Kodi mukudziwa kuti ndi njira zingati zomwe zilipo zokhazikika pazida za CNC?

Njira ya Touch Probe: - Njirayi imagwiritsa ntchito kafukufuku womwe umakhudza chida kuti chiyezetse malo ake malinga ndi malo owonetsera makina. Zimapereka deta yolondola pazida ziwiri ndi kutalika kwake.

Chida Chokonzekeratu:Chida-pre-setter fixture chimagwiritsidwa ntchito kuyeza kukula kwa chida kunja kwa makina. Njirayi imalola kukhazikitsa mwachangu komanso molondola kwa chida.

Tool Offset Njira:- Munjira iyi, wogwiritsa ntchito amayesa kutalika ndi kutalika kwa chidacho pogwiritsa ntchito zida monga ma calipers ndi ma micrometer. Makhalidwewa amalowetsedwa mu makina owongolera makina.

Kuyeza kwa Chida cha Laser:Makina a laser amagwiritsidwa ntchito kuyika ndi kuyeza kukula kwa zida. Pogwiritsa ntchito kuwala kwa laser pamphepete mwa chidacho, amapereka deta yolondola komanso yachangu.

Njira Yozindikiritsa Zithunzi:Makina apakompyuta apamwamba amatha kugwiritsa ntchito ukadaulo wozindikira zithunzi kuti awerengeretu kukula kwa zida. Amachita izi pojambula zithunzi za chidacho, kusanthula mbali zake ndi kuwerengera miyeso yake.

Nkhaniyi ndi yothandiza kwambiri. Nkhaniyi imatchula poyamba mfundo ndi malingaliro a "mayesero-kudula chida-njira" yomwe imagwiritsidwa ntchito ndi CNC lathes. Kenako imayambitsa njira zinayi zopangira zida zodulira zoyeserera za CNC kutembenuza kachitidwe. Kuwongolera kulondola kwa zoikamo zake zida, pulogalamu yoyang'anira njira yodulira yoyeserera yokhazikika pa "kudula-kuyesa - kubweza zolakwika" idapangidwa. Njira zinayi zolondola zokhazikitsira zida zafotokozedwanso mwachidule.

1. Mfundo ndi malingaliro kumbuyo kwa chida chokhazikitsa njira ya CNC lathes

Kumvetsetsa mfundo zokhazikitsira zida za CNC ndikofunikira kwa ogwiritsira ntchito omwe akufuna kusunga malingaliro omveka bwino okhudza kukhazikitsa zida, kukonza zida, ndikuwonetsa njira zatsopano. Kuyika kwa zida ndikuzindikira komwe kumayambira makina ogwiritsira ntchito, zomwe zimasintha mukakonza makina opangira makina. Kukonzekera kwa zida kumaphatikizapo kupeza makina ogwiritsira ntchito poyambira pulogalamu yachidziwitso, ndikuzindikira chida chogwirizana ndi chidacho.

