1. Pezani zakudya zocheperako mochenjera ndikugwiritsa ntchito ma trigonometric mochenjera

Pezani zakudya zazing'ono mwanzeru ndikugwiritsa ntchito ntchito za trigonometric mogwira mtima.Panthawi yotembenuza, zida zogwirira ntchito zokhala ndi mabwalo amkati ndi akunja omwe amafunikira kulondola kwambiri amakonzedwa pafupipafupi. Zovuta monga kudula kutentha, kukangana komwe kumapangitsa kuti zida zivale, komanso kubwereza mobwerezabwereza kwa chosungira chida kumapangitsa kuti zikhale zovuta kutsimikizira kuti zili bwino.

Kuti tithane ndi kuya kwenikweni kwa micro-intake, timasintha chosungira chida chotalikirapo pamakona potengera ubale wapakati pa mbali zotsutsana ndi hypotenuse ya makona atatu, kulola kuzama kolondola kodutsa panthawi yokhotakhota. Njirayi ikufuna kupulumutsa nthawi ndi ntchito, kusunga zinthu zabwino, komanso kupititsa patsogolo ntchito.

The muyezo lonse mtengo wa C620 lathe chida chofukizira ndi 0.05mm pa gawo. Kuti mukwaniritse kuya kwapakati kwa 0.005mm, kutengera tebulo la sine trigonometric ntchito: sinα=0.005/0.05=0.1 α=5º44′Choncho, kusintha chogwirizira chida kukhala 5º44′ kumathandizira chida chotembenuza kuti chikwaniritse kuya pang'ono kwa 0.005mm mu mayendedwe odutsa ndikuyenda kulikonse kwa chimango chautali.

2. Milandu itatu yaukadaulo woyendetsa mobwerera

Zochitika zambiri zopanga zawonetsa kuti kugwiritsa ntchito matekinoloje osinthika m'njira zina zosinthira kumatha kukhala ndi zotsatira zabwino. Zochitika pano zikuphatikiza:

(1) Zigawo zazitsulo zosapanga dzimbiri za Martensitic zimagwiritsidwa ntchito ngati ulusi wodula m'mbuyo.

Pamene ntchito workpieces ulusi ndi phula la 1.25 ndi 1.75mm, ndi wamba kukumana nkhani zokhudzana ndi kubweza chida ndi buckling. Ma lathe wamba nthawi zambiri alibe chipangizo chodziyimira pawokha, chomwe chimafuna njira zotengera nthawi. Zotsatira zake, ulusi wokonza ulusi womwe uli ndi magawo enieniwa ukhoza kukhala wotengera nthawi komanso kutembenuka kocheperako kungakhale njira yokhayo yotheka.

Komabe, kudula pang'onopang'ono kungayambitse kuluma kwa zida ndi kusauka kwapamwamba pamtunda, makamaka pogwira ntchito ndi zitsulo zosapanga dzimbiri za martensitic monga 1Crl3 ndi 2 Crl3. Kuti athetse mavutowa, njira yodulira "tatu reverses" idapangidwa muzochita zamakina.

Njira iyi, yomwe imaphatikizapo kutsitsa zida zobwerera m'mbuyo, kudula m'mbuyo, ndi njira zodulira zosiyana, zatsimikizira kukhala zothandiza pakudulira ulusi wothamanga kwambiri ndikuchotsa chida chosalala. Njirayi ndiyothandiza makamaka chifukwa imathandizira kudula bwino ndikupewa zovuta zomwe zingagwiritsidwe ntchito ndi kutembenuka kothamanga.

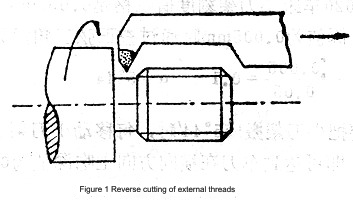

Pamene kunja kwa galimoto, pogaya chogwirira chofanana ndi mkati ulusi galimoto mpeni (Chithunzi 1);

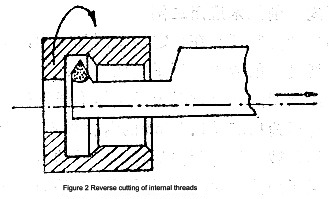

Pamene ulusi wamkati wa galimotoyo ukuphwanyidwa, mpeni wokhotakhota wamkati (Chithunzi 2).

