Kodi mukudziwa kuti ndi magawo ati omwe amafunikira kulondola kwambiri pamagawo amakina?

Zamlengalenga:

Zigawo zamakampani apamlengalenga monga ma turbine turbine kapena zida za ndege ziyenera kupangidwa mwaluso kwambiri, komanso mosagwirizana. Izi zimachitidwa kuti zitsimikizire kugwira ntchito ndi chitetezo. Mwachitsanzo, tsamba la injini ya jet, mwachitsanzo, lingafunike kulondola mkati mwa ma microns kuti likhalebe ndi mphamvu zokwanira komanso kuyenda kwa mpweya.

Zida zamankhwala:

Kuonetsetsa kuti chitetezo ndi kugwirizana, mbali zonse zomwe zimapangidwira zipangizo zachipatala monga zida za opaleshoni kapena zoikidwa ziyenera kukhala zolondola. Mwachitsanzo, kuyika kwa mafupa am'mafupa, mwachitsanzo, kungafunike miyeso yolondola ndi kumaliza pamwamba kuti zitsimikizire kukwanira bwino ndi kuphatikizana m'thupi.

Zagalimoto:

M'makampani amagalimoto, kulondola kumafunika pazigawo monga zotumizira ndi zida za injini. Chida cholumikizira chopangidwa ndi makina olondola kapena chojambulira mafuta chingafunike kulolerana molimba kuti zitsimikizire kuti zimagwira ntchito bwino komanso kulimba.

Zamagetsi:

Zida zamakina mumakampani opanga zamagetsi zimafunikira kuti zikhale zolondola kwambiri pazofunikira zinazake. Nyumba ya microprocessor yokonzedwa bwino ingafunike kulolerana kolimba kuti igwirizane bwino ndi kugawa kutentha.

Mphamvu zongowonjezedwanso:

Kuti muwonjezere kupanga mphamvu, ndikuwonetsetsa kudalirika, zida zamakina zamakina ongowonjezedwanso monga zokwera solar panel kapena zida za turbine zamphepo zimafunikira kulondola. Makina opangidwa bwino ndi makina amphepo atha kufuna mbiri yeniyeni ndikuyanjanitsa kuti apititse patsogolo mphamvu zamagetsi.

Nanga bwanji madera omwe kulondola kwa zida zomangika sikuli kofunikira kwenikweni?

Zomanga:

Zigawo zina, monga zomangira ndi zomangira, zomwe zimagwiritsidwa ntchito pomanga, sizingafune kulondola kofanana ndi zida zamakina ofunikira kapena zida zamlengalenga. Maburaketi achitsulo m'mapulojekiti omanga sangafune kulekerera kofanana ndi magawo olondola pamakina olondola.

Kupanga Mipando:

Zina mwazinthu zopangira mipando, monga zokongoletsera zokongoletsera, mabulaketi kapena ma hardware, siziyenera kukhala zolondola kwambiri. Ziwalo zina, monga zida zomangika mwatsatanetsatane pamakina osinthika amipando zomwe zimafuna kulondola, zimakhala ndi zololera zokhululuka.

Zida zogwiritsira ntchito ulimi:

Zigawo zina zamakina aulimi monga mabulaketi, zothandizira kapena zotchingira zoteteza sizingafunikire kugwiridwa ndi kulolerana kolimba kwambiri. Buraketi yomwe imagwiritsidwa ntchito kuyika zida zosalondola sizingafune kulondola mofanana ndi zida zamakina olondola.

Kulondola kwa kukonza ndi kuchuluka kwa kugwirizana kwa kukula kwa pamwamba, mawonekedwe ndi malo ku magawo a geometrical omwe afotokozedwa pachithunzichi.

Kukula kwapakati ndi geometric parameter yoyenera kukula.

Surface geometry ndi bwalo, silinda kapena ndege. ;

N'zotheka kukhala ndi malo omwe ali ofanana, perpendicular kapena coaxial. Kulakwitsa kwa Machining ndikusiyana pakati pa magawo a geometric a gawo ndi magawo awo abwino a geometric.

