1. Ndi mwaluso kupeza chakudya chozama pang'ono. Potembenuza, ntchito ya katatu imagwiritsidwa ntchito pokonza zida zina zokhala ndi mabwalo amkati ndi akunja pamwamba pa kulondola kwachiwiri. Chifukwa cha kutentha kwapakati, kukangana pakati pa workpiece ndi chida kumapangitsa chida kuvala ndi kubwereza mobwerezabwereza kulondola kwa chogwiritsira ntchito chida, etc., kotero kuti khalidweli n'zovuta kutsimikizira. Kuti tithane ndi kuzama kwakuya kwakung'ono pakutembenuka, titha kugwiritsa ntchito mgwirizano pakati pa mbali ina ndi mbali yopingasa ya makona atatu ngati pakufunika kusuntha chonyamula mpeni chaching'ono pamakona kuti tifikire pakuya kopingasa kudya. chida chotembenuza cha micro-moving. Cholinga: kupulumutsa ntchito ndi nthawi, kuonetsetsa kuti zinthu zili bwino, ndikuwongolera magwiridwe antchito. The C620 lathe chida chogwirizira sikelo mtengo ndi 0.05mm pa gululi. Ngati mukufuna kupeza chopingasa chodyera chakuya cha 0.005mm, yang'anani tebulo la ntchito ya sine trigonometric: sinα=0.005/0.05=0.1 α=5o44′, kotero sunthani chogwirizira chaching'ono. Pamene ndi 5o44', pamene kusuntha longitudinally chosema chimbale pa chofukizira mpeni yaing'ono, akhoza kufika yaying'ono-mayendedwe a chida kudula ndi mtengo kuya 0.005mm mu malangizo ofananira nawo.

2. Kugwiritsa ntchito ukadaulo wokhotakhota m'machitidwe atatu anthawi yayitali akutsimikizira kuti munjira yeniyeni yokhotakhota, ukadaulo wodula ukhoza kupeza zotsatira zabwino. Zitsanzo zotsatirazi ndi izi:

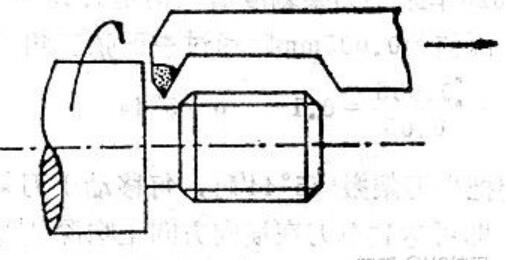

(1) Pamene ulusi wodula kumbuyo ndi chidutswa chachitsulo chosapanga dzimbiri cha martensitic chokhala ndi ulusi wamkati ndi wakunja wokhala ndi phula la 1.25 ndi 1.75 mm popeza phula la wononga lathe limachotsedwa ndi phula la workpiece, mtengo womwe wapezeka. ndi Mtengo wosatha. Ngati ulusi wapangidwa mwa kukweza chogwirira cha nati wa counter, ulusiwo umathyoka nthawi zambiri. Nthawi zambiri, lathe wamba alibe chipangizo chomangira chomangira, ndipo chimbale chodzipangira chokha chimatenga nthawi yambiri pakukonza mawuwo. Pamene ulusi, nthawi zambiri. Njira yomwe idakhazikitsidwa ndi njira yochepetsera yosalala yotsika kwambiri chifukwa kunyamula mwachangu sikokwanira kubweza mpeni, chifukwa chake kupanga bwino kumakhala kochepa, fayilo imapangidwa mosavuta pakutembenuka, ndipo kuuma kwapamwamba kumakhala koyipa, makamaka. pokonza zitsulo zosapanga dzimbiri za martensite monga 1Crl3, 2 Crl3, etc. Mukadula pa liwiro lotsika, chikwakwa chodziwika bwino kwambiri. Njira zodula, zokhotakhota, komanso zotsutsana ndi "zitatu zopingasa" zomwe zidapangidwa muzochita zamakina zimatha kukwaniritsa bwino kwambiri chifukwa njirayo imatha kutembenuza ulusi pa liwiro lalikulu, ndikuwongolera chidacho. imachotsedwa kuchokera kumanzere kupita kumanja, kotero palibe cholepheretsa kuti chidacho chitha kubwezeredwa podula ulusi pa liwiro lalikulu. Njira yeniyeni ndi iyi: Pamene ulusi wakunja umagwiritsidwa ntchito, perani chida chofanana cha mkati chotembenuza ulusi (mkuyu 1);

