Makina opangira makina amaphatikiza mafuta, gasi, magetsi, ndi kuwongolera manambala, ndipo amatha kuzindikira kugunda kwanthawi imodzi kwa magawo osiyanasiyana ovuta monga ma discs, mbale, zipolopolo, makamera, nkhungu, ndi zina zambiri, ndipo amatha kumaliza kubowola, mphero, kutopa, kukulitsa. , reming, Kugogoda kolimba ndi njira zina zimakonzedwa, kotero ndi zida zabwinomakina apamwamba kwambiri. Nkhaniyi igawana kugwiritsa ntchito malo opangira makina kuchokera kuzinthu izi:

Kodi malo opangira makina amayika bwanji chida?

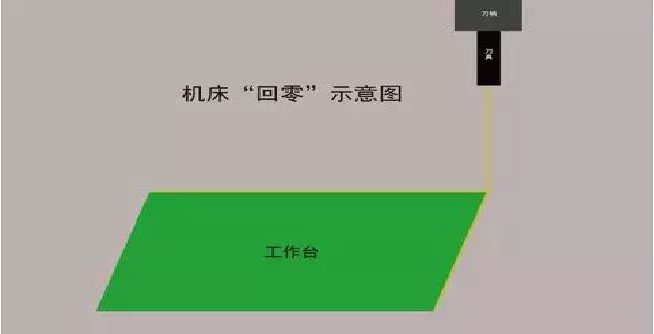

1. Bwererani ku ziro (bwererani ku chiyambi cha makina)

Musanakhazikitse chida, onetsetsani kuti mwachita ntchito yobwerera ku zero (kubwerera ku chiyambi cha chida cha makina) kuti mufufuze deta yogwirizanitsa ntchito yomaliza. Dziwani kuti X, Y, ndi Z nkhwangwa zonse ziyenera kubwerera ku ziro.

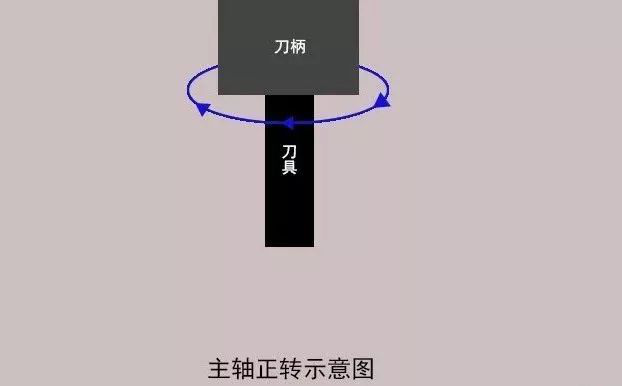

2. Spindle imazungulira kutsogolo

Mu "MDI" mode, spindle imazunguliridwa kutsogolo ndikulowetsa malamulo, ndikusunga liwiro lozungulira. Kenako sinthani ku "handwheel" mode, ndikusuntha chida cha makina posintha kusintha kosintha.

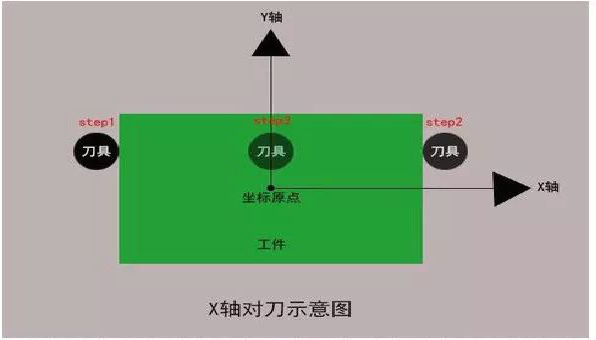

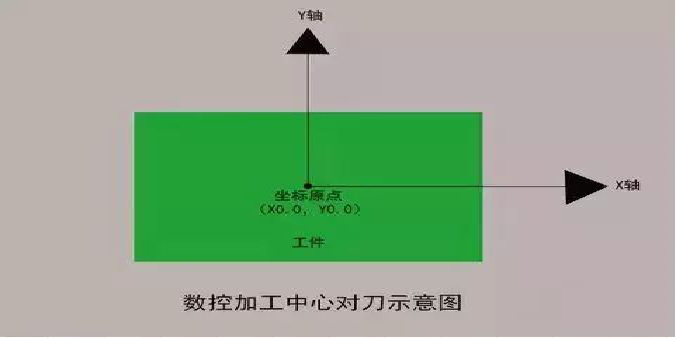

3. X-direction tool setting

Gwirani pang'onopang'ono chida chakumanja kwa chogwirira ntchito kuti muchotse zolumikizira zachibale za chida cha makina; kwezani chidacho motsatira njira ya Z, kenako sunthani chidacho kumanzere kwa chogwiriracho, mpaka kutalika komweko monga kale, sunthani chida ndi chogwirira ntchito Gwirani mopepuka, kwezani chidacho, lembani mtengo wa X wa mgwirizano wachibale. cha chida cha makina, sunthani chidacho ku theka la chibale chogwirizanitsa X, lembani mtengo wa X wa mgwirizano wamtundu wa makina, ndikusindikiza (INPUT) kuti mulowe mu dongosolo logwirizanitsa.