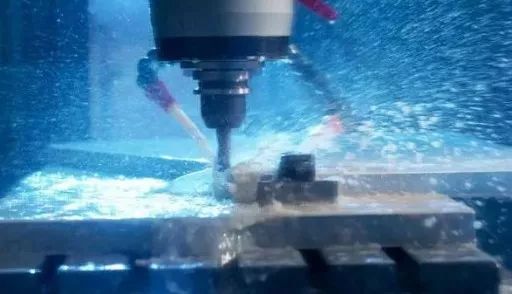

1. Mawu Oyamba

Cholinga chachikulu cha makina olondola ndi kupanga zinthu. Kulondola kwa makina ndi zolakwika zamakina ndi mawu omwe amagwiritsidwa ntchito poyesa magawo a geometric pamtunda wopangidwa ndi makina. Kulekerera kalasi kumagwiritsidwa ntchito kuyeza kulondola kwa makina. Kukwera kulondola, giredi laling'ono. Kulakwitsa kwa makina kungasonyezedwe ngati chiwerengero cha chiwerengero. Kuchuluka kwa manambala kumapangitsanso cholakwika chachikulu. Mosiyana ndi izi, kulondola kwapamwamba kwambiri kumalumikizidwa ndi zolakwika zazing'ono. Pali magawo 20 a kulolerana, kuyambira IT01 mpaka IT18. IT01 ndiye mulingo wa makina olondola kwambiri, IT18 yotsika kwambiri, ndipo IT7 ndi IT8 nthawi zambiri amakhala milingo yolondola kwambiri. mlingo.

Sizingatheke kupeza magawo enieni pogwiritsa ntchito njira iliyonse. Malingana ngati cholakwika chokonzekera chikugwera mkati mwa kulekerera komwe kumatchulidwa ndi gawo lojambula ndipo sikuli kwakukulu kuposa ntchito ya chigawocho, kulondola kwadongosolo kungaganizidwe kukhala kotsimikizika.

2. Zogwirizana nazo

Kulondola kwa dimensional:

Malo olekerera ndi malo omwe kukula kwa gawo lenileni ndi pakati pa malo olekerera ndi ofanana.

Kulondola kwa mawonekedwe:

Mulingo womwe mawonekedwe a geometric pamtunda wa gawo lopangidwa ndi makina amafanana ndi mawonekedwe abwino a geometric.

Kulondola kwamalo:

Kusiyana kwa malo olondola pakati pa malo a magawo omwe akukonzedwa.

Mgwirizano:

Popanga zigawo zamakina ndikuwonetsa kulondola kwa makina awo, ndikofunikira kuwongolera cholakwika cha mawonekedwe ndi kulolerana kwa malo. Cholakwika chamalo chiyeneranso kukhala chaching'ono kusiyana ndi kulekerera kwa dimension. Pazigawo zolondola komanso malo ofunikira, zofunikira pakuwongolera mawonekedwe ziyenera kukhala zapamwamba.

3. Kusintha Njira

1. Kusintha kwadongosolo kwadongosolo

Kusintha njira yodulira mayeso: Yesani kukula, sinthani kuchuluka kwa chida ndikudula. Bwerezani mpaka mufikire kukula komwe mukufuna. Njirayi imagwiritsidwa ntchito makamaka popanga magulu ang'onoang'ono komanso amodzi.

Methode d'ajustement: Kuti mupeze kukula komwe mukufuna, sinthani malo achibale a chida cha makina, kukonza ndi workpiece. Njirayi ndi yopindulitsa kwambiri ndipo imagwiritsidwa ntchito makamaka popanga zambiri.

2. Chepetsani zolakwika za zida zamakina

1) Sinthani kulondola kwa gawo la spindle

Kuwongolera kozungulira kozungulira kuyenera kuwongoleredwa.

1 Sankhani mayendedwe apamwamba kwambiri;

2 Gwiritsani ntchito mayendedwe othamanga okhala ndi mizere yolondola kwambiri yamafuta ambiri.

3 Kugwiritsa ntchito mayendedwe olondola kwambiri a hydrostatic

Ndikofunikira kuwongolera kulondola kwa zida zonyamula.

1 Sinthani kulondola kwa magazini ya spindle ndi mabowo othandizira mabokosi;

2 Sinthani kulondola kwapamwamba kofananira ndi kunyamula.

3 Yezerani ndikusintha ma radial a magawo kuti muthetse kapena kubweza zolakwikazo.

2) Kwezani ma berelo moyenera

1 Itha kuthetsa mipata;

2 Wonjezerani kuuma kwapakati

3 Vuto logudubuza lofanana.

3) Pewani kuwonetsera kulondola kwa spindle pa workpiece.

3. Zolakwa za unyolo: Chepetsani

1) The kufala kulondola ndi chiwerengero cha zigawo ndi mkulu.

2) Chiŵerengero chopatsirana ndi chocheperapo pamene kupatsirana kuli pafupi ndi mapeto.