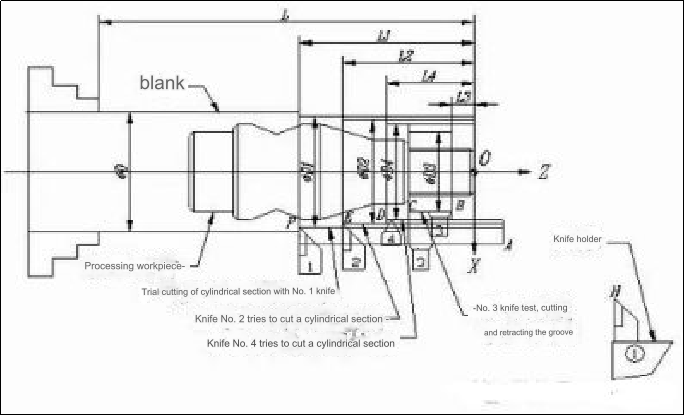

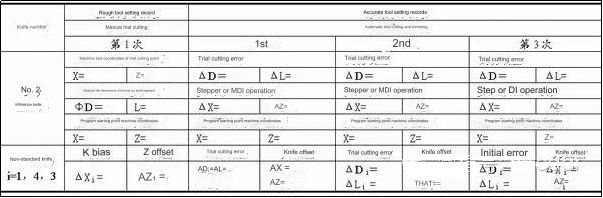

Misonkhano yotsatirayi imagwiritsidwa ntchito kuwonetsa malingaliro ndi malingaliro kumbuyo kwa zida pogwiritsa ntchito njira yodulira. Gwiritsani ntchito Hua Medieval Star Teaching Turning System (chiwerengero cha 5.30 cha pulogalamu yogwiritsira ntchito); gwiritsani ntchito chapakati chakumanja chakumanja pachidutswa choyambira pulogalamuyo ndikuyiyika ndi lamulo la G92. Mapulogalamu a diameter, ma coordinates a pulogalamu yoyambira poyambira H ndi (100,50); ikani zida zinayi pachosungira chida. Chida cha No.1 ndi 90deg rough converting tool ndipo No. Reference tool 2 ndi 90deg kunja kwa bwalo kutembenuza bwino. mpeni, No. No. Mpeni wa 4 ndi mpeni wa ulusi wa katatu wokhala ndi ngodya ya 60deg (zitsanzo zomwe zili m'nkhaniyi ndizofanana).

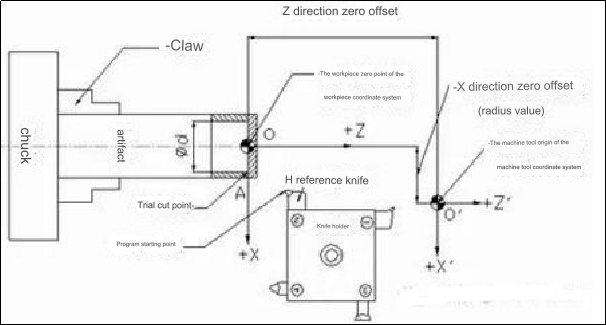

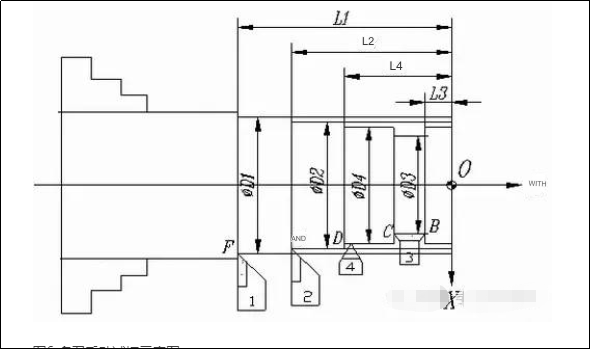

Mapangidwe a "chida cha makina" amagwiritsidwa ntchito pakukhazikitsa zida. Monga tawonera mu chithunzi 1, chida cholozera "kuyesa pamanja kumadula bwalo lakunja ndi nkhope yomaliza ya chogwirira ntchito ndikulemba zida zamakina a XZ pazowonetsera. Chida cha makina chimagwirizanitsa chiyambi cha pulogalamu O chimachokera ku chiyanjano pakati pa makina opangira makina pa A ndi O: XO = XA - Phd, ZO = ZA. Pogwiritsa ntchito ma workpiece a H molingana ndi mfundo O (100,50), tikhoza kupeza makina opangira makina a mfundo H: XH = 100 - Phd, ZH = ZA+50. Dongosolo logwirizanitsa la workpiece limatengera malo omwe chidacho chili pa chida cholozera.

