Kulakwitsa kwa Machining kumatanthawuza kuchuluka kwa kupatuka pakati pa magawo enieni a geometric (kukula kwa geometric, mawonekedwe a geometric, ndi malo ogwirizana) pambuyo pokonza ndi magawo abwino a geometric.

Mlingo wa mgwirizano pakati pa magawo enieni ndi abwino a geometric pambuyo popangidwa ndi makina olondola. Kuchepa kwa kulakwitsa kwa makina, kumapangitsanso kuchuluka kwa kufanana ndi kulondola.7075 aluminiyamu Machining

Kulondola kwa Machining ndi cholakwika cha makina ndi njira ziwiri zavuto. Chifukwa chake, kukula kwa cholakwika cha makina kumawonetsa kuchuluka kwa kulondola kwa makina. Zifukwa zazikulu za zolakwika za makina ndi izi:

1. Kupanga zolakwika za chida cha makina

Cholakwika chopanga chida cha makina chimaphatikizapo cholakwika chozungulira cha spindle, cholakwika cha njanji yowongolera, ndi cholakwika cha tcheni chotumizira.

Kulakwitsa kwa spindle kumatanthawuza kusinthika kwa nsonga yeniyeni yozungulira ya spindle yogwirizana ndi ma axis ake ozungulira nthawi iliyonse, zomwe zimakhudza kulondola kwa chogwirira ntchito chomwe chiyenera kukonzedwa. Zifukwa zazikulu za kulakwitsa kwa spindle ndi kulakwitsa kwa spindle, cholakwika chonyamula, cholakwika cha coaxiality pakati pa ma bearings, ndi kuzungulira kwa spindle. Sitima yolondolera ndiye chizindikiro chodziwira ubale wapagawo lililonse la chida cha makina pazida zamakina, komanso ndiye chizindikiro cha kayendedwe ka zida zamakina.Aluminium CNC Machining

Kulakwitsa kopanga njanji yowongolera, kusafanana kwa njanji yowongolera, komanso kuyika kwake ndizofunika kwambiri zomwe zimayambitsa cholakwikacho. Vuto la unyolo wopatsirana limatanthawuza cholakwika choyenda pakati pa zinthu zopatsirana kumayambiriro ndi kumapeto kwa unyolo wotumizira. Zimayambitsidwa ndi zolakwa za kupanga ndi kusonkhanitsa kwa chigawo chilichonse mu chingwe chotumizira ndi kuvala panthawi yogwiritsira ntchito.

2. Cholakwika cha geometric chida

Chida chilichonse chidzavala mosakayikira panthawi yodula, zomwe zingayambitse kusintha kwa kukula ndi mawonekedwe a workpiece. Chikoka cha chida cholakwika cha geometric pa cholakwika cha makina chimasiyanasiyana ndi mtundu wa chida: pomwe chida chokhazikika chimagwiritsidwa ntchito popanga makina, cholakwika chopanga chida chidzakhudza mwachindunji kulondola kwa makina a workpiece; kwa zida zonse (monga kutembenuza zida, etc.), zolakwika zake zopanga Zilibe zotsatira zachindunji pakulakwitsa kwa makina.

3. Kulakwitsa kwa geometric pakukonzekera

Ntchito yokonza makinawo ndikupangitsa kuti chogwiriracho chifanane ndi chidacho, ndipo chida cha makina chimakhala ndi malo olondola, kotero kulakwitsa kwa geometric kumakhudza kwambiri cholakwika cha makina (makamaka cholakwika cha malo).

4. Poyika zolakwika

Vuto la malo makamaka limaphatikizapo cholakwika cholozera molakwika ndi cholakwika chopanga chopanga cha awiriwo. Mukakonza chogwiritsira ntchito pa chida cha makina, zinthu zingapo za geometric pa workpiece ziyenera kusankhidwa ngati malo osungira panthawi yokonza. datum) sizigwirizana, cholakwika cha datum chidzachitika.

Poyikira malo ogwirira ntchito ndi choyikapo choyikapo zimapanga gulu loyikirapo. Kusiyana kwakukulu kwa malo ogwirira ntchito komwe kumachitika chifukwa cha kupanga molakwika kwa malo awiriwo komanso kusiyana kofananira pakati pa awiriawiri oyika kumatchedwa cholakwika chopanga cholakwika cha malo awiriwo. Kulakwitsa kopanga kolakwika kwa oyika awiriwo kudzachitika kokha pamene njira yosinthira ikugwiritsidwa ntchito pokonza ndipo sizichitika mu njira yodulira.

