Kubereka ndi chiyani?

Zimbalangondo ndi zigawo zomwe zimathandizira tsinde, zomwe zimagwiritsidwa ntchito kutsogolera kayendetsedwe ka shaft, ndikunyamula katundu wochokera kumtengo kupita ku chimango. Ma bearings amagwiritsidwa ntchito kwambiri komanso amafunikira magawo othandizira ndi magawo oyambira pamakina. Ndizigawo zothandizira ma shafts ozungulira kapena magawo osunthika a makina osiyanasiyana, komanso ndi zigawo zothandizira zomwe zimadalira kugudubuza kwa matupi ogubuduza kuti azindikire kuzungulira kwa injini yaikulu. Amadziwika kuti ma mechanical joints.

Kodi ma bearings ayenera kugawidwa bwanji?

Malingana ndi mitundu yosiyanasiyana ya mikangano pamene magazini imagwira ntchito, zotengerazo zimagawidwa m'magulu awiri:

mayendedwe otsetsereka ndi mayendedwe ogudubuza.

-

Plain kubereka

Malingana ndi momwe katunduyo amayendera, zitsulo zotsetsereka zimagawidwa m'magulu atatu:①Radial bearing--kunyamula katundu wa radial, ndipo mayendedwe olemetsa amakhala pakatikati pa shaft;

②Kuthyola——kunyamula katundu wa axial, ndipo njira yolemetsa imayenderana ndi mzere wapakati wa kutsinde;

③Radial-thrust bear--nthawi imodzi imanyamula katundu wozungulira ndi axial.

Malingana ndi momwe mikangano imakhalira, mayendedwe otsetsereka agawidwa m'magulu awiri: zitsulo zosasunthika zopanda madzi komanso zotsekemera zamadzimadzi. Yoyamba ili mumkhalidwe wa kukangana kowuma kapena kukangana kwa malire, ndipo yotsirizirayo ili m'nyengo yamadzimadzi.

-

kugudubuza kubereka

(1) Malinga ndi momwe katundu akuyendetsedwera, akhoza kugawidwa kukhala:①Zokhala ndi ma radial makamaka zimanyamula katundu wozungulira.

②Thrust bear imanyamula katundu wa axial.

(2) Malinga ndi mawonekedwe a zinthu zogubuduza, zitha kugawidwa kukhala: mayendedwe a mpira ndi mayendedwe odzigudubuza. Zinthu zogubuduza muzotengera zimakhala ndi mzere umodzi ndi mizere iwiri.

(3) Malinga ndi kalozera wa katundu kapena ngodya yolumikizirana mwadzina ndi mtundu wa zinthu zogubuduza, zitha kugawidwa m'magulu awiri:

1. Mipira yozama yakuya.

2. Cylindrical wodzigudubuza mayendedwe.

3. Zovala za singano.

4. Kudzigwirizanitsa ndi mpira.

5. Angular kukhudzana mpira mayendedwe.

6. Zozungulira zozungulira.

7. Tapered wodzigudubuza mayendedwe.

8. Kukankhira mayendedwe ang'onoang'ono a mpira.

9. Kondani mayendedwe ozungulira ozungulira.

10. Kukankhira tapered wodzigudubuza mayendedwe.

11. Kukankhira mpira mayendedwe.

12. Kukantha cylindrical wodzigudubuza mayendedwe.

13. Kukankha singano wodzigudubuza mayendedwe.

14. Zimbalangondo zamagulu.

Mu mayendedwe ogudubuza, pali mfundo kapena mzere kukhudzana pakati pa zinthu zogudubuza ndi msewu wothamanga, ndipo kukangana pakati pawo ndi kukangana. Liwiro likakhala lalitali, moyo wa chonyamuliracho umatsika kwambiri; pamene katundu ndi waukulu ndipo zotsatira zake ndi zazikulu, ndi kugubuduza kubala mfundo kapena mizere kukhudzana.