Musanayambe ndondomekoyi, sinthani spindle yozungulira yozungulira ya friction disc kuti muwonetsetse kuthamanga kozungulira poyambitsa kusinthasintha. Kenako, ikani ndikuteteza chodulira ulusi, yambitsani kuzungulira kutsogolo pang'onopang'ono, ndikusunthira kumalo opanda zida. Kenako, pitilizani kuyika chida chokhotakhota kukuya koyenera kodulira musanasinthe mozungulira. Panthawi imeneyi, chida chotembenuza chiyenera kuzungulira kuchokera kumanzere kupita kumanja pa liwiro lalikulu. Pambuyo podula kangapo potsatira njirayi, ndizotheka kupeza ulusi wokhala ndi ulusi wabwino kwambiri komanso wolondola kwambiri.

(2) Maluwa odana ndi galimoto

Mukamagwiritsa ntchito lathe yachikhalidwe, zimakhala zachilendo kuti tinthu tachitsulo ndi zinyalala zilowe muzogwiritsira ntchito ndi chida chodulira. Kugwiritsira ntchito njira yatsopano yogwiritsira ntchito mphira wa lathe kungathe kuchepetsa mavuto omwe amakumana nawo panthawi yachikhalidwe ndikubweretsa zotsatira zabwino.

(3) Kutembenuza mbuyo kwa ulusi wa chitoliro wamkati ndi kunja

Pamene ntchito mkati ndi kunja tapered ulusi chitoliro ndi zofunika otsika mwatsatanetsatane ndi m'magulu ang'onoang'ono, mukhoza kugwiritsa ntchito mwachindunji njira yatsopano ya n'zosiyana kudula ndi n'zosiyana unsembe chida popanda kufunikira kwa Chinsinsi chipangizo, kukhalabe njira kudula mosalekeza.

Kugwira ntchito kwa mpeni wosambira wamanja, womwe umasesa kuchokera kumanzere kupita kumanja potembenuza ulusi wa chitoliro chakunja, kungathe kuwongolera bwino kuya kwa mpeni wodula kuchokera m'mimba mwake mpaka kumimba yaying'ono chifukwa cha kukanikiza kusanachitike. slicing ndondomeko. Kugwiritsiridwa ntchito kwa ukadaulo watsopanowu potembenuza kukupitilira kukula ndipo kumatha kusinthidwa kuti zigwirizane ndi zochitika zosiyanasiyana.

3. Ntchito yatsopano ndi zida zatsopano zoboola mabowo ang'onoang'ono

Pa kutembenuza ntchito, pamene kubowola mabowo ang'onoang'ono kuposa 0.6mm, zochepa m'mimba mwake ndi osauka rigidity wa kubowola pang'ono kuteteza kuwonjezeka kudula liwiro. Zida zogwirira ntchito, alloy osagwira kutentha ndi chitsulo chosapanga dzimbiri, zimawonetsa kukana kwambiri. Chotsatira chake, kugwiritsa ntchito njira yodyetsera mawotchi pobowola mosavuta kuswa pobowola. Njira yosavuta komanso yothandiza ndiyo kugwiritsa ntchito njira yodyetsera pamanja ndi chida chapadera.

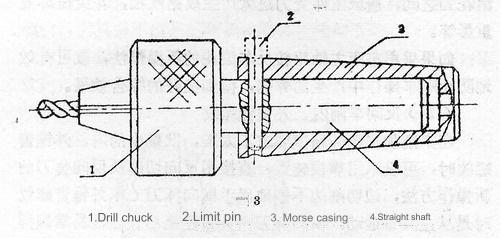

Gawo loyamba limaphatikizapo kusintha chobowola choyambira kukhala choyandama cha shank. Pokanikizira kabowo kakang'ono pa chuck yoyandama, kubowola kosalala kumatheka. Mbali yakumbuyo ya kubowola imaphatikizapo chogwirira chowongoka ndi chotsetsereka, chomwe chimalola kuyenda kwaulere mkati mwa chokoka. Pakadali pano, pobowola kabowo kakang'ono, kudyetsa pang'ono kwapang'onopang'ono ndi chuck chogwirizira pamanja kumathandizira kubowola mwachangu, kusunga bwino ndikutalikitsa moyo wautumiki wa tizibowo tating'ono.