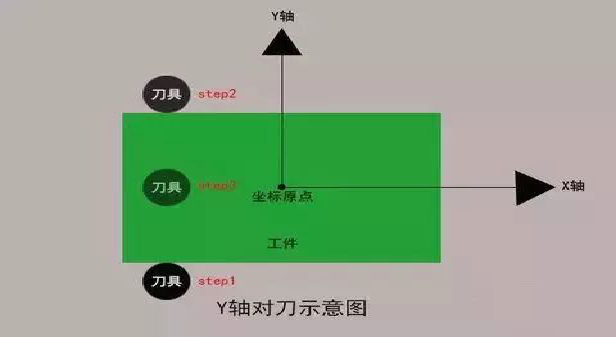

4.Y-chida chowongolera chida

Gwirani pang'onopang'ono chida kutsogolo kwa workpiece kuti muchotse makonzedwe apachibale a chida cha makina; kwezani chidacho motsatira njira ya Z, kenako sunthani chida kumbuyo kwa chogwiriracho, mpaka kutalika komweko monga kale, sunthani chida ndi chogwirira ntchito Gwirani mopepuka, kwezani chidacho, lembani mtengo wa Y wa mgwirizano wachibale wa chida cha makina, sunthani chidacho ku theka la chibale chogwirizanitsa Y, lembani mtengo wa Y wa mgwirizano wamtundu wa makina, ndikusindikiza (INPUT) kuti mulowe mu dongosolo logwirizanitsa.

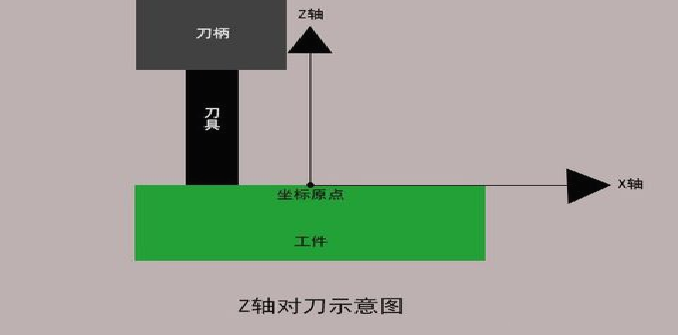

5. Z-direction tool setting

Sunthani chida pamwamba pa workpiece yomwe imayenera kuyang'anizana ndi zero point ya Z direction, pang'onopang'ono sunthani chidacho kuti chigwirizane ndi pamwamba pa workpiece, lembani mtengo wa Z mu dongosolo logwirizanitsa la chida cha makina panthawiyi. , ndikusindikiza (INPUT) kuti mulowetse mu coordinate system.

6. Kuyimitsa kwa spindle

Choyamba, imitsani ulusi wopota, sunthani chopondera pamalo abwino, imbani pulogalamu yokonza, ndipo konzekerani kukonzedwa.

Kodi malo opangira makinawa amapangidwa bwanji ndi kukonza zida zopunduka mosavuta?

Kwa magawo omwe ali ndi kulemera kopepuka, kusasunthika kosasunthika ndi mphamvu zofooka, amapunduka mosavuta ndi mphamvu ndi kutentha panthawi yokonza, ndipo kutsika kwakukulu kwazitsulo kumabweretsa kuwonjezeka kwakukulu kwa mtengo. Pazigawo zotere, choyamba tiyenera kumvetsetsa zomwe zimayambitsa mapindikidwe:

Limbikitsani kusintha:

Ziwalo zoterezi zimakhala ndi makoma opyapyala, ndipo pansi pa mphamvu ya clamping, zimakhala zosavuta kukhala ndi makulidwe osiyanasiyana mu makina opangira ndi kudula, ndipo kusungunuka kumakhala kovutirapo, ndipo mawonekedwe a ziwalozo ndi ovuta kuchira okha.

Thermal deformation:

Ntchitoyi ndi yopepuka komanso yopyapyala, ndipo mphamvu ya radial panthawi yodula imapangitsa kuti ntchitoyo ikhale yopunduka chifukwa cha kutentha, motero kumapangitsa kukula kwa workpiece kukhala kolakwika.