M'mayendedwe otsetsereka, pali kukhudzana kwapamtunda pakati pa magazini ndi zonyamula, ndi kukangana kotsetsereka pakati pa malo olumikizana. Mapangidwe a chotengera chotsetsereka ndikuti magaziniyo imagwirizana ndi chitsamba chonyamula; mfundo kusankha ndi kupereka patsogolo kusankha kugubuduza fani, ndi ntchito kutsetsereka mayendedwe mu milandu yapadera. Kutsetsereka konyamula pamwamba kukhudzana; mawonekedwe apadera amafunikira mawonekedwe apamwamba kwambiri, ndipo mtengo wamayendedwe otsetsereka ndi otsika.

-

Ma bearings amagawidwa kukhala ma fani a radial ndi ma thrust fani molingana ndi komwe amalowera kapena ngodya yolumikizirana mwadzina.

-

Malinga ndi mtundu wa chinthu chogubuduza, chimagawidwa kukhala: mayendedwe a mpira, mayendedwe odzigudubuza.

-

Malingana ndi momwe angagwirizanitsire, amagawidwa kukhala: mayendedwe odzipangira okha, osagwirizana (olimba mayendedwe).

-

Malingana ndi chiwerengero cha mizere ya zinthu zogubuduza, zimagawidwa kukhala: mayendedwe a mzere umodzi, mizere iwiri, ndi mizere yambiri.

-

Malingana ndi ngati zigawozo zikhoza kupatulidwa, zimagawidwa kukhala: mayendedwe olekanitsidwa ndi mayendedwe osalekanitsidwa.

Komanso, pali magulu ndi structural mawonekedwe ndi kukula.

Nkhaniyi imagawana makamaka mawonekedwe, kusiyana ndi kugwiritsiridwa ntchito kofanana kwa 14 mayendedwe wamba.

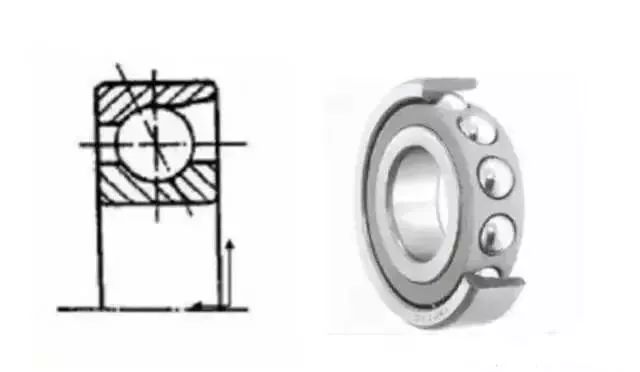

1. Angular kukhudzana mpira mayendedwe

Pali njira yolumikizirana pakati pa ferrule ndi mpira. Njira yolumikizirana ndi 15 °, 30 ° ndi 40 °. Kukula kwa ngodya yolumikizana ndi, ndikokulirapo kwa mphamvu ya axial. Kucheperako komwe kumakhala kolumikizana, ndikokomera kwambiri kuzungulira kothamanga kwambiri. Mizere ya mzere umodzi imatha Kunyamula katundu wa radial ndi njira imodzi ya axial. Pamapangidwe ake, mizere iwiri yolumikizana ndi mizere yolumikizana kumbuyo imagawana mphete yamkati ndi mphete yakunja, yomwe imatha kunyamula katundu wa radial ndi bidirectional axial load.

Angular kukhudzana mpira mayendedwe

Cholinga chachikulu:

Mzere umodzi: spindle chida cha makina, mota yama frequency apamwamba, turbine ya gasi, cholekanitsa chapakati, gudumu lakutsogolo lagalimoto yaying'ono, pinion shaft yosiyana.

Mzere wapawiri: pampu yamafuta, chowombera Mizu, kompresa ya mpweya, ma transmission osiyanasiyana, pampu ya jakisoni wamafuta, makina osindikizira.

