Kusiyana ndi kugwiritsa ntchito mabawuti amphamvu kwambiri komanso mabawuti wamba

Maboti amphamvu kwambiri ndi ma bolts wamba ndi mitundu iwiri ya zomangira zomwe zimagwiritsidwa ntchito mosiyanasiyana.

Nayi kufananiza kwa kusiyana kwawo ndi momwe amagwiritsidwira ntchito:

Mphamvu: Maboti amphamvu kwambiri amapangidwa kuti akhale ndi mphamvu zolimba kwambiri komanso zometa ubweya poyerekeza ndi mabawuti wamba. Amapangidwa kuchokera ku chitsulo cha alloy ndipo amakumana ndi njira zapadera zochizira kutentha kuti awonjezere mphamvu zawo. Komano, mabawuti wamba amakhala ndi mphamvu zochepa ndipo amapangidwa kuchokera ku kabonimakina zitsulo.

Zizindikiro: Maboti amphamvu kwambiri nthawi zambiri amakhala ndi zolembera pamutu posonyeza kalasi yawo kapena gulu lamphamvu. Zolemba izi zimathandiza kuzindikira zomwe bolt ili nayo, monga mphamvu yake yolimba komanso zinthu zakuthupi. Maboti wamba nthawi zambiri sakhala ndi zilembo zenizeni zokhudzana ndi mphamvu.

Kuyika: Maboti amphamvu kwambiri amafunikira njira zoyikitsira zolondola kuti akwaniritse mphamvu zomwe mukufuna ndikuchita. Amagwiritsidwa ntchito nthawi zambiri m'malo omwe kukhulupirika kwapangidwe ndi kunyamula katundu ndikofunikira. Njira zoyikira ma bolts amphamvu kwambiri nthawi zambiri zimaphatikizapo kugwiritsa ntchito ma wrenche a torque kapena zida zama hydraulic tensioning kuti mukwaniritse zomwe zatchulidwa kale. Maboti wamba nthawi zambiri amakhala osavuta kukhazikitsa ndipo safuna zida zapadera kapena kuwongolera torque.

Mapulogalamu: Maboti amphamvu kwambiri amagwiritsidwa ntchito pomanga, ntchito zomanga, milatho, nyumba, ndi ntchito zina zomwe zimayembekezeredwa kulemedwa kwambiri kapena kupsinjika kwakukulu. Ndikofunikira kuti mulumikizane ndi zida zachitsulo, monga matabwa, mizati, ndi ma trusses. Ma bawuti wamba amapeza ntchito pazosowa zochepa, kuphatikizamakina a cnckuphatikiza mipando, zida zamagalimoto, kulumikizana kosagwirizana ndi kapangidwe kake, komanso kumangirira kwanthawi zonse.

