Kuchiza pamwamba ndi kupanga wosanjikiza pamwamba wokhala ndi chinthu chimodzi kapena zingapo pamwamba pa zinthuzo pogwiritsa ntchito njira zakuthupi kapena zamankhwala. Chithandizo chapamtunda chimatha kukonza mawonekedwe, mawonekedwe, magwiridwe antchito, ndi zina zantchito.

1. Anodizing

Ndi makamaka anodic makutidwe ndi okosijeni wa zotayidwa, amene amagwiritsa ntchito mfundo electrochemistry kupanga wosanjikiza Al2O3 (zotayidwa okusayidi) filimu padziko zotayidwa ndi zotayidwa aloyi. Filimu ya oxide iyi ili ndi zinthu zapadera monga chitetezo, kukongoletsa, kutchinjiriza komanso kukana kuvala.Anodized golide CNC kutembenukira gawo

Njira yoyenda:

Monochrome, mtundu wa gradient: kupukuta/kupukutira mchenga/kujambula→kuchepetsa →kuchepetsa →anodizing→kusaulira →kudaya→kusindikiza→kuyanika

Mitundu iwiri:

①Kupukuta / kupukuta mchenga / kujambula waya → kuchotsa mafuta → masking → anodizing 1 → anodizing 2 → kusindikiza → kuyanika

②Kupukuta / kupukuta mchenga / kujambula waya → kuchotsa mafuta → anodizing 1 → kujambula ndi laser → anodizing 2 → kusindikiza → kuyanika

Zaukadaulo:

1. Wonjezerani mphamvu

2. Zindikirani mtundu uliwonse kupatula woyera

3. Kukwanilitsa kusindikiza kopanda faifi tambala ndikukwaniritsa zofunikira za ku Europe, United States ndi mayiko ena opanda nickel

Zovuta zaukadaulo ndi mfundo zazikuluzikulu: kuchuluka kwa zokolola za anodizing kumakhudzana ndi mtengo wa chinthu chomaliza. Chinsinsi cha kuwongolera zokolola za okosijeni ndi kuchuluka koyenera kwa okosijeni, kutentha koyenera komanso kachulukidwe kamakono, zomwe zimafuna opanga chigawo chamagulu kuti apitirize kufufuza popanga, fufuzani zopambana. (Tikupangira kuti mutchere khutu ku akaunti ya anthu onse ya "Mechanical Engineer", komanso kudziwa zambiri zazinthu zowuma komanso zambiri zamakampani mwachangu momwe mungathere)

Malingaliro azinthu: E + G chogwirira cha arc, chopangidwa ndi zinthu zokometsera, zokonda zachilengedwe komanso zolimba.CNC Machining zitsulo zosapanga dzimbiri.

2. Electrophoresis

Zogwiritsidwa ntchito muzitsulo zosapanga dzimbiri, aloyi ya aluminiyamu, ndi zina zotero, zimatha kupanga mankhwala kusonyeza mitundu yosiyanasiyana, kusunga zitsulo zonyezimira, ndipo panthawi imodzimodziyo kumapangitsanso ntchito ya pamwamba, ndi ntchito yabwino yotsutsana ndi dzimbiri.

Njira yoyenda: kuchiritsa → electrophoresis→ kuyanika

ubwino:

1. Mitundu yolemera;

2. Palibe mawonekedwe achitsulo, omwe angagwirizane ndi sandblasting, kupukuta, kujambula waya, etc.;

3. Processing mu madzi chilengedwe akhoza kuzindikira pamwamba mankhwala a nyumba zovuta;

4. Ukadaulo ndi wokhwima ndipo ukhoza kupangidwa mochuluka.

Zoipa: Kutha kuphimba zolakwika ndizofala, ndipo electrophoresis of die castings imafuna chisamaliro chapamwamba.

3. Micro-arc oxidation

Njira yogwiritsira ntchito mphamvu yamagetsi mu njira ya electrolyte (yomwe nthawi zambiri imakhala yofooka ya alkaline yankho) kuti ipange filimu ya ceramic pamwamba, yomwe ndi zotsatira za synergistic zotsatira za kumaliseche kwa thupi ndi electrochemical oxidation.

Kutuluka kwa ndondomeko: Kukonzekera → kusamba m'madzi otentha → MAO → kuyanika

ubwino:

1. Maonekedwe a ceramic, mawonekedwe osawoneka bwino, osapanga zinthu zonyezimira kwambiri, kukhudzidwa kwamanja, kutsutsa zala;

2. Magawo osiyanasiyana: Al, Ti, Zn, Zr, Mg, Nb, ndi ma aloyi awo, ndi zina zotero;

3. The pretreatment ndi yosavuta; mankhwalawo ali ndi dzimbiri zabwino kwambiri komanso kukana kwanyengo komanso ntchito yabwino yochotsa kutentha.