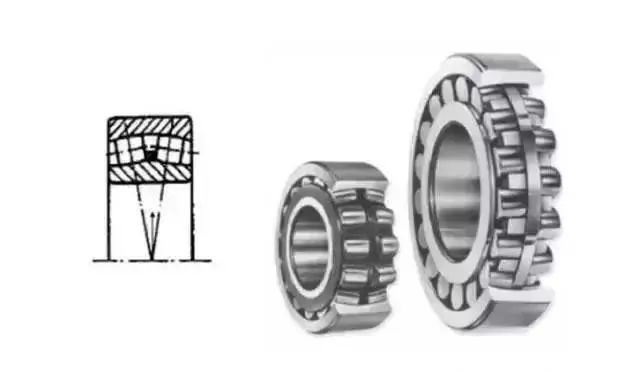

2. Kudzigwirizanitsa ndi mpira

Mizere iwiri ya mipira yachitsulo, mpikisano wa mphete yakunja ndi mtundu wamkati wozungulira, kotero ukhoza kusintha kusintha kolakwika kwa shaft chifukwa cha kupotoza kapena kusalongosoka kwa shaft kapena chipolopolo, ndipo kunyamula ndi dzenje la tapered kungakhale kosavuta. amaikidwa pa shaft pogwiritsa ntchito zomangira. kupirira katundu wa radial.

Mpira wodzipangira okha

Ntchito yayikulu: makina opangira matabwa, shaft yotumizira makina ojambulira, yodziyimira payokha yokhala ndi mpando.

3. Zozungulira zozungulira

Mtundu woterewu umakhala ndi zodzigudubuza zozungulira pakati pa mphete yakunja ya msewu wozungulira komanso mphete yamkati yanjira yapawiri. Malinga ndi mapangidwe amkati osiyanasiyana, amagawidwa m'mitundu inayi: R, RH, RHA ndi SR. Malo onyamula ndi okhazikika ndipo ali ndi machitidwe odzigwirizanitsa okha, kotero amatha kusintha molakwika pakati pa shaft chifukwa cha kupotoza kapena kusokonezeka kwa shaft kapena chipolopolo, ndipo amatha kunyamula katundu wa radial ndi bidirectional axial load.

Zozungulira zozungulira

Ntchito zazikulu: makina opangira mapepala, zida zochepetsera, ma axle agalimoto ya njanji, mipando ya magiya ogubuduza, matebulo ogubuduza mphero, ma crushers, zowonera zonjenjemera, makina osindikizira, makina opangira matabwa, zochepetsera m'mafakitale osiyanasiyana, mayendedwe odziyimira okha okhala ndi mipando.

4. Kukankhira wodzigudubuza wodzigudubuza

Zodzigudubuza zozungulira mumtundu woterewu zimakonzedwa mozungulira.Chifukwa chakuti msewu wothamanga wa mphete ya mpando ndi wozungulira komanso umakhala wodzigwirizanitsa, ukhoza kulola kuti shaft ikhale ndi malingaliro ena, ndipo mphamvu ya axial katundu ndi yaikulu kwambiri.

Ma radial katundu nthawi zambiri amathiridwa ndi mafuta.

Mapiritsi ozungulira ozungulira

Ntchito zazikuluzikulu: ma hydraulic jenereta, ma mota oyimirira, ma propeller shafts a zombo, zochepetsera zomangira zomangira mphero, ma crane a nsanja, mphero zamakala, makina otulutsa, ndi makina opangira.

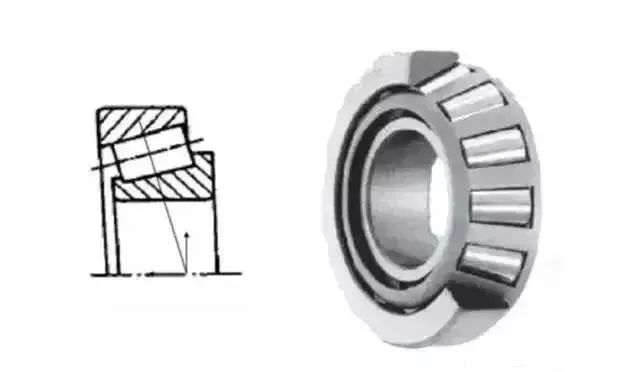

5. Tapered wodzigudubuza mayendedwe

Mtundu woterewu uli ndi ma roller a truncated cylindrical, ndipo odzigudubuza amatsogoleredwa ndi nthiti yaikulu ya mphete yamkati. Pansonga yamtundu uliwonse wamtundu wamtundu wamkati wa mphete, msewu wakunja wa mphete ndi wodzigudubuza umadutsa pakati pa mzere wapakati wa kamangidwe. pa mfundo. Mizere ya mzere umodzi imatha kunyamula katundu wa radial ndi njira imodzi ya axial katundu, mizere iwiri ya mizere imatha kunyamula katundu wa radial ndi njira ziwiri za axial, ndipo ndi yoyenera katundu wolemetsa ndi katundu wokhudzidwa.

