Poyerekeza ndi kukonzanso kwakunja kwakunja, mikhalidwe yopangira dzenje imakhala yoyipa kwambiri, ndipo ndizovuta kukonza mabowo kuposa kukonza mabwalo akunja. Izi ndichifukwa:

1) Kukula kwa chida chomwe chimagwiritsidwa ntchito popanga dzenje kumachepa ndi kukula kwa dzenje lomwe likuyenera kupangidwa, ndipo kulimba kwake ndi koyipa, komwe kumakonda kupindika ndikugwedezeka;

2) Popanga dzenje ndi chida chokhazikika, kukula kwa dzenje nthawi zambiri kumatsimikiziridwa mwachindunji ndi kukula kwake kwa chidacho, ndipo cholakwika chopanga ndi kuvala kwa chidacho chidzakhudza mwachindunji kulondola kwa makina a dzenje;

3) Popanga mabowo, malo odulira amakhala mkati mwa workpiece, kuchotsa chip ndi kutentha kwa kutentha kumakhala kosauka, ndipo kulondola kwa makina ndi khalidwe lapamwamba sikophweka kulamulira.

1. Kubowola ndi kukonzanso

1. kubowola

Kubowola ndiye njira yoyamba yopangira mabowo muzinthu zolimba, ndipo m'mimba mwake mabowo nthawi zambiri amakhala osakwana 80mm. Pali njira ziwiri zobowola: imodzi ndiyo kuzungulira kwa kubowola; ina ndi kuzungulira kwa workpiece. Zolakwika zomwe zimapangidwa ndi njira ziwiri zomwe zili pamwambazi ndizosiyana. Mu njira yobowola ndi kubowola mozungulira, pamene kubowola pang'onopang'ono kumasokonekera chifukwa cha asymmetry ya m'mphepete mwa kudula ndi kusakwanira kwachitsulo chobowola, mzere wapakati wa dzenje lopangidwa ndi makina udzagwedezeka kapena kupotozedwa. Siyowongoka, koma m'mimba mwake ya dzenje sikusintha; m'malo mwake, pobowola momwe chogwirira ntchito chimazungulira, kupatuka kwa kubowola kumapangitsa kuti dzenje lisinthe, pomwe dzenje lapakati likadali lolunjika.

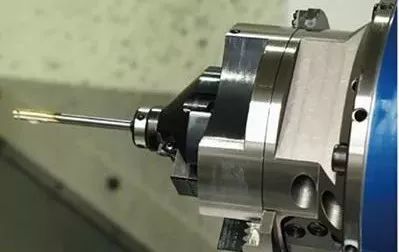

Zomwe zimagwiritsidwa ntchito pobowola zida zimaphatikizapo: kupotoza kubowola, kubowola pakati, kubowola dzenje lakuya, etc. Pakati pawo, zomwe zimagwiritsidwa ntchito kwambiri ndi kupotoza kubowola, zomwe m'mimba mwake ndi Image.

Chifukwa cha zoperewera zamapangidwe, kulimba kopindika ndi kulimba kwa torsional pobowola zonse ndizotsika, kuphatikiza ndi kusakhazikika pakati, kubowola kumakhala kotsika, nthawi zambiri kumangofika ku IT13 ~ IT11; pamwamba pa roughness ndi lalikulu, ndipo Ra zambiri 50 ~ 12.5μm; koma zitsulo zochotsa pobowola ndi zazikulu, ndipo kudula kwachangu ndikwambiri. Kubowola kumagwiritsidwa ntchito kwambiri popanga mabowo okhala ndi zofunikira zotsika, monga mabowo a bawuti, mabowo opindika pansi, mabowo amafuta, ndi zina. Kwa mabowo okhala ndi makina olondola kwambiri komanso zofunikira zapamtunda, ziyenera kukwaniritsidwa mwa kukonzanso, kubwezeretsanso, kusasangalatsa kapena kugaya mkati. makina otsatila.

2. Kulingalira

Reaming ndi imodzi mwa njira zomaliza za mabowo, omwe amagwiritsidwa ntchito kwambiri popanga. Kwa mabowo ang'onoang'ono, kukonzanso ndi njira yochepetsera ndalama komanso yothandiza kusiyana ndi kugaya mkati ndi kutopa.