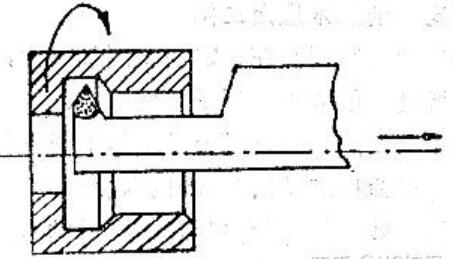

Pogaya chida chosinthira ulusi wamkati (Chithunzi 2).

M'mbuyomumakina, sinthani ulusi wopota wa mbale yokhotakhota pang'ono kuti muwonetsetse kuthamanga kozungulira. Kwa wodula ulusi wabwino, tsekani ndikutsegula ndi kutseka nati, yambani kutsogolo ndi liwiro lotsika kupita ku sipe yopanda kanthu, ndiyeno ikani chida chotembenuza ulusi mukuya koyenera kwa kudula; mukhoza kusintha kuzungulira. Panthawiyi, chida chotembenuza chimasiyidwa pa liwiro lalikulu. Mwa kudula mpeni kumanja ndi kudula chiwerengero cha mipeni molingana ndi njirayi, ulusi wokhala ndi khwimbi lapamwamba komanso kulondola kwakukulu ukhoza kupangidwa.

(2) Mu chikhalidwe knurling ndondomeko reverse knurling, filings chitsulo ndi zinyalala mosavuta analowa pakati workpiece ndi knurling mpeni, kuchititsa workpiece kukhala overstressed, kuchititsa mizere kuti mitolo, chitsanzo ndi wophwanyika kapena ghosted, etc. Ngati njira yatsopano yogwiritsira ntchito Kutembenuza ndi kugwedeza kwa lathe spindle ikugwiritsidwa ntchito, zovuta zomwe zimachitika chifukwa cha kusalaza zimatha kukhala zovuta. kutetezedwa bwino, ndipo zotsatira zabwino zonse zitha kupezeka.

(3) Kutembenuza kutembenuka kwa ulusi wamkati ndi wakunja wa chitoliro Mukatembenuza ulusi wa chitoliro chamkati ndi kunja molunjika pang'ono komanso pang'ono pang'ono, ndizotheka kugwiritsa ntchito mwachindunji kudula mobwerera ndikubwezeretsanso popanda chipangizo cha nkhungu. Mu njira yatsopano yogwiritsira ntchito, podula mbali ya chidacho, chidacho chimasunthidwa mozungulira kuchokera kumanzere kupita kumanja. Fayilo yopingasa imapangitsa kuti zikhale zosavuta kumvetsetsa kuya kwa fayilo kuyambira lalikulu mpaka laling'ono. Chifukwa chake ndi fayilo. Pali pre-stress. Kusiyanasiyana kwa ntchito zamtundu watsopanowu waukadaulo wogwiritsa ntchito m'mbuyo paukadaulo wakutembenuza ukuchulukirachulukira ndipo zitha kugwiritsidwa ntchito mosiyanasiyana pamikhalidwe yosiyanasiyana.

