Ichi ndi chidule cha anthu omwe ali m'makampaniwo pofotokoza mwachidule mapangidwe apangidwe, koma ndizosavuta. Polumikizana ndi ma ziwembu osiyanasiyana, tapeza kuti nthawi zonse pamakhala zovuta zoyika ndi zomangirira pamapangidwe oyamba. Mwanjira imeneyi, chiwembu chilichonse chatsopano chidzataya tanthauzo lake lenileni. Pokhapokha pomvetsetsa chidziwitso choyambira ndikuyika ndi kukakamiza tingathe kutsimikizira kukhulupirika kwa kapangidwe kake ndi kukonza dongosolo.

Chidziwitso cha malo

1, Mfundo yoyambira yoyika kuchokera kumbali ya workpiece

Mukayika kuchokera kumbali ya ntchito, mfundo ya mfundo zitatu ndiyo mfundo yofunika kwambiri, monganso chithandizo. Izi ndizofanana ndi mfundo yothandizira, yomwe imatchedwa mfundo zitatu, zomwe zimachokera ku mfundo ya "mfundo zitatu zomwe siziri pamzere womwewo zimatsimikizira ndege". Mfundo zitatu mwa zinayizi zimatha kudziwa nkhope, kotero kuti nkhope zonse zinayi zimatha kuzindikirika. Komabe, ziribe kanthu momwe mungapezere, nkovuta kunena mfundo yachinayi mundege yomweyo.

▲ Mfundo zitatu

Mwachitsanzo, mukamagwiritsa ntchito ma 4 okhazikika kutalika, mfundo zitatu zokha pamalo amodzi zimatha kulumikizana ndi chogwirira ntchito, ndipo mfundo 4 zotsalazo ndizosakayikitsa kuti musagwirizane ndi workpiece.

Chifukwa chake, pokonza choyikapo, nthawi zambiri chimatengera mfundo zitatu, ndipo mtunda wapakati pa mfundo zitatuzi uyenera kuwonjezeka momwe mungathere.

Kuphatikiza apo, pokonza poyikirapo, ndikofunikira kutsimikizira mayendedwe omwe amagwiritsidwa ntchito pokonza pasadakhale. Chitsogozo cha katundu wokonza ndinso njira yogwiritsira ntchito chida / kuyenda kwa chida. Choyikacho chimakonzedwa kumapeto kwa kayendetsedwe ka chakudya, zomwe zingakhudze kulondola kwathunthu kwa workpiece.

Nthawi zambiri, mtundu wa bawuti wosinthika umagwiritsidwa ntchito poyika malo opanda kanthu a workpiece, ndi mtundu wokhazikika (Zigawo Zotembenuza za CNCcontact surface is ground) positioner imagwiritsidwa ntchito poyika makina a workpiece.

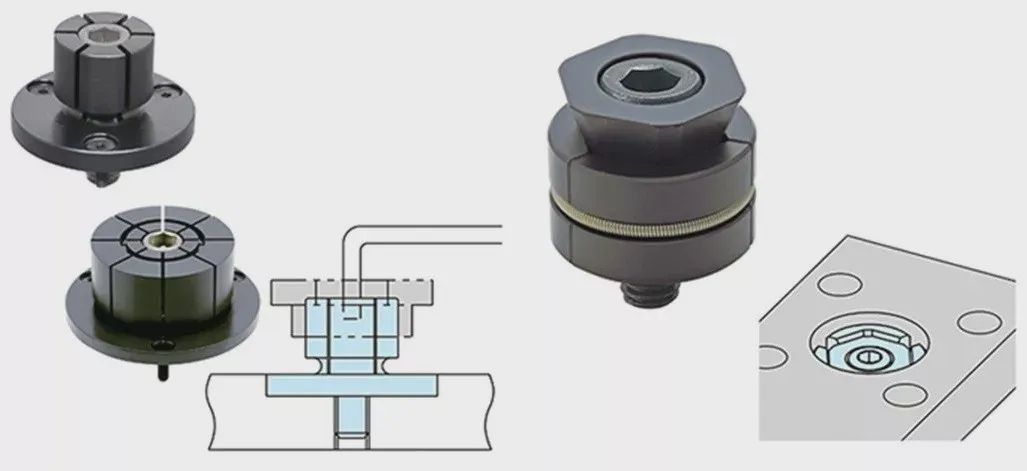

2. Mfundo yofunikira yoyika pa dzenje la workpiece

Mukamagwiritsa ntchito dzenje lomwe lidakonzedwa kale la workpiece kuti muyikepo, m'pofunika kugwiritsa ntchito pini yololera kuti muyike. Mwa kufananiza kulondola kwa dzenje la workpiece ndi kulondola kwa mbiri ya pini ndikuphatikiza molingana ndi kulekerera koyenera, kulondola kwa malo kumatha kukwaniritsa zofunikira zenizeni.

