Kodi mumadziwa bwanji za njira yopangira ulusi mu makina a CNC?

Mu CNC Machining, ulusi amapangidwa ndi kudula kapena kupanga ntchito. Nazi njira zingapo zopangira ulusi zomwe zimaperekedwa ndi gulu la Anebon:

Kugogoda:Njira imeneyi imaphatikizapo kudula ulusi pogwiritsa ntchito kampopi, chomwe ndi chida chokhala ndi ma helical grooves. Kugogoda kumatha kuchitidwa ndi dzanja kapena makina, ndipo ndikoyenera kupanga ulusi wamkati.

Kugaya Ulusi: Kugaya ulusi kumagwiritsa ntchito chida chodulira chozungulira chokhala ndi zitoliro zingapo kuti apange ulusi. Ndi njira yosunthika yomwe ingagwiritsidwe ntchito pa ulusi wamkati ndi kunja. Kugaya ulusi nthawi zambiri kumakonda ngati ulusi wokulirapo kapena ulusi wosiyanasiyana ndi mitundu ikufunika.

Kutembenuza Ulusi:Njirayi imaphatikizapo kugwiritsa ntchito chida chodulira chimodzi chomwe chimayikidwa pa lathe kuti apange ulusi wakunja. Kutembenuza ulusi nthawi zambiri kumagwiritsidwa ntchito ngati ulusi waukulu kapena wautali ndipo ndikoyenera ulusi wowongoka komanso wopindika.

Kugudubuza Ulusi:Pakugudubuza ulusi, chitsulo cholimba chachitsulo chimagwiritsa ntchito kukakamiza kwa workpiece kuti iwononge zinthu ndikupanga ulusi. Njirayi ndi yothandiza komanso imapanga ulusi wapamwamba kwambiri, zomwe zimapangitsa kuti zikhale zoyenera kupanga mawu apamwamba.

Kugaya Ulusi:Kugaya ulusi ndi njira yolondola yopangira makina omwe amagwiritsa ntchito gudumu lopera kuti apange ulusi. Nthawi zambiri amagwiritsidwa ntchito popanga ulusi wolondola komanso wapamwamba kwambiri, makamaka ulusi wovuta kapena wapadera.

Posankha njira yopangira ulusi, zinthu monga kukula kwa ulusi, zofunikira zolondola, katundu wakuthupi, kuchuluka kwa kupanga, ndi kulingalira mtengo ziyenera kuganiziridwa.

Mbiri

Mawu achingerezi ofanana ndi screw ndi Screw. Tanthauzo la mawuwa lasintha kwambiri m’zaka mazana aposachedwapa. Osachepera mu 1725, amatanthauza "mating".

Kugwiritsiridwa ntchito kwa mfundo ya ulusi kungayambikenso ku chida chonyamulira madzi chozungulira chomwe chinapangidwa ndi katswiri wachi Greek Archimedes mu 220 BC.

M’zaka za m’ma 400 AD, maiko a m’mphepete mwa Nyanja ya Mediterranean anayamba kugwiritsa ntchito mfundo ya ma bolts ndi mtedza ku makina osindikizira omwe amagwiritsidwa ntchito popangira vinyo. Panthawiyo, ulusi wakunja unkakulungidwa ndi chingwe ku cylindrical bar, ndiyeno amalembedwa motsatira chizindikiro ichi, pamene ulusi wamkati nthawi zambiri unkapangidwa ndi kumenyetsa kuzungulira ulusi wakunja ndi zipangizo zofewa.

Cha m'ma 1500, pachithunzi cha chipangizo chopangira ulusi chojambulidwa ndi Leonardo da Vinci waku Italiya, panali kale lingaliro logwiritsa ntchito screw yachikazi ndi zida zosinthira kukonza ulusi wamitundu yosiyanasiyana. Kuyambira pamenepo, njira yodulira ulusi mwa makina yayambika m’makampani opanga mawotchi ku Ulaya.

