Chidule cha njira zisanu ndi zitatu zopangira ulusi zomwe muyenera kudziwa mukamakonza.

.Mawu a Chingerezi ofanana ndi Screw ndi Screw. Tanthauzo la mawuwa lasintha kwambiri m’zaka mazana aposachedwapa. Osachepera mu 1725, amatanthauza "mating".

Kugwiritsiridwa ntchito kwa mfundo ya ulusi kungayambikenso ku chida chonyamulira madzi chozungulira chomwe chinapangidwa ndi katswiri wachi Greek Archimedes mu 220 BC.

M’zaka za m’ma 400 AD, mayiko a ku Mediterranean anayamba kugwiritsa ntchito mfundo ya ma bolts ndi mtedza ku makina osindikizira omwe amagwiritsidwa ntchito popanga vinyo. Panthaŵiyo, ulusi wakunjawo unkakulungidwa ndi chingwe kupita ku cylindrical bar ndiyeno wosemedwa motsatira chizindikirochi, pamene ulusi wamkati kaŵirikaŵiri unkapangidwa mwa kumenya ulusi wakunja ndi chinthu chofewa.

Cha m'ma 1500, muzojambula za chipangizo chopangira ulusi chojambulidwa ndi Leonardo da Vinci wa ku Italy, panali lingaliro logwiritsa ntchito Screw yachikazi ndi zida zosinthira kuti zigwirizane ndi ulusi wokhala ndi mafunde osiyanasiyana. Kuyambira pamenepo, njira yodulira ulusi mwa makina yayambika m’makampani opanga mawotchi ku Ulaya.

Mu 1760, abale a ku Britain J. Wyatt ndi W. Wyatt anapeza chilolezo chodulira zitsulo zamatabwa pogwiritsa ntchito chipangizo china. Mu 1778, British J. Ramsden anapanga chipangizo chodulira ulusi choyendetsedwa ndi giya ya nyongolotsi, yomwe imatha kupanga ulusi wautali molunjika kwambiri. Mu 1797, Mngelezi wina dzina lake H. Maudsley anagwiritsa ntchito Screw yachikazi ndi zida zosinthira kutembenuza ulusi wazitsulo wamitundu yosiyanasiyana pa lathe yake yowongoleredwa, yomwe idayika njira yoyamba yokhotakhota.

M'zaka za m'ma 1820, Maudsley adatulutsa matepi oyambirira ndipo amafa chifukwa cha ulusi.

Kumayambiriro kwa zaka za m'ma 1900, chitukuko cha makampani opanga magalimoto chinalimbikitsanso kukhazikika kwa ulusi ndi chitukuko cha njira zosiyanasiyana zolondola komanso zogwira mtima. Mitundu yosiyanasiyana ya mitu yotsegulira yokha ndi matepi ocheperako okha adapangidwa motsatizana, ndipo mphero ya ulusi idayamba kugwiritsidwa ntchito.

Kumayambiriro kwa zaka za m'ma 1930, ulusi ukupera udawonekera.

Ngakhale ukadaulo wogubuduza ulusi unali wovomerezeka koyambirira kwa zaka za zana la 19, chifukwa cha zovuta kupanga nkhungu, chitukukocho chinatalikitsidwa mpaka Nkhondo Yachiwiri Yapadziko Lonse (1942-1945) chifukwa chofuna kupanga zida ndi chitukuko chaukadaulo wogaya ulusi. Vuto lenileni la kupanga nkhungu lakula mofulumira.Kusintha kwa mtengo wa CNC

Ulusi umagawidwa makamaka mu ulusi wolumikiza ndi ulusi wotumizira.

Njira zapakati zogwirira ntchito zolumikizira ulusi ndikugogoda, kusaka, ulusi, kugudubuza ulusi, kugudubuza ulusi, etc.

Njira zapakati zopangira ulusi wopatsirana ndizovuta komanso zokhotakhota bwino---kupera, mphero ---zozungulira komanso zokhotakhota bwino, ndi zina.