Chithunzi 1 Chojambula chojambula chocheka pamanja ndi zoikamo za zida

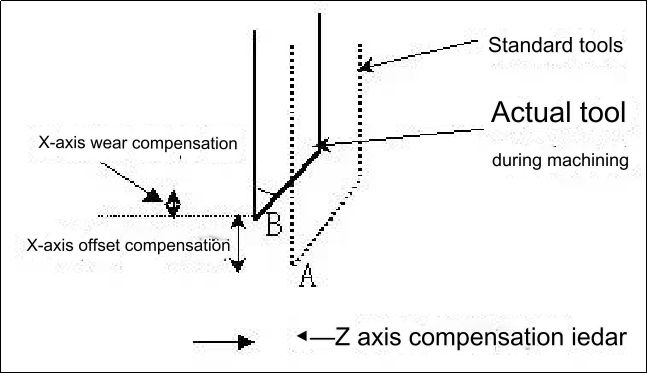

Pachithunzi 2, kusinthana pakati pa mfundo A ndi nsonga B kumachitika chifukwa cha kusiyana kwa zowonjezera ndi malo omwe ali mu X- ndi Z-kuwongolera kwa zida zomwe zimakanikizidwa mu chogwiritsira ntchito. Dongosolo lothandizira loyambirira la workpiece silikugwiranso ntchito. Chida chilichonse chidzavalanso pamlingo wosiyana pakagwiritsidwe ntchito. Chifukwa chake, zida zochotsera ndi kuyika mtengo pa chida chilichonse ziyenera kulipidwa.

Kuti mudziwe chida chothandizira, chida chilichonse chiyenera kugwirizanitsidwa ndi malo enieni (mfundo A kapena B mu Chithunzi 1) pa workpiece. CRT ikuwonetsa zida zamakina zomwe ndizosiyana ndi zida zochotsera zida zomwe sizinatchulidwe. Choncho, iwo ali pa malo omwewo. Pogwiritsa ntchito kuwerengera pamanja kapena kuwerengera mapulogalamu, makonzedwe a zida zamakina amachotsedwa ku zomwe zida zolozera. Chida chotsitsacho chimawerengedwa pa chipangizo chilichonse chomwe sichikhala chokhazikika.

Chithunzi 2 Kulipiritsa zida zochotsera ndi kuvala

The zolondola Buku mayesero kudula chida zoikamo ndi malire. Izi zimatchedwa rough tooling. Monga momwe chithunzi 3 chasonyezera, kuti tipeze zotsatira zolondola kwambiri mkati mwa malipiro a makina acnc auto gawo, pulogalamu yosavuta yodzipangira yokha yoyeserera imatha kupangidwa. Mpeni wolozera umasinthidwa mosalekeza pogwiritsa ntchito lingaliro la "malipiro olakwika odulira okha". Chida chochepetsera ndi poyambira pulogalamu ya chida chosalozera chimagwiritsidwa ntchito kuwonetsetsa kuti kusiyana pakati pa mtengo wa malangizo okonzekera ndi mtengo weniweni woyezera kumakwaniritsa zofunikira. Kukonzekera kwa zida zolondola ndizomwe zimachitika panthawiyi.

Ndizofala kukonza zolakwika zomwe sizinali zokhazikika pambuyo pokonza koyamba. Izi zili choncho chifukwa kuonetsetsa kuti poyambira chida cholozera ndi cholondola ndikofunikira kuti zida zolondola zichotsedwe.

Njira yokhazikitsira chida ichi imatheka pophatikiza magawo awiriwa: yesani pamanja kudula mpeni ndikulozera kuti mupeze zida zamakina zolumikizira zida zowonetsera zida. - Werengetsani kapena kuwerengera zokha zida zochotsera zida zilizonse zomwe sizinatchulidwe. - Mpeni wolozera umapezeka poyambira pulogalamuyo. - Mpeni wolozera mobwerezabwereza umayitanitsa pulogalamu yodula mayeso. Chogwirizira chida chidzasunthidwa mu MDI kapena masitepe kuti abwezere zolakwika ndikuwongolera malo oyambira. Mukayeza kukula kwake, mpeni wosakhazikika umayimba mobwerezabwereza pulogalamu yodula. Chida chotsitsacho chimakonzedwa kutengera kuchotsera uku. Izi zikutanthauza kuti chida cholozera chizikhala choyimilira kumayambiriro kwenikweni kwa pulogalamuyo.