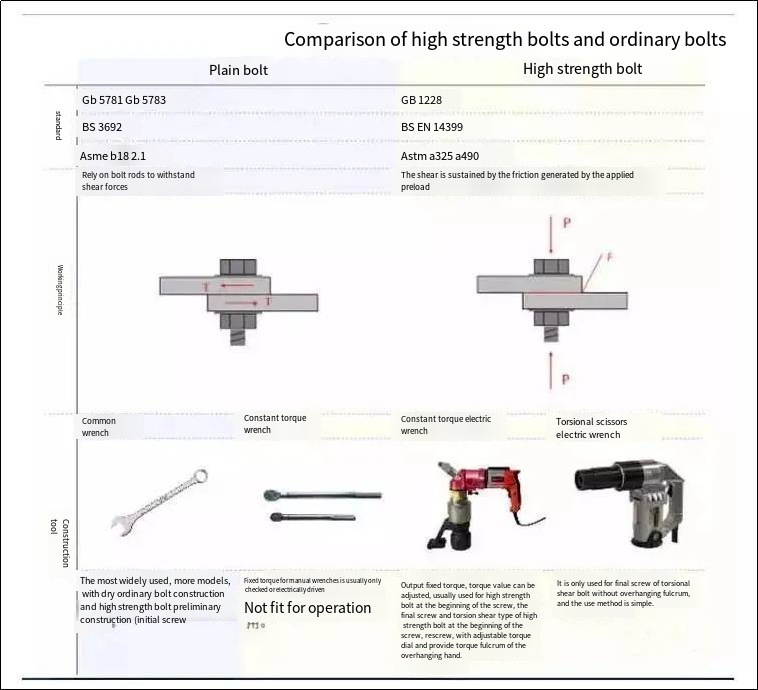

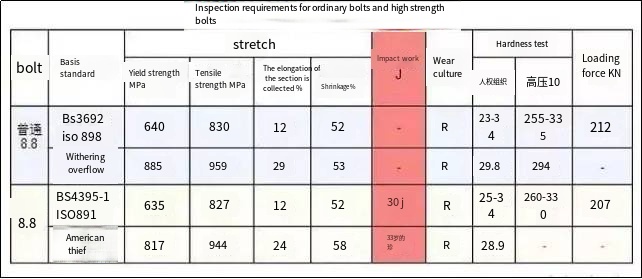

Miyezo: Maboti amphamvu kwambiri nthawi zambiri amapangidwa ndikufotokozedwa molingana ndi miyezo yamakampani, monga ASTM A325 ndi ASTM A490 ku United States. Miyezo iyi imatanthauzira zofunikira zamakina, mawonekedwe amakina, makulidwe, ndi njira zoyika ma bolts amphamvu kwambiri. Mabawuti wamba nthawi zambiri amatsatira miyezo wamba, monga ASTM A307, yomwe imagwira ntchito zosiyanasiyana komanso zofunikira zochepa zamphamvu.

Kodi mabawuti olimba kwambiri ndi chiyani?

High-Strength Friction Grip Bolt , kumasulira kwenikweni kwa Chingerezi ndi: bawuti yolimba kwambiri yolimba kwambiri, chidule cha Chingerezi: HSFG. Zitha kuwoneka kuti ma bolts amphamvu kwambiri omwe atchulidwa pamapangidwe athu aku China ndi chidule cha ma bolts amphamvu kwambiri. Pakulankhulana kwa tsiku ndi tsiku, mawu oti "Friction" ndi "Grip" amangotchulidwa mwachidule, koma akatswiri ambiri ndi akatswiri sanamvetsetse tanthauzo lachidziwitso cha ma bolts amphamvu kwambiri.

Kusamvetsetsa chimodzi:

Maboti okhala ndi giredi yakuthupi yopitilira 8.8 ndi "mabawuti olimba kwambiri"?

Kusiyana kwakukulu pakati pa ma bolts amphamvu kwambiri ndi ma bolts wamba si mphamvu ya zinthu zomwe zimagwiritsidwa ntchito, koma mawonekedwe a mphamvu. Chofunikira ndichakuti mugwiritse ntchito kudzaza ndikugwiritsa ntchito kukangana kokhazikika kuti mupewe kukameta ubweya.

M'malo mwake, ma bolt amphamvu kwambiri (HSFG BOLT) otchulidwa mulingo waku Britain ndi muyezo waku America ndi 8.8 ndi 10.9 (BS EN 14399 / ASTM-A325&ASTM-490), pomwe mabawuti wamba amaphatikiza 4.6, 5.6, 8.8, 10.9, 12,9, etc. (BS 3692 11 Table 2); zikhoza kuwoneka kuti mphamvu ya zinthuzo sichinsinsi chosiyanitsa ma bolts amphamvu kwambiri kuchokera kuzitsulo wamba.

Kumvetsetsa kolondola kwa "mphamvu zazikulu", mphamvu zili kuti

Malinga ndi GB50017, kuwerengera mphamvu yamakokedwe ndi kukameta ubweya wa bawuti wamba wamba (Mtundu B) 8,8 kalasi ndi mkulu-mphamvu bawuti 8,8 kalasi.

Kupyolera mu kuwerengera, tikhoza kuona kuti pansi pa kalasi yomweyi, mapangidwe ndialuminium cnc serviceMakhalidwe amphamvu yamphamvu ndi kumeta ubweya wa ma bawuti wamba ndi apamwamba kuposa ma bawuti amphamvu kwambiri.

Ndiye "amphamvu" a mabawuti amphamvu ali kuti?

Kuti tiyankhe funsoli, m'pofunika kuti tiyambe ndi mapangidwe a ntchito ya mabotolo awiri, kuphunzira lamulo la zotanuka-pulasitiki mapindikidwe, ndi kumvetsa malire boma pa nthawi ya kulephera mapangidwe.