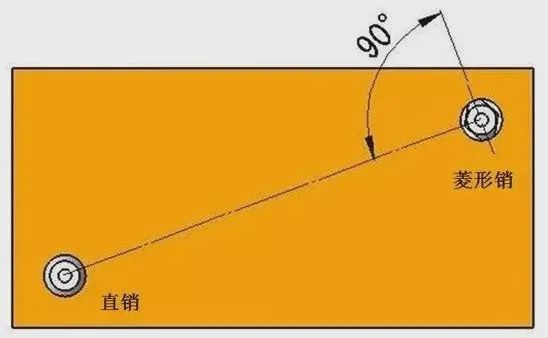

Kuonjezera apo, pogwiritsira ntchito pini poyika, nthawi zambiri wina amagwiritsa ntchito pini yowongoka ndipo wina amagwiritsa ntchito pini ya diamondi, kotero zimakhala zosavuta kusonkhanitsa ndi kusokoneza chogwiriracho. Sikovuta kuti chogwirira ntchito chikakamira ndi pini.

▲ Kuyika ndi pini

Inde, ndizothekanso kugwiritsa ntchito pini yowongoka pazikhomo zonse ziwiri posintha kulolerana koyenera. Kuti muyike bwino, nthawi zambiri imakhala yothandiza kwambiri kugwiritsa ntchito pini yowongoka ndi pini ya diamondi.

Pamene pini yowongoka ndi pini ya diamondi imagwiritsidwa ntchito, chingwe cholumikizira mumayendedwe a kasinthidwe (komwe pini ya diamondi imagwira ntchito) ya pini ya diamondi nthawi zambiri imakhala 90 ° perpendicular ku mzere wolumikiza pakati pa pini yowongoka ndi pini ya diamondi. Kukonzekera uku ndi kwa angular positioning (kuzungulira kozungulira kwa workpiece).