Chithunzi cha 3 Schematic Diagram of Tool Setting for Multi-Knife Trial Cutting

Kufotokozera mwachidule njira zopangira mpeni

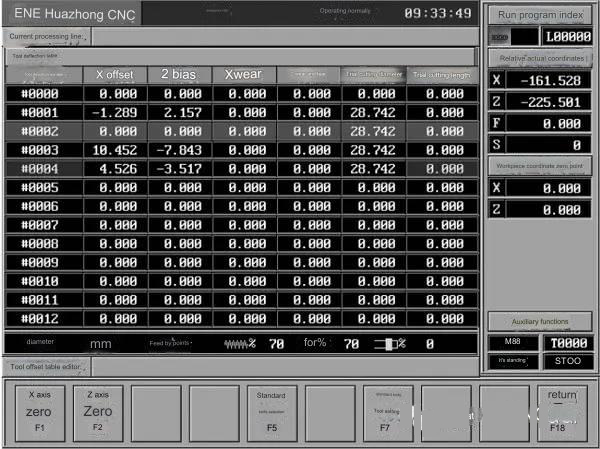

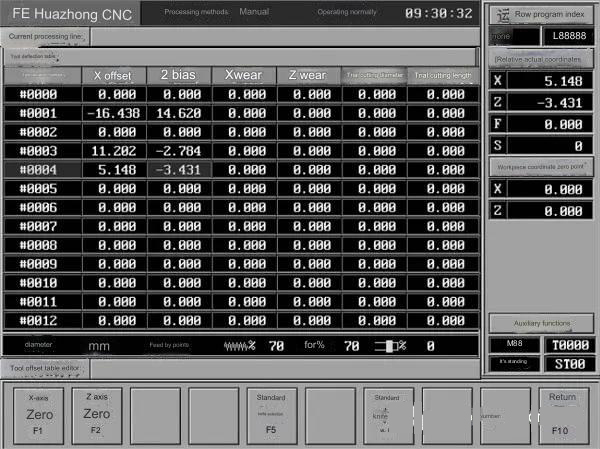

Kuti mukonzekere kuyika zida, mutha kugwiritsa ntchito njira izi: dinani batani F2 mu submenu ya dongosolo la MDI kuti mupeze tebulo lotsitsa zida. Gwiritsani ntchito makiyi kuti musunthire kapamwamba ku malo a nambala ya chida omwe amagwirizana ndi chida chilichonse ndikusindikiza batani F5. Sinthani mikhalidwe ya X ndi Z ya manambala ochotsera zida #0000 ndi #0001, kenako dinani batani F5.

1) Khazikitsani njira yosinthira chida posankha chida cholozera.

Njira zokhazikitsira chida zikuwonetsedwa muzithunzi 1 ndi 4.

Buluu labuluu lomwe likuwonetsedwa ndi makiyi likhoza kusunthidwa kuti ligwirizane ndi chida chochotsera #0002 pa chida cha nambala 2. Chida cholozera 2. Kuti muyike No.2, dinani batani la F5. Chida cha 2 chidzakhazikitsidwa ngati chida chosasinthika.

2) Dulani bwalo lakunja ndi chida cholozera ndipo zindikirani makina a X makina-chida. Pambuyo pochotsa chidacho, imitsani makinawo ndikuyesa kukula kwa gawo la shaft.

3) Tsamba lofotokozera limabwerera ku mfundo A yolembedwa ndi njira ya "jog + step". Lowetsani PhD ndi ziro m'zaza za kudula kwa mayeso ndi kutalika kwa mayeso motsatana.

4) Bwezerani chida chokhazikika ndikusankha nambala ya chida chosavomerezeka. Ndiye, pamanja kusintha chida. Chida chothandizira pazida zilizonse zomwe sizili zokhazikika zigwirizane ndi mfundo A pogwiritsa ntchito njira ya "jog+step". Sinthani cholumikizira chofananira chida chikalumikizidwa ndikuwoneka. Mukayika ziro ndi PhD m'mizere ya kutalika kwa kuyesa kuyesa ndi m'mimba mwake, mipeni ya mipeni yonse yosalozera imangowonetsedwa pa X offset ndi Z offset column.

5) Chida chothandizira chikabwerera kumalo A, MDI idzayendetsa "G91 G00/kapena" G01 X[100 PhD] Z50 kuti ifike poyambira pulogalamuyo.

Chithunzi 4 Chithunzi cha Schematic cha chida cholozera chokha chokhazikitsa chida chosinthira chida chokhazikika

2. Khazikitsani ma coordinates a chida cholozera kukhala ziro pa malo pomwe zida zoyambilira ndikuwonetsa zokha njira yochotsera zida.