1. Wokonzanso

Reamers nthawi zambiri amagawidwa m'mitundu iwiri: zopangira manja ndi makina opangira makina. Chogwirizira cha dzanja chowongolera ndi chowongolera chowongoka, gawo logwira ntchito ndi lalitali, ndipo ntchito yowongolera ndi yabwinoko. Chowotcha pamanja chili ndi zigawo ziwiri zamtundu wofunikira komanso m'mimba mwake osinthika. Pali mitundu iwiri ya makina opangira makina, mtundu wa shank ndi mtundu wa manja. Reamers sangangopanga mabowo ozungulira, komanso mabowo a taper amatha kukonzedwa ndi ma taper reamer.

2. Tekinoloje ya Reaming ndi kagwiritsidwe ntchito kake

Chilolezo cha kubwezeretsanso chimakhala ndi chikoka chachikulu pamtundu wa kubwezeretsanso. Ngati choperekacho ndi chachikulu kwambiri, katundu wa reamer ndi wamkulu, m'mphepete mwake mumasokonekera mwachangu, sikophweka kupeza malo osalala opangidwa ndi makina, ndipo kulolerana kwazithunzi sikophweka kutsimikizira; ngati malipirowo ndi ochepa kwambiri, Ngati zizindikiro za chida zomwe zasiyidwa ndi ndondomeko yapitayi sizingachotsedwe, mwachibadwa sizingasinthe khalidwe la kubowo. Nthawi zambiri, mahinji okhwima ndi 0.35 ~ 0.15mm, ndipo hinji yabwino ndi 01.5 ~ 0.05mm.

Pofuna kupewa mapangidwe a m'mphepete mwake, kubwezeretsanso kumachitika pang'onopang'ono (v <8m / min kwa zitsulo zothamanga kwambiri zachitsulo ndi chitsulo). Mtengo wa chakudya umagwirizana ndi kabowo koyenera kukonzedwa. Pokhala pobowo, ndiye kuti chakudyacho chimakhala chachikulu. Pamene zitsulo zothamanga kwambiri zimayendetsa zitsulo ndi chitsulo choponyedwa, chakudya chimakhala 0.3 ~ 1mm / r.

Pokonzanso mabowo, amayenera kuziziritsidwa, kupakidwa mafuta ndikutsukidwa ndi madzi odulira oyenera kuti asamangidwe komanso kuchotsa tchipisi munthawi yake. Poyerekeza ndi akupera ndi wotopetsa, reming ali mkulu zokolola ndipo n'zosavuta kuonetsetsa kulondola kwa dzenje; komabe, kubwezeretsanso sikungathe kukonza zolakwika za malo a dzenje, ndipo malo olondola a dzenje ayenera kutsimikiziridwa ndi ndondomeko yapitayi. Mabowo opondedwa ndi mabowo akhungu sali oyenera kukonzanso.

Kulondola kwapang'onopang'ono kwa dzenje lobwezeretsa nthawi zambiri ndi IT9~IT7, ndipo kuuma kwapamtunda Ra nthawi zambiri kumakhala 3.2 ~ 0.8. Kwa mabowo apakati omwe ali ndi zofunikira zolondola kwambiri (monga mabowo olondola a mulingo wa IT7), njira yobowola-yokulitsa ndi njira yomwe imagwiritsidwa ntchito popanga.

3. Wotopetsa

Kutopetsa ndi njira yopangira yomwe imagwiritsa ntchito zida zodulira kuti zikulitse mabowo opangidwa kale. Ntchito yotopetsa imatha kuchitika pamakina otopetsa kapena lathe.

1. Njira yotopetsa

Pali njira zitatu zosiyana zopangira makina otopetsa.

1) Chogwirira ntchito chimazungulira ndipo chida chimadyetsa. Zambiri zotopetsa pa lathe zimakhala za njira yotopetsa iyi. The ndondomeko mbali ndi: mzere olamulira dzenje pambuyo Machining n'zogwirizana ndi kasinthasintha olamulira workpiece, kuzungulira kwa dzenje makamaka zimadalira kasinthasintha kulondola kwa makina chida spindle, ndi axial geometry cholakwa dzenje makamaka zimadalira. pa njira ya chakudya cha chida chokhudzana ndi kuzungulira kwa workpiece. kulondola kwamalo. Njira yotopetsayi ndiyoyenera kukonza mabowo omwe ali ndi zofunikira za coaxiality ndi kunja.

2) Chidacho chimazungulira ndipo chogwirira ntchito chimapanga kuyenda kodyetsa. Spindle ya makina otopetsa imayendetsa chida chotopetsa kuti chizizungulira, ndipo chogwirira ntchito chimayendetsa chogwirira ntchito kuti chipange kudyetsa.