5. Cholakwika chifukwa cha mphamvu mapindikidwe a ndondomeko dongosolo

Kuuma kwa workpiece: Ngati kuuma kwa workpiece mu makina opangira zinthu kumakhala kotsika poyerekeza ndi zida zamakina, zida, ndi zida, pogwira ntchito yodula, mapindikidwe a workpiece chifukwa cha kuuma kosakwanira kudzakhala ndi vuto lalikulu pakulakwitsa kwa makina.

Kukhazikika kwa chida: Kukhazikika kwa chida chotembenuza cha cylindrical pamtunda wapakati (y) wopangidwa ndi makina ndikokwanira, ndipo kusinthika kwake kumatha kunyalanyazidwa. Potopetsa dzenje lamkati lomwe lili ndi mainchesi ang'onoang'ono, kulimba kwa chida kumakhala koyipa kwambiri, ndipo kusinthika kwamphamvu kwa chida kumakhudza kwambiri kulondola kwa dzenjelo.

Kukhazikika kwa zida zamakina: Zida zamakina zimapangidwa ndi magawo ambiri. Palibe njira yosavuta yowerengera kuuma kwa zida zamakina. Njira zoyesera zimatsimikizira kuuma kwa zida zamakina. Zomwe zimakhudza kulimba kwa zida zamakina zimaphatikizirapo kukhudzidwa kwa kukhudzana kwa malo olumikizirana, kukhudzidwa kwa mikangano, kukopa kwa magawo olimba, komanso chikoka cha chilolezo.Aluminiyamu CNC Machining zigawo

6. Zolakwa chifukwa mapindikidwe matenthedwe a dongosolo ndondomeko

The ndondomeko dongosolo matenthedwe mapindikidwe kwambiri zimakhudza Machining zolakwika, makamaka mwatsatanetsatane ndi lalikulu Machining. Zolakwa za machuring zomwe zimayambitsidwa ndi matenthedwe amafuta nthawi zina zimatha kuwerengera 50% ya cholakwika chonse cha workpiece.

7. Kusintha zolakwika

Mu njira iliyonse yopangira makina, nthawi zonse pali njira imodzi kapena yosinthira ku dongosolo la ndondomeko. Popeza kusintha sikungakhale kolondola, cholakwika chosintha chimachitika. Mu makina opangira, kulondola kwapang'onopang'ono kwa chogwirira ntchito ndi chida chomwe chili pazida zamakina chimatsimikiziridwa ndikusintha chida cha makina, chida, mawonekedwe, kapena ntchito. Pamene kulondola koyambirira kwa zida zamakina, zida, zosintha, ndi zosoweka zogwirira ntchito zikukwaniritsa zofunikira zaukadaulo popanda kuganizira zamphamvu, zolakwika zosintha zimakhala ndi gawo lalikulu pakulakwitsa kwa makina.

8. Cholakwika choyezera

Pamene gawolo likuyesedwa panthawi kapena pambuyo pokonza, kulondola kwa muyeso kumakhudzidwa mwachindunji ndi njira yoyezera, kulondola kwa chida choyezera, chogwirira ntchito, ndi zinthu zomwe zimakhalapo komanso zolinga.

9. Kupsinjika kwamkati

Kupsinjika komwe kumakhala mkati mwa gawo popanda mphamvu yakunja kumatchedwa kupsinjika kwamkati. Kupanikizika kwamkati kumapangidwa pa workpiece, chitsulocho chidzakhala chosakhazikika komanso kukhala ndi mphamvu zambiri. Izo mwachibadwa kusintha kwa chikhalidwe khola mlingo otsika mphamvu, limodzi ndi mapindikidwe, kotero workpiece amataya Machining ake oyambirira kulondola.

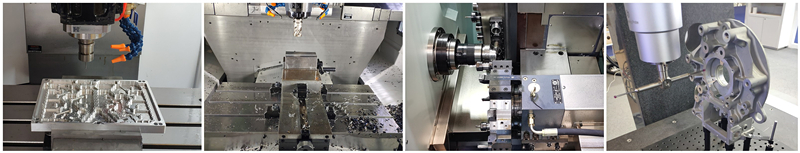

Anebon Metal Products Limited ikhoza kupereka CNC Machining, Die Casting, Sheet Metal Fabrication service, chonde omasuka kulankhula nafe.

Tel: +86-769-89802722 E-mail: info@anebon.com URL: www.anebon.com

Nthawi yotumiza: Jan-11-2022