Mu 1760, abale a ku Britain J. Wyatt ndi W. Wyatt anapeza chilolezo chodulira zitsulo zamatabwa pogwiritsa ntchito chipangizo chapadera. Mu 1778, British J. Ramsden nthawi ina anapanga chipangizo chodulira ulusi choyendetsedwa ndi nyongolotsi, zomwe zimatha kupanga ulusi wautali molunjika kwambiri. Mu 1797, British H. Mozley anagwiritsa ntchito screw lead yachikazi ndi zida zosinthira kutembenuza ulusi wachitsulo ndi maphikidwe osiyanasiyana pa lathe yomwe iye adakonza, ndikukhazikitsa njira yosinthira ulusi.

M'zaka za m'ma 1820, Maudsley anapanga gulu loyamba la matepi ndipo amafa pokonza ulusi.

Kumayambiriro kwa zaka za m'ma 1900, chitukuko cha makampani opanga magalimoto chinalimbikitsanso kukhazikika kwa ulusi ndi chitukuko cha njira zosiyanasiyana zolondola komanso zogwira mtima. Mitundu yosiyanasiyana ya mitu yotsegulira yokha ndi matepi ocheperako okha adapangidwa motsatizana, ndipo mphero ya ulusi idayamba kugwiritsidwa ntchito.

Kumayambiriro kwa zaka za m'ma 1930, ulusi ukupera udawonekera.

Ngakhale ukadaulo wogubuduza ulusi unali wovomerezeka koyambirira kwa zaka za zana la 19, chifukwa cha zovuta kupanga nkhungu, chitukukocho chinali chochepa kwambiri. Sizinali mpaka Nkhondo Yachiwiri Yapadziko Lonse (1942-1945) kuti chifukwa cha zosowa za kupanga zida zankhondo ndi chitukuko cha ulusi wopera ulusi, vutoli linathetsedwa. Vuto lolondola la kupanga nkhungu lapeza chitukuko chofulumira.

Ulusiwo umagawidwa makamaka mu ulusi wolumikiza ndi ulusi wotumizira

Pakuti kulumikiza ulusi, njira processing makamaka: kugogoda, ulusi, ulusi, kugudubuza, akugudubuza, etc.

Pa ulusi wopatsira, njira zazikulu zopangira ndi: kutembenuza movutikira komanso kosalala - kugaya, mphero yamkuntho - kutembenuka koyipa, ndi zina zambiri.

Gulu loyamba: kudula ulusi

Nthawi zambiri amatanthauza njira yopangira ulusi pazigawo zogwirira ntchito ndi zida zopangira kapena zida zowononga, makamaka kuphatikiza kutembenuza, mphero, kugogoda ndi kugaya ulusi, kugaya ndi kudula kamvuluvulu. Potembenuza, mphero ndi ulusi wopera, nthawi zonse pamene chogwiritsira ntchito chimayenda, chingwe chotumizira cha chida cha makina chimatsimikizira kuti chida chotembenuza, chodula mphero kapena gudumu lopukuta chimasuntha chitsogozo molondola komanso molingana ndi axis ya workpiece. Pogogoda kapena ulusi, chida (pampopi kapena kufa) ndi workpiece kupanga wachibale kasinthasintha kayendedwe, ndipo woyamba anapanga ulusi poyambira amatsogolera chida (kapena workpiece) kusuntha axially.

1. Kutembenuza ulusi

Kutembenuza ulusi pa lathe kutha kugwiritsa ntchito chida chopota kapena chipeso cha ulusi. Kutembenuza ulusi ndi chida chosinthira ndi njira yodziwika yopangira chidutswa chimodzi komanso chochepa chamagulu ang'onoang'ono opangira ulusi chifukwa cha mawonekedwe osavuta a chida; kutembenuza ulusi ndi ulusi chisa chida ali mkulu kupanga dzuwa, koma dongosolo chida n'zovuta ndipo ndi oyenera kupanga sing'anga ndi zazikulu Kutembenuza workpieces zazifupi ulusi ndi phula bwino. Kulondola kwa phula kwa ulusi wa trapezoidal kutembenukira pa lathes wamba kumatha kufika pa giredi 8 mpaka 9 (JB2886-81, chimodzimodzi pansipa); kukonza ulusi pazingwe zapadera za ulusi kumatha kupititsa patsogolo zokolola kapena kulondola.