Tapered Roller Bearings

Ntchito yayikulu:Galimoto: gudumu lakutsogolo, gudumu lakumbuyo, kufala, kusiyanitsa kwa pinion shaft. Makina opangira zida zamakina, makina omangira, makina akulu aulimi, zida zochepetsera zida zamagalimoto a njanji, ma khosi opukutira ndi zida zochepetsera mphero.

Kodi pali kulumikizana kotani pakati pa ma bearings ndi CNC?

Bearing ndi CNC Machining amalumikizana kwambiri munjira zamakono zopangira. Makina a CNC (Computer Numerical Control) amagwiritsidwa ntchito kuwongolera ndi kusinthira makinawo, pogwiritsa ntchito makina othandizidwa ndi makompyuta (CAD) ndi mapulogalamu opangira makompyuta (CAM) kuti apange magawo ndi zinthu zolondola kwambiri. Ma bearings ndi gawo lofunikira kwambiri pamakina ozungulira komanso ozungulira a makina a CNC, omwe amapereka chithandizo ndikuchepetsa kukangana pakati pa magawo ozungulira. Izi zimalola kuyenda kosalala komanso kolondola kwa chida chodulira kapena chogwirira ntchito, zomwe zimapangitsa mabala olondola komanso zinthu zapamwamba zomalizidwa.

CNC makinandi teknoloji yobereka yathandizira kwambiri kupanga bwino ndi kulondola, kulola opanga kupanga zigawo zovuta ndi kulolerana kolimba pamlingo wachangu kwambiri kuposa njira zamakina zamakina. Ponseponse, kuphatikiza kwaCNC Machining magawondi teknoloji yobereka yasintha kupanga zamakono ndikuthandizira kupanga zigawo zapamwamba ndi zinthu zambiri pamlingo waukulu.

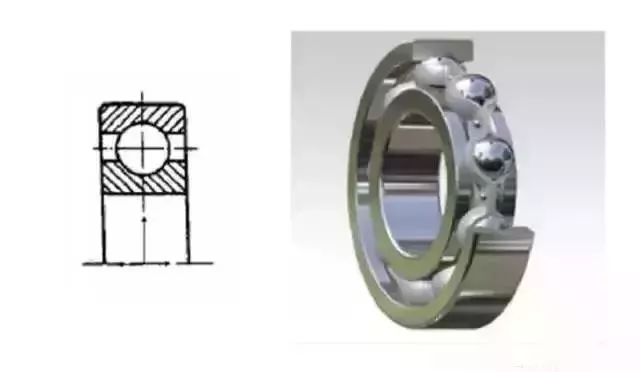

6. Mipira yozama ya groove

Mwamadongosolo, mphete iliyonse ya mpira wakuzama wa groove imakhala ndi mtundu wopitilira wamtundu wa groove wokhala ndi gawo limodzi mwamagawo atatu a mpirawo. Mipira yozama kwambiri imagwiritsidwa ntchito makamaka kunyamula katundu wa radial, komanso imatha kunyamula katundu wina wa axial.

Chilolezo cha radial chikachulukirachulukira, chimakhala ndi mawonekedwe amtundu wolumikizana ndi mpira ndipo chimatha kunyamula katundu wosiyanasiyana wa axial mbali ziwiri. Poyerekeza ndi mitundu ina ya mayendedwe omwe ali ndi kukula kofanana, kunyamula kwamtundu uwu kumakhala ndi kagawo kakang'ono kameneka, kuthamanga kwambiri, ndi kulondola kwambiri. Ndilo mtundu wonyamulira womwe umakondedwa kwa ogwiritsa ntchito posankha zitsanzo.