Monga chithunzi 1 ndi Chithunzi 5, njira zokhazikitsira zida ndi motere:

1) Mofanana ndi sitepe (2) pamwamba.

2) Mpeni wolozera umabwerera kumalo odulira mayeso A kudzera munjira ya "jog + step" molingana ndi mtengo wolembedwa.

3) Mu mawonekedwe omwe akuwonetsedwa mu Chithunzi 4, yesani fungulo la F1 kuti "kukhazikitsa X-axis ku zero" ndikusindikiza fungulo la F2 "kukhazikitsa Z-axis ku zero". Kenako "magwirizano enieni" omwe akuwonetsedwa ndi CRT ndi (0, 0).

4) Sinthani pamanja chida chosagwiritsidwa ntchito kuti chida chake chikhale chogwirizana ndi mfundo A. Panthawiyi, mtengo wa "magwirizano enieni achibale" omwe akuwonetsedwa pa CRT ndi chida chothandizira chida chokhudzana ndi chida chofotokozera. Gwiritsani ntchito ▲ ndi makiyi kuti musunthe buluu Yang'anani nambala yosinthira chida cha chida chosalozera, chilembeni ndikuchiyika molingana.

5) Mofanana ndi sitepe yapitayi (5).

Chithunzi 5 Schematic Diagram of the Tool Offset imangowonetsedwa pomwe Chida Cholozera chakhazikitsidwa paziro muzowongolera zida zolumikizira.

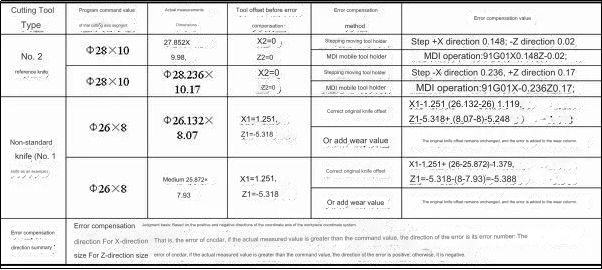

3. Njira yochotsera mpeni imawerengedwa mwa kuwerengera pamanja kudula kwa mayesero ndi mipeni yambiri ya gawo lakunja lozungulira shaft.

Monga momwe chithunzi 6 chikusonyezera, dongosololi limagwirizanitsa mipeni 1, 2 ndi 4 ndikudula olamulira. Kenako imalemba momwe makina amagwirizanirana ndi mbali zodula za mpeni uliwonse. (Mfundo F, D, ndi E mu chithunzi 6). Yezerani kukula kwake ndi kutalika kwa gawo lililonse. Bwezerani Mpeni Wodula 1. Monga momwe chithunzicho chikusonyezera, dulani chopumira cha chida. Gwirizanitsani tsamba lodula ndi nsonga yolondola, lembani zolumikizira za point B ndikuyesa L3 ndi PhD3 malinga ndi chithunzicho. Kuwonjezeka kwa mgwirizano pakati pa mfundo za F, E ndi D pa chida chilichonse, ndipo chiyambi cha O chingadziwike poyerekezera zomwe zili pamwambapa.

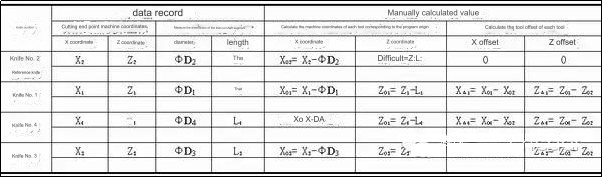

Zitha kuwoneka kuti zida zamakina zimagwirizanitsa (X2-PhD2 + 100 ndi Z2-L2 + 50) ndi zida zamakina zomwe zimagwirizanitsa pulogalamu yoyambira yogwirizana ndi chida cholozera. Njira yowerengera ikuwonetsedwa mu tebulo 1. M'malo opanda kanthu, lowetsani ziwerengero zowerengedwa ndi zolembedwa. Zindikirani: Mtunda wodula mayesero ndi mtunda wapakati pa zero zero point of workpiece ndi mapeto a mayesero odulidwa mu Z-direction. Mayendedwe abwino ndi oyipa amatsimikiziridwa ndi coordinate axis.

