Chida Chotembenuza

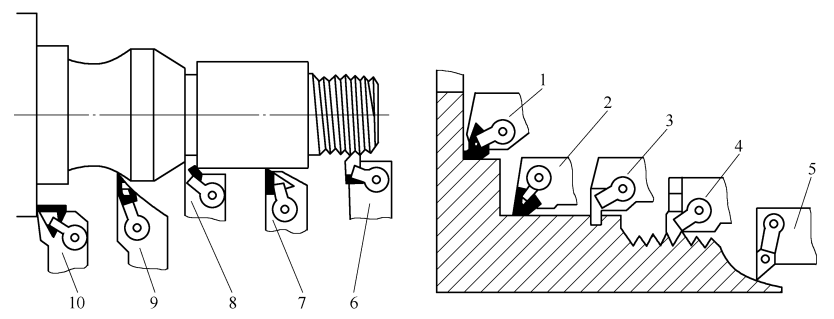

Chida chofala kwambiri pakudula zitsulo ndi chida chotembenuza. Zida zotembenuza zimagwiritsidwa ntchito podula mabwalo akunja, mabowo pakati, ulusi, grooves, mano, ndi maonekedwe ena pa lathes. Mitundu yake yayikulu ikuwonetsedwa mu Chithunzi 3-18.

Chithunzi 3-18 Mitundu yayikulu ya zida zotembenuza

1. 10—Chida chotembenuza malekezero 2. 7—Chida chotembenuza bowo lakunja 3. 8—Chida chotembenuza 4. 6—Chida chotembenuza ulusi 5. 9—Chida chotembenuza mbiri

Zida zotembenuza zimagawidwa kutengera kapangidwe kawo kukhala kutembenuka kolimba, kuwotcherera, kutembenuza makina, ndi zida zolozera. Zida zosinthira zosinthika zikukhala zodziwika kwambiri chifukwa cha kuchuluka kwakugwiritsa ntchito. Chigawochi chimayang'ana kwambiri pakuyambitsa mfundo zamapangidwe ndi njira zosinthira zida zosinthira ndi kuwotcherera.

1. Chida chowotcherera

Chida chowotcherera chowotcherera chimapangidwa ndi tsamba la mawonekedwe apadera komanso chogwirizira cholumikizidwa ndi kuwotcherera. Masamba nthawi zambiri amapangidwa kuchokera kumagulu osiyanasiyana azinthu za carbide. Zibowo za zida nthawi zambiri zimakhala zitsulo 45 ndipo zimanoleredwa kuti zigwirizane ndi zofunikira pakagwiritsidwe ntchito. Ubwino wa zida kuwotcherera kutembenukira ndi ntchito zimadalira tsamba kalasi, chitsanzo tsamba, chida magawo geometric ndi mawonekedwe ndi kukula kagawo. Akupera khalidwe, etc. Akupera khalidwe, etc.

(1) Pali ubwino ndi kuipa kwa zida zowotcherera

Amagwiritsidwa ntchito kwambiri chifukwa cha mawonekedwe ake osavuta, osakanikirana; mkulu chida kuuma; ndi kukana kwabwino kwa vibration. Ilinso ndi zovuta zambiri, kuphatikiza:

(1) Kudula kwa tsamba ndikovuta. Kudula kwa tsamba kudzachepetsedwa pambuyo powotchedwa pa kutentha kwakukulu. Kutentha kwakukulu komwe kumagwiritsidwa ntchito powotcherera ndikunola kumapangitsa kuti tsambalo likhale lopanikizika mkati. Popeza kuti mzere wowonjezera wowonjezera wa carbide ndi theka la thupi la chida, izi zingayambitse ming'alu kuwonekera mu carbide.

(2) Chogwiritsira ntchito sichigwiritsidwanso ntchito. Zopangira zidawonongeka chifukwa chogwirizira sichingagwiritsidwenso ntchito.

(3) Nthawi yothandizira ndi yayitali kwambiri. Kusintha kwa chida ndi kukhazikitsa kumatenga nthawi yambiri. Izi sizigwirizana ndi zofuna za makina a CNC, makina opangira makina, kapena zida zamakina.