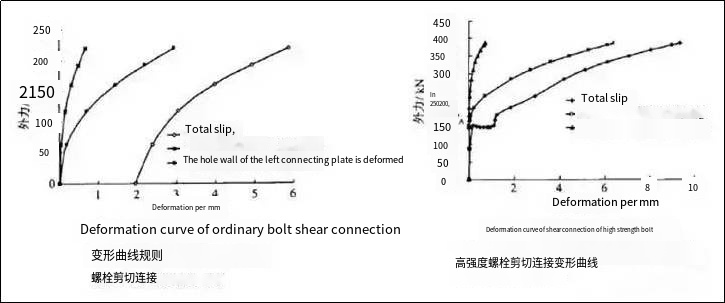

Mapiritsi a kupsinjika kwa mabawuti wamba ndi ma bawuti amphamvu kwambiri pansi pamikhalidwe yogwirira ntchito

Chepetsani mkhalidwe pakulephera kupanga

Maboti wamba: Kupindika kwa pulasitiki kwa wononga palokha kumapitilira malire apangidwe, ndipo zomangira zimawonongeka ndi kumeta.

Pa kulumikizana kwa bawuti wamba, kutsetsereka kwachibale kudzachitika pakati pa mbale zolumikizira mphamvu yakumeta ubweya isanayambike, ndiyeno ndodo ya bawuti ndi kulumikizana kwa mbale yolumikizira, kusinthika kwa pulasitiki kumachitika, ndipo mphamvu yakumeta ubweya imapirira.

Maboti amphamvu kwambiri: Kukangana kosasunthika pakati pa malo othamanga kwambiri kumagonjetsedwa, ndipo kusamutsidwa kwachibale kwa mbale ziwiri zachitsulo kumachitika, zomwe zimaganiziridwa kuti zawonongeka pazolinga zamapangidwe.

Polumikizana ndi bawuti yamphamvu kwambiri, mphamvu yokangana imayamba ndi mphamvu yakumeta ubweya. Pamene katunduyo akuwonjezeka kufika pamene mphamvu yotsutsana sikwanira kukana kukameta ubweya wa ubweya, mphamvu yowonongeka imagonjetsedwa, ndipo kutsetsereka kwa mbale yolumikizira kumachitika (malire a boma). Komabe, ngakhale kuti yawonongeka panthawiyi, ndodo ya bawuti imalumikizana ndi mbale yolumikizira, ndipo imatha kugwiritsabe ntchito mapindikidwe ake otanuka-pulasitiki kuti athe kupirira mphamvu yakumeta ubweya.

Kusamvetsetsa 2:

Kuthekera kwa mabawuti amphamvu kwambiri ndikwambiri kuposa ma bawuti wamba. Kodi ndi "mphamvu zazikulu"?

Zitha kuwoneka kuchokera kuwerengera kwa bolt imodzi kuti mphamvu ya mapangidwe a ma bolts amphamvu kwambiri pazovuta ndi kumeta ubweya ndizochepa kusiyana ndi ma bolts wamba. Chofunikira chake champhamvu kwambiri ndi: panthawi yogwira ntchito bwino, node siziloledwa kukhala ndi zotsalira zachibale, ndiko kuti, kusinthika kwa pulasitiki-pulasitiki ndi kochepa, ndipo kuuma kwa node ndi kwakukulu.

Zitha kuwoneka kuti pakapangidwe kake kamangidwe kameneka, node yopangidwa ndi ma bolts amphamvu kwambiri sangapulumutse chiwerengero cha mabawuti ogwiritsidwa ntchito, koma imakhala ndi mapindikidwe ang'onoang'ono, owuma kwambiri, ndi malo otetezeka kwambiri. Ndikoyenera kwa ma girders akuluakulu ndi malo ena omwe amafunikira kuuma kwa node, ndipo amagwirizana ndi ndondomeko yoyambira ya seismic ya "mfundo zolimba, mamembala ofooka".

Mphamvu zazitsulo zolimba kwambiri sizikhala pamtengo wopangira mphamvu zake zonyamula katundu, koma mu kuuma kwakukulu kwa mapangidwe ake, chitetezo chapamwamba, ndi kukana mwamphamvu kuwonongeka.

Kuyerekeza ma bolts amphamvu kwambiri ndi ma bolt wamba

Maboti wamba ndi ma bolts amphamvu kwambiri amasiyana kwambiri munjira zoyendera zomanga chifukwa chamalingaliro awo osiyanasiyana.