2. Kupera ulusi

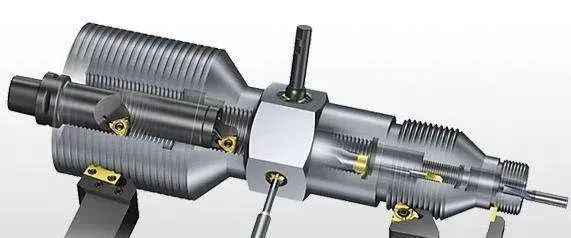

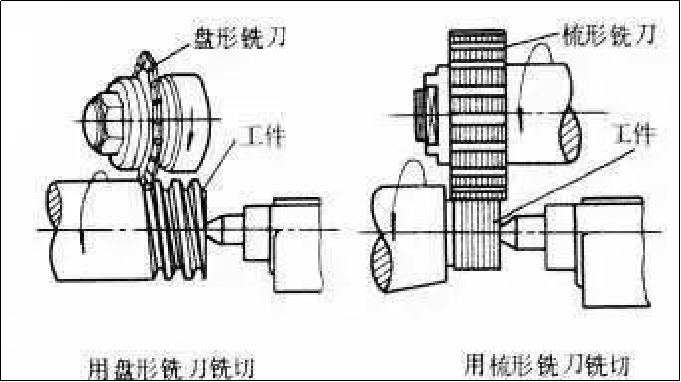

Prototype cnc mpherondi chodulira diski kapena chocheka zisa pa makina opera ulusi.

Ma disc mphero amagwiritsidwa ntchito makamaka pogaya ulusi wakunja wa trapezoidal pazinthu zogwirira ntchito monga zomata ndi nyongolotsi. Chodula chofanana ndi chisa chimagwiritsidwa ntchito popera ulusi wamba wamkati ndi kunja ndi ulusi wa taper. Popeza amagayidwa ndi chodula chamitundu yambiri ndipo kutalika kwa gawo lake logwirira ntchito ndi lalikulu kuposa kutalika kwa ulusi wokonzedwa, chogwiriracho chimangofunika kuzunguliridwa kwa 1.25 mpaka 1.5 kutembenuka. Zachitika, zokolola zachuluka. Kulondola kwa phula kwa mphero ya ulusi nthawi zambiri kumatha kufika magiredi 8-9, ndipo kuuma kwapamtunda ndi ma microns a R5-0.63. Njirayi ndi yoyenera pakupanga ma batch a ulusi wopangidwa ndi ulusi wokhazikika kapena wowuma musanayambe kugaya.

Ulusi mphero wocheka Machining mkati ulusi

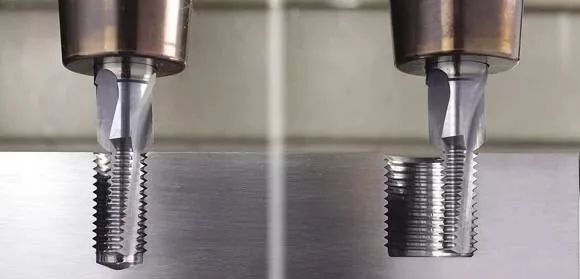

3. Kupera ulusi

Amagwiritsidwa ntchito makamaka pokonza ulusi wolondola wa zida zolimba pa makina opera ulusi. Malingana ndi mawonekedwe a gudumu lopera, amatha kugawidwa m'mitundu iwiri: gudumu lopera la mzere umodzi ndi gudumu lopukuta la mizere yambiri. Kulondola kwa phula kwa gudumu logaya la mzere umodzi kumatha kukhala magiredi 5-6, kuuma kwapamtunda ndi ma microns a R1.25-0.08, ndipo kuvala kwa gudumu lopera ndikosavuta. Njirayi ndi yoyenera kugaya zomangira zotsogola zolondola, zoyezera ulusi, nyongolotsi, timagulu tating'ono tating'onoting'ono ta ulusi wopangidwa ndi ulusi ndi kugaya mpumulo.kulondola kotembenuzidwa gawo.