Deep Groove Ball Bearings

Ntchito zazikulu: magalimoto, mathirakitala, zida zamakina, ma mota, mapampu amadzi, makina aulimi, makina opangira nsalu, etc.

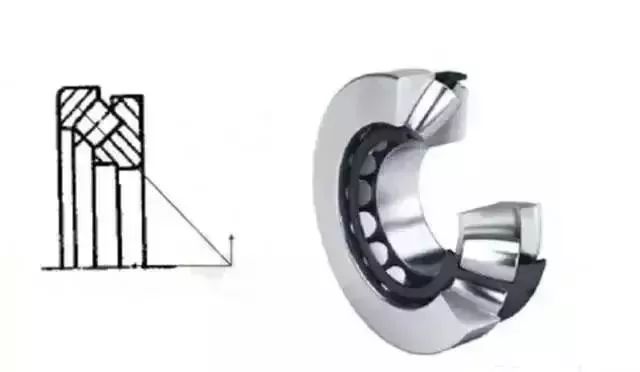

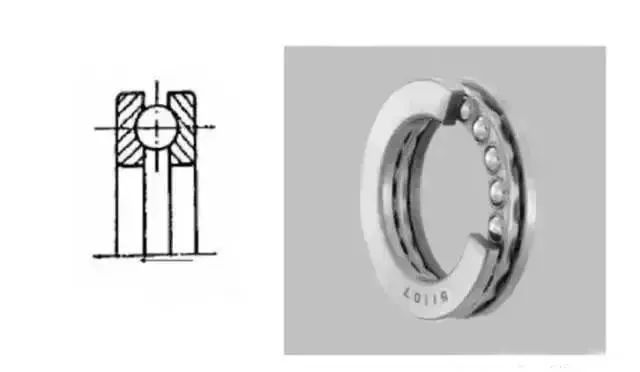

7. Kukankhira mpira mayendedwe

Zimapangidwa ndi mphete yojambulira ngati washer yokhala ndi msewu wothamanga, mpira ndi msonkhano wa khola. Mphete yothamanga yomwe imafanana ndi shaft imatchedwa mphete ya shaft, ndipo mphete yothamanga yomwe imagwirizana ndi nyumbayo imatchedwa mphete ya mpando. Mapiritsi anjira ziwiri amafanana ndi tsinde lachinsinsi la mphete yapakati, mayendedwe anjira imodzi amatha kunyamula katundu wa axial wanjira imodzi, ndipo mayendedwe anjira ziwiri amatha kunyamula katundu wanjira ziwiri (pamodzi mwa iwo sangathe kunyamula katundu wa radial).

Kuthamanga kwa mpira

Ntchito yayikulu: pini yowongolera galimoto, spindle chida cha makina.

8. Kukankha zodzigudubuza mayendedwe

Mapiritsi a thrust roller amagwiritsidwa ntchito kunyamula ma axial load-based shafts, ophatikizira warp katundu, koma katundu wa warp sayenera kupitirira 55% ya katundu wa axial. Poyerekeza ndi mayendedwe ena odzigudubuza, mayendedwe amtunduwu amakhala ndi ma coefficient otsika, kuthamanga kwambiri komanso kudziwongolera. Odzigudubuza a 29000 mayendedwe amtundu ndi odzigudubuza asymmetrical ozungulira, omwe amatha kuchepetsa kutsetsereka pakati pa ndodo ndi mpikisano pa nthawi ya ntchito, ndipo odzigudubuza ndi aatali, aakulu m'mimba mwake, ndipo chiwerengero cha odzigudubuza ndi chachikulu. Mphamvu yonyamula ndi yayikulu, ndipo mafuta opaka mafuta nthawi zambiri amagwiritsidwa ntchito. Kupaka mafuta kumapezeka pa liwiro lotsika.

Ma Roller Bearings

Ntchito yayikulu: jenereta ya hydroelectric, mbedza ya crane.

