1 kudula ulusi

Nthawi zambiri, amatanthauza njira yopangira ulusi pa workpiece ndi chida chopangira kapena chida chopera, makamaka kuphatikiza kutembenuza, mphero, kugogoda ndi kupukuta, kupukuta ndi kudula kamvuluvulu, etc. chida cha makina chimatsimikizira kuti chida chokhotakhota, chodula mphero kapena gudumu lopukuta chimasuntha chitsogozo molondola komanso molingana ndi njira ya axial ya workpiece kuzungulira kulikonse kwa workpiece. Pogogoda kapena ulusi, chida (pampopi kapena kufa) chimazungulira chogwirizana ndi chogwiritsira ntchito, ndipo choyamba chopangidwa ndi ulusi chimatsogolera chida (kapena chogwirira ntchito) kuti chisunthe axially.

2 kutembenuka kwa ulusi

Chida chotembenuza kapena chida chokhomerera ulusi chingagwiritsidwe ntchito potembenuza ulusi pa lathe (onani chida chopangira ulusi). Kutembenuza ulusi ndi chida chosinthira ndi njira wamba yachidutswa chimodzi ndi kupanga batch yaying'ono ya ulusi wopangira ulusi chifukwa cha kapangidwe kake kosavuta; kutembenuza ulusi ndi chida chophatikizira ulusi kumakhala bwino kwambiri, koma mawonekedwe ake ndi ovuta, kotero ndi oyenera kutembenuza ulusi waufupi wokhala ndi mano abwino pakupanga batch yayikulu komanso yayikulu. Kulondola kwa phula kwa kutembenuza ulusi wa trapezoidal ndi lathe wamba kumatha kufika pamiyeso ya 8-9 (jb2886-81, chimodzimodzi pansipa); zokolola kapena kulondola kungawongoleredwe bwino kwambiri popanga ulusi pa ulusi wapadera wa lathe.