Zoipa: Pakali pano, mtunduwo ndi wochepa; wakuda ndi imvi okha ndi omwe ali okhwima, ndipo mitundu yowala ndiyovuta kukwaniritsa; mtengo umakhudzidwa makamaka ndi kugwiritsa ntchito mphamvu zambiri, ndipo ndi imodzi mwazokwera mtengo kwambiri pamankhwala apamwamba.

4. PVD vacuum plating

Dzina lonse ndi kuyika kwa nthunzi wakuthupi, njira yopangira mafakitale makamaka pogwiritsa ntchito njira zakuthupi kuyika mafilimu opyapyala.CNC Machining gawo

Kutuluka kwa ndondomeko: kuyeretsa PVD isanayambe → kupukuta m'ng'anjo → kuchapa chandamale ndi kuyeretsa ayoni → zokutira → kumaliza zokutira, kuziziritsa m'ng'anjo → post-processing (kupukuta, AFP) (Tikukulimbikitsani kuti musamalire "Mechanical Engineer" akaunti yovomerezeka, nthawi yoyamba kumvetsetsa zinthu zowuma, zambiri zamakampani)

Zaukadaulo: PVD (Physical Vapor Deposition, Physical Vapor Deposition) imatha kuvala zitsulo pamalo olimba kwambiri komanso kuvala zokutira kukongoletsa kwa cermet.

5. Electroplating

Ndi teknoloji yomwe imagwiritsa ntchito electrolysis kuti igwirizane ndi filimu yachitsulo pamwamba pazitsulo kuti zisawonongeke, kupititsa patsogolo kukana kuvala, kuyendetsa magetsi, kuwunikira, ndi kupititsa patsogolo kukongola.

Mayendedwe a ndondomeko: kupangiratu → mkuwa wopanda sianidi → kapunikeli wopanda sianidi → plating ya chrome

Ubwino:

1. Chophimbacho chimakhala ndi gloss yapamwamba komanso maonekedwe achitsulo apamwamba;

2. Zinthu zoyambira ndi SUS, Al, Zn, Mg, etc.; mtengo wake ndi wotsika kuposa PVD.

Zoipa: kusatetezedwa bwino kwa chilengedwe komanso chiopsezo chachikulu cha kuipitsidwa kwa chilengedwe.

6. Kupaka ufa

Kupaka kwa ufa kumapopera pamwamba pa workpiece ndi zida zopopera ufa (makina opopera a electrostatic). Pansi pa magetsi osasunthika, ufawo udzakhala wokongoletsedwa mofanana pamwamba pa workpiece kuti apange zokutira ufa. Amachiritsa lathyathyathya ndipo amakhala ❖ kuyanika komaliza ndi zotsatira zosiyanasiyana (mitundu yosiyanasiyana ya zotsatira kwa zokutira ufa).

Njira yaukadaulo: kumtunda → kuchotsa fumbi lamagetsi → kupopera → kutentha kochepa → kuphika

Ubwino:

1. Mitundu yolemera, yonyezimira kwambiri ndi matte;

2. Mtengo wotsika, woyenera kumanga katundu wa mipando ndi zipolopolo zazitsulo zotentha, ndi zina zotero;

3. Kugwiritsa ntchito kwakukulu, 100% kugwiritsidwa ntchito, kuteteza chilengedwe;

4. Luso lamphamvu lophimba zolakwika; 5. Ikhoza kutsanzira mtengo wambewu.

Zoipa: Panopa amagwiritsidwa ntchito pamagetsi ocheperako.

7. Chojambula chachitsulo chachitsulo

Ndi njira yochizira pamwamba yomwe imapanga mizere pamwamba pa workpiece pogaya mankhwala, omwe ali ndi zokongoletsera. Mizere yosiyana, itatha kujambula, ikhoza kugawidwa muzojambula zowongoka, zowonongeka, zowonongeka, ndi zozungulira.

Mawonekedwe aukadaulo: Njira yopangira mawaya imatha kupatsa chitsulo pamwamba pazitsulo zosakhala ngati galasi, komanso kukonza mawaya kumathanso kuthetsa zolakwika zobisika pazitsulo.

Malingaliro azinthu: Chigwiriro cha LAMP, chithandizo cha Zwei L, pogwiritsa ntchito ukadaulo wapamwamba kwambiri wakupera kuwonetsa kukoma.

