Kukonzekera homuweki

(1) Zambiri zogwirira ntchito:

Kuphatikizapo zojambula za msonkhano waukulu, chigawo cha msonkhano zojambula, zigawo zojambula, zinthu BOM, etc., mpaka mapeto a polojekiti, kukhulupirika ndi ukhondo wa zojambula ndi kukhulupirika kwa ndondomeko zolemba zambiri ayenera kutsimikiziridwa.

(2) Malo antchito:

Kuyika magawo ndi kuphatikiza zigawo ziyenera kuchitidwa pamalo ogwirira ntchito. Malo omwe makina athunthu amayikidwa ndikusonkhanitsidwa ayenera kukonzedwa momveka bwino. Mpaka kumapeto kwa ntchito yonseyo, malo onse ogwirira ntchito ayenera kusungidwa mwaudongo, okhazikika komanso mwadongosolo.

(3) Zida Zophatikiza:

Asanayambe kugwira ntchito, zipangizo zochitira msonkhano zomwe zafotokozedwa pamsonkhanowo ziyenera kuchitika panthawi yake. Ngati zinthu zina zosadziwika bwino sizili m'malo, ndondomeko yoyendetsera ntchitoyi ingasinthidwe, ndiyeno lembani fomu yokumbutsa za zinthuzo ndikutumiza ku dipatimenti yogula.

(4) Kapangidwe kake, luso la msonkhano ndi zofunikira za ndondomeko ya zipangizo ziyenera kumveka musanayambe msonkhano.

Zofunikira:

Zojambulajambula:

Maluso aukadaulo wamakina amaphatikizanso zojambula zomwe zikuwonetsa magawo omwe akuyenera kusonkhanitsidwa, miyeso yawo, kulolerana, ndi mawonekedwe aliwonse apadera kapena zofunikira.

Bill of Materials (BOM):

Uwu ndi mndandanda wazinthu zonse zomwe zimafunikira pakusokonekera kwamakina, kuphatikiza kuchuluka kwake ndi manambala agawo.

Zofunika:

Zolemba zamakina zaukadaulo zitha kuphatikizanso zakuthupi, monga mtundu wazinthu zomwe zingagwiritsidwe ntchito pagawo lililonse, kuuma kwake, kachulukidwe, ndi zina.

Njira za Assembly:

Awa ndi malangizo a sitepe ndi sitepe pakusonkhanitsa zigawozo, kuphatikizapo zida zilizonse zapadera kapena njira zomwe zimafunikira.

Miyezo yoyendetsera bwino:

Mafotokozedwe aukadaulo amisonkhano yamakina angaphatikizeponso miyezo yoyendetsera bwino, monga zofunikira pakuwunika ndi njira zovomerezera.

Pakuyika ndi kutumiza:

Mafotokozedwe aukadaulo amisonkhano yamakina angaphatikizeponso kulongedza ndi kutumiza, monga mtundu wa zinthu zomwe zingagwiritsidwe ntchito komanso njira yotumizira.

Mafotokozedwe oyambira

(1) Msonkhano wamakina uyenera kusonkhanitsidwa mosamalitsa malinga ndi zojambula za msonkhano ndi zofunikira za ndondomeko zomwe zimaperekedwa ndi dipatimenti yokonza mapulani, ndipo ndizoletsedwa kusintha zomwe zili mu ntchito kapena kusintha magawo m'njira yachilendo.

(2) Thecnc Machining zitsulo mbalikuti asonkhanitsidwe ayenera kukhala amene amapambana kuyendera dipatimenti yoyendera khalidwe. Ngati mbali zina zosayenerera zapezeka panthawi ya msonkhano, ziyenera kufotokozedwa panthawi yake.

(3) Malo ochitira msonkhano amafunika kukhala aukhondo popanda fumbi kapena kuipitsa kwina, ndipo mbali zake ziyenera kusungidwa pamalo owuma, opanda fumbi okhala ndi mapepala oteteza.

(4) Panthawi ya msonkhano, zigawozo sizidzagwedezeka, kudulidwa, kapena pamwamba pazigawozo zidzawonongeka, kapena zigawozo ziyenera kukhala zopindika, zopotoka kapena zopunduka, ndipo pamwamba pazigawo sizidzawonongeka. .