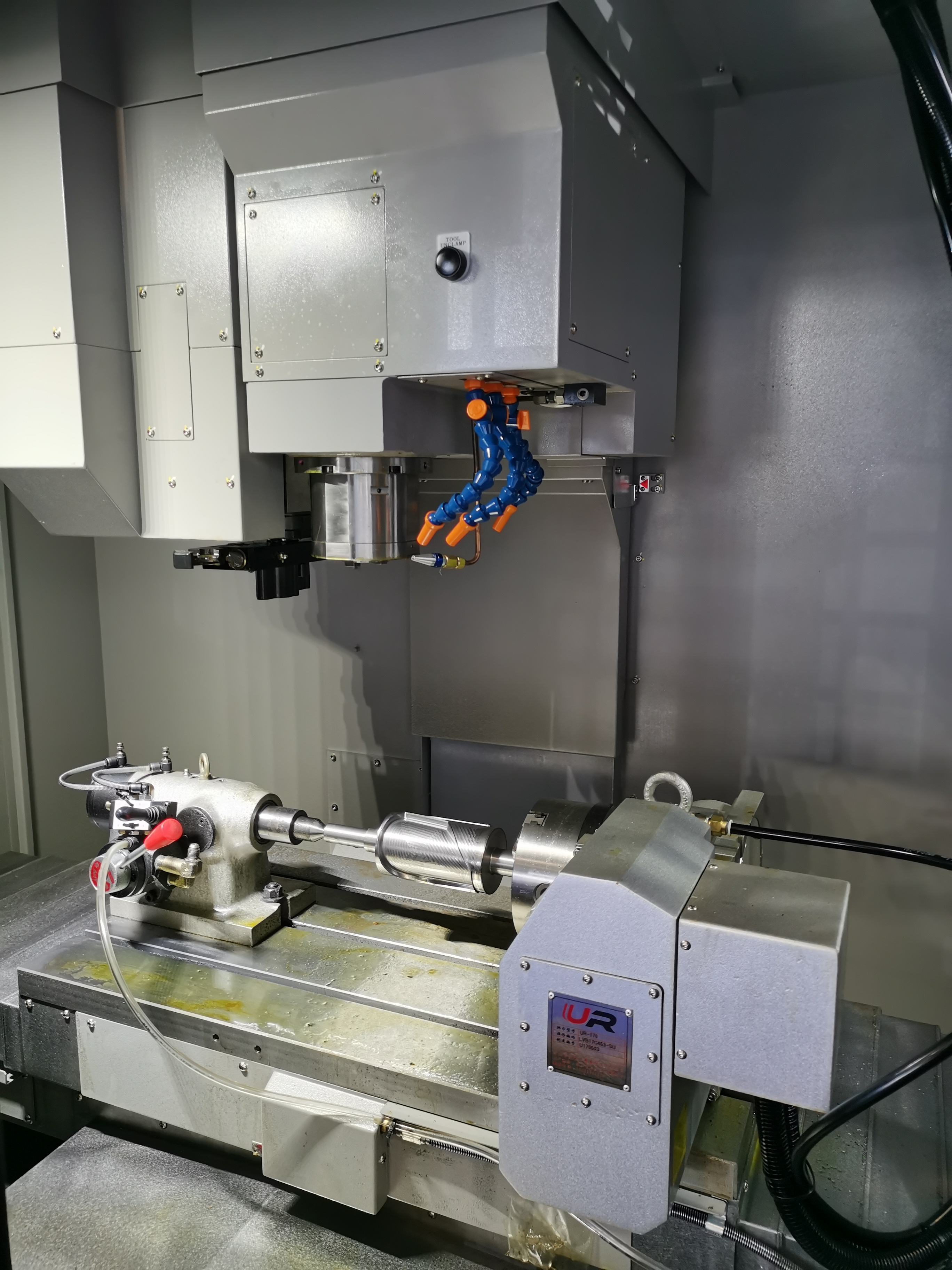

3 kugaya ulusi

Pa makina opera ulusi, chodulira mphero cha disc kapena chodulira mphero chimagwiritsidwa ntchito pogaya. Chimbale mphero wodula zimagwiritsa ntchito mphero trapezoid kunja ulusi wa wononga ndodo, nyongolotsi ndi workpieces ena. Chisa chodula mphero chimagwiritsidwa ntchito mphero mkati ndi kunja wamba ulusi ndi taper ulusi. Chifukwa kutalika kwa gawo lake logwirira ntchito ndi lalitali kuposa kutalika kwa ulusi womwe umakonzedwa ndi chodula cham'mphepete mwa mipikisano, chogwiriracho chimatha kukonzedwa kokha ndi kuzungulira kwa 1.25-1.5, ndikuchita bwino kwambiri. Kulondola kwa phula kwa ulusi mphero kungafikire magiredi 8-9, ndipo kukhaula pamwamba ndi r5-0.63 μ M. Njira iyi ndiyoyenera kupanga ulusi wambiri wa ulusi kapena ulusi wovuta musanagaye.

4 ulusi akupera

Amagwiritsidwa ntchito makamaka pokonza ulusi wolondola wa chopukusira ulusi. Malinga ndi mawonekedwe osiyanasiyana a gudumu lopera, amatha kugawidwa m'mitundu iwiri: gudumu lopukutira mzere umodzi ndi gudumu lopera la mizere yambiri. Kulondola kwa phula la gudumu lopukuta mzere umodzi ndi magiredi 5-6, ndipo kuuma kwapamwamba ndi r1.25-0.08 μ m, kotero ndikosavuta kumaliza gudumu lopera. Njirayi ndi yoyenera kugaya mwatsatanetsatane wononga, geji ya ulusi, nyongolotsi, tinthu tating'ono ta ulusi ndi hob yolondola. Pali mitundu iwiri ya njira zopera: kugaya kotalika ndi kudula mukupera. M'lifupi mwa gudumu lopera ndi njira yopera yotalika ndi yocheperapo kutalika kwa ulusi woti upere, ndipo ulusi ukhoza kupukutidwa mpaka kukula komaliza pambuyo poti gudumu lopera likuyenda motalika kamodzi kapena kangapo. M'lifupi gudumu lopera la chodulidwa mu njira yopera ndi yayikulu kuposa kutalika kwa ulusi woti upere. Gudumu logaya limadula pamwamba pa chogwirira ntchito mozungulira, ndipo chogwiriracho chimatha kupukutidwa pambuyo pa kutembenuka kwa 1.25. Zokolola ndizokwera, koma kulondola kumakhala kotsika pang'ono, ndipo kuvala kwa gudumu lopera kumakhala kovuta kwambiri. Njira yodulira ndi yoyenera kufosholo matepi ochuluka komanso popera ulusi womangira. Metal processing, woyenera chidwi!