3. Njira yatsopano yogwiritsira ntchito ndi zida zatsopano zobowola mabowo ang'onoang'ono Potembenuza, pamene dzenje liri losakwana 0.6mm, m'mimba mwake ya kubowola ndi yaying'ono, kulimba kwake ndi kopanda pake, kuthamanga kwa kudula sikukukwera, ndi zinthu zogwirira ntchito. ndi aloyi zosagwira kutentha ndi chitsulo chosapanga dzimbiri, ndipo kukana kudula kuli Kwakukulu, kotero pobowola, monga kugwiritsa ntchito makina opatsirana ndi chakudya, kubowola ndikosavuta kuswa, zotsatirazi zikufotokoza njira yosavuta komanso yothandiza komanso njira yodyetsera pamanja. Choyamba, chuck yobowola yoyambirira imasinthidwa kukhala mtundu woyandama wa shank. Pobowola pang'ono akamangika pa chuck yoyandama, kubowolako kumatha kuchitidwa bwino. Chifukwa mbali yakumbuyo ya bowolo ndi yolunjika shank yotsetsereka, imatha kuyenda momasuka mu manja ake. Bowo laling'ono likabowoledwa, chuck yobowola imatha kugwidwa mwapang'onopang'ono ndi dzanja, chakudya chaching'ono chamanja chimatha kuzindikirika, ndipo dzenje laling'ono limatha kutulutsa mwachangu. Quality ndi kuchuluka ndi kuwonjezera moyo utumiki wa kubowola yaing'ono. Chobowola chosinthika chamitundu yambiri chingagwiritsidwenso ntchito pogogoda ulusi wamkati waung'ono wamkati, kubwezeretsanso, ndi zina zotere (Ngati dzenje lalikulu libowoleredwa, pini yotsekera imatha kuyikidwa pakati pa mkono wokoka ndi shank yowongoka).

4. Anti-vibration mu makina a dzenje lakuya M'makina akuya-bowo, chifukwa cha kabowo kakang'ono, chida chotopetsa chimakhala chochepa. Ndizosapeŵeka kupanga kugwedezeka pamene dzenje lalikulu ndi Φ30 ~ 50mm, ndipo dzenje lakuya liri pafupi 1000mm. Ndiwothandiza kwambiri komanso othandiza poletsa kugwedezeka kwa arbor. Njirayi ndikugwirizanitsa zothandizira ziwiri (pogwiritsa ntchito zinthu monga nsalu bakelite) ku thupi la shank, ndipo kukula kwake kuli kofanana ndi kukula kwake. Panthawi yodula, arbor imakhala yochepa kugwedezeka chifukwa cha malo a slats, ndipo mbali zakuya za dzenje zabwino zimatha kukonzedwa.

5. Anti-break of the small center kubowola ndi yocheperapo pakati pa dzenje la Φ1.5mm pamene kubowola kuli kochepa kuposa dzenje lapakati la Φ1.5mm. Njira yosavuta komanso yothandiza yolimbana ndi kupuma ndiyo kusatseka tailstock pobowola dzenje lapakati koma kusiya tailstock. Kudzilemera komanso kukangana komwe kumachitika pakati pa bedi la makina kumagwiritsidwa ntchito kubowola dzenje lapakati. Pamene kukana kudula kuli kwakukulu kwambiri, tailstock imabwerera yokha, motero imateteza kubowola kwapakati.

6. Anti-vibration ya kutembenukira woonda-mipanda workpieces Pa kutembenuza ndondomeko woonda-mipanda workpieces, kugwedezeka nthawi zambiri kwaiye chifukwa cha osauka zitsulo katundu workpieces; makamaka pamenekutembenuza chitsulo chosapanga dzimbirindi ma aloyi osagwira kutentha, kugwedezeka kumawoneka kowoneka bwino, kuuma kwapamwamba kwa chogwiriracho ndi koyipa kwambiri, ndipo moyo wautumiki wa chida umafupikitsa. Njira zosavuta zodzipatula pazochita zingapo zafotokozedwa pansipa.

(1) Mukatembenuza bwalo lakunja la chitsulo chosapanga dzimbiri chocheperako, dzenjelo limatha kudzazidwa ndi tchipisi tamatabwa ndikumangika. Panthawi imodzimodziyo, malekezero onse a workpiece amalumikizidwa ndi pulagi ya bakelite, ndiyeno chingwe chothandizira pa chogwiritsira ntchito chimasinthidwa ndi vwende wothandizira wa zinthu za bakelite akhoza kukonza arc yofunikira kuti apange Kutembenuza kwazitsulo zosapanga dzimbiri. ndodo yowonda. Njira yosavuta iyi imatha kuteteza kugwedezeka ndi kusinthika kwa ndodo yowonda yoboola panthawi yodula.