(5) Pazigawo zomwe zimayenda pang'onopang'ono, mafuta opaka mafuta (mafuta) ayenera kuwonjezeredwa pakati pa malo olumikizana panthawi ya msonkhano.

(6) Miyeso yofananira ya zigawo zofananira ziyenera kukhala zolondola.

(7) Posonkhanitsa, zigawo ndi zida ziyenera kukhala ndi malo apadera oyikapo. Kwenikweni, zigawo ndi zida siziloledwa kuyikidwa pamakina kapena mwachindunji pansi. Ngati ndi kotheka, makapeti oteteza kapena makapeti ayenera kuikidwa pamalo omwe aikidwa.

(8) Kwenikweni, kuponda pamakina sikuloledwa panthawi ya msonkhano. Ngati pakufunika kukwera, mateti oteteza kapena makapeti ayenera kuyalidwa pamakina. Kuponda pazigawo zofunika komanso zopanda zitsulo zokhala ndi mphamvu zochepa ndizoletsedwa.

Join njira

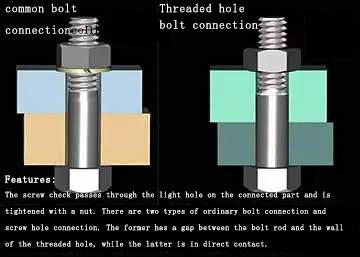

(1) Kulumikizana kwa bolt

A. Mukamangitsa ma bolts, musagwiritse ntchito ma wrenches osinthika, ndipo musagwiritse ntchito makina ochapira amodzi pansi pa nati iliyonse. Pambuyo polimbitsa zomangira zomangira, mitu ya misomali iyenera kuyikidwa mu makinazitsulo zosapanga dzimbiri za cncndipo sayenera kuwululidwa.

B. Nthawi zambiri, maulalo a ulusi ayenera kukhala ndi ma washer odana ndi lotayirira masika, ndipo njira yomangirira ma bolts angapo ayenera kumangirizidwa pang'onopang'ono molingana, ndipo zolumikizira zingwe ziyenera kulumikizidwa pang'onopang'ono kuchokera pakati kupita mbali zonse ziwiri.

C. Maboti ndi mtedza zikamangika, ma bolts ayenera kuwulula mizati 1-2 ya mtedza; pamene zomangira sizifunikira kusokoneza mbali panthawi yomanga chipangizo chosuntha kapena kukonza, zomangirazo ziyenera kuphimbidwa ndi guluu ulusi musanayambe kusonkhana.

D. Kwa zomangira zomwe zili ndi zofunikira zolimbitsa ma torque, wrench ya torque iyenera kugwiritsidwa ntchito kuwalimbitsa molingana ndi torque yomwe yatchulidwa. Kwa ma bolts opanda torque yomangirira, torque yolimbitsa imatha kutanthauza malamulo omwe ali mu "Zowonjezera".

(2) Kulumikizana kwa pini

A. Mapeto a pini yoyika nthawi zambiri amayenera kukhala okwera pang'ono kuposa gawolo. Pini yopindika yokhala ndi screw tail itayikidwa m'malo oyenera, mathero ake akulu ayenera kumira mu dzenje.

B. Pambuyo pini ya cotter imakwezedwa muzoyeneramilled zigawo, michira yake iyenera kulekanitsidwa ndi 60 ° -90 °.

(3) Kulumikizana kwakukulu

A. Mbali ziwiri za kiyi wa kiyi yaflatthyathyathya ndi kiyi yokhazikika ziyenera kukhudzana, ndipo pasakhale kusiyana pakati pa malo okwerera.

B. Pambuyo pa kiyi (kapena spline) yokhala ndi chilolezo chosonkhanitsidwa, pamene zigawo zosuntha zachibale zimayenda motsatira njira ya axial, sipayenera kukhala kusagwirizana mu kulimba.

C. Pambuyo posonkhanitsidwa kiyi ya mbedza ndi kiyi ya wedge, malo omwe amalumikizana nawo sayenera kukhala ochepera 70% a malo ogwirira ntchito, ndipo magawo osalumikizana nawo sayenera kuyikika pamalo amodzi; kutalika kwa gawo lowonekera liyenera kukhala 10% -15% ya kutalika kwa malo otsetsereka.