9. Cylindrical wodzigudubuza mayendedwe

Odzigudubuza a ma cylindrical roller bearings nthawi zambiri amatsogoleredwa ndi nthiti ziwiri za mphete yonyamula, ndipo khola lodzigudubuza ndi mphete yotsogolera zimapanga msonkhano womwe ungathe kupatulidwa ndi mphete ina yonyamula, yomwe imakhala yolekanitsa.

Mtundu woterewu ndi wosavuta kukhazikitsa ndi kusokoneza, makamaka pamene mphete zamkati ndi zakunja ndi shaft ndi nyumba zimafunika kuti zikhale ndi zosokoneza. Miyendo yotereyi nthawi zambiri imagwiritsidwa ntchito kunyamula katundu wa radial, ndipo mizere yokhala ndi mizere imodzi yokha yokhala ndi nthiti pa mphete zamkati ndi zakunja imatha kunyamula katundu wokhazikika wa axial kapena katundu wamkulu wapakatikati.

Ma Cylindrical Roller Bearings

Ntchito zazikuluzikulu: ma mota akulu, masipingo a zida zamakina, mabokosi a axle, ma crankshafts a injini ya dizilo, magalimoto, ma gearbox, ndi zina zambiri.

10. Zinayi zolumikizana ndi mpira

Imatha kunyamula katundu wa radial ndi bi-directional axial load. Chimbalangondo chimodzi chingathe m'malo mwa makwerero a mpira wa angular ophatikizidwa kutsogolo kapena kumbuyo. Ndizoyenera kunyamula katundu wa axial kapena katundu wopangidwa ndi gawo lalikulu la axial katundu. Mtundu woterewu ukhoza kupirira njira iliyonse Mmodzi mwa ma angles okhudzana akhoza kupangidwa pamene katundu wa axial umagwiritsidwa ntchito, choncho mphete ndi mpira nthawi zonse zimagwirizana ndi mbali ziwiri ndi mfundo zitatu pa mzere uliwonse wokhudzana.

Mfundo zinayi zolumikizana ndi mpira

Ntchito zazikulu: injini za jet za ndege, ma turbine a gasi.

11. Kukantha cylindrical wodzigudubuza mayendedwe

Zimapangidwa ndi mphete zamtundu wa washer (mphete za shaft, mphete zapampando) zokhala ndi ma cylindrical rollers ndi ma khola. Ma cylindrical rollers amakonzedwa ndi malo owoneka bwino, kotero kugawa kwapakati pakati pa odzigudubuza ndi malo othamanga kumakhala kofanana, ndipo amatha kunyamula katundu wa axial unidirectional. Mphamvu ya axial katundu ndi yaikulu ndipo axial rigidity ndi yamphamvu.

Mapiritsi a Thrust Cylindrical Roller Bearings

Ntchito zazikulu: zopangira mafuta, makina achitsulo ndi zitsulo.

12. Kukankha singano wodzigudubuza mayendedwe

Zimbalangondo zolekanitsa zimapangidwa ndi mphete zojambulira, zodzigudubuza za singano ndi zomangira za khola, zomwe zimatha kuphatikizidwa ndi mphete zoonda zapamsewu zomwe zimakonzedwa ndi kupondaponda kapena mphete zokhuthala zokonzedwa ndi kudula. Ma fani osasiyanitsidwa ndi ma fani ophatikizika omwe amapangidwa ndi mphete zoduliridwa bwino, zodzigudubuza za singano ndi zomangira za khola, zomwe zimatha kupirira katundu wa unidirectional axial. Mtundu woterewu umatenga malo ochepa ndipo umathandizira kupanga makina ophatikizika. Ndiwodzigudubuza wa singano ndi khola lokha lomwe limagwiritsidwa ntchito, ndipo pamwamba pa shaft ndi nyumba zimagwiritsidwa ntchito ngati malo othamanga.

Mapiritsi a Needle Roller Bearings

Ntchito yayikulu: Zida zotumizira zamagalimoto, olima, zida zamakina, ndi zina zambiri.