3) Chidacho chikazungulira ndikuyendetsa kudyetsa, njira yotopetsa iyi imagwiritsidwa ntchito potopetsa. Kutalika kwa bar yotopetsa kumasinthidwa, ndipo mphamvu ndi kusinthika kwa bar yotopetsa zimasinthidwanso. Bowolo ndi laling'ono, limapanga dzenje la tapered. Kuphatikiza apo, kutalika kwa bar yotopetsa kumawonjezeka, ndipo kupindika kwa shaft yayikulu chifukwa cha kulemera kwake kumawonjezekanso, ndipo olamulira a dzenje lopangidwa ndi makina amapindika moyenerera. Njira yotopetsayi ndiyoyenera kumabowo aafupi okha.

2. Daimondi wotopetsa

Poyerekeza ndi wamba wotopetsa, wotopetsa wa diamondi amadziwika ndi kudula pang'ono kumbuyo, chakudya chaching'ono, komanso kuthamanga kwambiri. Ikhoza kupeza kulondola kwa makina apamwamba (IT7~IT6) ndi pamwamba kwambiri (Ra ndi 0.4~ 0.05). Daimondi wotopetsa poyamba kukonzedwa ndi zida diamondi wotopetsa, ndipo tsopano zambiri kukonzedwa ndi simenti carbide, CBN ndi kupanga diamondi zida. Amagwiritsidwa ntchito kwambiri pokonza zitsulo zopanda chitsulo, komanso pokonza chitsulo ndi chitsulo.

Zomwe zimagwiritsidwa ntchito kwambiri podula miyala ya diamondi ndizo: kuchuluka kwa kudulidwa kumbuyo kwa 0.2 ~ 0.6mm, ndipo chomaliza chotopetsa ndi 0.1mm; mlingo wa chakudya ndi 0.01 ~ 0.14mm / r; liwiro kudula ndi 100 ~ 250m/mphindi pamene Machining kuponyedwa chitsulo, ndi Machining 150 ~ 300m/mphindi kwa zitsulo, 300 ~ 2000m/mphindi pokonza zitsulo sanali ferrous.

Pofuna kuwonetsetsa kuti diamondi yotopetsa imatha kukwaniritsa makina olondola kwambiri komanso mawonekedwe apamwamba, chida cha makina (makina otopetsa a diamondi) omwe amagwiritsidwa ntchito ayenera kukhala olondola kwambiri a geometric komanso osasunthika. Tsinde lalikulu la chida cha makina nthawi zambiri limathandizidwa ndi mayendedwe olondola aang'ono a mpira kapena ma hydrostatic sliding bearings, ndi magawo ozungulira kwambiri. Iyenera kukhala yolinganizidwa ndendende; komanso, kayendedwe ka kudyetsa limagwirira ayenera kukhala okhazikika kwambiri kuonetsetsa kuti worktable akhoza kuchita khola ndi otsika kudyetsa kayendedwe.

Daimondi wotopetsa ali wabwino pokonza ndi kuchita bwino kwambiri kupanga, ndipo chimagwiritsidwa ntchito pomaliza kukonza mabowo mwatsatanetsatane pakupanga misa, monga mabowo a silinda ya injini, mabowo a piston, ndi mabowo a spindle pamabokosi opota a zida zamakina. Komabe, tisaiwale kuti pogwiritsira ntchito diamondi wotopetsa pokonza zitsulo zachitsulo, zida zotopetsa zokha zopangidwa ndi simenti ya carbide ndi CBN zingagwiritsidwe ntchito, ndipo zida zotopetsa zopangidwa ndi diamondi sizingagwiritsidwe ntchito, chifukwa maatomu a carbon mu diamondi ali ndi chiyanjano chachikulu. ndi zinthu zamagulu achitsulo. , moyo wa chida ndi wotsika.

3. Chida chotopetsa

Zida zotopetsa zitha kugawidwa kukhala zida zotopetsa zamtundu umodzi komanso zida zotopetsa zapawiri.

4. Umisiri makhalidwe ndi ntchito osiyanasiyana wotopetsa

Poyerekeza ndi kubowola-kukulitsa-reaming ndondomeko, awiri a dzenje si malire ndi kukula kwa chida, ndi wotopetsa ali amphamvu zolakwa kuwongolera luso. Malo otopetsa ndi oyika amakhalabe olondola kwambiri.

Poyerekeza ndi bwalo lakunja la dzenje wotopetsa, chifukwa cha kusakhazikika bwino ndi mapindikidwe lalikulu la chida chofukizira dongosolo, kutentha dissipation ndi Chip kuchotsa zinthu si zabwino, ndi mapindikidwe matenthedwe workpiece ndi chida ndi lalikulu. The Machining khalidwe ndi kupanga bwino za dzenje wotopetsa si mkulu ngati bwalo akunja. .