Kuphatikiza apo, chuck yosinthidwa yokhala ndi zolinga zingapo imatha kugwiritsidwa ntchito pogogoda ulusi wamkati wamkati, kukonzanso, ndi zina zofananira. Kwa mabowo akuluakulu, kuyika pini yomalirira pakati pa mkono wokoka ndi chogwirira chowongoka kumalangizidwa. Onani Chithunzi 3 kuti muwone zambiri.

4. Shockproof kwa processing dzenje lakuya

Pakukonza dzenje lakuya, kuphatikiza kabowo kakang'ono ndi kabowo kakang'ono kabowo kakang'ono kabowo kakang'ono kabowo kakang'ono kabowo kakang'ono kabowo kakang'ono kabowo kakang'ono kabowo kakang'ono kamene kamayambitsa kugwedezeka kosalephereka kumapangitsa kugwedezeka kosalephereka potembenuza magawo okhala ndi dzenje lakuya kuyambira Φ30 mpaka Φ50mm ndi kuya pafupifupi 1000mm. Kuti muchepetse kugwedezeka ndikuonetsetsa kuti dzenje lakuya lapamwamba kwambiri, njira yowongoka komanso yothandiza imaphatikizapo kumangirira zothandizira ziwiri, zopangidwa kuchokera ku zinthu monga nsalu ndi bakelite, kupita ku ndodo.

Zothandizira izi ziyenera kufanana ndi kukula kwa dzenjelo ndendende. Pogwiritsa ntchito chipika cha bakelite chomangidwa ndi nsalu ngati chothandizira pakudula, chidacho chimakhazikika, kuchepetsa mwayi wa kugwedezeka ndikupangitsa kuti pakhale dzenje lakuya kwambiri.

5. Kupewa kusweka kwa zobowola zazing'ono zapakati

Pokhotakhota, kubowola dzenje lapakati lochepera Φ1.5mm kumabweretsa chiopsezo chachikulu chothyoka pobowola pakati. Njira yabwino yopewera kusweka ndikupewa kutseka mchira ndikubowola dzenje lapakati. Izi zimalola kulemera kwa tailstock ndi mphamvu yakugunda pakati pake ndi bedi la zida zamakina kuti zigwiritsidwe ntchito pobowola. M'malo omwe kudula kukaniza kumakhala kochulukira, tailstock imangobweza, potero kuteteza kubowola pakati.

6. Vuto processing zinthu ntchito

Tikakhala ndi vuto lokonza zinthu monga aloyi yotentha kwambiri ndi zitsulo zozimitsa, kuuma kwapamwamba kwa workpiece kumafunika kukhala mu RA0.20 mpaka 0.05 μm, ndipo kukula kwake kulinso kwakukulu. Pomaliza, kukonza bwino nthawi zambiri kumachitika pabedi lopera.

7. Kutsitsa mwachangu ndikutsitsa spindle

Pokhotakhota, nthawi zambiri timakumana ndi zida zosiyanasiyana zokhala ndi zozungulira zozungulira bwino komanso zopindika. Chifukwa cha kukula kwawo kwakukulu, amafunikira kutsitsa ndi kutsitsa panthawi yonse yokonza. Nthawi yofunikira pakusintha zida ndi yotalikirapo kuposa nthawi yeniyeni yodulira, zomwe zimapangitsa kuti pakhale kuchepa kwachangu.

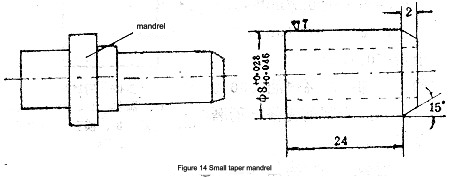

Kutsitsa mwachangu ndi kutsitsa mandrel, pamodzi ndi chida chotembenuza chamtundu umodzi (tungsten carbide) chomwe chafotokozedwa pansipa, chingachepetse nthawi yothandizira ndikuwonetsetsa kuti zinthu zili bwino pokonza magawo osiyanasiyana a manja. Njira yopangira ili motere: Kupanga mandrel ang'onoang'ono osavuta, taper pang'ono ya 0.02mm imagwiritsidwa ntchito kumbuyo.

Chingwecho chikayikidwa, zigawozo zimatetezedwa ku mandrel kupyolera mu kukangana, ndiyeno chida chotembenuza chokhala ndi mbali zambiri chimagwiritsidwa ntchito kuti chigwire ntchito pamwamba. Pambuyo pozungulira, ngodya ya cone imatembenuzidwa kukhala 15 °, pomwe wrench imagwiritsidwa ntchito kutulutsa mwachangu komanso moyenera zigawozo, monga momwe chithunzi 14 chikusonyezera.

