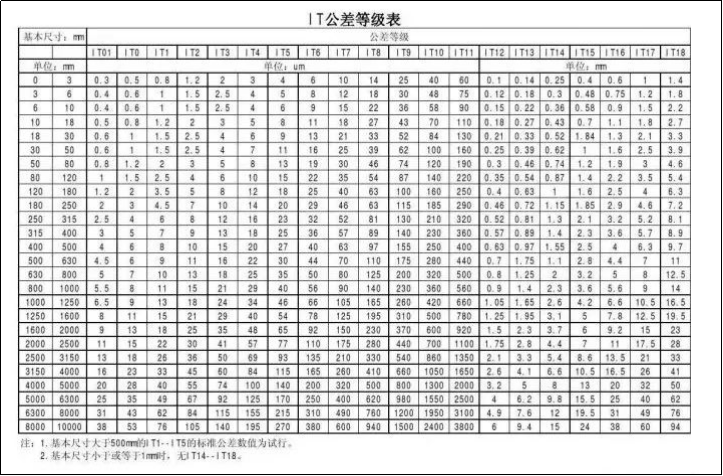

The Machining mwatsatanetsatane zimagwiritsa ntchito kusonyeza fineness mankhwala, mongaCNC kutembenuza magawondiCNC mphero zigawo, ndipo ndi mawu omwe amagwiritsidwa ntchito poyesa magawo a geometric a malo opangidwa ndi makina. Kulondola kwa Machining kumayesedwa ndi kulekerera kalasi. Mtengo wa giredi wocheperako, umakhala wolondola kwambiri.

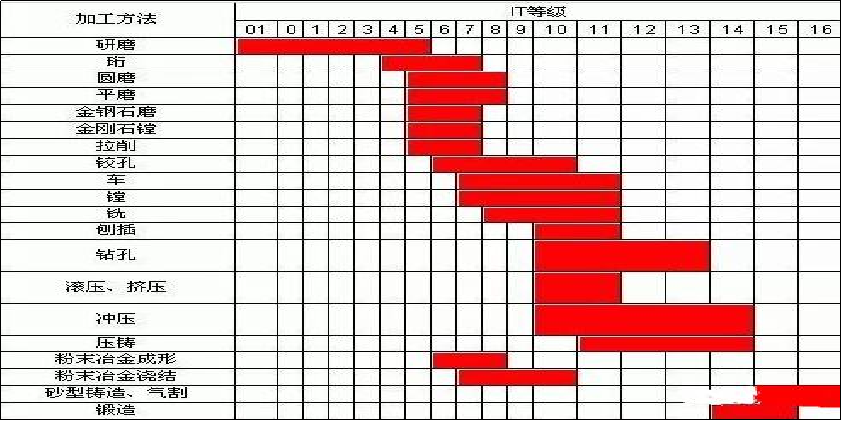

Pali makalasi 20 olekerera kuchokera ku IT01, IT0, IT1, IT2, IT3 mpaka IT18, pomwe IT01 imayimira kulondola kwambiri kwa gawolo, IT18 imayimira kulondola kwapang'onopang'ono kwa gawolo, makina amigodi wamba ndi a IT7, komanso zaulimi wamba. makina ndi a IT8. Malinga ndi ntchito zosiyanasiyana zamagulu azinthu, kulondola kwa makina kumafunika kuti kukwaniritsidwe komanso mawonekedwe opangira ndi njira zosankhidwa zimasiyananso. Pepalali likuwonetsa kulondola kwa makina otembenuza, mphero, kupanga, kugaya, kubowola, kutayitsa, ndi mitundu ina yodziwika bwino.

Kusintha kwa CNC

Njira yodulira yomwe chogwirira ntchito chimazungulira ndipo chida chotembenuza chimayenda molunjika kapena pamapindikira mu ndege. Kutembenuza nthawi zambiri kumachitika pa lathe, yomwe imagwiritsidwa ntchito pokonza malo amkati ndi kunja kwa cylindrical, nkhope zakumapeto, zowoneka bwino, zopanga, ndi ulusi wazinthu zogwirira ntchito.

Kutembenuka kolondola nthawi zambiri kumakhala IT8-IT7, ndipo kuuma kwapamtunda ndi 1.6-0.8 μ m.

1) Kutembenuza kovutirako kumatengera kuya kocheperako komanso kuchuluka kwa chakudya kuti apititse patsogolo kusinthasintha popanda kuchepetsa kuthamanga. Komabe, kulondola kwa makina kumangofikira IT11, ndipo kuuma kwapamtunda ndi R α 20—10 μ m.

2) Kuthamanga kwambiri, kuchuluka kwa chakudya chochepa, ndi kuya kwakuya zidzalandiridwa momwe zingathere kuti mutembenuzire theka-malize ndi kutembenuka. Kulondola kwa makina kumatha kufika IT10-IT7, ndipo kuuma kwapamwamba ndi R α 10-0.16 μ m.