Kudziwa koyenera kwa clamp

1, Gulu la grippers

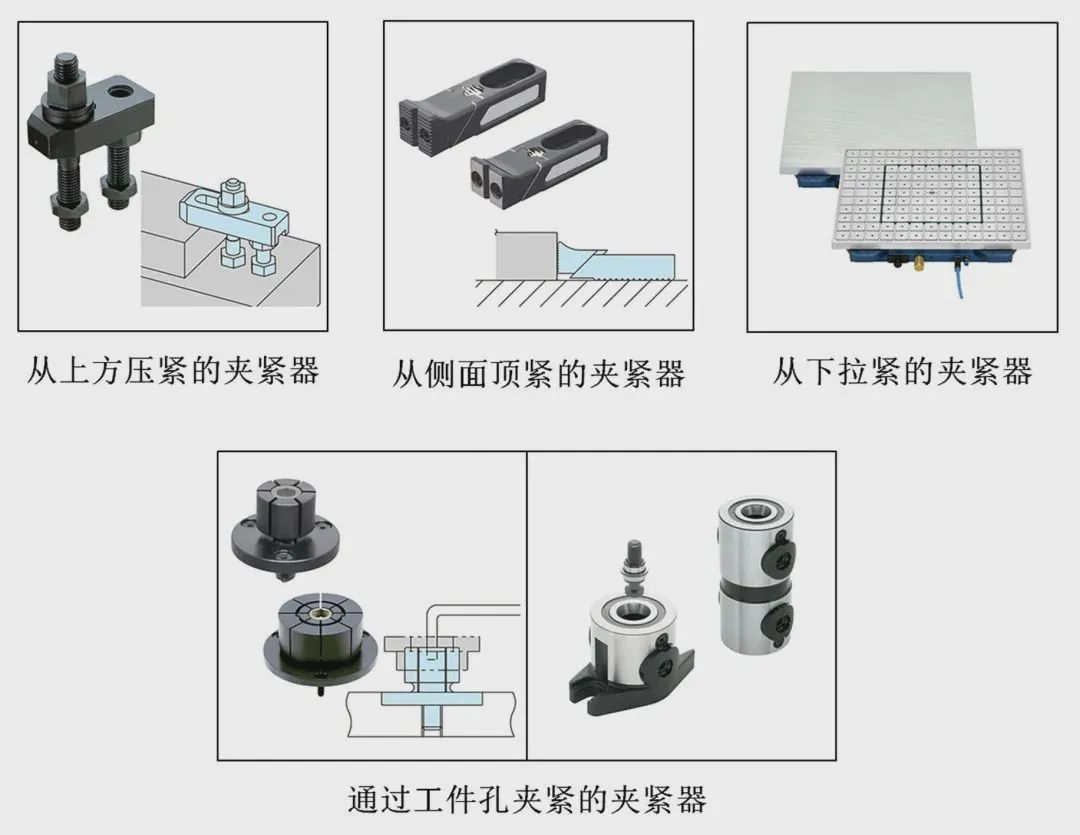

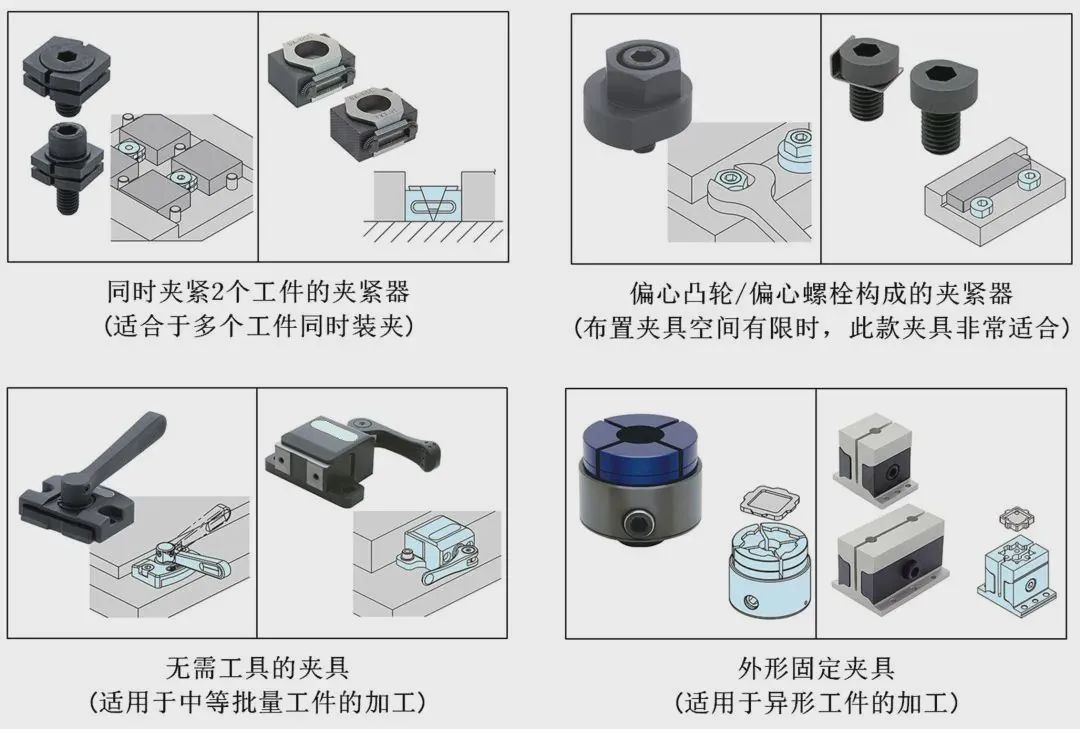

Malinga ndi malangizo a clamping, nthawi zambiri amagawidwa m'magulu awa:

Kenako, tiyeni tiwone mawonekedwe a ma clamp osiyanasiyana.