Mipikisano mizere akupera gudumu akupera agawidwa mitundu iwiri: longitudinal akupera njira ndi agwere akupera njira. M’njira yopera motalika, m’lifupi mwa gudumu lopera ndi locheperapo kuposa kutalika kwa ulusi woti ausinthidwe, ndipo ulusiwo ukhoza kupedwa mpaka kufika kukula komalizira mwa kusuntha gudumu lopera motalika kamodzi kapena kangapo. Mu njira yodulira-pera, m'lifupi mwake gudumu lopera ndi lalikulu kuposa kutalika kwa ulusi woti upulidwe.

Gudumu logaya limadula pamwamba pa chogwirira ntchito mozungulira, ndipo chogwiriracho chimatha kugwedezeka pambuyo pa kusinthika pafupifupi 1.25. Zokolola ndizokwera, koma kulondola kumakhala kotsika pang'ono, ndipo kuvala kwa gudumu lopera kumakhala kovuta kwambiri. Njira yoperayo ndi yoyenera popopera mpumulo ndi magulu akuluakulu ndikupera ulusi wina kuti amange.

4. Kupera ulusi

Chopukusira chamtundu wa nati kapena chopukutira chimapangidwa ndi zinthu zofewa monga chitsulo choponyedwa, ndicnc kutembenuza magawoya ulusi wokonzedwa pa workpiece yomwe ili ndi vuto la phula imazunguliridwa kutsogolo ndi kumbuyo komwe kumapangitsa kuti phokoso likhale lolondola. Ulusi wolimba wamkati nthawi zambiri umakhazikikanso kuti uchotse mapindikidwe ndikuwongolera kulondola.

5. Kugogoda ndi ulusi

Kugogoda

Ndiko kugwiritsa ntchito torque inayake kukhomera mpopi mu dzenje lobowoledwa kale pa chogwirira ntchito kuti mukonze ulusi wamkati.

Ulusi

Ndiko kugwiritsa ntchito kufa kudula ulusi wakunja pa bar (kapena chitoliro) chogwirira ntchito. Kulondola kwa makina pogogoda kapena kulumikiza kumadalira kulondola kwa mpopi kapena kufa.

Ngakhale pali njira zambiri zopangira ulusi wamkati ndi kunja, ulusi wamkati waung'ono waung'ono ukhoza kukonzedwa ndi matepi. Kugogoda ndi ulusi kutha kuchitidwa ndi manja, kapena ndi lathes, makina osindikizira, makina opopera ndi makina opangira ulusi.

Gulu lachiwiri: kugudubuza ulusi

A processing njira imene workpiece ndi pulasitiki wopunduka ndi kupanga anagubuduza kufa kupeza ulusi. Kugudubuza ulusi nthawi zambiri kumachitika pamakina ogubuduza ulusi kapena pa lathe lodziwikiratu lomwe limakhala ndi ulusi wongotsegula ndi kutseka. Ulusi wakunja wopangira kuchuluka kwa zomangira zokhazikika ndi maulalo ena a ulusi. Kuzungulira kwakunja kwa ulusi wokulungidwa nthawi zambiri sikuposa 25 mm, kutalika kwake sikuposa 100 mm, kulondola kwa ulusi kumatha kufika pamlingo wa 2 (GB197-63), ndipo m'mimba mwake wa ulusi wogwiritsidwa ntchito ndi wofanana ndi phula. awiri a ulusi wokonzedwa. Kugudubuza nthawi zambiri sikungathe kupanga ulusi wamkati, koma kwa zida zogwirira ntchito zofewa, matepi opanda grooveless extrusion angagwiritsidwe ntchito kuzizira-kutulutsa ulusi wamkati (kuzama kwake kumatha kufika pafupifupi 30 mm), ndipo mfundo yogwirira ntchito ndi yofanana ndi kugogoda. The makokedwe zofunika kwa ozizira extrusion ulusi mkati ndi pafupi

Kuwirikiza kawiri kugogoda, ndi kulondola kwa makina ndi kukongola kwa pamwamba ndizokwera pang'ono kuposa za kugogoda.