Chithunzi 6 Chojambula chojambula chamipeni yambiri pamanja

Table 1 Kuwerengera kwa zida zochotsera zida zomwe sizili mulingo

Njirayi imalola njira yosavuta yodulira mayeso, chifukwa imachotsa kufunikira koyang'ana zoyeserera zodulira. Komabe, kuchepetsa mpeni kuyenera kuwerengedwa pamanja. Mutha kuwerengera chida chothandizira mwachangu ngati musindikiza pepalalo ndi fomula ndikudzaza zomwe zikusowekapo.

Chithunzi 7 Schematic chithunzi chokhazikitsa zida zokha pa Century Star CNC system

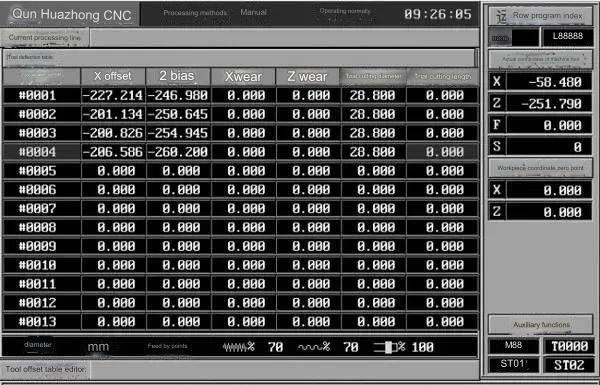

Zida zambiri zodzipangira zida zokhazikitsira njira ya 4th Century Star CNC system

Njira zonse zomwe tazitchula pamwambapa zochotsera zida ndi njira zofananira. Pambuyo pa akatswiri ogwira ntchito kuyika magawo ndi kuyesa machitidwe, HNC-21T imalola ogwiritsa ntchito kusankha "njira yochotsera kwathunthu" pokhazikitsa zida. M'makina opangira makina, njira yochotsera chida chilichonse ndi yosiyana pang'ono ndi njira yochotsera chida. Sikoyenera kugwiritsa ntchito G92 kapena G54 pamakina ogwirizanitsa ntchito, komanso sikoyenera kuletsa chipukuta misozi. Onani pulogalamu O1005 mwachitsanzo. Monga momwe tawonetsera pa Chithunzi 6, dongosolo likabwerera ku ziro, lolani mpeni uliwonse uyese pamanja kudula gawo la silinda.

Lembani zida zochotsera zida za mpeni uliwonse mutayeza kutalika ndi m'mimba mwake. Mlandu kudula kutalika zalembedwa ndime kwa mayesero kudula awiri. Pulogalamu yamakina, pogwiritsa ntchito njira yofotokozedwa mu "Multiknife Cutting of External Shaft Segment - Manual Calculation for Knife Offset", imatha kuwerengera zokha zida zamakina zomwe zimagwirizanitsa mpeni uliwonse malinga ndi komwe pulogalamuyo idayambira. Njira yokhazikitsira zida iyi ndiyofulumira kwambiri, ndipo ndiyoyenera makamaka kupanga mafakitale.

Chidule cha njira zisanu zolondola zoyika zida

Mfundo yoyendetsera bwino chida ndi "kuyezera zokha, kudula koyeserera ndi kubweza zolakwika". Kubwezera kolakwika kungathe kugawidwa m'magulu awiri: Kwa chida cholozera MDI ntchito, kapena sitepe yosuntha chida nsanamira kubweza pulogalamu yake poyambira; ndi chida chopanda muyezo kuti chibwezere zida zake zochotsera kapena zotayika. Pofuna kupewa chisokonezo, Table 2 idapangidwa kuti iwerengere ndikulemba ma values.

Table 2 Tool Setting Record Table for Trial Cutting Method (Unit: mm

1. Sinthani njira yochotsera pa chida chilichonse chomwe sichinali chokhazikika pambuyo poti chida cholozera chawongolera poyambira.

Njira zokhazikitsira chida zikuwonetsedwa mu Chithunzi 3.