(4) Kuthamanga

A. Zida ndi mafotokozedwe a riveting ayenera kukwaniritsa zofunikira za mapangidwe, ndipo kukonza mabowo a rivet kuyenera kukwaniritsa zofunikira.

B. Pamene riveting, pamwamba pa mbali zokhotakhota sizidzawonongeka, komanso pamwamba pa zigawo zowonongeka sizidzawonongeka.

C. Pokhapokha ngati pali zofunikira zapadera, sipayenera kukhala kumasuka pambuyo pa riveting. Mutu wa rivet uyenera kukhala wogwirizana kwambiri ndi mbali zokhotakhota ndipo ukhale wosalala komanso wozungulira.

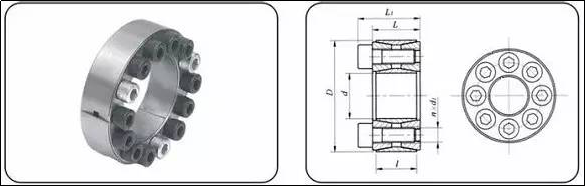

(5) Kulumikizana kwa manja okulitsa

Kusonkhana kwa manja okulitsa: Pakani mafuta opaka pamanja okulitsa, ikani dzanja lokulitsa mu dzenje lomwe lalumikizidwa, ikani shaft yoyikapo, sinthani malo a msonkhano, ndiyeno kumangitsa mabawuti. Dongosolo la kumangitsa limamangidwa ndi kung'ambika, ndipo kumanzere ndi kumanja zimawoloka ndikumangika motsatizana motsatizana kuti kuwonetsetsa kuti mtengo wa torque wovotera wafika.

(6) kulumikizana kolimba

Mapeto a tapered ndi dzenje la screw set ndi conical end liyenera kukhala 90 °, ndipo zomangirazo ziyenera kumangika molingana ndi dzenje.

Msonkhano wa maupangiri a mzere

(1) Sipayenera kukhala dothi pa gawo loyikapo njanji yowongolera, ndipo kusalala kwa malo oyikapo kuyenera kukwaniritsa zofunikira.

(2) Ngati pali nsonga yowonetsera pambali pa njanji yowongolera, iyenera kuikidwa pafupi ndi malire. Ngati palibe m'mphepete mwake, njira yotsetsereka ya njanji yowongolera iyenera kukhala yogwirizana ndi kapangidwe kake. Mukalimbitsa zomangira za njanji yowongolera, fufuzani ngati pali kupatuka kulikonse komwe kumalowera kwa slider. Apo ayi iyenera kusinthidwa.

(3) Ngati slider imayendetsedwa ndi lamba wotumizira, pambuyo pa lamba wotumizira ndi slider atakhazikika ndi kugwedezeka, lamba wotumizira sayenera kukoka mosasamala, mwinamwake pulley iyenera kusinthidwa kuti kayendetsedwe ka kayendetsedwe ka lamba wotumizira kufanana ndi njanji yowongolera.

Msonkhano wa sprocket chain

(1) Mgwirizano pakati pa sprocket ndi shaft uyenera kukwaniritsa zofunikira.

(2) Ndege zapakati pa geometric za mano a giya a sprocket yoyendetsa ndi sprocket yoyendetsedwa ziyenera kugwirizana, ndipo kuchotserako kuyenera kupitilira zomwe zimafunikira. Ngati sichinatchulidwe pamapangidwewo, iyenera kukhala yocheperapo kapena yofanana ndi 2 ‰ ya mtunda wapakati pakati pa mawilo awiriwo.

(3) Unyolo ukakhala ndi sprocket, mbali yogwira ntchito iyenera kumangika kuti iwonetsetse kuti meshing yosalala.

(4) Sag ya mbali yosagwira ntchito ya unyolo iyenera kukwaniritsa zofunikira za mapangidwe. Ngati sichinatchulidwe pamapangidwewo, iyenera kusinthidwa molingana ndi 1% mpaka 2% ya mtunda wapakati pakati pa ma sprockets awiri.