Zofunikira zamakina zamabawuti wamba a giredi lomwelo ndizokwera pang'ono kuposa ma bawuti amphamvu kwambiri, koma ma bawuti amphamvu kwambiri amakhala ndi chofunikira chimodzi chovomerezeka kuti chiwonjezeke mphamvu kuposa mabawuti wamba.

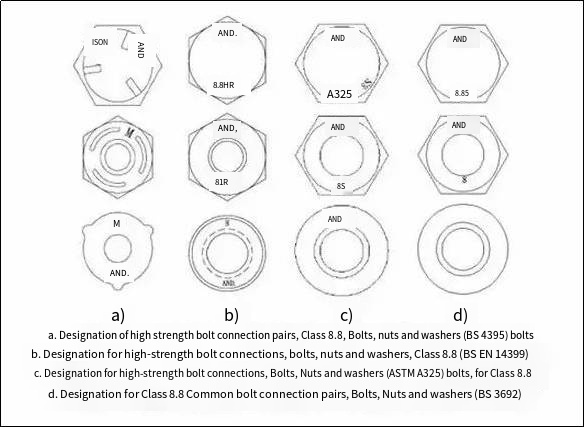

Kuyika chizindikiro kwa mabawuti wamba ndi mabawuti amphamvu kwambiri ndiyo njira yoyambira yozindikiritsira ma bawuti amtundu womwewo pamalowo. Popeza kuti ziwerengero zomwe zimawerengedwa pamtengo wa torque wa ma bolts amphamvu kwambiri m'miyezo ya Britain ndi America sizofanana, ndikofunikira kuzindikira ma bolts amiyezo iwiriyi.

Maboti amphamvu kwambiri: (M24, L60, giredi 8.8)

Mabawuti wamba: (M24, L60, giredi 8.8)

Zitha kuwoneka kuti ma bolts wamba ndi pafupifupi 70% ya mtengo wazitsulo zamphamvu kwambiri. Kuphatikizana ndi kufananiza kwa zofuna zawo zovomerezeka, zikhoza kuganiziridwa kuti gawo loyamba liyenera kukhala loonetsetsa kuti mphamvu zowonongeka (zolimba) zikugwira ntchito.

Fotokozerani mwachidule

Kwa vuto lomwe likuwoneka ngati losavuta, si nkhani yapafupi kukhala ndi chidziwitso chozama, chokwanira komanso cholondola cha chiyambi chake. Tanthauzo, tanthawuzo ndi kusiyana kwakukulu pakati pa mabawuti amphamvu kwambiri ndi mabawuti wamba ndiye maziko oyambira kuti timvetsetse bwino, kugwiritsa ntchito mabawuti amphamvu kwambiri, ndikuyendetsa ntchito yomanga.

Onani:

1) Zimanenedwadi m'mabuku ena opangira zitsulo kuti ma bolts amphamvu kwambiri amatanthawuza mabawuti omwe mphamvu zawo zimaposa magiredi 8.8. Kwa malingaliro awa, choyamba, miyezo ya Anglo-America siyichirikiza, ndipo palibe tanthauzo la "mphamvu" ndi "zofooka" pamlingo wina wa mphamvu. Chachiwiri, sichikugwirizana ndi "maboti amphamvu kwambiri" omwe atchulidwa mu ntchito yathu.

2) Kuti zikhale zosavuta kufanizitsa, kupsinjika kwa magulu ovuta a bolt sikuganiziridwa pano.

3) Kuthamanga kwa mphamvu ya wononga kumaganiziridwanso popanga bolt yolimba kwambiri, yomwe idzadziwitsidwa mwatsatanetsatane "Kuyerekeza kwazitsulo zothamanga ndi zotsutsana zamtundu wapamwamba".

Kodi mumadziwa bwanji za mabawuti amphamvu kwambiri?

Dzina lonse la ma bolts amphamvu kwambiri popanga limatchedwa high-strength bolt connection pair, ndipo nthawi zambiri samatchulidwa kuti ma bolts amphamvu kwambiri mwachidule.

Malinga ndi mawonekedwe oyika, amagawidwa kukhala: mabawuti akuluakulu a hexagon ndi ma bawuti ometa ubweya. Pakati pawo, mtundu wa torsional shear umangogwiritsidwa ntchito pamlingo wa 10.9.