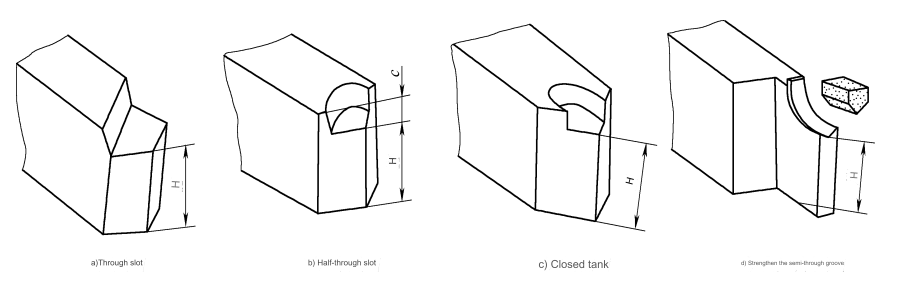

(2) Mtundu wa poyambira zida

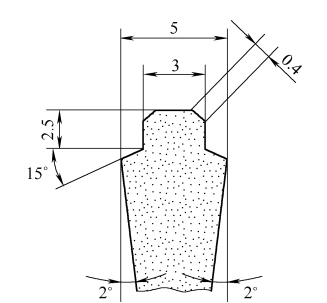

Pazida zotembenuza zowotcherera, zida za shank grooves ziyenera kupangidwa molingana ndi mawonekedwe ndi kukula kwa tsamba. Chida cha shank grooves chimaphatikizapo kupyola mu grooves, semi-through grooves, grooves yotsekedwa, ndi kulimbitsa ma semi-through grooves. Monga momwe chithunzi 3-19 chikusonyezera.

Chithunzi 3-19 Tool holder geometry

Chida chogwirizira groove chiyenera kukwaniritsa zofunikira izi kuti zitsimikizire kuwotcherera kwabwino:

(1) Sungani makulidwe. (1) Kuwongolera makulidwe a thupi locheka.

(2) Sinthani kusiyana pakati pa tsamba ndi poyambira zida. Kusiyana pakati pa tsamba ndi potengera zida sikuyenera kukhala kwakukulu kapena kocheperako, nthawi zambiri 0.050.15mm. Mgwirizano wa arc uyenera kukhala wofanana momwe ungathere ndipo kusiyana kwakukulu kwapafupi sikuyenera kupitirira 0.3mm. Apo ayi, mphamvu ya weld idzakhudzidwa.

(3) Lamulirani kuchuluka kwa roughness pamwamba pa potengera zida. Mphepete mwa zida zili ndi roughness pamwamba pa Ra = 6.3mm. Pamwamba pa tsamba ayenera kukhala lathyathyathya ndi yosalala. Musanayambe kuwotcherera, poyambira wa chogwiritsira ntchito ayenera kutsukidwa ngati pali mafuta. Kuti pamwamba pa malo owotcherera akhale oyera, mutha kugwiritsa ntchito sandblasting kapena mowa kapena petulo kuti mutsuke.

Sinthani kutalika kwa tsamba. Munthawi yabwinobwino, tsamba lomwe limayikidwa polowera zida liyenera kutuluka ndi 0.20.3mm kuti liwongolere. Chogwirizira chida chikhoza kupangidwa motalika ndi 0.20.3mm kuposa tsamba. Pambuyo kuwotcherera, chida thupi ndiye welded. Kuti muwoneke bwino, chotsani chilichonse chowonjezera.

(3) Njira yowotcha masamba

Solder yolimba imagwiritsidwa ntchito kuwotcherera masamba a simenti a carbide (solder yolimba ndi yokanira kapena yowotcha yomwe imakhala ndi kutentha kwapamwamba kuposa 450degC). Solder imatenthedwa mpaka kusungunuka, yomwe nthawi zambiri imakhala 3050degC pamwamba pa malo osungunuka. The flux amateteza solder ku malowedwe ndi kufalikira padzikozigawo zamakina. Imathandizanso kuyanjana kwa solder ndi gawo lopangidwa ndi welded. Kusungunuka kumapangitsa tsamba la carbide kuti lilowerere mwamphamvu mu slot.

Pali njira zambiri zowotchera moto zopangira moto, monga kuwotcherera moto kwa gasi komanso kuwotcherera pafupipafupi. Kuwotcherera magetsi ndi njira yabwino kwambiri yowotchera. Kukaniza pa malo ogwirizana pakati pa chipika chamkuwa, ndi mutu wodula ndi wapamwamba kwambiri, ndipo apa ndi pamene kutentha kwakukulu kudzapangidwira. Thupi lodula limayamba kukhala lofiira ndiyeno kutentha kumasamutsidwa kutsamba. Izi zimapangitsa kuti tsambalo litenthe pang'onopang'ono ndikukwera pang'onopang'ono kutentha. Kupewa ming'alu ndikofunikira.