Kuphatikizika kwa zida

(1) Pambuyo posonkhanitsidwa magiya amtundu wina ndi mnzake, pomwe m'lifupi mwake m'lifupi mwake ndi ochepera kapena wofanana ndi 20mm, kusamvana kwa axial sikudutsa 1mm; pamene m'lifupi mwake m'mphepete mwa giya ndi wamkulu kuposa 20mm, axial misalignment si upambana 5% ya m'lifupi mwake.

(2) Zofunikira pakuyika bwino kwa magiya a cylindrical, magiya a bevel, ndi ma drive a nyongolotsi ziyenera kufotokozedwa mu JB179-83 "Involute Cylindrical Gear Accuracy", JB180-60 "Bevel Gear Transmission Tolerance" ndi JB162 motsatana motsatana ndi kulondola ndi kukula kwa magawo opatsirana -60 "Worm Drive Tolerance" amatsimikiziridwa.

(3) Malo opangira ma giya amayenera kuthiridwa mafuta molingana ndi zofunikira zaukadaulo, ndipo bokosi la gear lidzadzazidwa ndi mafuta opaka pamzere wamafuta malinga ndi zofunikira zaukadaulo.

(4) Phokoso la bokosi la giya litadzaza kwathunthu silingapitirire 80dB.

Kusintha kwa rack ndi kugwirizana

(1) Kusintha kwa kutalika kwa ma racks a magawo osiyanasiyana kuyenera kusinthidwa kumtunda womwewo molingana ndi mfundo yomweyi.

(2) Mapanelo a khoma azitsulo zonse ayenera kusinthidwa ku ndege yofanana yofanana.

(3) Pambuyo pazitsulo za gawo lililonse zimasinthidwa ndikukwaniritsa zofunikira, mbale zogwirizanitsa zokhazikika pakati pawo ziyenera kuikidwa.

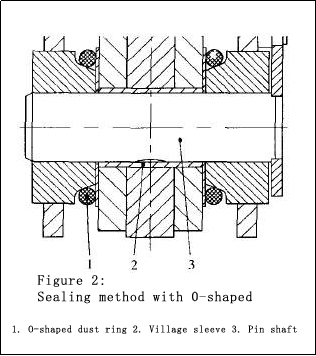

Msonkhano wa zigawo za pneumatic

(1) Kukonzekera kwa chipangizo chilichonse cha pneumatic drive chiyenera kugwirizanitsidwa motsatira ndondomeko ya mpweya woperekedwa ndi dipatimenti yokonza mapulani, ndipo kugwirizana kwa thupi la valve, chitoliro cholowa, silinda, ndi zina zotero ziyenera kufufuzidwa bwino.

(2) Kulowetsa ndi kutuluka kwa valavu yochepetsera mpweya wokwanira kumalumikizidwa kumbali ya muvi, ndipo chikho chamadzi ndi chikho chamafuta cha fyuluta ya mpweya ndi lubricator ziyenera kuikidwa pansi.

(3) Musanayambe kupopera, ufa wodula ndi fumbi mu chitoliro ziyenera kuphulika kwathunthu.

(4) Chitoliro cholumikizana ndi chopindika. Ngati ulusi wa chitoliro ulibe guluu wa ulusi, tepiyo iyenera kudulidwa. Njira yokhotakhota imakhala yozungulira kuchokera kutsogolo. Tepi yakuthupi sayenera kusakanikirana ndi valve. Pamene akumangirira, ulusi umodzi uyenera kusungidwa.

(5) Kukonzekera kwa trachea kuyenera kukhala kokongola komanso kokongola, yesetsani kuti musadutse dongosolo, ndipo 90 ° zigongono ziyenera kugwiritsidwa ntchito pamakona. Pamene trachea yakhazikika, musamalowetse mafupa kupsinjika kowonjezera, apo ayi zingayambitse mpweya.

(6) Pogwirizanitsa valavu ya solenoid, tcherani khutu ku gawo la nambala iliyonse ya doko pa valve: P: kudya kwathunthu; A: chotuluka 1; B: chotuluka 2; R (EA): mpweya wofanana ndi A; S (EB) : Exhaust yofanana ndi B.

(7) Pamene silinda yasonkhanitsidwa, nkhwangwa ya pisitoni ndodo ndi kayendedwe ka katundu ziyenera kukhala zogwirizana.