Malinga ndi kalasi yamasewera a mabawuti olimba kwambiri, amagawidwa kukhala: 8.8 ndi 10.9. Pakati pawo, pali mabawuti amphamvu kwambiri a hexagonal mu giredi 8.8. Mu njira yolembera, chiwerengero chisanafike pa decimal point chimasonyeza mphamvu yamphamvu pambuyo pa chithandizo cha kutentha; nambala pambuyo pa decimal point imasonyeza chiŵerengero cha zokolola, ndiko kuti, chiŵerengero cha mtengo woyezedwa wa mphamvu zokolola ku mtengo woyezedwa wa mphamvu yomaliza yokhazikika. . Gulu la 8.8 limatanthauza kuti mphamvu yolimba ya shaft ya bawuti si yochepera 800MPa, ndipo chiŵerengero cha zokolola ndi 0.8; Gulu la 10.9 limatanthauza kuti kulimba kwa shaft ya bawuti sikuchepera 1000MPa, ndipo chiŵerengero cha zokolola ndi 0.9.

Ma diameter a mabawuti amphamvu kwambiri pamapangidwe amapangidwe amaphatikiza M16/M20/M22/M24/M27/M30, koma M22/M27 ndiye sankhani yachiwiri, ndipo M16/M20/M24/M30 ndiye chisankho chachikulu muzochitika zabwinobwino.

Pankhani ya kumeta ubweya wa ubweya, ma bolts amphamvu kwambiri amagawidwa kukhala: mtundu wothamanga kwambiri wa bolt wothamanga ndi mtundu wa mikangano yamphamvu kwambiri malinga ndi zofunikira za mapangidwe.

Mphamvu yonyamula ya mtundu wa mikangano imadalira pa anti-slip coefficient of the force transmission friction surface ndi kuchuluka kwa malo otsutsana. Mkangano wamtundu wa dzimbiri wofiira pambuyo pa sandblasting (kuwombera) ndiwokwera kwambiri, koma umakhudzidwa kwambiri ndi msinkhu wa zomangamanga ponena za ntchito yeniyeni. Magawo ambiri oyang'anira Onse adakweza ngati mulingo utha kutsitsidwa kuti ntchitoyo ikhale yabwino.

Mphamvu yonyamula katundu wamtundu wopanikizika imadalira mtengo wochepa wa kumeta ubweya wa bolt ndi mphamvu yokakamiza ya bolt. Pankhani yamtundu umodzi wokha wolumikizira, kumeta ubweya wamtundu wamtundu wa M16 ndi 21.6-45.0 kN, pomwe kumeta ubweya wamtundu wamtundu wa M16 ndi 39.2-48.6 kN, ndipo magwiridwe ake ndi abwino kuposa a mtundu wa kukangana.

Pankhani yoyika, njira yamtundu wokakamiza imakhala yosavuta, ndipo malo olumikizira amangofunika kutsukidwa ndi mafuta ndi dzimbiri loyandama. Kuthekera kokhala ndi mphamvu motsata njira ya shaft ndikosangalatsa kwambiri pamapangidwe achitsulo. Mtengo wamapangidwe amtundu wamtunduwu ndi wofanana ndi nthawi 0,8 mphamvu yamphamvu isanachitike, ndipo mtengo wamapangidwe amtundu wapanikizilo ndi wofanana ndi gawo lothandiza la wononga chochulukitsidwa ndi mtengo wamapangidwe amphamvu yamphamvu yazinthu. Zikuwoneka kuti Pali kusiyana kwakukulu, kwenikweni, mfundo ziwirizi ndizofanana.

Ponyamula mphamvu yometa ubweya ndi mphamvu yolimba molunjika ku ndodo ya ndodo panthawi imodzimodziyo, mtundu wa mikangano umafuna kuti chiŵerengero cha mphamvu ya kumeta ubweya wotengedwa ndi bolt ndi kumeta ubweya wa ubweya kuphatikizapo kuchuluka kwa chiŵerengero cha kupsinjika kwa mphamvu ya axial ndi wononga ku mphamvu yamakokedwe ndi yochepera 1.0, ndipo mtundu wapanikizi umafunika Ndi kuchuluka kwa sikweya ya chiŵerengero cha mphamvu yakumeta ubweya ku mphamvu yakumeta ubweya wa bawuti kuphatikiza masikweya a chiŵerengero cha mphamvu ya axial ku mphamvu yamakomedwe a wononga ndi yocheperapo 1.0, ndiko kuti, pansi pa kuphatikizika kwa katundu womwewo, m'mimba mwake momwemo, Chitetezo cha mapangidwe a mabawuti amphamvu kwambiri ndi apamwamba kuposa a mikwingwirima-mtundu wapamwamba-mphamvu mabawuti.