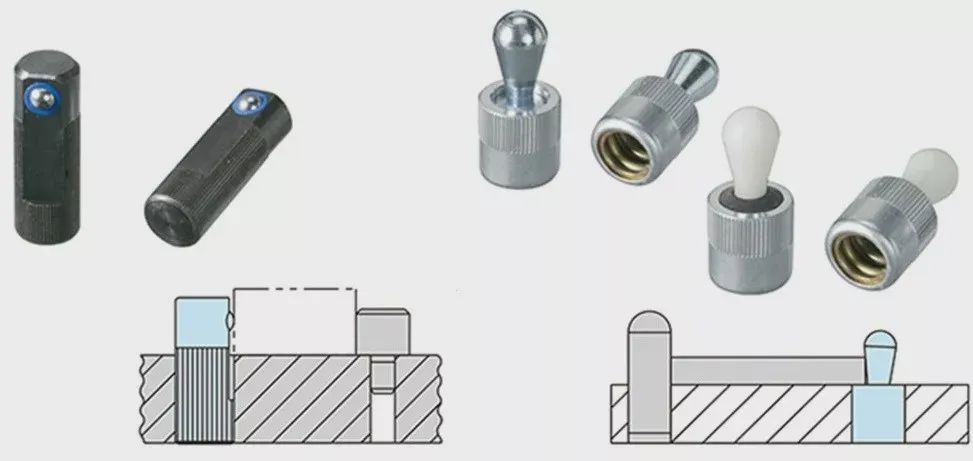

1. Zingwe zotsekera kuchokera pamwamba

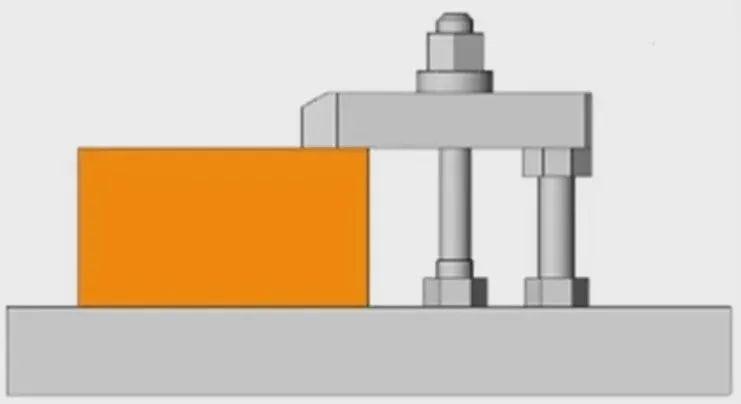

The clamping chipangizo kuti mbamuikha kuchokera pamwamba workpiece ali ndi mapindikidwe osachepera pa clamping, ndipo ndi khola kwambiri pa workpiece processing. Chifukwa chake, mwachizoloŵezi, choyambira choyamba ndikuchepetsa kuchokera pamwamba pa workpiece. Chokhazikika chodziwika bwino chopondereza kuchokera pamwamba pa workpiece ndi makina omata. Mwachitsanzo, chithunzi chotsatirachi chimatchedwa "lose leaf type" clamp. Chotsekereza chophatikiziridwa ndi kukakamiza mbale, stud bolt, jack ndi nati amatchedwa "loose leaf" clamp.

Kuphatikiza apo, mbale zosindikizira zokhala ndi mawonekedwe osiyanasiyana zitha kusankhidwa molingana ndi mawonekedwe a workpiece. MongaZigawo za CNC Machining, Zigawo Zotembenuza ndi Zigawo Zogaya.

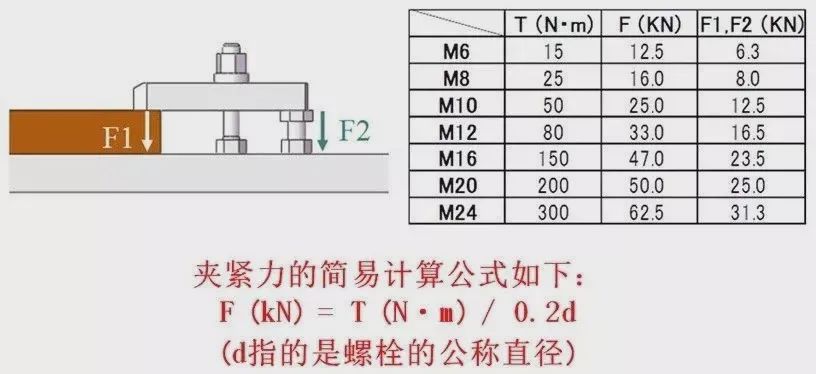

Ubale pakati pa torque ndi clamping mphamvu ya mtundu wa tsamba lotayirira ukhoza kuwerengedwa ndi kukankha mphamvu ya bawuti.

Kuphatikiza pa chotchinga chamasamba chotayirira, ma clamp otsatirawa amapezeka kuti amangirire kuchokera pamwamba pa workpiece.

