndi kuuma kwapamwamba komwe kumafunikira, komanso pazinthu zomwe zasankhidwa pa chida ndi workpiece. Kuchuluka kwa chakudya kumatengera kulimba kwa makina komanso momwe makina amagwirira ntchito.

Mfundo zowunikira liwiro la chakudya:

1) Ngati mtundu wa workpiece ukhoza kutsimikiziridwa, ndipo mukufuna kuwonjezera kupanga bwino, ndiye kuti kuthamanga kwachangu kumalimbikitsidwa. Nthawi zambiri, liwiro la chakudya limayikidwa pakati pa 100m / min ndi 200m / min.

2) Ngati mukudula kapena kukonza mabowo akuya, kapena kugwiritsa ntchito zitsulo zothamanga kwambiri, ndi bwino kugwiritsa ntchito liwiro laling'ono la chakudya. Izi ziyenera kukhala pakati pa 20 ndi 50m / min.

Pamene kufunikira kwa kulondola kwa makina ndi kuuma kwa pamwamba kuli kwakukulu, ndi bwino kusankha liwiro laling'ono la chakudya, kawirikawiri pakati pa 20m / min ndi 50m / min.

Mukhoza kusankha mlingo wapamwamba wa chakudya chokhazikitsidwa ndi makina a CNC chida chida pamene chida sichikugwira ntchito, makamaka "kubwerera zero" patali.

4. Kutsimikiza kwa liwiro la spindle

Spindle iyenera kusankhidwa kutengera kuthamanga kwakukulu komwe kumaloledwa komanso kukula kwa chogwirira ntchito kapena chida chanu. Njira yowerengera liwiro la spindle ndi:

n=1000v/pD

Kukhazikika kwa chida kumatsimikizira liwiro.

Kuthamanga kwa spindle kumayesedwa mu r/min.

D -- M'mimba mwake kapena kukula kwa chida, kuyeza mu mm.

Liwiro lomaliza la spindle limawerengedwa posankha liwiro lomwe chida cha makina chingathe kukwaniritsa kapena kuyandikira, malinga ndi buku lake.

Posakhalitsa, mtengo wamtengo wodula ukhoza kuwerengedwa ndi fanizo, pogwiritsa ntchito makina, zolemba, ndi zochitika zenizeni. Kuthamanga kwa spindle ndi kuya kwa kudula kumatha kusinthidwa ku liwiro la chakudya kuti mupange kuchuluka koyenera kwa kudula.

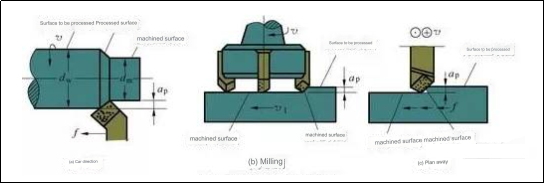

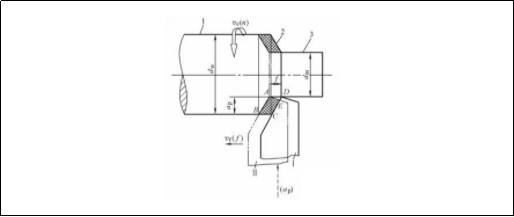

1) Kudula kumbuyo (kudula kuya) ap

Kudula kumbuyo ndi mtunda wowongoka pakati pa pamwamba kupita ku makina ndi pamwamba omwe adapangidwa. Kudula kumbuyo ndi kuchuluka kwa kudula kuyeza perpendicularly kwa ndege ya ntchito kudzera m'munsi mfundo. Kuzama kwa kudula ndi kuchuluka kwa kudula komwe chida chotembenuza chimapanga chogwirira ntchito ndi chakudya chilichonse. Kuchuluka kwa kudula kumbuyo kwa bwalo lakunja kumatha kuwerengedwa pogwiritsa ntchito njira ili pansipa:

ap = ( dw — dm ) /2

Mwachidule, ap——kuchuluka kwa mpeni kumbuyo (mm);

dw——Kutalikirana kwa pamwamba kuti kukonzedwa kwa workpiece (mm);

dm - m'mimba mwake mwa makina a workpiece (mm).