Poganizira kuti pansi mobwerezabwereza zochita za zivomezi zamphamvu, kugwirizana kukangana pamwamba akhoza kulephera, ndi kukameta ubweya mphamvu pa nthawi ino akadali zimadalira kukameta ubweya mphamvu bawuti ndi kuthamanga mphamvu mbale. Choncho, zivomezi zimasonyeza mphamvu yomaliza yometa ubweya wa ma bolts amphamvu kwambiri Kunyamula fomu yowerengera mphamvu.

Ngakhale mtundu wonyamula kukakamiza uli ndi mwayi pamapangidwe ake, chifukwa ndi wa mtundu wolephera wa kukameta ubweya, mabowo a bolt ndi mabowo amtundu wa pore ofanana ndi mabawuti wamba, ndipo kupindika pansi pa katunduyo ndi wamkulu kuposa wa mtundu wa mikangano, kotero kuti mabawuti amphamvu kwambiri amanyamula kupanikizika Mtunduwu umagwiritsidwa ntchito makamaka polumikizana ndi zinthu zopanda zivomezi, kulumikizana kwazinthu zopanda mphamvu, komanso kusabwerezabwereza. kugwirizana zigawo.

Malire ovomerezeka amitundu iwiriyi ndi osiyananso:

Kulumikizana kwamtundu wa friction kumatanthawuza kutsetsereka kwachibale kwa kugwirizana kwa mikangano pansi pa kuphatikiza kofunikira kwa katundu;

Kulumikizana kokakamiza kumatanthawuza kutsetsereka kwachibale pakati pa magawo olumikizira pansi pa kuphatikiza kwa muyezo wa katundu;

Bawuti wamba

1. Maboti wamba amagawidwa m'mitundu itatu: A, B, ndi C. Awiri oyambirira ndi ma bolts oyeretsedwa, osagwiritsidwa ntchito pang'ono. Nthawi zambiri, mabawuti wamba amatanthawuza ma bawuti wamba a C-level.

2. M'malumikizidwe ena akanthawi ndi maulumikizidwe omwe akufunika kupasuka, mabawuti wamba a C-level amagwiritsidwa ntchito kwambiri. Mabawuti wamba omwe amagwiritsidwa ntchito pomanga nyumba ndi M16, M20, M24. Maboti ena ovuta mumsika wamakina amatha kukhala ndi mainchesi okulirapo ndipo amagwiritsidwa ntchito pazinthu zapadera.

Maboti amphamvu kwambiri

3. Zida zazitsulo zamphamvu kwambiri ndizosiyana ndi mabotolo wamba. Maboti amphamvu kwambiri nthawi zambiri amagwiritsidwa ntchito polumikizana kosatha. Nthawi zambiri amagwiritsidwa ntchito ndi M16 ~ M30. Kuchita kwa mabawuti amphamvu kwambiri ndi osakhazikika ndipo kuyenera kugwiritsidwa ntchito mosamala.

4. Kulumikizana kwa bolt kwa zigawo zikuluzikulu za nyumba yomanga nthawi zambiri kumalumikizidwa ndi ma bolts amphamvu kwambiri.

5. Maboti amphamvu kwambiri omwe amaperekedwa ndi fakitale samagawidwa kukhala kukakamiza kapena kugundana.

6. Kodi ndi ma bawuti amphamvu kwambiri amtundu wa friction kapena mabawuti amphamvu kwambiri? M'malo mwake, pali kusiyana mu njira yowerengera mamangidwe:

1) Kwa ma bolts amphamvu kwambiri, kutsetsereka pakati pa mbale kumawonedwa ngati malire a mphamvu yonyamula.

2) Kwa ma bolts amphamvu kwambiri, kutsetsereka pakati pa mbale kumawonedwa ngati malire ogwiritsira ntchito mwachizolowezi, ndipo kulephera kwa kugwirizana kumaonedwa ngati malire a mphamvu yobereka.