Tsambalo silina "kuwotchedwa" chifukwa mphamvu imatsekedwa pamene zinthuzo zimasungunuka. Kuwotcherera magetsi kwatsimikiziridwa kuti kumachepetsa ming'alu ya masamba ndi kuwononga. Brazing ndi yosavuta komanso yokhazikika, yokhala ndi khalidwe labwino. Njira yopangira brazing ndiyosavuta kuposa ma welds othamanga kwambiri, ndipo ndizovuta kuyika zida zokhala ndi m'mphepete zingapo.

Ubwino wa brazing umakhudzidwa ndi zinthu zambiri. Zida zowotchera, kutulutsa ndi njira yotenthetsera ziyenera kusankhidwa bwino. Kwa chida cha carbide brazing, zinthuzo ziyenera kukhala ndi malo osungunuka kuposa kutentha kwa kudula. Ndizinthu zabwino zodulira chifukwa zimatha kusunga mphamvu yolumikizana ndi tsamba ndikusunga madzi ake, kunyowa komanso kuwongolera kwamafuta. Zida zotsatirazi zimagwiritsidwa ntchito kwambiri pomanga masamba a simenti-carbide:

(1) Kutentha kosungunuka kwa aloyi amkuwa kapena mkuwa-nickel (electrolytic) ndi pafupifupi 10001200degC. Kutentha kololedwa kugwira ntchito ndi 700900degC. Izi zitha kugwiritsidwa ntchito ndi zida zomwe zimakhala ndi ntchito zolemetsa.

(2) Copper-zinc kapena 105# filler zitsulo ndi kutentha kusungunuka pakati pa 900920degC & 500600degC. Zoyenera kugwiritsa ntchito zida zapakatikati.

Malo osungunuka a alloy siliva-mkuwa ndi 670820. Kutentha kwake kwakukulu kogwira ntchito ndi madigiri 400. Komabe, ndiyoyenera kuwotcherera mwatsatanetsatane zida zosinthira ndi cobalt otsika kapena titanium carbide yayikulu.

Ubwino wa brazing umakhudzidwa kwambiri ndi kusankha ndi kugwiritsa ntchito flux. The flux ntchito kuchotsa oxides pamwamba pa workpiece kuti brazed, kuonjezera wettability ndi kuteteza weld ku okosijeni. Ma fluxes awiri amagwiritsidwa ntchito kupaka zida za carbide: Borax Na2B4O2 yopanda madzi kapena Borax 25% (massfraction) + boric Acid 75% (massfraction). Kutentha kwa Brazing kumachokera ku 800 mpaka 1000degC. Borax imatha kutaya madzi m'thupi mwa kusungunula borax, kenako ndikuiphwanya itatha kuzirala. Sefa. Mukawotcha zida za YG, borax yamadzimadzi nthawi zambiri imakhala yabwinoko. Mungathe kukwaniritsa zotsatira zokhutiritsa pamene brazing zida YT ntchito chilinganizo dehydrated borax (massfraction) 50% + boric (massfraction) 35% + dehydrated potaziyamu (massfraction) fluoride (15%).

Kuphatikiza kwa potaziyamu fluoride kumathandizira kunyowa komanso kusungunuka kwa titaniyamu carbide. Pofuna kuchepetsa kupsinjika kwa kuwotcherera pakuwotcherera ma aloyi apamwamba a titaniyamu (YT30 ndi YN05), kutentha kochepa pakati pa 0.1 ndi 0.5mm nthawi zambiri amagwiritsidwa ntchito. Monga gasket yamalipiro pakati pa masamba ndi zida zogwiritsira ntchito, chitsulo cha carbon kapena iron-nickel chimagwiritsidwa ntchito nthawi zambiri. Kuti muchepetse kupsinjika kwa kutentha, tsambalo liyenera kutetezedwa. Nthawi zambiri chida chotembenuza chimayikidwa mu ng'anjo yotentha ya 280 ° C. Sungani kwa maola atatu pa 320degC, ndiyeno muziziziritsa pang'onopang'ono mu ng'anjo, kapena mu asbestosi kapena ufa wa phulusa.