5 ulusi akupera

Chida cha nati kapena wononga ulusi chimapangidwa ndi zinthu zofewa monga chitsulo choponyedwa. Zigawo za ulusi wokonzedwa pa workpiece zokhala ndi vuto la phula zimapukutidwa ndi matembenuzidwe a kutsogolo ndi kumbuyo kuti mawuwo amveke bwino. Ulusi woumitsa wamkati nthawi zambiri umathetsedwa ndi kugaya kuti ukhale wolondola.

6 kugogoda ndi ulusi

Kugogoda ndiko kugwiritsa ntchito torque inayake kukhomera mpopi mu dzenje lobowoledwa kale pachogwirira ntchito kuti mukonze ulusi wamkati.

Kuwombera ndikudula ulusi wakunja pa bar (kapena chubu) chogwirira ntchito ndi kufa. Kulondola kwa makina pakugogoda kapena ulusi kumatengera kulondola kwa tap kapena kufa. Ngakhale pali njira zambiri zopangira ulusi wamkati ndi kunja, ulusi wamkati waung'ono ukhoza kukonzedwa ndi matepi. Kugogoda ndi ulusi kutha kuchitidwa ndi dzanja kapena ndi lathe, makina obowola, makina opopera ndi makina opangira ulusi.

7 kugudubuza ulusi

The processing njira kupanga ndi anagubuduza kufa kubala mapindikidwe pulasitiki workpiece kupeza ulusi anagubuduza zambiri ikuchitika pa ulusi anagubuduza makina kapena lathe basi Ufumuyo ndi kutsegula basi ndi kutseka ulusi anagubuduza mutu, amene ali oyenera kupanga misa ulusi kunja. chitsanzo cha zomangira muyezo ndi mfundo zina ulusi. Nthawi zambiri, kutalika kwa ulusi wozungulira sikupitirira 25 mm, kutalika kwake sikuposa 100 mm, ndipo kulondola kwa ulusi kumatha kufika pamlingo wa 2 (gb197-63). Kutalika kwa chinthu chomwe sichinasonkhanitsidwe chimakhala chofanana ndi kukula kwa ulusi womwe uyenera kukonzedwa. Nthawi zambiri, ulusi wamkati sungathe kukonzedwa ndi kugubuduza, koma kwa workpiece yofewa, ulusi wozizira wamkati ungagwiritsidwe ntchito popanda kagawo kakang'ono kamene kamakhala (m'mimba mwake mpaka 30mm), ndipo mfundo yogwira ntchito ndi yofanana ndi kugogoda. Makokedwe ofunikira pakutulutsa kozizira kwa ulusi wamkati ndi wokulirapo kuwirikiza ka 1 kuposa kugunda, ndipo kulondola kwa makina ndi mtundu wapamtunda ndizokwera pang'ono kuposa kugunda.