Chitsanzo 1:Amadziwika kuti m'mimba mwake wa workpiece kuti kukonzedwa ndi Φ95mm; tsopano m'mimba mwake ndi Φ90mm mu chakudya chimodzi, ndipo kuchuluka kwa kudula kumbuyo kumapezeka.

Yankho: ap = (dw — dm) /2= (95 —90) /2=2.5mm

2) Kuchuluka kwa chakudya f

The kusamutsidwa wachibale wa chida ndi workpiece mu malangizo a chakudya kuyenda kwa aliyense kusintha kwa workpiece kapena chida.

Malinga ndi njira zosiyanasiyana zodyetserako, zimagawidwa kukhala kuchuluka kwa chakudya chotalikirapo komanso kuchuluka kwa chakudya chodutsa. Kuchuluka kwa chakudya chotalikirapo kumatanthawuza kuchuluka kwa chakudya komwe kumayendera njanji yowongolera bedi lathe, ndipo kuchuluka kwa chakudya chodutsa kumatanthawuza komwe kumayenderana ndi njanji yowongolera bedi. Mtengo wa chakudya.

Zindikirani:Kuthamanga kwa chakudya vf kumatanthawuza kuthamanga kwanthawi yomweyo kwa malo osankhidwa pamphepete mwachitsulo chokhudzana ndi kayendedwe ka chakudya cha workpiece.

vf=fn

kumene vf——liwiro la chakudya (mm/s);

n——Liwiro la spindle (r/s);

f——kuchuluka kwa chakudya (mm/s).

3) Kudula liwiro vc

Nthawi yomweyo liwiro lalikulu zoyenda pa malo enieni pa kudula tsamba wachibale workpiece. Kuwerengeredwa ndi:

vc=(pdwn)/1000

Kumene vc —-kudula liwiro (m/s);

dw = m'mimba mwake kuti athandizidwe (mm);

-- Kuthamanga kwa kuzungulira kwa workpiece (r/min).

Kuwerengera kuyenera kupangidwa kutengera kuthamanga kwambiri kwa kudula. Mawerengedwe amayenera, mwachitsanzo, kutengera kukula kwake ndi kuchuluka kwa mavalidwe a pamwamba omwe akupangidwa.

Pezani vc. Chitsanzo 2: Potembenuza bwalo lakunja kwa chinthu chokhala ndi m'mimba mwake Ph60mm pa lathe, liwiro la spindle losankhidwa ndi 600r/min.

Yankho:vc=(pdwn)/1000 = 3.14x60x600/1000 = 113 m/mphindi

Pakupanga kwenikweni, ndizofala kudziwa kukula kwa chidutswacho. Kudula liwiro kumatsimikiziridwa ndi zinthu monga zinthu za workpiece, zida za zida ndi zofunikira pakukonza. Kuti musinthe lathe, liwiro lodulira limasinthidwa kukhala liwiro la spindle la lathe. Fomula iyi ikhoza kupezeka:

n=(1000vc)/pdw

Chitsanzo 3: Sankhani vc mpaka 90m/mphindi ndikupeza n.

Yankho: n = (1000v c)/ pdw=(1000×90)/ (3.14×260) =110r/mphindi

Pambuyo powerengera kuthamanga kwa lathe spindle, sankhani mtengo womwe uli pafupi ndi nambala, mwachitsanzo, n = 100r / min ngati liwiro lenileni la lathe.

3. Mwachidule:

Kudula ndalama

1. Kuchuluka kwa mpeni wakumbuyo ap (mm) ap= (dw – dm) / 2 (mm)

2. Kuchuluka kwa chakudya f (mm/r)

3. Kudula liwiro vc (m/min). Vc=dn/1000 (m/mphindi).

n=1000vc/d(r/mphindi)

Kufikira wamba wathuZida za aluminiyamu za CNCokhudzidwa, ndi njira zochepetsera mapindikidwe processing wa mbali zotayidwa?