(4) Kulumikizana kwachilengedwe

Kulumikizana kwachilengedwe kumagwiritsa ntchito njira ya phosphoric ndi ufa wamkuwa wa inorganic, womwe umaphatikiza chemistry, zimango, ndi fizikiki kuti zigwirizane ndi masamba. Kulumikizana kwachilengedwe ndikosavuta kugwiritsa ntchito kuposa kuwotcha ndipo sikumayambitsa kupsinjika kwamkati kapena ming'alu ya tsamba. Njirayi ndiyothandiza makamaka pazida zamasamba zomwe zimakhala zovuta kuwotcherera, monga zoumba.

Zochita zamakhalidwe ndi zochitika zenizeni za Machining

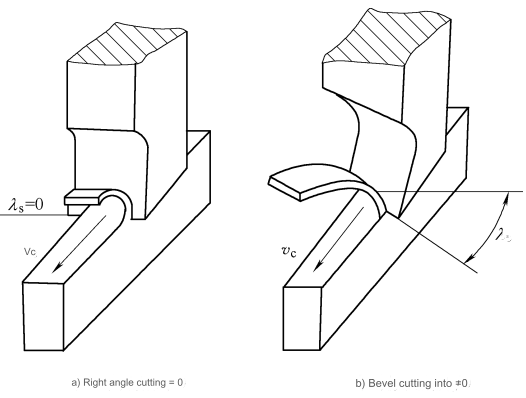

4. Kusankha ngodya ya m'mphepete mwake ndi kudula bevel

(1) Kudula kwa bevel ndi lingaliro lomwe lakhalapo kwa nthawi yayitali.

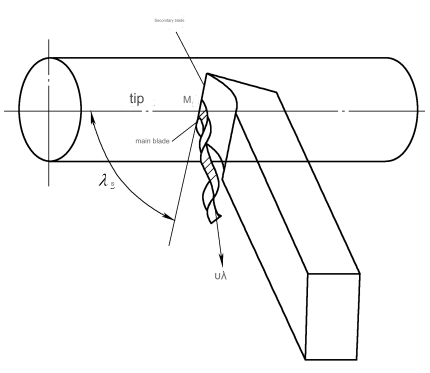

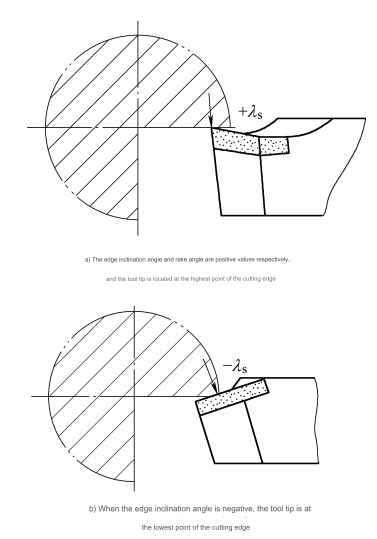

Kudula-kumanja ndiko kudula komwe tsamba lodulira la chidacho limafanana ndi momwe kudulako kungatengere. Bevel kudula ndi pamene kudula m'mphepete mwa chida si perpendicular ndi malangizo a kudula zoyenda. Monga zosavuta, zotsatira za chakudya zimatha kunyalanyazidwa. Kudula komwe kuli perpendicular ndi liwiro lalikulu loyenda kapena m'mphepete mwa ngodya lss = 0 kumawonedwa ngati kudula koyenera. Izi zikuwonetsedwa mu Chithunzi 3-9. Kudula komwe sikuli perpendicular ndi liwiro lalikulu loyenda kapena m'mphepete mwa ngodya lss0, kumatchedwa oblique angle-cutting. Mwachitsanzo, Monga momwe tawonetsera pa Chithunzi 3-9.b, pamene mbali imodzi yokha ndiyo kudula, izi zimadziwika kuti kudula kwaulere. Kudula kwa bevel ndikofala kwambiri pakudula zitsulo.