2. Clamping clamp kuchokera kumbali

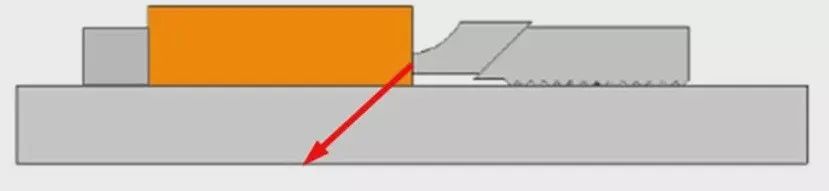

Poyambirira, njira yokhotakhota yokhomerera chogwirira ntchito kuchokera pamwamba ndiyokhazikika kwambiri komanso yocheperako pakukonza katundu wantchitoyo. Komabe, ngati kuli kofunikira kukonza pamwamba pa workpiece, kapena sikoyenera kumangirira kuchokera pamwamba pa workpiece, zomwe zimapangitsa kuti zikhale zosatheka kugwedeza kuchokera pamwamba pa workpiece, mukhoza kusankha kumangirira kumbali ya workpiece. Komabe, kunena kwake, chogwiriracho chikatsekeredwa kumbali, chimatulutsa mphamvu yoyandama. Momwe mungathetsere mphamvuyi iyenera kuganiziridwa popanga mapangidwe.

Monga momwe tawonera pamwambapa, chotchingira cham'mbali chimakhalanso ndi mphamvu yotsikira pansi pomwe ikupanga thrust, yomwe ingalepheretse chogwirira ntchito kuti chiyandama mmwamba.

Ma clamps omwe amathina kuchokera kumbali amakhalanso ndi zolembera zofananira.

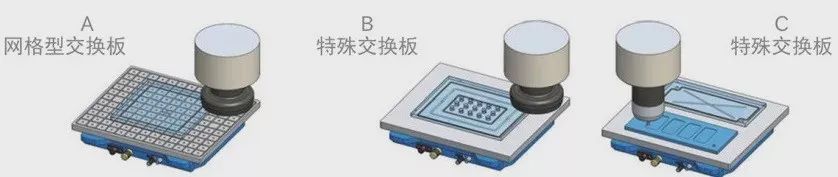

3. Clamping chipangizo chomangitsa workpiece kuchokera kukokera-pansi

Mukamapanga kumtunda kwa mbale yopyapyala yogwirira ntchito, sikutheka kungoyimitsa kuchokera pamwamba, komanso kuti ndi yopanda nzeru kuyiyika pambali. Njira yokhayo yolumikizira ndiyo kulimbitsa chogwirira ntchito kuchokera pansi. Pamene workpiece ndi tensioned kuchokera pansi, ngati wapangidwa ndi chitsulo, ndi maginito mtundu clamp angagwiritsidwe ntchito. Kwa zitsulo zopanda chitsulo, makapu akuyamwa vacuum amatha kugwiritsidwa ntchito ngati mphamvu.

Pazigawo ziwirizi, mphamvu yokhotakhota imayenderana ndi malo olumikizirana pakati pa chogwirira ntchito ndi maginito kapena vacuum chuck. Ngati katundu processing ndi lalikulu kwambiri pokonza workpieces yaing'ono, zotsatira processing sadzakhala abwino.

Kuphatikiza apo, mukamagwiritsa ntchito maginito kapena vacuum suckers, malo olumikizirana ndi maginito ndi vacuum suckers ayenera kupangidwa mofewa pang'ono asanayambe kugwiritsidwa ntchito mosamala komanso moyenera.

4. Clamping chipangizo ndi mabowo

Mukamagwiritsa ntchito makina opangira 5-axis kuti mugwiritse ntchito nkhope zingapo nthawi imodzi kapena kukonza nkhungu, kuti muteteze kukhudzidwa kwa zida ndi zida pakukonza, ndizoyenera kugwiritsa ntchito njira yobowoleza. Poyerekeza ndi njira ya clamping kuchokera pamwamba ndi mbali ya workpiece, njira ya dzenje clamping ali ndi katundu wochepa pa workpiece ndipo akhoza bwino deform workpiece.