3) Kulondola kwachidutswa chomaliza kuyenera kukhala kwakukulu kuposa magawo ena opatsirana.

4. Chepetsani Kuvala kwa Zida

Zida zopangiranso ndizofunikira zisanafike pagawo lakuvala kwambiri.

5. Kuchepetsa kupsinjika maganizo mu dongosolo ndondomeko

Zochokera ku:

1) Wonjezerani kuuma ndi mphamvu ya dongosolo. Izi zikuphatikizapo zofooka zofooka za dongosolo la ndondomeko.

2) Kuchepetsa katundu ndi kusiyana kwake

Wonjezerani kuuma kwadongosolo

1 Mapangidwe omveka bwino

1) Momwe mungathere, chepetsani kuchuluka kwa malo omwe amalumikizana.

2) Pewani maulalo am'deralo a kuuma kochepa;

3) Zigawo zoyambira ndi zothandizira ziyenera kukhala ndi dongosolo loyenera komanso gawo lopingasa.

2 Limbikitsani kuuma kolumikizana pamtunda wolumikizana

1) Sinthani mawonekedwe ndi kusasinthika kwa malo omwe amalumikizana ndi zida zamakina.

2) Kuyikanso zida za zida zamakina

3) Wonjezerani kulondola kwa malo ogwira ntchito ndikuchepetsa roughness pamwamba.

3 Kutengera njira zolumikizirana bwino komanso zokhazikika

Chepetsani katunduyo ndi zotsatira zake

1 Sankhani magawo a geometry a zida ndi kudula kuchuluka kuti muchepetse mphamvu yodula.

2 Zosokonekerazo ziyenera kuphatikizidwa pamodzi ndipo ndalama zolipirira ziyenera kukhala zofanana ndi kusintha.

6. Matenthedwe matenthedwe a dongosolo ndondomeko akhoza kuchepetsedwa

1 Patulani magwero otentha ndikuchepetsa kupanga kutentha

1) Gwiritsani ntchito ndalama zochepa;

2) Kulekanitsa roughing ndi kumaliza pamenemphero zigawozimafuna kulondola kwambiri.

3) Momwe mungathere, alekanitse gwero la kutentha ndi makina kuti muchepetse kutentha kwa kutentha.

4) Ngati magwero a kutentha sangathe kulekanitsidwa (monga ma spindle bearings kapena screw nut pairs), sinthani mikangano kuchokera kumapangidwe, mafuta ndi zina, kuchepetsa kupanga kutentha, kapena kugwiritsa ntchito zipangizo zotetezera kutentha.

5) Gwiritsani ntchito kuziziritsa mpweya mokakamiza kapena kuziziritsa madzi komanso njira zina zochotsera kutentha.

2 Munda wofanana wa kutentha

3 Landirani miyezo yoyenera yolumikizira zida za makina ndi kapangidwe kake

1) Kutengera mawonekedwe a thermally-symmetrical mu gearbox - ma symmetrically ma shafts, ma bere ndi magiya opatsirana amatha kuchepetsa kupunduka kwa bokosilo powonetsetsa kuti kutentha kwa khoma la bokosi ndikofanana.

2) Sankhani muyezo wa msonkhano wa zida zamakina mosamala.

4 Limbikitsani kusamutsa kutentha

5 Control yozungulira kutentha

7. Chepetsani kupsinjika kotsalira

1. Onjezani ndondomeko ya kutentha kuti muthetse nkhawa mkati mwa thupi;

2. Konzani ndondomeko yanu m'njira yoyenera.

4. Zifukwa za chikoka

1 Machining mfundo zolakwika

Mawu akuti "machining principle error" amatanthauza cholakwika chomwe chimachitika pamene makina apangidwa pogwiritsa ntchito njira yochepetsera, kapena mgwirizano wotumizira. Kukonzekera kwa malo ovuta, ulusi ndi magiya kungayambitse vuto la makina.

Kuti zikhale zosavuta kugwiritsa ntchito, m'malo mogwiritsa ntchito nyongolotsi yoyambira, mphutsi za Archimedean kapena zoyambira zowongoka zimagwiritsidwa ntchito. Izi zimayambitsa zolakwika mu mawonekedwe a dzino.

Posankha zida, mtengo wa p ukhoza kuyerekezedwa (p = 3.1415) chifukwa pali mano ochepa pa lathe. Chida chomwe chimagwiritsidwa ntchito popanga workpiece (spiral motion), sichikhala cholondola. Izi zimabweretsa kulakwitsa kwa mawu.