Chithunzi 3-9 Kudula ngodya yakumanja ndi kudula kwa bevel

(2) Chikoka cha bevel kudula pa ndondomeko kudula

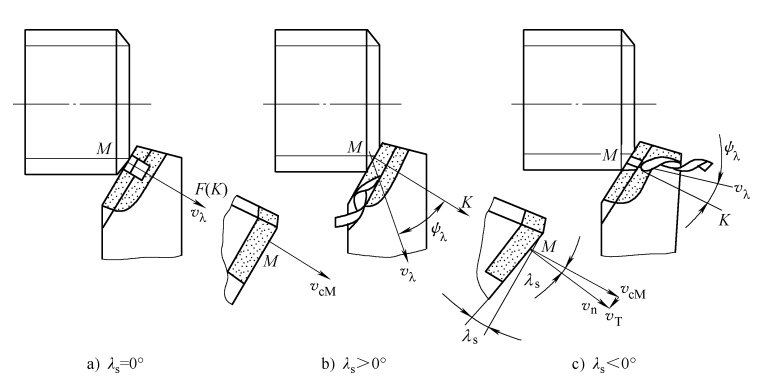

1. Yang'anani mbali ya chip outflow

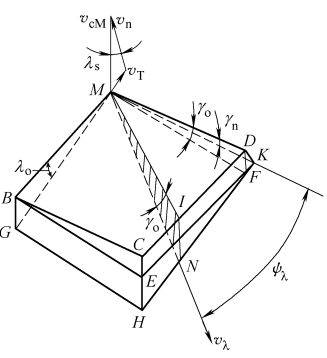

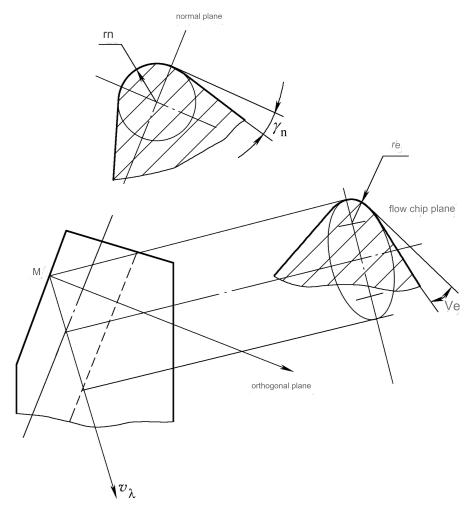

Chithunzi 3-10 chikuwonetsa kuti chida chotembenuza chakunja chimagwiritsidwa ntchito kutembenuza chitoliro choyenera. Pamene kokha waukulu kudula m'mphepete nawo mu kudula, tinthu M mu kudula wosanjikiza (poganiza kuti ndi msinkhu wofanana pakati pa gawo) amakhala Chip pansi extrusion kutsogolo kwa chida ndi ukuyenda kunja pamodzi kutsogolo. Ubale pakati pa mayendedwe a chip ndi mbali yolowera m'mphepete ndikulumikizana ndi gulu la MBCDFHGM ndi ndege ya orthogonal ndi ndege yodula ndi ndege ziwiri zofananira nawo kudzera pa point M.

Chithunzi 3-10 Zotsatira za λs pamayendedwe a flow chip

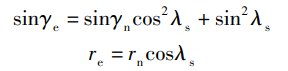

MBCD ndiye ndege yoyambira pa Chithunzi 3-11. Pamene ls = 0, MBEF ndi kutsogolo mu Chithunzi 3-11, ndi ndege MDF ndi orthogonal ndi ndege yachibadwa. Point M tsopano ndi perpendicular yodula. Pamene tchipisi tatulutsidwa, M ndi gawo la liwiro motsatira mbali yodula. The MF ndi perpendicularly kufanana ndi kudula m'mphepete. Monga momwe tawonetsera pa Chithunzi 3-10a, panthawiyi, ma Chips amapindika mu mawonekedwe a masika kapena amayenda molunjika. Ngati ls ali ndi mtengo wabwino ndiye kuti ndege ya MGEF ili kutsogolo ndipo kayendetsedwe kake kakudula liwiro la vcM sikufanana ndi MG yodula. The particle M liwirocnc kutembenuza zigawovT wachibale ndi chida molunjika kwa kudula m'mphepete mfundo ku MG. Mfundo M ikasinthidwa kukhala chip chomwe chimatuluka kutsogolo ndikukhudzidwa ndi vT liwiro la chip vl lidzachoka pa ndege yanthawi zonse ya MDK pa ngodya ya psl. ls ikakhala ndi mtengo waukulu, tchipisi timayenda molowera komwe kumapangidwira pamwamba.