Ubwino wakugudubuza ulusi ndi motere: ① kukhwinyata kwa pamwamba ndikocheperako kuposa kutembenuka, mphero ndi kugaya; ② pamwamba pa ulusi pambuyo pakugubuduza kumatha kulimbitsa mphamvu ndi kuuma chifukwa cha kuzizira kwa ntchito; ③ kuchuluka kwa zinthu zomwe zimagwiritsidwa ntchito ndizokwera; ④ zokolola zimachulukitsidwa kawiri poyerekeza ndi kudula, ndipo ndikosavuta kuzindikira makina; ⑤ moyo wautumiki wa rolling kufa ndi wautali kwambiri. Komabe, kuuma kwa workpiece zakuthupi sikuposa hrc40, kulondola kwa kukula kopanda kanthu kumafunika kukhala kwapamwamba, kulondola ndi kuuma kwa kufa kwa gudumu kumafunikanso kukhala kwakukulu, kotero zimakhala zovuta kupanga kufa, ndipo siyoyenera ulusi wokhala ndi asymmetric rolling Profile.

Malingana ndi mitundu yosiyanasiyana yogubuduza, kugudubuza ulusi kumatha kugawidwa m'mitundu iwiri: kugudubuza ulusi ndi kugudubuza ulusi.

Ma mbale awiri ogubuduza ulusi okhala ndi mbiri ya ulusi amasunthidwa ndi 1/2 phula, ndipo mbale yokhazikika imakhazikika, ndipo mbale yosuntha imayenda mumzere wowongoka wowongoka wofanana ndi mbale yosasunthika. Mukufuna kuphunzira UG mapulogalamu mu gulu 565120797 kungakuthandizeni, pamene workpiece mu mbale ziwiri, kusuntha mbale patsogolo kupaka ndi kukanikiza workpiece, kupanga pamwamba ake mapindikidwe pulasitiki kukhala ulusi.

Pali mitundu itatu ya kugudubuza: kugudubuza kozungulira, kugudubuza kozungulira komanso kugudubuza mutu.

① Kugudubuzika kwa ulusi wozungulira: mawilo awiri (kapena atatu) ozungulira ulusi amaikidwa pamiyendo yofanana, chogwirira ntchito chimayikidwa pa chothandizira pakati pa mawilo awiri, ndipo mawilo awiriwo amazungulira pa liwiro lomwelo mbali imodzi, zomwe zimapanganso kayendedwe ka radial feed. Chogwirira ntchito chimayendetsedwa ndi gudumu lozungulira kuti lizizungulira, ndipo pamwamba pake amatuluka mozungulira kuti apange ulusi. Njira yolumikizira yofananira ingagwiritsidwenso ntchito pazomangira zina zokhala ndi zofunikira zochepa zolondola.

(2) Kugudubuzika kwa ulusi: kumadziwikanso kuti kugudubuzika kwa ulusi wapadziko lapansi. Chida chogudubuza chimakhala ndi gudumu lozungulira lapakati ndi ulusi wokhazikika wokhala ngati arc. Pakugubuduza, workpiece akhoza kudyetsedwa mosalekeza, kotero zokolola ndi apamwamba kuposa ulusi kusisita ndi ma radial kugudubuza.

③ Kugudubuzika kwa ulusi wa ulusi: kumapangidwa pa lathe yokha ndipo nthawi zambiri amagwiritsidwa ntchito pokonza ulusi waufupi pa workpiece. Pali zodzigudubuza 3-4 zomwe zimagawidwa mofanana mozungulira chogwirira ntchito. Pogubuduza, chogwirira ntchito chimazungulira, ndipo mutu wozungulira umadyetsa axially kuti utulutse ulusiwo.

| Cnc Machining Components | Amazing Cnc Machining | Cnc Online Service |

| Machining Aluminium Parts | Zigawo za Machining Ndege | Custom Metal Manufacturing |

| Cnc Processing | Zida Zopangidwa ndi Brass | Magawo a Brass Cnc |

www.anebon.com

Anebon Metal Products Limited ikhoza kupereka makina a CNC, kuponyera kufa, ntchito zopangira zitsulo, chonde omasuka kutilankhula nafe.

Tel: +86-769-89802722 Email: info@anebon.com Website : www.anebon.com

Nthawi yotumiza: Oct-04-2019