Kukonzekera Kwabwino:

Kukonza workpiece molondola n'kofunika kuti kuchepetsa kupotoza pa makina. Powonetsetsa kuti zida zogwirira ntchito zakhazikika bwino, kugwedezeka ndi kusuntha kumatha kuchepetsedwa.

Adaptive Machining

Ndemanga za sensor zimagwiritsidwa ntchito kusintha magawo odulira mwamphamvu. Izi zimathandizira kusiyanasiyana kwazinthu, komanso zimachepetsa mapindikidwe.

Kudula Ma Parameters Kukhathamiritsa

Deformation imatha kuchepetsedwa pokulitsa magawo monga kudula liwiro, feedrate, ndi kudula mozama. Pochepetsa mphamvu zodulira ndi kupanga kutentha pogwiritsa ntchito magawo oyenera odulira, kupotoza kumatha kuchepetsedwa.

Kuchepetsa Kutulutsa Kutentha:

Kutentha komwe kumapangidwa popanga makina kumatha kupangitsa kuti matenthedwe asinthe komanso kukula. Kuti muchepetse kutentha, gwiritsani ntchito zoziziritsa kukhosi kapena zothira mafuta. Chepetsani liwiro lodula. Gwiritsani ntchito zida zapamwamba kwambiri.

Pang'onopang'ono Machining

Ndi bwino kupanga maulendo angapo pokonza aluminiyamu kusiyana ndi kudula kolemetsa. Kupanga pang'onopang'ono kumachepetsa kupindika pochepetsa kutentha ndi mphamvu zodulira.

Kutenthetsa:

Kutenthetsa aluminiyamu musanayambe kupanga kungachepetse chiopsezo cha kupotoza nthawi zina. Kutentha kumapangitsa kuti zinthuzo zikhale zokhazikika ndipo zimapangitsa kuti zisasokonezedwe pamene mukukonza.

Kuchepetsa Kupsinjika Maganizo

Kuchepetsa kupsinjika kumatha kuchitidwa mutapanga makina kuti muchepetse kupsinjika kotsalira. Gawolo likhoza kukhazikika politentha ku kutentha kwina, kenaka kuziziritsa pang'onopang'ono.

Kusankha Zida Zoyenera

Kuti muchepetse kusinthika, ndikofunikira kusankha zida zoyenera zodulira, zokhala ndi zokutira zoyenera ndi ma geometries. Zida zopangidwa mwapadera zopangira ma aluminium machining zimachepetsa mphamvu zodulira, kukonza kutha kwa pamwamba, ndikuletsa kupanga m'mphepete mwake.

Machining mu magawo:

Ntchito zambiri zamakina kapena magawo angagwiritsidwe ntchito kugawa mphamvu zodulira pazovutamagawo a aluminiyamu a cncndi kuchepetsa deformation. Njirayi imalepheretsa kupsinjika komwe kumakhalapo komanso kumachepetsa kupotoza.

Kufunafuna kwa Anebon ndi cholinga chakampani nthawi zonse ndi "Nthawi zonse kukwaniritsa zomwe ogula amafuna". Anebon pitilizani kupeza ndi kupanga masitayelo apamwamba kwambiri kwa makasitomala athu akale komanso atsopano ndikupeza mwayi wopambana kwa ogula a Anebon komanso ife ku Original Factory Profile extrusions aluminium,cnc anatembenuka gawo, cnc mphero nayiloni. Timalandila abwenzi moona mtima kusinthanitsa mabizinesi ndikuyamba mgwirizano nafe. Anebon akuyembekeza kugwirana manja ndi abwenzi apamtima m'mafakitale osiyanasiyana kuti apange tsogolo labwino.

China Manufacturer wa China High Precision and Metal Stainless Steel Foundry, Anebon akufunafuna mwayi wokumana ndi abwenzi onse ochokera kunyumba ndi kunja kuti apambane. Anebon akuyembekeza moona mtima kukhala ndi mgwirizano wanthawi yayitali ndi nonse pamaziko a phindu limodzi ndi chitukuko chofanana.

Ngati mukufuna kudziwa zambiri, chonde lemberani gulu la Anebon painfo@anebon.com.

Nthawi yotumiza: Nov-03-2023