Gulu loyamba ndi kudula ulusi

Nthawi zambiri amatanthauza kupanga ulusi wokhala ndi zida zopangira kapena zonyezimira, makamaka kuphatikiza kutembenuza, mphero, kugogoda ndi kupera ulusi, kupera, ndi kudula kamvuluvulu. Potembenuza, mphero, ndi kugaya ulusi, tcheni choyendetsa cha chida cha makina chimatsimikizira kuti chida chotembenuza, chodulira mphero, kapena gudumu lopera limayenda ndendende ndi mogawaniza chitsogozo chimodzi pamzere wa chogwirirapo pakusintha kulikonse kwa chogwiriracho. Pogogoda kapena ulusi, chida (pampopi kapena kufa) ndi workpiece atembenuza wachibale wina ndi mzake, ndipo kale anapanga ulusi poyambira amatsogolera chida (kapena workpiece) kusuntha axially.

1. Kutembenuza ulusi

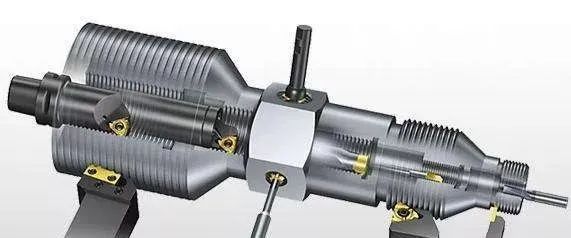

Kutembenuza ulusi pa lathe kumatha kuchitidwa ndi chida chotembenuza kapena chipeso cha ulusi. Kutembenuza ulusi ndi chida chosinthira ndi njira yokhazikika yopangira chidutswa chimodzi komanso tinthu tating'ono tating'ono tating'ono tating'onoting'ono ta ulusi chifukwa cha zida zosavuta; kutembenuza ulusi ndi chida chophatikizira ulusi kumakhala ndi kuthekera kwakukulu kopanga, koma mawonekedwe a zida ndi ovuta, oyenera kupanga batch yapakati komanso yayikulu. Amatembenuza ulusi waufupi wokhala ndi mawu abwino. Kulondola kwa phula kwa lathes wamba potembenuza ulusi wa trapezoidal kumatha kufika 8 mpaka 9 magiredi (JB2886-81, chimodzimodzi pansipa); Kupanga ulusi pazingwe zapadera za ulusi kumatha kukulitsa zokolola kapena kulondola.

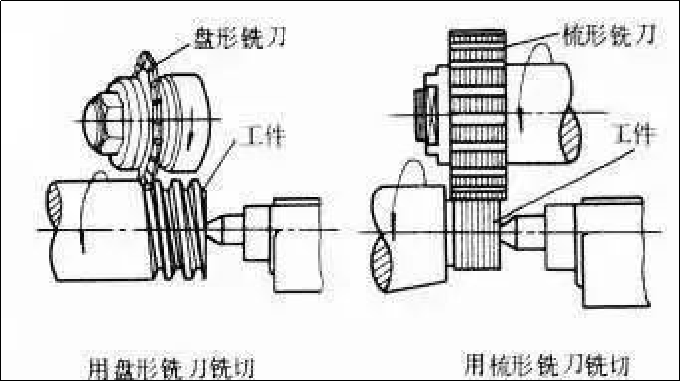

2. Kupera ulusi

Ndinali mphero ndi disc kapena chocheka zisa pa mphero ya ulusi.

Zimbale mphero cutter makamaka ntchito mphero trapezoidal kunja ulusi pa workpieces monga zomangira ndi mphutsi woboola pakati mphero cutter ntchito mphero mkati ndi kunja wamba ulusi ndi tapered ulusi. Popeza amagayidwa ndi chodula chamitundu yambiri ndipo kutalika kwa gawo lake logwirira ntchito ndi lalikulu kuposa kutalika kwa ulusi, chogwiriracho chimangofunika kuzunguliridwa 1.25 mpaka 1.5 kutembenuka kuti kukonzedwa ndikuchita zokolola zambiri. Kulondola kwa phula kwa mphero ya ulusi nthawi zambiri kumatha kufika giredi 8 mpaka 9, ndipo kuuma kwapamtunda ndi ma microns a R5 mpaka 0.63. Njirayi ndi yoyenera kupangira zida zopangira misala zotsogola bwino kwambiri kapena zopotoka musanazipere.