Pambuyo pokonza zida zovuta, chida cholozera chiyenera kukhala kumayambiriro kwa pulogalamuyo. Lowetsani kuchotsera kwa chida chilichonse chomwe sichikhala chokhazikika pamalo oyenera patebulo.

Gwiritsani ntchito pulogalamu ya O1000 kukonza PhD2xL2 kuti muchepetse kuyesa.

Kenaka, yesani m'mimba mwake ndi kutalika kwa shaft yodulidwa, yerekezerani ndi mtengo wa pulogalamu ya lamulo, ndikuwona cholakwikacho.

Sinthani poyambira pulogalamuyo ngati mtengo wolakwika wa MDI kapena kusuntha kwamasitepe kuli kwakukulu kuposa mtengo wolakwika wa MDI.

5) Sinthani mtengo wamalamulo a O1000 mwamphamvu kutengera miyeso yoyezedwa ndikusunga pulogalamuyo. Bwerezani masitepe (2) mpaka malo oyambira chida cholozera ali mkati mwazolondola. Onani momwe zida zamakina zimalumikizirana poyambira pulogalamu yokonzedwa. Khazikitsani ma coordinates pa ziro.

6) Imbani O1001 (mpeni no. 1, No. O1002 (mpeni no. 3) pachiyeso chilichonse chodulidwa, ndipo yesani kutalika kwa Li (i=1, 2, 3) ndi PhDi awiri a gawo lililonse.

7) Lipirani zolakwika pogwiritsa ntchito njira ya tebulo 3.

Bwerezani masitepe 6 mpaka 7 mpaka zolakwika za makina zili mkati mwazolondola ndipo chida cholozera chidayimitsidwa poyambira pulogalamuyo ndipo sichisuntha.

Table 3 Chitsanzo cha kubwezeredwa zolakwika pakudula koyeserera kwa magawo a cylindrical shaft (gawo: mm).

2. Kusintha poyambira chida chilichonse payekhapayekha

Mfundo yokhazikitsira zida za njirayi ndikuti chida chilichonse chimasintha poyambira pulogalamu yake, motero zimagwirizana mosagwirizana ndi malo omwewo.

Njira zokhazikitsira chida zikuwonetsedwa mu Chithunzi 3.

Pambuyo pokonza zida zovuta, No. Pambuyo pokonza zida zowonongeka ndi kujambula zowonongeka, chida cha nambala 2 chiyenera kukhala pachiyambi cha pulogalamuyo.

Masitepe 2) mpaka (5) a njira yolondola yokhazikitsa zida ndizofanana.

Gwiritsani ntchito pulogalamu ya O1000 kuti muchepetse kuyesa. Yezerani kutalika kwa Li ndi kutalika kwa PhDi pagawo lililonse.

Chida choyendetsa masitepe kapena chosungira chida cha MDI chimalipira zolakwika ndikusintha poyambira pulogalamu ya chida chilichonse.

Bwerezani masitepe (6) mpaka malo oyambira pa chida chilichonse chomwe sichinali chokhazikika chili mkati mwa kulondola kololedwa.

Gome lachida lothandizira litha kupezeka polowetsa maulalo achibale omwe akuwonetsedwa pa CRT mu X offset ndi Z offset column yolingana ndi kuchuluka kwa zida zosinthira. Njirayi ndi yabwino komanso yosavuta. Njirayi ndi yosavuta komanso yabwino.

3. Sinthani njira zonse zochotsera zida zosagwiritsidwa ntchito nthawi yomweyo mutatha kusintha malo oyambira pulogalamu yolozera zida.

Njirayi ndi yofanana ndi yoyamba yolondola yoyika zida. Kusiyana kokha pakati pa awiriwa ndi chakuti mu sitepe 7, pulogalamu ya O1003 imatchedwa, yomwe imayitana mipeni itatu panthawi imodzi (O1004 imachotsa No. Pulogalamu ya O1003 imalowa m'malo mwa gawo la 2 lachindunji chazitsulo. Njira zotsalira ndizofanana.