Kukonza kumachitika nthawi zambiri poganizira kuti zolakwika zamalingaliro zitha kuchepetsedwa kuti zikwaniritse zofunikira pakuwongolera (10% -15% kulolerana pamiyeso) kuti muwonjezere zokolola ndikuchepetsa ndalama.

2 cholakwika chosintha

Tikamanena kuti chida cha makina chili ndi kusintha kolakwika, tikutanthauza cholakwika.

3 Kulakwitsa kwa makina

Mawu akuti cholakwika chida cha makina amagwiritsidwa ntchito kutanthauza cholakwika chopanga, cholakwika choyika, ndi kutha kwa chida. Izi zikuphatikizapo makamaka zolakwika zowongolera ndi kuzungulira kwa njanji yowongolera zida zamakina komanso cholakwika chotumizira pamakina otumizira zida zamakina.

Cholakwika chowongolera makina

1. Ndiko kulondola kwa chiwongolero cha njanji ya kalozera - kusiyana pakati pa kayendetsedwe ka kayendetsedwe ka magawo osuntha ndi njira yabwino. Zimaphatikizapo:

Kalozerayo amayezedwa ndi kuwongoka kwa Dy (ndege yopingasa) ndi Dz (ndege yolunjika).

2 Kufanana kwa njanji zakutsogolo ndi zakumbuyo (kusokoneza);

(3) Zolakwika za verticality kapena parallelism pakati pa kuzungulira kwa spindle ndi njanji yowongolera mu ndege zopingasa komanso zowongoka.

2. Kulondola kowongolera njanji kumakhudza kwambiri kudula makina.

Izi zili choncho chifukwa zimaganizira kusamuka kwachibale pakati pa chida ndi workpiece chifukwa cha zolakwika za njanji. Kutembenuza ndi ntchito yokhota pomwe mbali yopingasa ili ndi vuto. Zolakwika zamayendedwe oima zitha kunyalanyazidwa. Njira yozungulira imasintha komwe chida chimakhudzidwa ndi cholakwika. Njira yoyima ndiyomwe imakhudzidwa kwambiri ndi zolakwika pokonza. Kuwongoka kwa maupangiri a bedi mu ndege yowongoka kumatsimikizira kulondola kwa flatness ndi kuwongoka kwa malo opangidwa ndi makina.

Kulakwitsa kwa makina ozungulira spindle

Cholakwika chozungulira cha spindle ndikusiyana pakati pa nsonga yeniyeni ndi yabwino yozungulira. Izi zimaphatikizapo nkhope ya spindle yozungulira, yozungulira yozungulira yozungulira komanso yopindika.

1, Chikoka cha spindle runout zozungulira pakuwongolera kulondola.

① Palibe chokhudza chithandizo chapamwamba cha cylindrical

② Zimayambitsa kulakwitsa kwapang'onopang'ono kapena kusalala pakati pa cylindrical axis ndi endface poitembenuza ndikuisokoneza.

③ Kulakwitsa kwa phula kumapangidwa pamene ulusi wapangidwa.

2. Mphamvu ya spindle radial imayendera kulondola kwake:

① Kulakwitsa kozungulira kwa bwalo la radial kumayesedwa ndi matalikidwe othamanga a dzenjelo.

② Utali wa bwalo ukhoza kuwerengedwa kuchokera kunsonga kwa chida kupita ku shaft wamba, mosasamala kanthu kuti shaft ikutembenuzidwa kapena kutopa.

3. Mphamvu ya ngodya yopendekeka ya nsonga yayikulu ya geometric pa kulondola kwa makina

① Mzere wa geometric umakonzedwa munjira yokhazikika yokhala ndi ngodya ya cone, yomwe imagwirizana ndi kayendedwe ka eccentric mozungulira ma axis a geometrical axis ikawonedwa kuchokera pagawo lililonse. Mtengo wa eccentric uwu umasiyana ndi mawonekedwe a axial.

② Axis ndi geometric yomwe imayenda mundege. Izi ndizofanana ndi olamulira enieni, koma zikuyenda mu ndege mumzere wowongoka wa harmonic.

③ Kunena zowona, mbali ya shaft yayikulu ya geometric axis imayimira kuphatikiza kwa mitundu iwiriyi ya kugwedezeka.

Kupatsira zolakwika za unyolo wotumizira zida zamakina

Cholakwika chopatsira ndi kusiyana kwa kayendedwe kake pakati pa chinthu choyamba chopatsira ndi chinthu chomaliza chotumizira.