▲ Kukonza mwachindunji ndi mabowo

▲ Khazikitsani rivet kuti mutseke

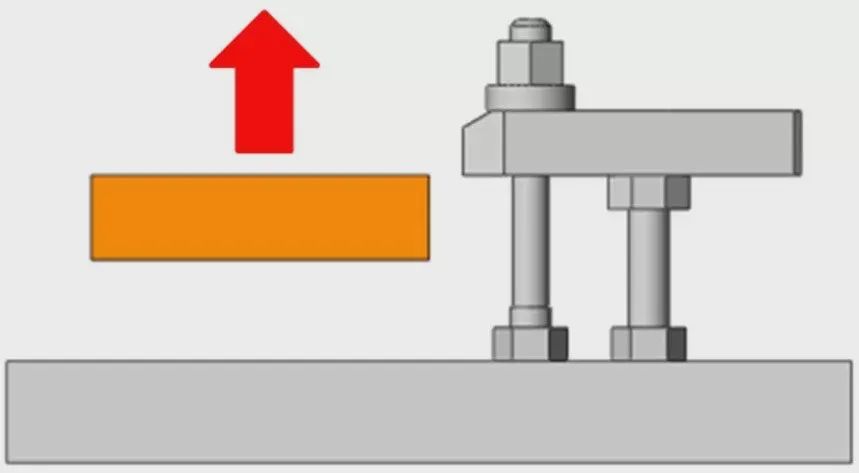

2, Pre clamping

Zomwe zili pamwambazi ndizokhudza clamping fixture ya workpiece. Momwe mungasinthire magwiridwe antchito ndikugwiritsa ntchito pre clamping ndikofunikira. Pamene workpiece ndi vertically anapereka pa maziko, workpiece adzagwa chifukwa cha mphamvu yokoka. Panthawiyi, chogwiriracho chiyenera kugwiritsidwa ntchito mutagwira ntchito ndi dzanja.

▲ Pre clamping

Ngati zida zogwirira ntchito ndi zolemetsa kapena zambiri zimatsitsidwa nthawi imodzi, ntchitoyo imachepetsedwa kwambiri ndipo nthawi yothina idzakhala yayitali kwambiri. Panthawiyi, kugwiritsa ntchito mtundu wa kasupe wa pre clamping kumatha kupangitsa kuti chogwiriracho chizitha kugwira ntchito pamalo osasunthika, ndikuwongolera magwiridwe antchito ndikuchepetsa nthawi yokhomerera ya workpiece.

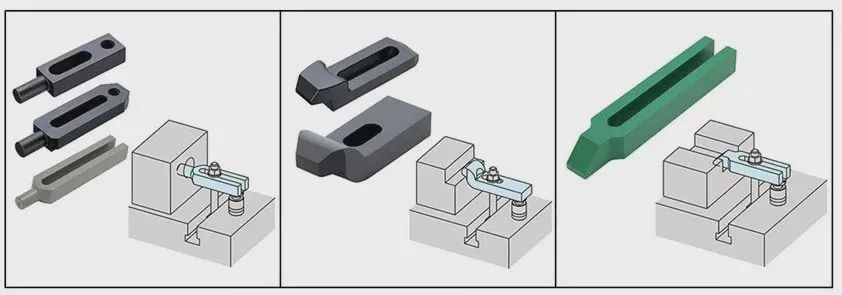

3, Kusamala posankha chogwirira

Mitundu ingapo ya ma clamp ikagwiritsidwa ntchito pazida zomwezo, zida zomangira ndi kumasula ziyenera kulumikizidwa. Mwachitsanzo, monga momwe zasonyezedwera kumanzere, mukamagwiritsa ntchito zida zosiyanasiyana zogwirira ntchito, zolemetsa zonse za wogwiritsa ntchitoyo zimakhala zazikulu, ndipo nthawi yonse yotsekera ya workpiece idzakhalanso yayitali. Mwachitsanzo, pa chithunzi chakumanja chomwe chili pansipa, ma wrenches ndi makulidwe a bawuti amalumikizidwa kuti athandizire ogwira ntchito m'munda.

▲ Kugwira ntchito kwapang'onopang'ono

Kuphatikiza apo, pokonza chogwirira, ndikofunikira kuganizira momwe kugwirira ntchito kwa workpiece clamping kungathekere. Ngati chogwirira ntchito chikufunika kupendekeka panthawi ya clamping, kugwira ntchito kumakhala kovuta kwambiri. Izi zikuyenera kupewedwa popanga chojambula.

Nthawi yotumiza: Oct-24-2022