(2) Potembenuza dzenje lamkati la chopanda kutentha (high-nickel-chromium) aloyi yopyapyala yokhala ndi mipanda yopyapyala, kulimba kwa chogwiriracho ndi kocheperako, shank ndi yowonda, ndipo chodabwitsa chachikulu chimachitika panthawi yodula; zomwe ndizovuta kwambiri kuwononga chida ndikuwononga. Ngati chinthu chochititsa mantha, monga mphira kapena siponji, chakulungidwa kuzungulira kunja kwa chopangiracho, mphamvu ya shockproof imatha kutheka.

(3) Potembenuza bwalo lakunja la aloyi wosagwira kutentha kwazitsulo zopyapyala zokhala ndi mipanda, chifukwa cha zinthu zambiri monga kukana kwakukulu kwa alloy yosagwira kutentha, ndikosavuta kupanga kugwedezeka ndi kupunduka panthawi yodula. Ngati dzenje la mphira kapena ulusi wa thonje ulowetsedwa mu dzenje la workpiece, zinyalala zimagwiritsidwa ntchito, ndiye kuti njira yopopera pamapeto onse awiri ingagwiritsidwe ntchito kuteteza kugwedezeka ndi kusinthika kwa workpiece panthawi yodula, komanso apamwamba kwambiri. woonda-mipanda workpiece akhoza kukonzedwa.

7. Chida chowonjezera chotsutsana ndi kugwedezeka chimapangitsa kugwedezeka mosavuta chifukwa cha kusasunthika kosasunthika kwa mtundu wa shaft-mtundu wa workpiece panthawi yodulira ma multi-groove, zomwe zimapangitsa kuti pakhale kusauka kwapamwamba kwa workpiece ndi kuwonongeka kwa chida. Zida zina zowonjezera zotsutsana ndi kugwedezeka zingathetsere bwino vuto la kugwedezeka kwa ziwalo zowonda mu ndondomeko ya grooving (onani Chithunzi 10). Ikani chida chodzipangira chokha chodzidzimutsa pamalo abwino pachosungira chida chisanachitike ntchito. Kenako, ikani chida chotembenuza chofanana ndi kagawo pachosungira chida, sinthani mtunda ndi kuchuluka kwa kasupe, kenako gwirani ntchito. Pamene chida chotembenuza chikudula mu workpiece, chida chowonjezera chotsutsana ndi kugwedezeka chimayikidwa pamwamba pa workpiece panthawi imodzimodzi, yomwe ndi yabwino kwa shockproofing. Zotsatira.

8. Zida zovuta ku makina zimakulitsidwa ndikumalizidwa. Tikakhala muzinthu zovuta ku makina monga ma alloys otentha kwambiri ndi zitsulo zolimba, kuuma kwapamwamba kwa workpiece kumafunika kukhala Ra0.20-0.05μm, ndipo kulondola kwa dimensional ndikwapamwamba. Kumaliza komaliza nthawi zambiri kumachitika pamakina opera. Chitani chida chodzipangira chosavuta chopangira honing ndi gudumu la honing, ndikulandila zabwino zachuma pochita honi m'malo mwa njira yopera pa lathe.