8. Kuphulika kwa mchenga

Ndi ndondomeko imene wothinikizidwa mpweya ntchito monga mphamvu kupanga mkulu-liwiro kutsitsi mtengo kuti kupopera zinthu kutsitsi pamwamba pa workpiece kuti azichitira pa liwiro lalikulu kuti maonekedwe kapena mawonekedwe a kunja kwa workpiece. kusintha pamwamba, ndi mlingo wina wa ukhondo ndi roughness osiyana amapezeka.

Zaukadaulo:

1. Kukwaniritsa zonyezimira zosiyanasiyana kapena matt.

2. Ikhoza kuyeretsa ting'onoting'ono tating'onoting'ono pamwamba pa workpiece ndi kupanga pamwamba pa workpiece yosalala, kuchotsa kuvulaza kwa burrs ndikuwongolera kalasi ya workpiece.

3. Chotsani dothi lotsalira lomwe latsala mu pretreatment, kusintha kusalala kwa workpiece, kupanga workpiece kuwulula yunifolomu ndi zitsulo mtundu wosasinthasintha, ndi kupanga mawonekedwe a workpiece kukhala okongola ndi okongola. (Tikupangira kuti musamalire akaunti yapagulu ya "Mechanical Engineer" ndikudziwiratu chidziwitso cha zinthu zowuma komanso zambiri zamakampani mwachangu momwe mungathere)

Malingaliro azogulitsa: E+G classic bridge handle, sandblasted surface, high-end atmosphere.

9. Kupukutira

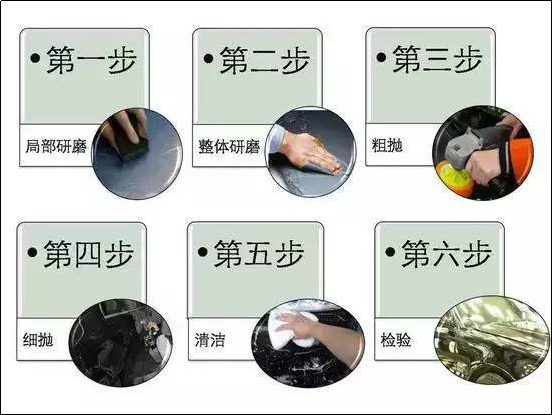

Malizitsani workpiece pamwamba ntchito zida zosinthika kupukuta, mpweya abrasive tinthu, ndi zina kupukuta TV. Pakuti njira zosiyanasiyana kupukuta, monga akhakula kupukuta (zofunikira kupukuta ndondomeko), sing'anga kupukuta (njira yomaliza), ndi kupukuta bwino (ndondomeko glazing), kusankha gudumu yoyenera kupukuta akhoza kukwaniritsa zotsatira zabwino kupukuta ndi bwino kupukuta dzuwa.

Zaukadaulo: Sinthani kulondola kwa mawonekedwe a workpiece kapena geometric, pezani malo osalala kapena magalasi owoneka bwino, ndikuchotsani gloss.

Malingaliro azinthu: E + G chogwirira chachitali, chopukutidwa, chosavuta komanso chokongola

10. Kuwotcha

Nthawi zambiri amatchedwa etching, yomwe imadziwikanso kuti photochemical etching, imakhudzana ndi kuchotsedwa kwa filimu yoteteza m'deralo kuti ikhazikike pambuyo powonekera pakupanga mbale ndikukula komanso kukhudzana ndi yankho lamankhwala panthawi ya etching kuti ikwaniritse kusungunuka ndi dzimbiri. , kupanga concave-convex kapena dzenje akamaumba zotsatira.

Njira yoyenda:

Njira yowonetsera: Pulojekitiyi imakonzekeretsa kukula kwa zinthuzo molingana ndi zojambulajambula - kukonza zinthu - kuyeretsa zinthu - kuyanika → filimu kapena kuyanika → kuyanika → kuwonetseredwa → chitukuko → kuyanika - etching → kuvula → OK

Njira yosindikizira pazenera: kudula zinthu → mbale yoyeretsera (chitsulo chosapanga dzimbiri ndi zitsulo zina) → kusindikiza pazenera → etching → kuvula → CHABWINO

Ubwino:

1. Ikhoza kuchita micro-processing ya zitsulo pamwamba;

2. Perekani zotsatira zapadera pamwamba pazitsulo;

Kuipa kwake: Zamadzimadzi zambiri zowononga (ma asidi, alkali, ndi zina zotero) zomwe zimagwiritsidwa ntchito pokolezera zimawononga chilengedwe.

Anebon Metal Products Limited ikhoza kupereka CNC Machining, Die Casting, Sheet Metal Fabrication service, chonde omasuka kulankhula nafe.

Tel: +86-769-89802722 E-mail: info@anebon.com URL: www.anebon.com

Nthawi yotumiza: Apr-08-2022