7. Maboti amphamvu kwambiri amtundu wa friction sangathe kupereka kusewera kwathunthu ku kuthekera kwa mabawuti. Muzochita zenizeni, mabawuti amphamvu kwambiri amtundu wa mikangano amayenera kugwiritsidwa ntchito pazinthu zofunika kwambiri kapena zomangidwa zomwe zimakhudzidwa ndi katundu wosunthika, makamaka pamene katunduyo amayambitsa kupsinjika. Panthawiyi, mphamvu ya bawuti yosagwiritsidwa ntchito ingagwiritsidwe ntchito ngati posungira chitetezo. M’madera ena, mabawuti okhala ndi mphamvu yamphamvu ayenera kugwiritsidwa ntchito kuti achepetse mtengo.

Kusiyana pakati pa mabawuti wamba ndi mabawuti amphamvu kwambiri

8. Maboti wamba amatha kugwiritsidwanso ntchito, koma ma bolts amphamvu kwambiri sangagwiritsidwenso ntchito.

9. Maboti amphamvu kwambiri nthawi zambiri amapangidwa ndi chitsulo champhamvu kwambiri (No. 45 zitsulo (8.8s), 20MmTiB (10.9S), zomwe zimakhala ndi ma bolts okhazikika. Mtundu wa mkangano umagwiritsa ntchito wrench ya torque kuti ugwiritse ntchito prestress yomwe yatchulidwa, ndi Kupanikizika kwamtundu kumamasula mutu wa maluwa a maula Nthawi zambiri amapangidwa ndi chitsulo wamba (Q235) komanso afunika kumangitsa.

10. Maboti wamba amakhala giredi 4.4, giredi 4.8, giredi 5.6 ndi giredi 8.8. Maboti olimba kwambiri amakhala giredi 8.8 ndi giredi 10.9, pomwe giredi 10.9 ndi ambiri.

11. Mabowo opondera a mabawuti wamba sakhala okulirapo kuposa amphamvu kwambiri. M'malo mwake, mabawuti wamba amakhala ndi timabowo tating'onoting'ono.

12. Mabowo owononga a magiredi A ndi B a mabawuti wamba nthawi zambiri amakhala okulirapo ndi 0.3~0.5mm kuposa mabawuti. Mabowo a Class C nthawi zambiri amakhala akulu 1.0 ~ 1.5mm kuposa mabawuti.

13. Mabawuti amphamvu kwambiri amtundu wa friction amatumiza katundu mwa kukangana, kotero kusiyana pakati pa screw ndodo ndi bowo poto kumatha kufika 1.5-2.0mm.

14. Makhalidwe otumizira mphamvu zazitsulo zokhala ndi mphamvu zowonjezera mphamvu ndizoonetsetsa kuti pansi pa ntchito yabwino, kumeta ubweya sikudutsa mphamvu yothamanga, yomwe imakhala yofanana ndi yamtundu wa friction-high-power bolts. Pamene katundu ukuwonjezeka kachiwiri, slippage wachibale zidzachitika pakati kulumikiza mbale, ndi kugwirizana amadalira kukameta ubweya wa wononga ndi kupsyinjika kwa dzenje khoma kufalitsa mphamvu, amene ali ofanana ndi mabawuti wamba, kotero kuti kusiyana pakati pa wononga ndi wononga dzenje ndi laling'ono pang'ono, 1.0-1.5mm.

Anebon amatsatira mfundo yakuti "Woona mtima, wolimbikira, wochita chidwi, wanzeru" kuti apeze mayankho atsopano mosalekeza. Anebon amawona ziyembekezo, kupambana ngati kupambana kwake. Lolani Anebon amange tsogolo labwino m'manja pazigawo zamakina zamkuwa ndi zida za Complex titanium cnc / zida zopondaponda. Anebon tsopano ili ndi katundu wokwanira komanso mtengo wogulitsa ndi mwayi wathu. Takulandilani kuti mufunse za malonda a Anebon.

Zomwe Zili Padziko Lapansi China CNC Machinging Part ndi Precision Part, ngati chilichonse mwazinthuzi chingakusangalatseni, chonde tidziwitseni. Anebon adzakondwera kukupatsani mawu oti mutenge mwatsatanetsatane. Anebon ali ndi akatswiri athu a R&D akatswiri kuti akwaniritse zofunikira zilizonse. Anebon akuyembekezera kulandira zofunsa zanu posachedwa ndipo ndikuyembekeza kukhala ndi mwayi wogwira ntchito limodzi nanu mtsogolo. Takulandilani kuti muwone bungwe la Anebon.

Nthawi yotumiza: Jun-01-2023