8. Kuyendetsa kwa zigawo zazitsulo zozimitsa

(1) Chimodzi mwa zitsanzo zazikulu za kuzimitsacnc zopangidwa ndi makina

①Chitsulo chothamanga kwambiri W18CR4V kukonzanso ndi kukonzanso (kukonza pambuyo popuma)

② Miyezo Yopanga Panyumba Yopanda -Standard Slocculus (Kutha Kwambiri)

③ Kuyendetsa kwa hardware ndi zida zopopera mbewu mankhwalawa

④ Zoyendetsedwa ndi nkhope zopepuka za Hardware

⑤ Kampopi woyengedwa wa ulusi wokhala ndi mpeni wachitsulo wothamanga kwambiri

Pochita ndi zida zowumitsidwa ndi zida zosiyanasiyana zovuta pamakina pakupanga kwathu, kusankha mosamala zida zoyenera ndi kuchuluka kwa kudula, komanso ma angle a geometric ndi njira zogwirira ntchito, zitha kubweretsa phindu lalikulu pazachuma. Mwachitsanzo, pamene chingwe cha square mouth chathyoka ndi kupangidwanso kuti chigwiritsidwe ntchito popanga njira ina ya square mouth bronch, sichimangowonjezera nthawi yopangira zinthu komanso chimabweretsa ndalama zambiri.

Njira yathu imaphatikizira kugwiritsa ntchito carbide YM052 ndi malangizo ena a tsamba kuti ayeretse muzu wosweka wa broach yoyambirira kukhala yoyipa yakutsogolo r. = -6 ° ~ -8 °, kulola kuti m'mphepete mwake mubwezeretsedwe pambuyo pogaya mosamala ndi mwala wa whetstone. Kuthamanga kwachangu kumayikidwa pa V = 10 ~ 15m / min. Pambuyo potembenuza bwalo lakunja, poyambira opanda kanthu amadulidwa, ndiyeno ulusi umatembenuzidwa (wokhala wokhotakhota komanso wozungulira bwino). Kutsatira kutembenuka kwaukali, chidacho chiyenera kukongoletsedwa ndi nthaka musanamalize ulusi wakunja, ndipo pambuyo pake, gawo la ulusi wamkati limakonzekera kulumikiza ndodo ya tayi, yomwe imakonzedwa pambuyo pa kugwirizana. Chifukwa cha njira zokhotakhotazi, chophwanyika chosweka ndi kutayidwa cha square broach chinakonzedwa ndikubwezeretsedwa ku chikhalidwe chake choyambirira.

(2) Kusankhidwa kwa zida zopangira makina olimba

①Magiredi atsopano a zoyika za carbide monga YM052, YM053, ndi YT05 nthawi zambiri amagwiritsidwa ntchito podula liwiro lochepera 18m/mphindi, kukwaniritsa kuuma kwa workpiece kwa Ra1.6~0.80μm.

②Chida cha FD cubic boron nitride chimatha kukonza zitsulo zingapo zozimitsidwa ndi zida zokutira pa liwiro lotsika mpaka 100m/min, zomwe zimapangitsa kuti pakhale kuuma kwa Ra0.80 ~ 0.20μm. DCS-F composite cubic boron nitride chida chochokera ku boma Capital Machinery Factory ndi Guizhou No. 6 Grinding Wheel Factory amagawana ntchitoyi. Ngakhale kuti ntchito yake yogwiritsira ntchito sipamwamba kuposa carbide yopangidwa ndi simenti, ilibe mphamvu yofanana ndi kuzama kwa kulowa mkati, ndipo imabwera pamtengo wapamwamba komanso ndi chiopsezo cha kuwonongeka kwa mutu wodula ngati ikugwiritsidwa ntchito molakwika.

③Zida zodulira ceramic zimagwira ntchito mwachangu pa liwiro la 40-60m/min koma zimakhala ndi mphamvu zochepa.Chilichonse mwa zida izi chimapereka mawonekedwe apadera opangira zida zozimitsidwa ndipo ziyenera kusankhidwa kutengera mikhalidwe yapadera kuphatikiza kusiyanasiyana kwazinthu ndi kuuma.