Kusintha kwa vibration:

Pansi pa mphamvu yodulira ma radial, magawo amatha kugwedezeka komanso kupindika, zomwe zimakhudza kulondola kwa mawonekedwe, mawonekedwe, kulondola kwa malo komanso kuuma kwa malo ogwirira ntchito.

Njira yopangira zida zopunduka mosavuta:

The mosavuta deformable mbali akuimiridwa ndi mbali woonda-mipanda akhoza kutenga mawonekedwe a mkulu-liwiro Machining ndi mlingo waung'ono chakudya ndi lalikulu kudula liwiro kuchepetsa kudula mphamvu pa workpiece pa processing, ndipo nthawi yomweyo ambiri kudula kutentha ntchentche. kutali ndi tchipisi ta workpiece pa liwiro lalikulu. Chotsani, potero kuchepetsa kutentha kwa workpiece ndi kuchepetsa mapindikidwe matenthedwe workpiece.

Chifukwa chiyani zida zopangira makina ziyenera kuchotsedwa?

Zida za CNC sizili mwachangu momwe zingathere, chifukwa chiyani mukuzisiya? M'malo mwake, kugwiritsa ntchito chida sizomwe aliyense amamvetsetsa, koma njira yopititsira patsogolo moyo wautumiki wa chida. Limbikitsani luso la zida pogwiritsa ntchito njira monga kusanja, kupukuta, ndi kuchotsa. Izi ndizochitika mwachizolowezi chida chikagwiritsidwa ntchito bwino komanso chisanayambe kupaka.

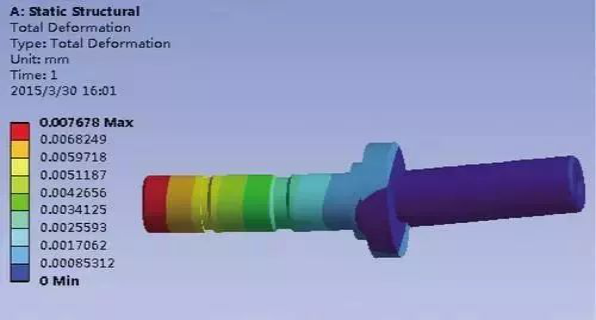

▲Kufanizira kwachida

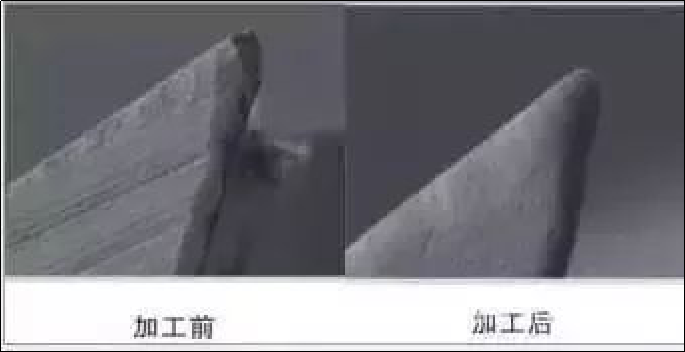

Chidacho chidzanoledwa ndi gudumu lopera lisanamalizidwe, koma kuwongolako kumayambitsa mipata yosiyanasiyana ya ma microscopic. Pamene makina opangira makina achita kudula kwambiri, micro-notch idzakulitsidwa mosavuta, zomwe zidzafulumizitsa kuvala ndi kuwonongeka kwa chida. Ukadaulo wamakono wodulira uli ndi zofunika kwambiri pa bata ndi kulondola kwa chida, chifukwa chake chida cha CNC chiyenera kupitilira musanayambe kupaka kuonetsetsa kulimba ndi moyo wautumiki wa ❖ kuyanika. Ubwino wa chida passivation ndi:

1. Pewani kuvala zida zakuthupi

Panthawi yodulira, pamwamba pa chidacho chidzachotsedwa pang'onopang'ono ndi workpiece, ndipo m'mphepete mwake mumakhalanso ndi mapindikidwe a pulasitiki pansi pa kutentha kwakukulu komanso kuthamanga kwambiri panthawi yodula. Passivation wa chida angathandize kusintha rigidity chida ndi kuteteza chida kutaya kudula ntchito msanga.

2. Sungani mapeto a workpiece

Ma Burrs pamphepete mwa chida amapangitsa kuti chidacho chivale ndipo pamwamba pa makina opangidwa ndi makinawo amakhala ovuta. Pambuyo pa chithandizo cha passivation, m'mphepete mwa chidacho chidzakhala chosalala kwambiri, chodabwitsachi chidzachepetsedwa moyenerera, ndipo mapeto a pamwamba a workpiece adzakhalanso bwino.

