Mu Machining, pofuna kukulitsa khalidwe la processing ndi kubwereza molondola, m'pofunika kusankha molondola ndi kudziwa chida choyenera. Kwa makina ovuta komanso ovuta, kusankha chida ndikofunikira kwambiri.

1. Njira ya zida zothamanga kwambiri

1. Njira ya zida zothamanga kwambiri

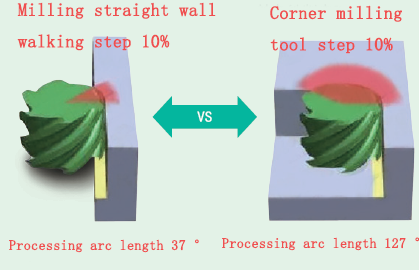

Dongosolo la CAD / CAM limakwaniritsa molondola kwambiri kudula mwa kuwongolera ndendende kutalika kwa chida chodulira mumsewu wothamanga kwambiri wa cycloid. Pamene wodula mphero amadula mu ngodya kapena mu mawonekedwe ena ovuta a geometric, kuchuluka kwa kudya kwa mpeni sikudzawonjezeka. Kuti apindule mokwanira ndi kupita patsogolo kwaukadaulo kumeneku, opanga zida apanga ndikupanga zida zapamwamba zodulira mphero. Odulira mphero ang'onoang'ono amatha kudula zida zambiri zogwirira ntchito munthawi imodzi pogwiritsa ntchito njira zothamanga kwambiri, ndikupeza kuchotsera kwachitsulo chokwera kwambiri.

Pa makina, kukhudzana kwambiri pakati pa chida ndi pamwamba pa workpiece kungachititse kuti chida chilephereke mwamsanga. Lamulo lothandiza la chala chachikulu ndikugwiritsa ntchito chodula mphero chokhala ndi mainchesi pafupifupi 1/2 ya gawo lopapatiza kwambiri la chogwiriracho. Pamene radius ya chodula mphero ndi yaying'ono kuposa kukula kwa gawo lochepetsetsa la workpiece, pali malo oti chidacho chisunthire kumanzere ndi kumanja, ndipo mbali yaying'ono yodyera ingapezeke. Odula mphero amatha kugwiritsa ntchito m'mbali zambiri komanso kuchuluka kwa chakudya. Kuonjezera apo, pamene chodula mphero chokhala ndi 1/2 ya mbali yopapatiza kwambiri ya workpiece imagwiritsidwa ntchito, ngodya yodulira imatha kukhala yaying'ono popanda kuwonjezera kutembenuka kwa wodulayo.

Kuuma kwa makina kumathandizanso kudziwa kukula kwa zida zomwe zingagwiritsidwe ntchito. Mwachitsanzo, podula makina 40-taper, m'mimba mwake wa chodula mphero nthawi zambiri uyenera kukhala <12.7mm. Kugwiritsa ntchito chodulira chokhala ndi mainchesi okulirapo kumatulutsa mphamvu yayikulu yodulira yomwe imatha kupitilira luso la makina, zomwe zimapangitsa kuti pakhale macheza, mapindikidwe, kutsika kosawoneka bwino, komanso kufupikitsa moyo wa zida.

Mukamagwiritsa ntchito njira yatsopano yothamanga kwambiri, phokoso la chodula mphero pakona ndi lofanana ndi la kudula mzere wowongoka. Phokoso lopangidwa ndi wodula mphero panthawi yodula ndilofanana, kusonyeza kuti silinayambe kugwedezeka ndi kutentha kwakukulu ndi makina. Wodula mphero amapanga phokoso nthawi iliyonse akatembenuka kapena kudula pakona, zomwe zimasonyeza kuti m'mimba mwake wa wodula mphero ungafunike kuchepetsedwa kuti achepetse kudya. Phokoso la kudula limakhalabe losasinthika, kusonyeza kuti kukakamiza kudula pa mphero wodula ndi yunifolomu ndipo sikusinthasintha mmwamba ndi pansi ndi kusintha kwa geometry ya workpiece. Izi ndichifukwa choti mbali ya mpeni imakhala yosasintha.