Ndege MIN, monga momwe ikuwonetsedwera mu Zithunzi 3-10b ndi 3-11, imadziwika kuti chip flow. Pamene ls ili ndi mtengo woipa gawo la velocity vT kumbali ya m'mphepete mwake limatembenuzidwa, kuloza ku GM. Izi zimapangitsa kuti tchipisi tisiyane ndi ndege yanthawi zonse. Kuthamanga kuli kosiyana ndi pamwamba pa makina. Monga momwe tawonetsera pa Chithunzi 3-10.c. Kukambitsiranaku kumangokhudza zotsatira za ls panthawi yodula kwaulere. Mayendedwe a pulasitiki achitsulo pansonga ya chida, m'mphepete mwaling'ono, ndi chip groove zonse zidzakhudza momwe tchipisi zimatulutsira panthawi ya makina enieni otembenuza mabwalo akunja. Chithunzi 3-12 chikuwonetsa kugogoda kwa mabowo ndi mabowo otsekedwa. Chikoka cha kupendekera kwa m'mphepete pakuyenda kwa chip. Mukagogoda ulusi wopanda bowo, mtengo ls ndi wabwino, koma pogogoda imodzi ndi dzenje, imakhala yotsika mtengo.

Chithunzi 3-11 Oblique kudula Chip otaya njira

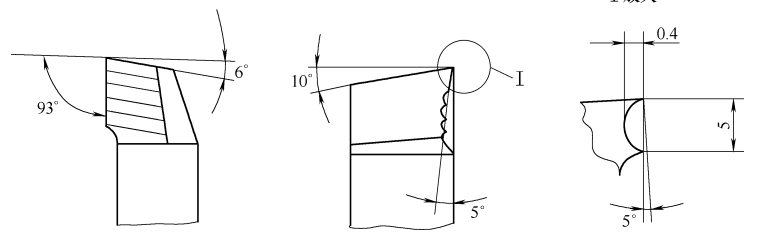

2. Chotengera chenichenicho ndi obtuse radii zimakhudzidwa

Pamene ls = 0, mu kudula kwaulere, ma angles ozungulira mu orthogonal ndege ndi chip flow plane ndi pafupifupi ofanana. Ngati ls si zero, zitha kukhudza kwambiri kuthwa kwa m'mphepete komanso kukana kukangana pomwe tchipisi tatulutsidwa. M'ndege yoyendera ma chip, ma angles ge ndi odula kwambiri obtuse radii re ayenera kuyeza. Chithunzi 3-13 ikufanizira geometry ya ndege yachibadwa yomwe imadutsa pa M-point ya m'mphepete mwake ndi obtuse radii re ya chip flow plane. Pamalo akuthwa, ndege yabwinobwino imawonetsa arc yopangidwa ndi obtuse radius rn. Komabe, mu mbiri ya chip flow, kudula ndi gawo la ellipse. Utali wopindika m'mbali mwa axis yayitali ndiye mbali yeniyeni ya obtuse radius re. Zotsatira zotsatirazi zitha kuwerengedwa kuchokera ku ziwerengero za ubale wa geometric mu Zithunzi 3-11 ndi 3-13.

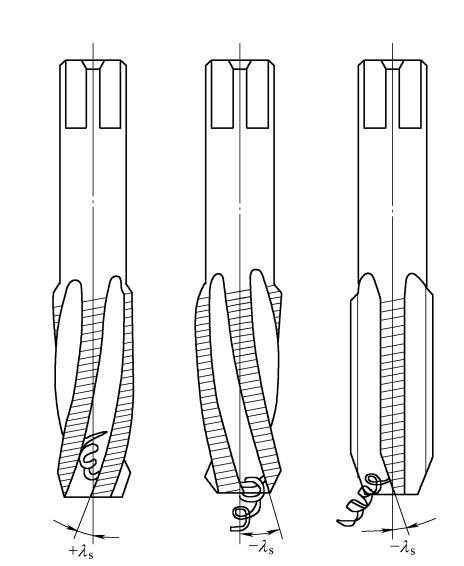

Njira yomwe ili pamwambapa ikuwonetsa kuti kuwonjezereka kumawonjezeka pamene mtengo wathunthu ls ukuwonjezeka, pamene ge amachepetsa. Ngati ls=75deg, ndi gn=10deg ndi rn=0.020.15mm ndiye ge akhoza kukhala wamkulu ngati 70deg. re akhozanso kukhala ochepa ngati 0.0039mm. Izi zimapangitsa m'mphepete mwake kukhala wakuthwa kwambiri, ndipo zimatha kukwaniritsa kudula pang'ono (ap0.01mm) pogwiritsa ntchito kudula pang'ono kumbuyo. Chithunzi 3-14 chikuwonetsa malo odulira chida chakunja pomwe ls imayikidwa pa 75deg. Mphepete zazikulu ndi zachiwiri za chida zakhala zikugwirizana molunjika. Mphepete mwa chidacho ndi yakuthwa kwambiri. Mphepete mwa kudula sikukhazikika panthawi yodula. Komanso ndi tangent ndi kunja cylindrical pamwamba. Kuyika ndi kusintha ndizosavuta. Chidacho chagwiritsidwa ntchito bwino pomaliza kutembenuza mwachangu kwachitsulo cha carbon. Itha kugwiritsidwanso ntchito kumaliza kukonza zinthu zovuta ku makina monga chitsulo cholimba kwambiri.