Wodula ulusi wopangira ulusi wamkati

3. Kupera ulusi

Amagwiritsidwa ntchito makamaka pokonza ulusi wolondola wa zida zolimba pa makina opera ulusi. Maonekedwe a mtanda gawo la gudumu akupera akhoza kugawidwa mu mitundu iwiri: umodzi mzere gudumu akupera ndi Mipikisano mizere gudumu kugaya. Kulondola kwa phula komwe kumakwaniritsidwa ndi kupera kwa magudumu amtundu umodzi ndi magiredi 5 mpaka 6, ndipo kuuma kwapamtunda ndi ma microns a R1.25 mpaka 0.08, omwe ndi osavuta pogaya magudumu. Njira imeneyi ndi yoyenera kugaya zomangira zolondola, zoyezera ulusi, nyongolotsi, timagulu tating'ono tating'ono tating'onoting'ono ta ulusi, ndi zomangira zopumira. Mipikisano mizere akupera gudumu akupera amagawidwa longitudinal ndi agwere akupera njira. M’njira yopera yautali, m’lifupi mwa gudumu lopera ndi locheperapo kusiyana ndi kutalika kwa ulusi woti ausike, ndipo gudumu lopera limayenda motalika kamodzi kapena kangapo kuti upere ulusiwo ufikire kukula kwake. M'lifupi mwa gudumu lopera la njira yoperayo ndi yokulirapo kuposa kutalika kwa ulusi wopukutidwa. Gudumu logaya limadulidwa mozungulira pamwamba pa chogwirira ntchito, ndipo chogwiriracho chimatha kugwedezeka pambuyo pa kusinthika pafupifupi 1.25. Zokolola ndizokwera, koma kulondola kumakhala kotsika pang'ono, ndipo kuvala kwa magudumu okupera kumakhala kovuta kwambiri. Plunge grinding ndi koyenera pogaya magulu akuluakulu a matepi komanso pogaya ulusi wina wake womanga.zigawo za aluminiyamu extrusion

4. Kupera ulusi

Chopukusira chamtundu wa nati kapena chopukutira chimapangidwa ndi zinthu zofewa monga chitsulo choponyedwa, ndipo mbali zomwe ulusi uli ndi vuto la phula pamakina ogwirira ntchito amatsogozedwa ndi kugaya mozungulira kuti amveke bwino. Ulusi wolimba wamkati nthawi zambiri umadulidwa kuti athetse kupindika ndikuwongolera kulondola.

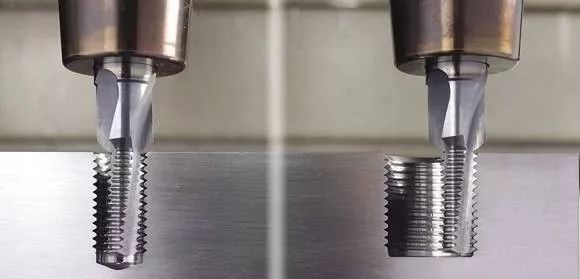

5. Kugogoda ndi ulusi

Kugogoda

Ndikokololera mpopi mu dzenje lobowoledwa kale pa chogwirira ntchito ndi torque inayake kuti mukonze ulusi wamkati.

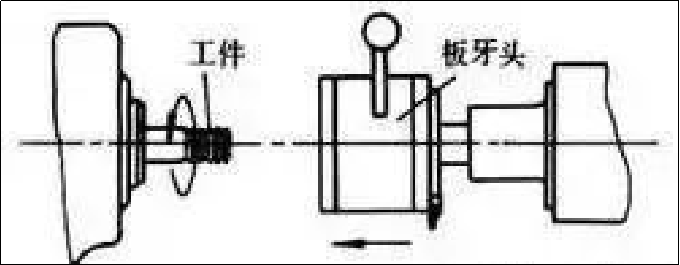

Ulusi

Dulani ulusi wakunja pa bar (kapena chitoliro) chogwirira ntchito ndi kufa. Kulondola kwa makina pogogoda kapena kulumikiza kumadalira kulondola kwa mpopi kapena kufa.zigawo za aluminiyamu

Ngakhale pali njira zambiri zopangira ulusi wamkati ndi kunja, ulusi wamkati waung'ono ukhoza kukonzedwa ndi matepi. Kugogoda ndi ulusi kungathe kuchitidwa ndi manja, komanso ndi lathes, makina osindikizira, makina opopera, ndi makina opangira ulusi.