2. Kupera tizigawo tating'ono

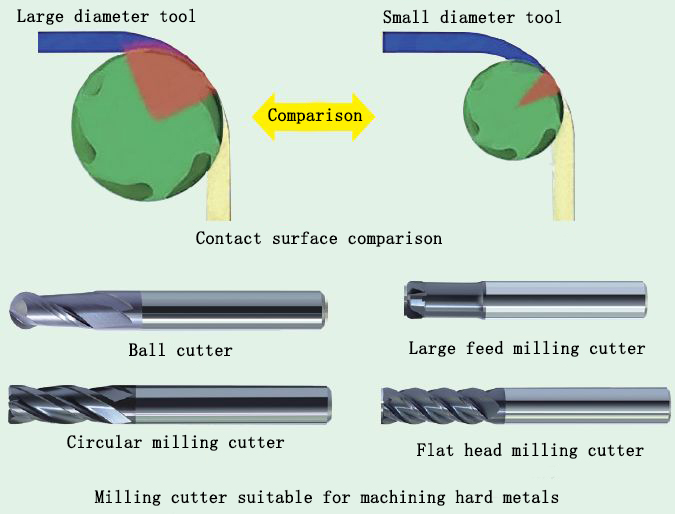

Chodula chachikulu cha mphero ndi choyenera kugaya tizigawo ting'onoting'ono, zomwe zimatha kutulutsa mphamvu yochepetsera chip, kupangitsa kuti mphero ikhale yokwera kwambiri.

Mu processing wa maenje ozungulira mphero ndi nthiti mphero, chida mosalephera kukhudzana kwambiri ndi Machining pamwamba, ndi ntchito yaikulu chakudya mphero wodula akhoza kuchepetsa kukhudzana pamwamba ndi workpiece, potero kuchepetsa kudula kutentha ndi mapindikidwe chida .

Mu mitundu iwiriyi yokonza, chodulira chachikulu cha chakudya chimakhala chotsekeka panthawi yodula. Chifukwa chake, gawo lalikulu kwambiri lodulira ma radial liyenera kukhala 25% ya mainchesi a chodula mphero, ndipo kuya kwa Z pakudula kulikonse kuyenera kukhala 2% ya mainchesi a chodula mphero.cnc Machining gawo

Mu dzenje la mphero, pamene wodula mphero adula mu chogwirira ntchito ndi njanji yodula, yozungulira yozungulira ndi 2 ° ~ 3 ° mpaka ifike kukuya kwa Z kwa 2% ya m'mimba mwake ya wodula mphero.

Ngati chodulira chodyera chachikulu chili pamalo otseguka panthawi yodula, masitepe ake oyenda mozungulira amadalira kuuma kwa zida zogwirira ntchito. Pamene mphero workpiece ndi kuuma HRC30-50 sitepe pazipita radial kudula sitepe ayenera kukhala 5% ya mphero wodula awiri; pamene kuuma kwa zinthu kuli kwakukulu kuposa HRC50, sitepe yodula kwambiri ya radial ndi Z padutsapo Kuzama kodula ndi 2% ya m'mimba mwake wa wodula mphero.gawo la aluminiyamu

3. Kupera makoma owongoka

Pogaya ndi nthiti zathyathyathya kapena makoma owongoka, ndi bwino kugwiritsa ntchito arc cutter. Ma Arc cutters okhala ndi 4 mpaka 6 m'mphepete ndiwoyenera kwambiri kugaya mbiri ya magawo owongoka kapena otseguka kwambiri. Kuchuluka kwa masamba a chodulira mphero, kuchuluka kwa chakudya komwe kungagwiritsidwe ntchito kumakulirakulira. Komabe, wopanga makinawo akufunikabe kuchepetsa kukhudzana pakati pa chida ndi pamwamba pa chogwirira ntchito ndikugwiritsa ntchito kachulukidwe kakang'ono kadulidwe ka radial. Pamene machining pa makina chida ndi osauka rigidity, ndi kopindulitsa ntchito mphero wodula ndi awiri ang'onoang'ono, amene akhoza kuchepetsa kukhudzana ndi pamwamba pa workpiece.cnc mphero gawo

Njira yodulira ndi kuzama kwa chodula chamitundu yambiri ya arc ndi yofanana ndi ya chodula chapamwamba kwambiri. Njira ya chida cha cycloid itha kugwiritsidwa ntchito kukulitsa zinthu zolimba. Onetsetsani kuti m'mimba mwake wa chodula mphero ndi pafupifupi 50% ya m'lifupi mwake, kotero kuti wodula mphero ali ndi malo okwanira kuti asunthe, ndikuwonetsetsa kuti mbali ya wodulayo isachuluke ndikupanga kutentha kwakukulu.

Chida chabwino kwambiri chopangira makina enaake chimadalira osati pazinthu zomwe zimadulidwa, komanso mtundu wa kudula ndi mphero zomwe zimagwiritsidwa ntchito. Mwa kukhathamiritsa zida, kuthamanga kwachangu, mitengo yazakudya ndi luso lopanga makina, magawo amatha kupangidwa mwachangu komanso bwino pamitengo yotsika yopangira makina.

Anebon Metal Products Limited ikhoza kupereka makina a CNC, kuponyera kufa, ntchito zopangira zitsulo, chonde omasuka kutilankhula nafe.

Tel: +86-769-89802722 Email: info@anebon.com Website : www.anebon.com

Nthawi yotumiza: Apr-28-2020