3. Yabwino poyambira chip kuchotsa

Kupukuta poyambira chida kumatha kupititsa patsogolo kukongola kwapamwamba komanso kutulutsa chip. Kusalala kwa groove kumapangitsa kuti chip chisamuke bwino, komanso kudula kosasintha kumatha kuchitika. Chida cha CNC cha malo opangira makina chikadutsa ndikupukutidwa, mabowo ang'onoang'ono ambiri adzasiyidwa pamtunda. Mabowo ang'onoang'ono awa amatha kuyamwa madzi odula kwambiri panthawi yokonza, zomwe zimachepetsa kwambiri kutentha komwe kumapangidwa panthawi yodula komanso kumathandizira kwambiri kudula. liwiro.

Kodi malo opangira makina amachepetsera bwanji kuuma kwa malo ogwirira ntchito?

The akhakula pamwamba mbali ndi imodzi mwa mavuto ambiri aCNC makinamalo, zomwe zimasonyeza mwachindunji processing khalidwe. Mmene kulamulira pamwamba roughness wa mbali processing, choyamba tiyenera kupenda zomwe zimayambitsa roughness, makamaka kuphatikizapo: zida zizindikiro chifukwa mphero; matenthedwe matenthedwe kapena pulasitiki mapindikidwe chifukwa kudula kulekana; chida ndi machined pamwamba kukangana pakati.

Posankha roughness pamwamba pa workpiece, sayenera kungokwaniritsa zofunikira za ntchito pamwamba pa gawolo, komanso kuganizira za kulingalira kwachuma. Pamaziko okhutiritsa ntchito yodula, mtengo wokulirapo wa roughness wa pamwamba uyenera kusankhidwa momwe mungathere kuti muchepetse mtengo wopanga. Monga executor wa malo kudula, chida ayenera kulabadira yokonza tsiku ndi yake akupera kupewa osayenera pamwamba roughness chifukwa cha kuzimiririka chida.

Ndiyenera kuchita chiyani malo opangira makina akamaliza?

Nthawi zambiri, malamulo opangira makina azida zamakina m'malo opangira makina ndi ofanana. Kusiyanitsa kwakukulu ndikuti malo opangira makina amachita mosalekeza makina opangira okha kuti amalize njira zonse zodulira kudzera mu clamping imodzi. Chifukwa chake, malo opangira makina amayenera kugwira ntchito zina "Zotsatira".

1. Chitani zoyeretsa. Malo opangira makina akamaliza ntchito yodula, ndikofunikira kuchotsa tchipisi ndikupukuta makinawo munthawi yake, ndikugwiritsa ntchito chida cha makina ndi chilengedwe kuti chikhale choyera.

2. Kuti muyang'ane ndikusintha zowonjezera zowonjezera, choyamba, samalani kuti muyang'ane mbale yopukuta mafuta pa njanji yowongolera, ndikuyisintha mu nthawi ngati yavala. Yang'anani momwe mafuta opaka mafuta alili komanso choziziritsa. Ngati chipwirikiti chikuchitika, chiyenera kusinthidwa pakapita nthawi, ndipo mlingo wa madzi pansi pa sikelo uyenera kuwonjezeredwa.

3. Kuti mukhazikitse ndondomeko yotsekera, magetsi ndi magetsi akuluakulu pagawo la opaleshoni ya makina ayenera kuzimitsidwa. Ngati palibe zochitika zapadera ndi zofunikira zapadera, mfundo yobwerera ku zero poyamba, pamanja, kuthamanga, ndi automatic iyenera kutsatiridwa. Malo opangira makinawo ayeneranso kuthamanga pa liwiro lotsika, liwilo lapakati, ndiyeno kuthamanga kwambiri. Nthawi yothamanga kwambiri komanso yapakati sikhala yochepera mphindi 2-3 musanayambe kugwira ntchito.

4. Opaleshoni yokhazikika, sangathe kumenya, kukonza kapena kukonza workpiece pa chuck kapena pamwamba, ndipo ntchito yotsatira iyenera kutsimikiziridwa pambuyo pa workpiece ndi chida chotsekedwa. Zida zoteteza chitetezo ndi chitetezo pamakina siziyenera kuchotsedwa ndikusunthidwa mosasamala. The kwambiri kothandiza processing kwenikweni otetezeka processing. Monga zida zogwirira ntchito zogwirira ntchito, ntchito ya makina opangira makina ikatsekedwa iyenera kukhala yovomerezeka, yomwe sikuti ndi yokonza ndondomeko yomwe yatsirizidwa, komanso kukonzekera kuyambika kotsatira.

Nthawi yotumiza: Sep-19-2022