Chithunzi 3-12 Mphamvu ya ngodya ya m'mphepete pamayendedwe a chip panthawi yogogoda ulusi

Chithunzi 3-13 Kuyerekeza kwa rn ndi re geometries

3. Impact kukana ndi mphamvu ya chida nsonga amakhudzidwa

Pamene ls ili yoipa, monga momwe tawonetsera pa Chithunzi 3-15b, nsonga ya chida idzakhala malo otsika kwambiri pamphepete. Pamene kudula m'mphepete kudula muzigawo za prototypeMfundo yoyamba yokhudzidwa ndi workpiece ndi chida (pamene kupita kuli ndi phindu labwino) kapena kutsogolo (pamene kuli koipa) Izi sizimangoteteza ndi kulimbitsa nsonga, komanso zimathandiza kuchepetsa chiopsezo cha kuwonongeka. Zida zambiri zokhala ndi ngodya yayikulu zimagwiritsa ntchito kupendekera koyipa. Iwo akhoza kuonjezera mphamvu ndi kuchepetsa zotsatira pa chida nsonga. Mphamvu yakumbuyo Fp ikuwonjezeka panthawiyi.

Chithunzi 3-14 Chida chachikulu chotembenuza mabala opanda nsonga yokhazikika

4. Zimakhudza kukhazikika kwa kudula mkati ndi kunja.

Pamene ls = 0, m'mphepete mwake mumadula ndikutuluka mu workpiece pafupifupi nthawi imodzi, mphamvu yodula imasintha mwadzidzidzi, ndipo zotsatira zake zimakhala zazikulu; pamene ls si zero, m'mphepete mwake pang'onopang'ono amadula ndikutuluka kuchokera ku workpiece, zotsatira zake zimakhala zochepa, ndipo kudula kumakhala kosavuta. Mwachitsanzo, zodula zazikulu za helix angle cylindrical mphero ndi mphero zili ndi m'mphepete mwake ndikudula bwino kuposa odula akale. Kupanga kwachangu kumachulukitsidwa ndi 2 mpaka 4, ndipo kuchuluka kwamphamvu kwa Ra kumatha kufika zosakwana 3.2 mm.

5. Kudula m'mphepete mawonekedwe

Mawonekedwe ang'onoang'ono a chida ndi chimodzi mwazofunikira za magawo oyenera a geometric a chida. Kusintha kwa mawonekedwe a tsamba la chida kumasintha mawonekedwe odulira. Chomwe chimatchedwa chodula chimatanthawuza dongosolo ndi mawonekedwe omwe chitsulo chosanjikiza chimayenera kukonzedwa chimachotsedwa ndi kudula. Zimakhudza kukula kwa katundu wodula kwambiri, kupsinjika maganizo, moyo wa chida ndi khalidwe lapamwamba la makina. dikirani. Zida zambiri zapamwamba zimagwirizana kwambiri ndi kusankha koyenera kwa mawonekedwe a masamba. Pakati pa zida zamakono zamakono, mawonekedwe a tsamba akhoza kufotokozedwa mwachidule m'magulu awa:

(1) Limbikitsani mawonekedwe a tsamba la m'mphepete mwake. Tsambali mawonekedwe makamaka kulimbitsa mphamvu ya kudula m'mphepete, kuonjezera kudula m'mphepete ngodya, kuchepetsa katundu pa unit kutalika m'mphepete m'mphepete, ndi kusintha kutentha disipation mikhalidwe. Kuphatikiza pa zida zingapo zomwe zikuwonetsedwa mu Chithunzi 3-8, palinso mawonekedwe a arc m'mphepete (zida zotembenuza m'mphepete mwa arc, zodulira m'mphepete mwa arc, zobowola m'mphepete, ndi zina), mawonekedwe akuthwa angapo (zobowola. , etc.) )dikirani;