Gulu lachiwiri: Kugudubuza ulusi

The processing njira ya plastically deforming workpiece ndi kupanga anagubuduza kufa kupeza ulusi. Kugubuduza ulusi nthawi zambiri kumachitika pamakina ogubuduza a Thread kapena lathe lodziwikiratu lomwe limatsegula ndi kutseka mutu wa Thread rolling, ulusi wakunja wopanga zomangira zokhazikika, ndi zolumikizira zina. Kuzungulira kwakunja kwa Ulusi Wokulungidwa Ndiwosapitilira 25 mm, kutalika kwake sikupitilira 100 mm, kulondola kwa ulusi kumatha kufika pamlingo wa 2 (GB197-63), ndipo m'mimba mwake mwachopanda chogwiritsidwa ntchito ndi pafupifupi wofanana ndi kukula kwake. wa Ulusi wokonzedwa. RThread nthawi zambiri siyitha kukonza ulusi wamkati, koma kwa zogwirira ntchito zokhala ndi zida zofewa, kampopi wopanda grooveless angagwiritsidwe ntchito kuziziritsa ulusi wamkati (kuzama kwake kumatha kufika pafupifupi 30 mm). Mfundo yogwira ntchito ndi yofanana ndi kugogoda. Makokedwe omwe amafunikira pakuzizira kwa ulusi wamkati ndi wokulirapo kuwirikiza ka 1 kuposa kugunda, ndipo kulondola kwa makina ndi mtundu wapamtunda ndizokwera pang'ono kuposa zopopera.

Ubwino wa Thread rolling:

①Kukhwinyata kwapamwamba ndi kocheperako kuposa kutembenuka, mphero, ndi kugaya;

②Pamwamba pa Thread afThreadlling imatha kupititsa patsogolo mphamvu ndi kuuma chifukwa cha kuzizira kwa ntchito;

③Mlingo wogwiritsa ntchito zinthu ndiwokwera;

④Zokolola zimachulukitsidwa kawiri poyerekeza ndi kudula, ndipo ndikosavuta kuzindikira makina;

⑤ Moyo wogubuduza ndi wautali kwambiri. Komabe, rolling Thread reThread kuti kuuma kwa workpiece sikudutsa HRC40; kulondola kwa dimensional kwa chopanda kanthu ndikwambiri; kulondola ndi kuuma kwa kufa kwa gudumu kulinso kwakukulu, ndipo ndizovuta kupanga kufa; siyoyenera kugudubuza ulusi wokhala ndi mawonekedwe a asymmetric dzino.

Malinga ndi ma rolling amafa osiyanasiyana, Ulusi ukhoza kugawidwa m'mitundu iwiri: Kugudubuzika kwa ulusi ndi Threadthreadd.