9. Kutsitsa mwachangu ndi kutsitsa mandrels nthawi zambiri kumakumana ndi mitundu yosiyanasiyana ya seti zonyamula potembenuza. Bwalo lakunja ndi kalozera wopindika wokhotakhota wa gulu lonyamula. Chifukwa cha kukula kwakukulu kwa batch, nthawi yotsitsa ndi yotsitsa ndi yochuluka kuposa nthawi yodula. Long, otsika kupanga dzuwa. Zida zotembenuza mwachangu za mandrel ndi mpeni umodzi wamitundu yambiri (zitsulo zolimba) zomwe zafotokozedwa pansipa zitha kupulumutsa nthawi yothandiza ndikuwonetsetsa kuti zinthu zili bwino pakukonza magawo osiyanasiyana a manja. Njira yopanga ndi motere. Pangani chosavuta, taper mandrel yaying'ono. Mfundo ndi kugwiritsa ntchito 0.02mm kufufuza taper kumbuyo kwa mandrel. Choyikacho chimalimbikitsidwa pa mandrel ndi mikangano, ndiyeno chida chotembenuza mpeni umodzi chimagwiritsidwa ntchito. Pambuyo pozungulira, mbali ya 15 ° cone imatembenuzidwa, ndipo malo oimikapo magalimoto amachitidwa kuti achotse mbalizo mofulumira komanso bwino, monga momwe tawonetsera pa Chithunzi.

10. Kutembenuza kwazitsulo zolimba

(1) Chimodzi mwa zitsanzo zazikulu za zitsulo zolimba zokhotakhota 1 Kumanganso chitsulo chothamanga kwambiri W18Cr4V chowumitsa broach (kukonza pambuyo pa kusweka) 2 zopanga zopanga tokha zosakhazikika ulusi pulagi gauge (hardware kuumitsa) 3 kuzimitsa hardware ndi kupopera mbewu mankhwalawaKutembenuza zidutswa zinayi za hardware kuzimitsa plugging yosalala pamwamba 5 Makapu opukutira ulusi opangidwa ndi zida zachitsulo zothamanga kwambiri Pozimitsa hardware ndi mbali zosiyanasiyana zovuta zakuthupi anakumana mu kupanga pamwamba, kusankha zoyenera chida chuma ndi kudula kuchuluka ndi chida ngodya za Geometric ndi njira ntchito angathe kukwaniritsa zabwino zonse zachuma. Mwachitsanzo, pamene square broach yathyoledwa, ngati itayambikanso kuti ipange square broach, sikuti nthawi yopangira kupanga imakhala yayitali komanso mtengo wake ndi wokwera. Pamizu ya broach yoyambirira, timagwiritsa ntchito tsamba la aloyi yolimba YM052 kuti tikule kuti ikhale yopanda pake. Mbali yakutsogolo r. =-6°~-8°, m’mphepete mwake mungatembenuzidwe pogaya mosamalitsa ndi mwala wamafuta. Liwiro lodula ndi V = 10 ~ 15m / min. Pambuyo pa bwalo lakunja, sipe yopanda kanthu imadulidwa, ndipo pamapeto pake, ulusiwo umagawidwa kukhala wobiriwira komanso wabwino. ), pambuyo roughing, chida ayenera remed ndi pansi pambuyo pakunola kwatsopano ndi akupera. Kenaka, ulusi wamkati wa ndodo yolumikizira uyenera kukonzedwa, ndipo mgwirizanowo uyenera kudulidwa. Chipinda cha square broach chokhala ndi zidutswa zosweka chinakonzedwa pambuyo pa kutembenuka, ndipo chinali chakale ngati chatsopano.

(2) Kusankhidwa kwa zida zothandizira kutembenuza ndi kuzimitsa hardware 1 Magiredi atsopano monga aloyi yolimba YM052, YM053, YT05, etc., liwiro lonse lodulira lili pansipa 18m/mphindi, ndipo kuuma kwa workpiece kumatha kufika Ra1.6 ~ 0.80μm 2 kiyubiki boron nitride chida FD akhoza pokonza mitundu yonse ya zitsulo anaumitsa ndi sprayed mbali, kudula liwiro mpaka 100m / min, pamwamba roughness mpaka Ra0.80 ~ 0.20μm. Chida chophatikizika cha kiyubiki boron nitride DCS-F chopangidwa ndi State Capital Machinery Plant ndi Guizhou No.6 Grinding Wheel Factory chilinso ndi ntchitoyi. Zotsatira zake zimakhala zoipitsitsa kuposa za carbide yopangidwa ndi simenti (koma mphamvuyo si yabwino ngati ya alloy yolimba; ndi yozama komanso yotsika mtengo kuposa aloyi yolimba, ndipo ndiyosavuta kuwononga ngati ikugwiritsidwa ntchito molakwika). Zida zisanu ndi zinayi za ceramic, kuthamanga kwa 40 ~ 60m / min, mphamvu ndizosauka. Zida zonse zomwe zili pamwambazi zili ndi makhalidwe awo potembenuza ndi kuzimitsa magawo ndipo ziyenera kusankhidwa molingana ndi zikhalidwe zenizeni za kutembenuza zipangizo zosiyanasiyana ndi kuuma kosiyana.