Ubwino wakugudubuza ulusi: ①Kukhwinyata kwa pamwamba ndi kochepa kuposa kutembenuka, mphero ndi kugaya; ②Pamwamba pa ulusi mutagubuduza amatha kuwonjezera mphamvu ndi kuuma chifukwa cha kuzizira kozizira; ③ Kugwiritsa ntchito zinthu zambiri; ④Zokolola zimachulukitsidwa kawiri poyerekeza ndi kudula, komanso zosavuta kupanga; ⑤ moyo wodzigudubuza ndi wautali kwambiri. Komabe, ulusi wogubuduza umafuna kuti kuuma kwa zinthu zogwirira ntchito sikudutsa HRC40; kufunikira kwa kulondola kwa dimensional kwa chopanda kanthu ndikwambiri; kulondola ndi kuuma kwa nkhungu yogubuduza kumakhalanso kwapamwamba, ndipo n'zovuta kupanga nkhungu; siyoyenera kugudubuza ulusi wokhala ndi mawonekedwe a mano asymmetric.

Malingana ndi mitundu yosiyanasiyana ya kugubuduza, kugudubuza ulusi kungathe kugawidwa m'mitundu iwiri: kugudubuza ulusi ndi kugudubuza ulusi.

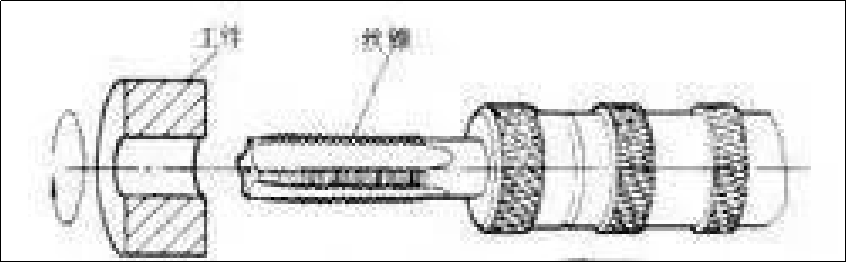

6. Kusisita

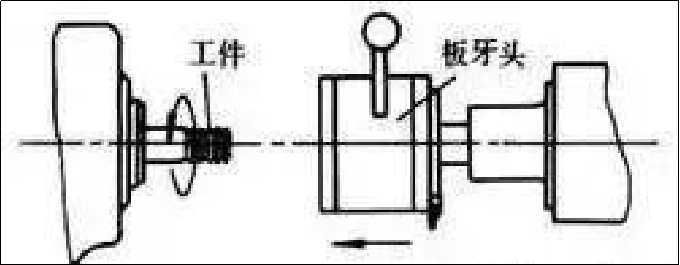

Ma board a ulusi awiri okhala ndi mbiri ya ulusi amapangidwa moyang'anizana wina ndi mnzake ndi 1/2 phula lokhazikika, bolodi lokhazikika limakhazikika, ndipo bolodi losuntha limapanga kusuntha kofanana kofanana ndi bolodi lokhazikika. Pamene azida zamakina mwamakondaimadyetsedwa pakati pa mbale ziwirizo, mbale yosuntha imapita patsogolo ndikupukuta workpiece, ndikupangitsa kuti pamwamba pake ikhale yopunduka kuti ipange ulusi (Chithunzi 6 [kugudubuza ulusi]).

7. Kugudubuza ulusi

Pali mitundu itatu ya ulusi wogubuduza, ulusi wozungulira, ulusi wopindika komanso ulusi wozungulira.