(3) Zofunikira Zogwirira Ntchito Pazida Zosiyanasiyana za Zitsulo Zozimitsidwa Zigawo zachitsulo zamitundu yosiyanasiyana zimafuna kuti zida zizigwira ntchito molimba molimba momwemo ndipo zitha kugawidwa m'magulu atatu awa:

High alloy steel:Izi zimakhudzana ndi chitsulo chachitsulo ndi chitsulo (makamaka zitsulo zosiyanasiyana zothamanga kwambiri) zokhala ndi ma alloying okwana 10%.

Chitsulo chachitsulo:Izi zikuphatikiza chitsulo chachitsulo ndi chitsulo chakufa chokhala ndi zinthu zoyambira 2 mpaka 9%, mwachitsanzo, 9SiCr, CrWMn, ndi chitsulo champhamvu champhamvu cha alloy.

Chitsulo cha carbon:Izi zikuphatikizapo zitsulo zosiyanasiyana za carbon tool ndi carburized steels monga T8, T10, No. 15 zitsulo kapena No. Izi zimabweretsa kuuma kosiyanasiyana kwa HV800 ~ 1000, komwe ndikwapamwamba kuposa kwa WC ndi TiC mu carbide yomangidwa ndi A12D3 mu zida za ceramic.

Kuphatikiza apo, kuuma kwake kotentha ndikotsika kuposa kwa martensite kopanda ma aloyi, nthawi zambiri sikudutsa 200 ° C.

Kuchulukitsa kukhalapo kwa zinthu zophatikizika muzitsulo kumabweretsa kuwonjezereka kofananira ndi zomwe zili muzitsulo za carbide pambuyo pozimitsa ndi kutenthetsa, zomwe zimapangitsa kusakanikirana kwamitundu ya carbide. Chitsulo chothamanga kwambiri chimagwira ntchito ngati fanizo, kumene carbide zili mu microstructure pambuyo kuzimitsa ndi kutentha zimatha kufika 10-15% (chiŵerengero cha voliyumu). Izi zikuphatikiza mitundu yosiyanasiyana ya ma carbides monga MC, M2C, M6, M3, 2C, ndi ena, okhala ndi VC yowonetsa kuuma kwakukulu (HV2800), kupitilira kuuma kwa zida zanthawi zonse.

Kuphatikiza apo, kuuma kotentha kwa martensite komwe kumakhala ndi ma alloying ambiri kumatha kukwezedwa mpaka pafupifupi 600 ° C. Chifukwa chake, ma machinability a chitsulo chozimitsidwa ndi kulimba kofananako kumasiyana kwambiri. Musanayambe kukonza chitsulo chozimitsidwa, ndikofunikira kuti muwunike kaye gulu lake, kumvetsetsa mawonekedwe ake, ndikusankha zida zoyenera, magawo odulira, ndi geometry ya zida. Ndi kulingalira koyenera, kutembenuza kwa zitsulo zolimba zingathe kuchitidwa mosiyanasiyana.

Anebon imanyadira kukwaniritsidwa kwamakasitomala apamwamba komanso kuvomerezedwa kochulukirapo chifukwa Anebon amalimbikira kufunafuna zapamwamba pazogulitsa ndi ntchito za CE Certificate Customized High Quality Computer Components.CNC Parts MillingMetal, Anebon yakhala ikuthamangitsa WIN-WIN ndi ogula athu. Anebon alandirirani mwachikondi makasitomala ochokera padziko lonse lapansi akubwera mopitilira kubwera kudzacheza ndikukhazikitsa ubale wachikondi wokhalitsa.

CE Certificate China cnc makina a aluminiyamu zigawo,CNC Inatembenuza Magawondi cnc lathe ziwalo. Ogwira ntchito onse mufakitale, sitolo, ndi ofesi ya Anebon akuvutika kuti akwaniritse cholinga chimodzi kuti apereke zabwino ndi ntchito zabwino. Bizinesi yeniyeni ndiyo kupeza mwayi wopambana. Tikufuna kupereka chithandizo chochulukirapo kwa makasitomala. Takulandilani ogula onse abwino kuti azilumikizana nafe tsatanetsatane wazogulitsa zathu ndi mayankho!

Ngati mukufuna kudziwa zambiri kapena kufunsa, lemberaniinfo@anebon.com.

Nthawi yotumiza: Feb-18-2024