(3) Kusankhidwa kwa mitundu yosiyanasiyana ya zida zowuma ndi zida zachitsulo Zida zosiyanasiyana zazitsulo zolimba pansi pa kuuma komweko, zofunikira pakugwiritsa ntchito zida ndizosiyana kwambiri, zazikulu monga magulu atatu otsatirawa: 1 chitsulo chapamwamba cha alloy: chimatanthawuza kusakaniza. zinthu Chida chitsulo ndi kufa zitsulo (makamaka zosiyanasiyana mkulu-liwiro zitsulo) ndi okwana kulemera oposa 10%. 2 aloyi chitsulo: amatanthauza chida chitsulo ndi kufa chitsulo ndi aloyi zili ndi zinthu zili 2 ~ 9%, monga 9SiCr, CrWMn, ndi mkulu mphamvu aloyi structural chitsulo. Zitsulo zitatu za kaboni: kuphatikiza mapepala osiyanasiyana a zitsulo zamtundu wa zitsulo ndi zitsulo zopangidwa ndi carburized monga T8, T10, 15 zitsulo, kapena 20 gauge steel carburizing zitsulo. Pakuti mpweya zitsulo, ndi microstructure pambuyo quenching ndi mtima martensite ndi pang'ono carbide, tsitsi lolimba HV800 ~ 1000, kuposa kuuma kwa WC ndi TiC mu simenti carbide ndi A12D3 mu zida ceramic. Ndiwotsika kwambiri, ndipo siwotentha kwambiri kuposa martensite popanda ma alloying zinthu ndipo nthawi zambiri sichidutsa 200 ° C. Pamene zomwe zili muzitsulo zowonjezera zimawonjezeka, zitsulo za carbide pambuyo pozimitsa ndi kutentha zimawonjezeka, ndipo mtundu wa carbide umakhala wovuta kwambiri. Kutenga mkulu-liwiro zitsulo monga chitsanzo, zili carbides mu microstructure pambuyo quenching ndi kutentha angafikire 10-15% (voliyumu chiŵerengero) ndipo lili carbides wa MC, M2C, M6 M3, 2C, etc. High kuuma (HV2800) ndi apamwamba kwambiri kuposa kuuma kwa gawo molimba mfundo zambiri zida zipangizo. Kuphatikiza apo, chifukwa cha kukhalapo kwa zinthu zambiri zopangira ma alloying, kuuma kotentha kwa martensite komwe kumakhala ndi ma alloying osiyanasiyana kumatha kuwonjezeka mpaka pafupifupi 600 ° C. Kugwira ntchito molimbika kwazitsulo zolimba ndi microhardness yomweyo sikufanana, ndipo kusiyana kwake ndi kwakukulu kwambiri. Asanatembenuzire zitsulo zolimba, zimawunikidwa kukhala za gululo. Dziwani bwino mawonekedwe ndikusankha zida zoyenera, kudula kuchuluka, ndi zida za geometry. Ngodya imatha kumaliza bwino zingwe zazitsulo zolimba.

Anebon Metal Products Limited ikhoza kupereka CNC Machining, Die Casting, Sheet Metal Fabrication service, chonde omasuka kulankhula nafe.

Tel: +86-769-89802722 E-mail: info@anebon.com URL: www.anebon.com

Nthawi yotumiza: Aug-30-2019