3) Kutembenuza kothamanga kwambiri kwazitsulo zopanda chitsulo ndi chida chotembenuzira cha diamondi chopukutidwa bwino pa lathe yolondola kwambiri kungapangitse kulondola kwa makina kufika IT7-IT5, ndipo kuuma kwapamwamba ndi R α 0.04-0.01 μ m. Kutembenuka kwamtunduwu kumatchedwa "kutembenuka kwagalasi."

CNC Milling

Kugaya kumatanthawuza kutembenuza zida zamitundu yambiri zodula zogwirira ntchito, njira yabwino kwambiri yopangira. Ndizoyenera kupanga ndege, ma grooves, malo osiyanasiyana opangira (monga spline, zida, ndi ulusi), komanso mawonekedwe apadera akufa. Iwo akhoza kugawidwa m'tsogolo mphero ndi n'zosiyana mphero malinga ndi njira yomweyo kapena zosiyana za liwiro waukulu kayendedwe ndi workpiece chakudya malangizo pa mphero.

Kulondola kwa makina a mphero nthawi zambiri kumatha kufika IT8~IT7, ndipo kuuma kwapansi ndi 6.3 ~ 1.6 μ m.

1) Kulondola kwa makina panthawi ya mphero ndi IT11 ~ IT13, ndipo kuuma kwapamwamba ndi 5 ~ 20 μ m.

2) Machining kulondola IT8~IT11 ndi pamwamba roughness 2.5~10 mu theka-mwatsatanetsatane mphero μ m.

3) Kulondola kwa makina pa mphero yolondola ndi IT16 ~ IT8, ndipo kuuma kwapamwamba ndi 0.63 ~ 5 μ m.

Kukonzekera

Kukonzekera ndi njira yodulira yomwe imagwiritsa ntchito pulani kuti ipangitse kusuntha kwachibale kopingasa molunjika pa chogwirira ntchito, chomwe chimagwiritsidwa ntchito kwambiri pokonza magawo.

Kulondola kwa makina a planing kumatha kufika IT9~IT7, ndipo kuuma kwapamtunda ndi Ra6.3 ~ 1.6 μ m.

1) Kulondola kwa makina okhwima kumatha kufikira IT12 ~ IT11, ndipo kuuma kwapamwamba ndi 25 ~ 12.5 μ m.

2) Theka-kumaliza makina olondola akhoza kufika IT10 ~ IT9, ndipo pamwamba roughness ndi 6.2 ~ 3.2 μ m.

3) Kukonzekera bwino kwa kumaliza kumatha kufika IT8~IT7, ndipo kuuma kwapansi ndi 3.2 ~ 1.6 μ m.

Kupera

Kugaya kumatanthauza njira yogwiritsira ntchito zida zowonongeka ndi zowonongeka kuti zidulire zinthu zowonjezera pa workpiece, zomwe zimakhala zomaliza ndipo zimagwiritsidwa ntchito kwambiri pamakampani opanga makina.

Kupera nthawi zambiri kumagwiritsidwa ntchito pomaliza ndi kumaliza, ndi kulondola kwa IT8~IT5 kapena kupitilira apo, ndipo kuuma kwapamwamba kumakhala 1.25~0.16 μ m.

1) Kuuma kwapamtunda kwa mphesa molondola ndi 0.16 ~ 0.04 μ m.

2) Kukula kwapamwamba kwambiri pogaya ndi 0.04-0.01 μ m.

3) Kuuma kwapamwamba kwa galasi kugaya kumatha kufika 0.01 μ M pansipa.

Kubowola

Kubowola ndi njira yofunika kwambiri pokonza dzenje. Kubowola kumachitika pamakina obowola ndi ma lathes kapena makina otopetsa kapena opera.

Kulondola kwa makina pakubowola kumakhala kochepa, nthawi zambiri kumafika ku IT10, ndipo kuuma kwapamtunda ndi gtypically12.5 ~ 6.3 μ m. Pambuyo pobowola, kubwezeretsanso ndi kubwezeretsanso nthawi zambiri kumagwiritsidwa ntchito pomaliza kumaliza.

Zotopetsa

Boring ndi njira yodula m'mimba mwake yomwe imagwiritsa ntchito chida chokulitsa dzenje kapena zozungulira. Kagwiritsidwe ntchito kake nthawi zambiri kumachokera ku makina ovuta kwambiri mpaka kumaliza. Chidacho nthawi zambiri chimakhala chida cham'mphepete chimodzi (chotchedwa boring bar).

1) Kulondola kosasangalatsa kwa zida zachitsulo kumatha kufika IT9 ~ IT7, ndipo kuuma kwapansi ndi 2.5 ~ 0.16 μ m.

2) Kulondola kwa makina otopetsa mwatsatanetsatane kumatha kufika IT7 ~ IT6, ndipo kuuma kwapamwamba ndi 0.63 ~ 0.08 μ m.

Nthawi yotumiza: Nov-22-2022