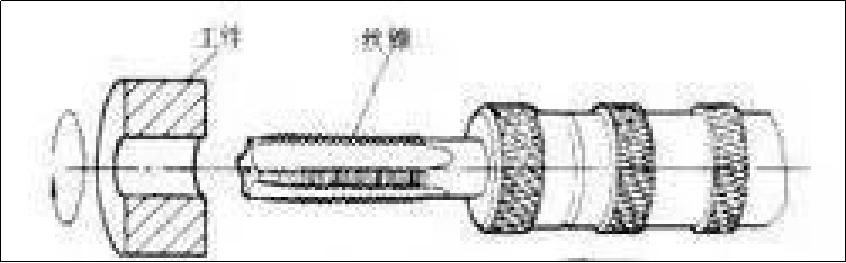

6. Kugudubuza ulusi

Ma mbale awiri opindika ulusi okhala ndi mawonekedwe a mano amakonzedwa moyang'anizana ndi phula la 1/2; mbale yosasunthika imakhazikika, ndipo mbale yosuntha imayenda motsatira mzere wofanana ndi mbale yosasunthika. Pamene workpiece imatumizidwa pakati pa mbale ziwirizo, mbale yosuntha imapita patsogolo ndikupukuta workpiece kuti iwonongeke pamwamba kuti ipange ulusi (Chithunzi 6 [Screwing]).

7. Kugudubuza ulusi

Pali mitundu itatu ya radial Thread roThread, tangential Thread roThread, ndi rolling head thread rolling.

①Radial Threathreadad 2 (kapena 3) mawilo ogudubuza ulusi okhala ndi mbiri ya ulusi amayikidwa pamiyendo yofananira; workpiece imayikidwa pa chithandizo pakati pa mawilo awiri, ndipo mawilo awiriwa amazungulira mbali imodzi ndi liwiro lomwelo (Chithunzi 7). [Radial Thread rolling]), imodzi mwazozungulira, imachitanso kayendedwe ka chakudya. Gudumu logudubuza ulusi limazungulira chogwirira ntchito, ndipo pamwamba pake amatuluka mozungulira kuti apange ulusi. Kwa zomangira zina zotsogola zomwe sizifuna kulondola kwambiri, njira yofananira ingagwiritsidwenso ntchito popanga mipukutu.

②Tangential Thread roThread Imadziwikanso kuti planetary Thread roThread, chida chogudubuza chimakhala ndi gudumu lozungulira lapakati ndi mbale zitatu zokhazikika zokhala ngati arc (mkuyu 8 [Tangential Thread rolling]). Chogwiritsira ntchito chimatha kudyetsedwa mosalekeza panthawi ya ulusi wa Thread, kotero kuti zokololazo zimakhala zapamwamba kuposa za Thread roThreadand radial Thread thread.

③ Ulusi wopangidwanso: Imapangidwa pa lathe yokha ndipo nthawi zambiri imagwiritsidwa ntchito popanga ulusi waufupi pa chogwirira ntchito. Pali 3 mpaka 4 mawilo akugudubuza ulusi wogawana anagawira pa periphery akunja workpiece mu anagubuduza mutu (mkuyu. 9 [Ulusi rethreaded kugudubuza]). Pakugubuduza ulusi, workpiece imazungulira, ndipo mutu wogubuduza umadyetsa axially kuti ugubuduze chogwirira ntchito kuchokera ku Ulusi.

Kusaka ulusi

Kukonza ulusi wamba nthawi zambiri kumagwiritsa ntchito malo opangira makina kapena zida ndi zida; nthawi zina, kugogoda pamanja kumathekanso. Komabe, nthawi zina zapadera, njira pamwamba si zophweka kupeza zotsatira zabwino processing, monga kufunika makina ulusi pambuyo kutentha mankhwala a mbali chifukwa cha kusasamala kapena chifukwa cha zopinga zakuthupi, monga kufunika ndikupeza mwachindunji pa carbide workpieces. . Panthawiyi, m'pofunika kuganizira njira yopangira pEDM.

Poyerekeza ndi njira yopangira makina, ndondomeko ya EDM ili mu dongosolo lomwelo: dzenje la pansi liyenera kukumbidwa poyamba, ndipo m'mimba mwake pansi pa dzenje liyenera kutsimikiziridwa malinga ndi momwe ntchito ikugwirira ntchito. Elekitirodi iyenera kupangidwa kuti ikhale yofanana ndi ulusi, ndipo electrode iyenera kusinthasintha panthawi yokonza makina.

Anebon Metal Products Limited ikhoza kupereka CNC Machining, Die Casting, Sheet Metal Fabrication service, chonde omasuka kulankhula nafe.

Tel: +86-769-89802722 E-mail: info@anebon.com URL: www.anebon.com

Nthawi yotumiza: Apr-15-2022