6. Mipeni inayi ikhoza kukonzedwa nthawi imodzi pogwiritsa ntchito njirayi

Kuti mudziwe zolakwika zamakina, yesani kukula kwa gawo lililonse, PhDi, ndi kutalika kwa gawo lililonse, Li (i=2, 1, 4), pogwiritsa ntchito njira yolumikizira chida. Gwiritsani ntchito MDI kapena kuyenda pang'onopang'ono kwa chogwiritsira ntchito chida cholozera. Sinthani poyambira pulogalamu. Pazida zomwe sizili wamba, choyamba konzani kuchotsera pogwiritsa ntchito choyambirira. Kenako, lowetsani chotsitsa chatsopano. Kulakwitsa kwa makina a chida cholozera kuyeneranso kulowetsedwa muzavalidwe. Imbani pulogalamu yodulira ya O1005 ngati chida chamtheradi chikugwiritsidwa ntchito kuwongolera chida. Kenako, bwezerani zolakwika zomakina za zida zomwe zili muzavalidwe za manambala awo osinthira zida.

Kodi kusankha njira yoyenera yokhazikitsira chida cha CNC lathes kumakhala ndi zotsatira zotani pamtundu waCNC Machining magawo?

Kulondola ndi kulondola:

Zida zodulira zidzalumikizidwa bwino ngati chidacho chakhazikitsidwa bwino. Izi zimakhudza mwachindunji kulondola komanso kulondola pamachitidwe a makina. Kukonzekera kolakwika kwa zida kungayambitse zolakwika za dimensional, kusamalidwa bwino kwa malo, ngakhalenso zidutswa.

Kusasinthasintha:

Kuyika kwa zida zofananira kumatsimikizira kuti makina amagwirira ntchito limodzi komanso kukhazikika kokhazikika m'magawo angapo. Imachepetsa kusiyanasiyana kwapamwamba komanso kukula kwake, komanso imathandizira kuti pakhale kulolerana kolimba.

Moyo wa Zida ndi Zida:

Poonetsetsa kuti chidacho chikugwiritsidwa ntchito bwino ndi chogwirira ntchito, kuyika chida choyenera kungapangitse moyo wa chida. Kuyika zida zosayenera kungapangitse kuvala kwambiri ndi kusweka kwa zida, zomwe zingachepetse moyo wa zida.

Zochita ndi Mwachangu

Njira zokhazikitsira zida zogwira mtima zimatha kuchepetsa nthawi yokhazikitsa makina ndikuwonjezera nthawi. Zimawonjezera zokolola pochepetsa nthawi zopanda ntchito komanso kukulitsa nthawi yodula. Izi zimathandizira kusintha kwachangu kwa zida ndikuchepetsa nthawi yonse ya makina.

Chitetezo cha Operekera

Chitetezo cha wogwiritsa ntchito chingakhudzidwe posankha njira yoyenera yokhazikitsira chida. Njira zina monga kuzindikira zithunzi kapena kuyeza kwa zida za laser zimachotsa kufunika kogwiritsa ntchito zida pamanja, kuchepetsa mwayi wovulala.

Cholinga cha Anebon ndikumvetsetsa kuwonongeka kwabwino kwamakampani opanga ndikupereka chithandizo chapamwamba kwamakasitomala akunyumba ndi akunja ndi mtima wonse 2022 Aluminium Aluminium Yapamwamba Yapamwamba Kwambiri Yopangidwa Mwaluso.Kusintha kwa CNC, Milingi,cnc zida zosinthirakwa Azamlengalenga, Pofuna kukulitsa msika wathu wapadziko lonse, Anebon makamaka amapereka makasitomala athu akunja kwa mawotchi apamwamba kwambiri, magawo opangidwa ndi milled ndi ntchito yotembenuza cnc.

China yogulitsa China Machinery Parts ndi CNC Machining Service, Anebon imachirikiza mzimu wa "zatsopano, mgwirizano, ntchito yamagulu ndi kugawana, mayendedwe, kupita patsogolo kwanzeru". Tipatseni mwayi ndipo tikhala tikuwonetsa kuthekera kwathu. Ndi chithandizo chanu chokoma mtima, Anebon amakhulupirira kuti titha kupanga tsogolo labwino ndi inu limodzi.

Nthawi yotumiza: Oct-19-2023