① Kugudubuzika kwa ulusi: 2 (kapena 3) mawilo ogudubuza ulusi okhala ndi mbiri ya ulusi amayikidwa pamiyendo yofananira, chogwirira ntchito chimayikidwa pa chothandizira pakati pa mawilo awiriwo, ndipo mawilo awiriwo amazungulira liwiro lomwelo mbali imodzi (Chithunzi 7). [Kuzungulira kwa ulusi]), imodzi mwazomwe zimapanganso kuyenda kwa chakudya cha radial. Chogwirira ntchito chimazungulira pansi pa kuyendetsa kwa gudumu lakugudubuza ulusi, ndipo pamwamba pake amatuluka mozungulira kuti apange ulusi. Kwa zomangira zina zotsogola zomwe sizifuna kulondola kwambiri, njira yofananira ingagwiritsidwenso ntchito popanga mipukutu.

②Kugubuduza kwa ulusi: Kumadziwikanso kuti kugudubuzika kwa ulusi wa mapulaneti, chida chogudubuza chimakhala ndi gudumu lozungulira lapakati ndi mbale zitatu za waya zooneka ngati arc (Chithunzi 8 [kugudubuza kwa ulusi]). Pakugubuduza ulusi, chogwiriracho chimatha kudyetsedwa mosalekeza, kotero kuti zokololazo zimakhala zapamwamba kuposa za ulusi wozungulira ndi ulusi wa radial.

③Kugubuduza ulusi wamutu: Imachitidwa pa lathe yokhayokha, ndipo nthawi zambiri imagwiritsidwa ntchito popanga ulusi waufupi pazantchito. Pali mawilo a ulusi a 3 mpaka 4 omwe amagawidwa mofanana pamphepete mwa kunja kwa workpiece mumutu wopukutira (Chithunzi 9 [mutu wopukutira]). Pakugubuduza ulusi, chogwirira ntchito chimazungulira, ndipo mutu wozungulira umadyetsa axially kuti agubuduze chogwiriracho kuchokera mu ulusi.

8. EDM ulusi processing

Kukonza ulusi wamba nthawi zambiri kumagwiritsa ntchito malo opangira makina kapena zida ndi zida, ndipo nthawi zina kugogoda pamanja kumathekanso. Komabe, nthawi zina zapadera, njira pamwamba si zophweka kupeza zotsatira zabwino processing, monga kufunika pokonza ulusi pambuyo kutentha mankhwala mbali chifukwa cha kunyalanyaza, kapena chifukwa cha zopinga zakuthupi, monga kugogoda mwachindunji pa simenti workpieces carbide. Panthawiyi, m'pofunika kuganizira njira yopangira makina a EDM.

Poyerekeza ndizitsulo cnc Machiningnjira, dongosolo la EDM ndilofanana, ndipo dzenje la pansi liyenera kukumbidwa poyamba, ndipo m'mimba mwake pansi pa dzenje liyenera kutsimikiziridwa malinga ndi momwe ntchito ikugwirira ntchito. Elekitirodi iyenera kusinthidwa kukhala mawonekedwe a ulusi, ndipo ma elekitirodi amayenera kusinthasintha pakukonza.

"Quality koyamba, Kuona mtima monga maziko, kuona kampani ndi phindu onse pamodzi" ndi lingaliro Anebon, kotero inu mukhoza kulenga mosalekeza ndi kutsata ubwino China Wholesale Mwambo Machining Part-Mapepala Zitsulo Part Factory-Auto Part, Anebon mwamsanga anakula kukula ndi dzina. chifukwa cha kudzipereka kwathunthu kwa Anebon pakupanga zinthu zabwino kwambiri, zamtengo wapatali komanso opereka makasitomala ambiri.

OEM Manufacturer China Machining Part ndi Stamping Part, Ngati mukuyenera kukhala ndi chilichonse mwazogulitsa ndi mayankho a Anebon, kapena kukhala ndi zinthu zina zoti zipangidwe, onetsetsani kuti mwatitumizira zofunsa zanu, zitsanzo kapena zojambula zakuya. Pakadali pano, ndicholinga chofuna kukhala gulu lamakampani apadziko lonse lapansi, Anebon adzakhalapo nthawi zonse kuyembekezera kulandira zopatsa zamabizinesi ogwirizana ndi ma projekiti ena amgwirizano.

Nthawi yotumiza: Jun-19-2023