Kutengera kusanthula pamwambapa, zitha kuwoneka kuti zotopetsa zimakhala ndi njira zambiri zogwirira ntchito, ndipo zimatha kukonza mabowo amitundu yosiyanasiyana komanso milingo yolondola. Pakuti mabowo ndi kachitidwe dzenje ndi diameters lalikulu ndi mkulu dimensional ndi positional kulondola zofunika, wotopetsa ndi pafupifupi processing yekha. njira. Kulondola kwa makina otopetsa ndi IT9 ~ IT7, ndipo roughness pamwamba Ra ndi . Kutopetsa kumatha kuchitika pazida zamakina monga makina otopetsa, ma lathes, ndi makina amphero. Zili ndi ubwino wosinthasintha ndipo zimagwiritsidwa ntchito kwambiri popanga. Pakupanga kwakukulu kwaCNC Machining magawo, pofuna kupititsa patsogolo ntchito yotopetsa, kufa kotopetsa nthawi zambiri kumagwiritsidwa ntchito.

4. honing mabowo

1. Honing mfundo ndi kulemekeza mutu

Honing ndi njira yomaliza dzenje ndi mutu wa honing ndi ndodo yopera (whitstone). Pa honing, workpiece imakhazikika, ndipo mutu wa honing umayendetsedwa ndi spindle ya makina kuti azungulire ndikupanga kubwereza kwa mzere. Mu honing ndondomeko, mphero kapamwamba amachita pamwamba pa workpiece ndi kupsyinjika kwina, ndi kudula wosanjikiza woonda kwambiri kuchokera pamwamba workpiece, ndi kudula trajectory ndi kuwoloka mauna. Pofuna kuti kayendetsedwe ka kayendetsedwe kake ka mchenga wa mchenga usabwerezenso, kusintha kwa kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe kapa bwino ka bwino kacha ngokwezve ngokwezve ngokweyisa ngokweyisa komansonganigqugqugqugqugqu zetu kwemizwa za Usajili wa Chiti

The mphambano ngodya Chithunzi cha honing njanji chikugwirizana ndi reciprocating liwiro Image ndi zotumphukira liwiro Image wa honing mutu. Kukula kwa Image ngodya kumakhudza processing khalidwe ndi dzuwa la honing. Nthawi zambiri, Image ° imagwiritsidwa ntchito pokulitsa movutikira, ndipo Image ° imagwiritsidwa ntchito popanga bwino. Kuti atsogolere kumaliseche kwa wosweka abrasive particles ndi tchipisi, kuchepetsa kudula kutentha ndi kusintha khalidwe processing, okwanira kudula madzimadzi ayenera kugwiritsidwa ntchito pa honing.

Kuti khoma la dzenjelo likhale lopangidwa mofanana, kugunda kwa mchenga kuyenera kupitirira kuchuluka kwakukulu kumapeto kwa dzenjelo. Pofuna kuonetsetsa yunifolomu honing allowance ndi kuchepetsa chikoka cha makina chida spindle kasinthasintha cholakwika pa Machining olondola, ambiri honing mitu ndi makina chida spindles olumikizidwa ndi kuyandama.

Kukula kwa ma radial ndi kusinthika kwapang'onopang'ono kwa mphero yopukusira mutu kumakhala ndi mawonekedwe osiyanasiyana monga manual, pneumatic and hydraulic.

2. The ndondomeko makhalidwe ndi ntchito osiyanasiyana honing

1) Honing imatha kupeza kulondola kwakukulu komanso mawonekedwe ake. Kulondola kwa makina ndi IT7~IT6. Zolakwika zozungulira ndi cylindricity zamabowo zitha kuwongoleredwa mkati mwamitundu yosiyanasiyana, koma kulemekeza sikungawongolere kulondola kwa malo.Zigawo zamakina za CNC'mabowo.

2) Honing akhoza kupeza apamwamba pamwamba khalidwe, pamwamba roughness Ra ndi Image, ndi kuya kwa metamorphic chilema wosanjikiza pamwamba zitsulo ndi laling'ono kwambiri (Image).

3) Poyerekeza ndi liwiro akupera, ngakhale zotumphukira liwiro la honing mutu si mkulu (vc = 16 ~ 60m/mphindi), koma chifukwa chachikulu kukhudzana m'dera pakati pa mchenga kapamwamba ndi workpiece, liwiro reciprocating ndi mkulu. (va=8~20m/mphindi). min), kotero kulemekeza kumakhalabe ndi zokolola zambiri.