(8) Mukamagwiritsa ntchito mayendedwe a mzere kuti muwongolere, pambuyo pa mapeto a kutsogolo kwa ndodo ya pistoni yolumikizidwa ndi katundu, sipayenera kukhala mphamvu yachilendo panthawi yonse ya sitiroko, mwinamwake silinda idzawonongeka.

(9) Mukamagwiritsa ntchito valavu yothamanga, chidwi chiyenera kulipidwa ku mtundu wa valve throttle. Nthawi zambiri, imasiyanitsidwa ndi muvi wawukulu womwe walembedwa pa valavu. Yemwe ali ndi muvi waukulu woloza kumapeto kwa ulusi amagwiritsidwa ntchito pa silinda; yomwe ili ndi muvi waukulu wolozera kumapeto kwa chitoliro imagwiritsidwa ntchito pa valve solenoid.

Ntchito yoyendera msonkhano

(1) Nthawi iliyonse kusonkhana kwa chigawocho kumalizidwa, ziyenera kufufuzidwa motsatira zinthu zotsatirazi. Ngati vuto la msonkhano likupezeka, liyenera kufufuzidwa ndikuthetsedwa munthawi yake.

A. Umphumphu wa ntchito ya msonkhano, yang'anani zojambula za msonkhano, ndikuwona ngati pali magawo omwe akusowa.

B. Kuti muwone kulondola kwa malo oyika gawo lililonse, yang'anani zojambula za msonkhano kapena zofunikira zomwe zafotokozedwa pamwambapa.

C. Kudalirika kwa gawo lililonse lolumikizira, ngati wononga chilichonse cholumikizira chimakumana ndi torque yomwe imafunikira kusonkhana, komanso ngati cholumikizira chapadera chikukwaniritsa zofunikira zoletsa kumasula.

D. Kusinthasintha kwa kayendetsedwe ka magawo osuntha, monga ngati pali kuyimirira kapena kuyimirira, kukhazikika kapena kupindika pamene odzigudubuza, ma pulleys, njanji zowongolera, ndi zina zotero akuzunguliridwa pamanja kapena kusuntha.

(2) Pambuyo pa msonkhano womaliza, kuyang'anitsitsa kwakukulu ndikuwunika kugwirizana pakati pa zigawo za msonkhano, ndipo zomwe zimayendera zimachokera ku "makhalidwe anayi" omwe atchulidwa mu (1) monga muyezo woyezera.

(3) Pambuyo pa msonkhano womaliza, zitsulo zachitsulo, zinyalala, fumbi, ndi zina zotero mu gawo lililonse la makina ziyenera kutsukidwa kuti zitsimikizire kuti palibe zopinga pa kufalitsa kulikonse.mbali zotembenuzidwa molondola.

(4) Poyesa makinawo, chitani ntchito yabwino yoyang'anira njira yoyambira. Makinawo akayamba, muyenera kuyang'ana nthawi yomweyo ngati magawo ogwirira ntchito ndi magawo osuntha akuyenda bwino.

(5) Zigawo zazikulu zogwirira ntchito zikuphatikizapo kuthamanga kwa kayendetsedwe kake, kukhazikika kwa kayendetsedwe kake, kusinthasintha kwa shaft iliyonse yotumizira, kutentha, kugwedezeka ndi phokoso, ndi zina zotero.

Anebon amamatira ku mfundo yofunikira ya "Quality ndiye moyo wabizinesi, ndipo udindo ukhoza kukhala moyo wake" kuti muchepetse kuchotsera kolondola kwambiri 5 Axis CNC Lathe CNC Machined Part, Anebon tili ndi chidaliro kuti titha kupereka zinthu zapamwamba kwambiri. ndi mayankho pamtengo wamtengo wapatali, chithandizo chapamwamba pambuyo pa kugulitsa kwa ogula. Ndipo Anebon adzamanga ulendo wautali.

Chinese Professional China CNC Part ndi Metal Machining Parts, Anebon amadalira zida zapamwamba, kapangidwe kabwino, ntchito yabwino kwamakasitomala komanso mtengo wampikisano kuti makasitomala ambiri kunyumba ndi kunja aziwakhulupirira. Zogulitsa mpaka 95% zimatumizidwa kumisika yakunja.

Nthawi yotumiza: May-03-2023