13. Kukankha tapered wodzigudubuza mayendedwe

Mtundu woterewu uli ndi zodzigudubuza za cylindrical (mapeto akulu ndi ozungulira), ndipo odzigudubuza amatsogoleredwa bwino ndi nthiti za mphete yothamanga (mphete ya shaft, mphete ya mpando). Ma vertices amtundu uliwonse wa conical amadutsa pamfundo yomwe ili pakatikati pa mzere. Ma mayendedwe anjira imodzi amatha kunyamula katundu wanjira imodzi, ndipo njira ziwiri zimatha kunyamula katundu wanjira ziwiri.

Mapiritsi a Thrust Tapered Roller Bearings

Cholinga chachikulu:

Njira imodzi: mbedza ya crane, chobowolera mafuta chozungulira.

Njira ziwiri: kugudubuza mphero khosi.

14. Mpira wakunja wozungulira wokhala ndi mpando

Mpira wakunja wozungulira wokhala ndi mpando umapangidwa ndi mpira wakunja wozungulira wokhala ndi zisindikizo mbali zonse ziwiri ndi mpando (kapena chitsulo chosindikizidwa). Mapangidwe amkati amtundu wakunja wozungulira mpira ndi wofanana ndi wakuya kwakuya kwa mpira, koma mphete yamkati yamtundu wotereyi ndi yotakata kuposa mphete yakunja, ndipo mphete yakunja imakhala ndi mawonekedwe akunja ozungulira, omwe amatha zilumikizidwe zokha zikafanana ndi malo ozungulira ozungulira ampando wonyamula.

MuKutembenuka kwa CNC, zitsulo zimagwira ntchito yofunika kwambiri powonetsetsa kuti mbali zomalizidwazo n'zolondola komanso zili bwino. Kutembenuza kwa CNC ndi njira yomwe chida chodulira chimachotsa zinthu kuchokera pagulu lozungulira kuti lipange mawonekedwe kapena mawonekedwe omwe mukufuna. Ma bearings amagwiritsidwa ntchito mu spindle ndi linear motion systemsChithunzi cha CNCkuthandizira chogwirira ntchito chozungulira ndi chida chodulira. Mwa kuchepetsa kukangana ndi kupereka chithandizo, mayendedwe amalola chida chodulira kuti chiziyenda bwino komanso molondola pamtunda wa workpiece, kupanga mabala olondola komanso ofanana. Izi zimabweretsa magawo osasinthika, apamwamba kwambiri omwe amakwaniritsa zofunikira.

Ukadaulo wotembenukira ku CNC wasintha kwambiri makampani opanga zinthu, zomwe zimapangitsa kuti zikhale zotheka kupanga zida zovuta zololera zolimba komanso kuchita bwino kwambiri.

Anebon imapereka kulimba kwabwino kwambiri pakuchita bwino komanso kupita patsogolo, kugulitsa, kugulitsa kwakukulu ndi kulimbikitsa ndi kugwira ntchito kwa OEM/ODM Manufacturer Precision Iron Stainless Steel. Chiyambireni gawo lopanga zinthu lomwe lidakhazikitsidwa, Anebon tsopano yadzipereka pakupita patsogolo kwa katundu watsopano. Pamodzi ndi mayendedwe azachuma komanso azachuma, tipitiliza kupititsa patsogolo mzimu wa "zapamwamba kwambiri, zogwira mtima, zaluso, kukhulupirika", ndikukhalabe ndi mfundo za "ngongole poyambirira, kasitomala woyamba, wabwino kwambiri". Anebon ipanga tsogolo labwino kwambiri pakutulutsa tsitsi ndi anzathu.

OEM/ODM Manufacturer China Casting and Steel Casting, Mapangidwe, kukonza, kugula, kuyang'anira, kusungirako, kusonkhanitsa ndondomeko zonse zili muzochitika zasayansi komanso zogwira mtima, kuonjezera kuchuluka kwa ntchito ndi kudalirika kwa mtundu wathu mozama, zomwe zimapangitsa Anebon kukhala wogulitsa wamkulu wa magulu anayi akuluakulu mankhwala, monga CNC Machining, CNC mphero mbali, CNC kutembenukira ndi castings zitsulo.

Nthawi yotumiza: Apr-10-2023