(2) Maonekedwe a m'mphepete omwe amachepetsa malo otsalira. Mawonekedwe am'mphepete awa amagwiritsidwa ntchito kwambiri pomaliza zida, monga zida zosinthira zakudya zazikulu komanso zodulira kumaso ndi ma wiper, zida zoyandama zosasangalatsa komanso zida wamba zotopetsa zokhala ndi ma cylindrical wipers. Reamers, etc.;

Chithunzi 3-15 Zotsatira za ngodya ya m'mphepete mwazomwe zimakhudzidwa podula chida

(3) Mawonekedwe a tsamba omwe amagawa bwino malire odulira ndikutulutsa bwino tchipisi. Makhalidwe a mtundu uwu wa mawonekedwe a tsamba ndikuti amagawaniza gawo lalikulu komanso lochepa thupi kukhala tchipisi tating'onoting'ono, zomwe sizimangolola kuti tchipisi tituluke bwino, komanso kumawonjezera kuchuluka kwamtsogolo. Perekani kuchuluka kwake ndikuchepetsa mphamvu yodulira unit. Mwachitsanzo, poyerekeza ndi mipeni wamba yowongoka yowongoka, mipeni yodulira mizere iwiri imagawaniza mbali zazikuluzikulu m'magawo atatu, monga momwe tawonetsera pa Chithunzi 3-16. Ma chips nawonso amagawidwa m'mizere itatu molingana. Kukangana pakati pa tchipisi ndi makoma awiriwa kumachepetsedwa, zomwe zimalepheretsa tchipisi kuti zisatseke ndipo zimachepetsa kwambiri mphamvu yodula. Pamene kuya kwa kudula kumawonjezeka, kutsika kumawonjezeka, ndipo zotsatira zake zimakhala bwino. Panthawi imodzimodziyo, kutentha kwa kudula kumachepetsedwa ndipo moyo wa chida umapangidwa bwino. Pali zida zambiri zamtundu wamtundu uwu, monga odulira masitepe, odulira mphero, macheka oyenda m'mphepete, ma chip kubowola, odulira chimanga, ndi mphero zam'mphepete. Ndi magudumu odulidwa-mabowo, etc.;

Chithunzi 3-16 Mpeni wodulira m'mphepete kawiri

(4) Maonekedwe ena apadera. Special tsamba akalumikidzidwa ndi masamba akalumikidzidwa kuti agwirizane ndi zinthu processing wa gawo ndi makhalidwe ake kudula. Chithunzi 3-17 chikuwonetsa mawonekedwe a bolodi lakutsogolo lomwe limagwiritsidwa ntchito pokonza mkuwa wotsogolera. Mphepete mwachidule cha tsamba ili ndi mawonekedwe angapo amitundu itatu. Mfundo iliyonse yomwe ili m'mphepete mwake imakhala ndi ngodya yomwe imakwera kuchoka ku zoipa, kupita ku ziro kenako kupita ku positive. Izi zimapangitsa kuti zinyalala zizifinyidwa kukhala tchipisi tooneka ngati riboni.

Anebon alyways amachirikiza filosofi ya "Khalani No.1 mu khalidwe lapamwamba, lokhazikika pa ngongole ndi kukhulupirika kwa kukula". Anebon ipitilizabe kupereka zoyembekezeka zam'mbuyomu komanso zatsopano kuchokera kunyumba ndi kutsidya kwanyanja kwathunthu kwa Ordinary Discount 5 Axis Precision Custom Rapid Prototype.5 olamulira cnc mpheroKutembenuza Machining, Ku Anebon ndi khalidwe lapamwamba kwambiri kuti tiyambe monga mwambi wathu, timapanga zinthu zomwe zimapangidwa ku Japan, kuchokera kuzinthu zogula zinthu mpaka kukonza. Izi zimathandiza makasitomala ochokera m'dziko lonselo kuti azolowere ndi mtendere wamaganizo.

Njira zopangira China, ntchito zogaya zitsulo ndi ntchito yoyeserera mwachangu. Anebon amawona "mitengo yabwino, nthawi yabwino yopanga komanso ntchito yabwino yogulitsa pambuyo pogulitsa" monga mfundo zathu. Anebon akuyembekeza kugwirizana ndi makasitomala ambiri kuti atukule pamodzi ndi kupindula. Tikulandira ogula kuti alankhule nafe.

Nthawi yotumiza: Dec-14-2023