Honing imagwiritsidwa ntchito kwambiri popanga mabowo a silinda ya injini ndi mabowo olondola pazida zosiyanasiyana zama hydraulic popanga misa. Komabe, honing sikoyenera pobowola mabowo pazitsulo zopanda chitsulo zokhala ndi pulasitiki yayikulu, komanso singatsegule mabowo okhala ndi makiyi, mabowo a spline, ndi zina zambiri.

5. Kokani dzenje

1. Kudumphadumpha ndi broaching

Hole broaching ndi njira yomaliza yopindulitsa kwambiri yomwe imachitika pamakina a broaching omwe ali ndi broach yapadera. Pali mitundu iwiri ya bedi loyatsira: bedi loyanjanitsa ndi bedi loyang'ana loyang'ana, lomwe lili ndi bedi loyang'ana lopingasa lomwe ndilofala kwambiri.

Pamene broach, broach imangopanga otsika-liwiro liniya zoyenda (main motion). Kuchuluka kwa mano a broach omwe amagwira ntchito nthawi imodzi sayenera kukhala osachepera 3, apo ayi broach siigwira ntchito bwino, ndipo n'zosavuta kupanga ma ripples a annular pamwamba pa workpiece. Pofuna kupewa kusweka kwa broach chifukwa champhamvu kwambiri, pamene broach ikugwira ntchito, chiwerengero cha mano ogwira ntchito sichiyenera kupitirira 6 mpaka 8.

Pali njira zitatu zopangira broaching, zomwe zikufotokozedwa motere:

(1) Layered broaching Makhalidwe a broaching njira imeneyi ndi kuti broach amadula workpiece Machining chilolezo wosanjikiza ndi wosanjikiza sequentially. Pofuna kuthyoka kwa chip, mano odulira amaphwanyidwa ndi ma groove olekana. Broach yopangidwa molingana ndi njira yopumira imatchedwa wamba broach.

(2) Block broaching Njira iyi ya broaching imadziwika kuti chitsulo chilichonse pamtunda wopangidwa ndi makina chimakhala ndi gulu la mano omwe ali ndi kukula kofanana koma mano ogwedezeka (kawirikawiri gulu lililonse limakhala ndi mano 2-3) ) amachotsedwa. Dzino lililonse limadula mbali imodzi ya chitsulo. Broach yopangidwa molingana ndi njira yolumikizira block imatchedwa wheel-cut broach.

(3) Comprehensive broaching Njira iyi imayang'ana ubwino wa broaching wosanjikiza ndi magawo. Dzino lolimba limatengera kumeta kwa magawo, ndipo gawo labwino kwambiri limatengera kumeta. Mwanjira iyi, kutalika kwa broach kumatha kufupikitsidwa, zokolola zimatha kuwongolera, ndipo mawonekedwe abwino a pamwamba amatha kupezeka. Broach yomwe idapangidwa molingana ndi njira yophatikizira imatchedwa comprehensive broach.

2. Makhalidwe a ndondomeko ndi kuchuluka kwa ntchito ya kukoka dzenje

1) Broach ndi chida chokhala ndi masamba ambiri, chomwe chimatha kumaliza roughing, kumaliza ndi kumaliza dzenje mumtundu umodzi wa broaching, ndikuchita bwino kwambiri.

2) Kulondola kwa broaching makamaka kumadalira kulondola kwa broach. M'mikhalidwe yabwinobwino, kulondola kwa broaching kumatha kufika IT9 ~ IT7, ndipo roughness ya Ra imatha kufika 6.3 ~ 1.6 μm.

3) Pokoka dzenje, chogwiriracho chimayikidwa ndi dzenje lopangidwa ndi makina okha (gawo lotsogolera la broach ndi gawo loyikapo la workpiece), ndipo sikophweka kuonetsetsa kuti dzenjelo ndi malo ena; Pokonza ziwalo za thupi, mabowo nthawi zambiri amakoka poyamba, ndiyeno malo ena amapangidwa pogwiritsa ntchito mabowowo ngati malo.

4) Broach sungangopanga mabowo ozungulira, komanso kupanga mabowo ndi mabowo a spline.

5) Broach ndi chida chokhazikika chokhala ndi mawonekedwe ovuta komanso mtengo wapamwamba, womwe suli woyenera kukonza mabowo akuluakulu.

Mabowo obowola amagwiritsidwa ntchito popanga zambiri popanga mabowo ang'onoang'ono ndi apakatikati okhala ndi mainchesi a Ф10 ~ 80mm ndi kuya kwa dzenje osapitilira 5 kuwirikiza kwake.

Nthawi yotumiza: Sep-26-2022