④ Kupanga zolakwika ndikuvala pazitsulo

Cholakwika chachikulu pamisonkhanoyi ndi: 1) kulakwitsa kopanga kwa chinthu choyikirapo ndi zida zowongolera zida, komanso njira yolozera ndi konkriti yokhotakhota. 2) Pambuyo pa kusonkhana kwazitsulo, kukula kwachibale kulakwitsa pakati pa zigawo zosiyanasiyanazi. 3) Valani pamwamba pa workpiece chifukwa cha fixture. Zomwe zili mu Metal Processing Wechat ndizabwino kwambiri, ndipo ndizofunika kuziganizira.

⑤ kupanga zolakwika ndi kuvala zida

Mitundu yosiyanasiyana ya zida imakhala ndi mphamvu zosiyana pa kulondola kwa makina.

1) Kulondola kwa zida zokhala ndi miyeso yokhazikika (monga kubowola, zowongolera, zodula ma keyway mphero, ma broaches ozungulira, ndi zina). Kulondola kwa dimensional kumakhudzidwa mwachindunji ndi workpiece.

2) Kulondola kwa chida chopangira (monga kutembenuza zida, zida za mphero, mawilo akupera, etc.), zidzakhudza mwachindunji mawonekedwe a mawonekedwe. Kulondola kwa mawonekedwe a workpiece kumakhudzidwa mwachindunji ndi mawonekedwe olondola.

3) Kulakwitsa kwa mawonekedwe pa tsamba la chodula chopangidwa (monga ma hobs a gear, ma hobo a spline, odula ma gear shaper, etc.). Kulondola kwa mawonekedwe a pamwamba kudzakhudzidwa ndi cholakwika cha tsamba.

4) Kulondola kwa kupanga kwa chida sikukhudza mwachindunji kulondola kwake. Komabe, ndizosavuta kugwiritsa ntchito.

⑥ Njira yosinthira kupsinjika kwadongosolo

Mothandizidwa ndi clamping mphamvu ndi mphamvu yokoka, dongosolo adzakhala deform. Izi zidzatsogolera ku zolakwika zokonza ndipo zidzakhudza kukhazikika. Zomwe zili zofunika kwambiri ndikusintha kwa zida zamakina, kusinthika kwa zida zogwirira ntchito komanso kusinthika kwathunthu kwa makina opangira.

Kudula mphamvu ndi makina olondola

Kulakwitsa kwa cylindricity kumapangidwa pamene gawo lopangidwa ndi makina limakhala lakuda pakati ndi lopyapyala kumapeto, kutengera kusinthika komwe kumachitika chifukwa cha makina. Pakukonza zigawo za shaft, kusinthika kokha ndi kupsinjika kwa workpiece kumaganiziridwa. Chogwirira ntchito chikuwoneka chokhuthala pakati komanso chowonda kumapeto. Ngati mapindikidwe yekha kuti amaganiziridwa kuti processing wacnc shaft Machining magawondi mapindikidwe kapena chida cha makina, ndiye mawonekedwe a chogwirira ntchito pambuyo pokonza chidzakhala chosiyana ndi magawo okonzedwa.

Zotsatira za clamping mphamvu mu Machining molondola

Chogwirira ntchito chimapunduka chikamizidwa chifukwa cha kuuma kwake kochepa kapena mphamvu yokhotakhota yosayenera. Izi zimabweretsa vuto pokonza.

⑦ Kutentha kwa kutentha mu machitidwe opangira

Njirayi imatenthedwa ndi kupunduka panthawi yokonza chifukwa cha kutentha komwe kumapangidwa ndi gwero la kutentha kwakunja kapena gwero la kutentha kwamkati. Kupindika kwa matenthedwe kumayambitsa 40-70% ya zolakwika zamakina pamakina akulu ndi makina olondola.

Pali mitundu iwiri ya matenthedwe matenthedwe a workpiece amene angakhudze processing golide: kutentha yunifolomu ndi kutentha m'njira.

⑧ Kupanikizika Kwambiri mkati mwa Workpiece

Kupanga kupsinjika m'malo otsalira:

1) Kupanikizika kotsalira komwe kumapangidwa panthawi ya chithandizo cha kutentha ndi njira yopangira mwana wosabadwayo;

2) Kuwongoka kozizira kwa tsitsi kumatha kuyambitsa kupsinjika kotsalira.

3) Kudula kungayambitse kupsinjika kotsalira.

⑨ Kukonza kukhudzidwa kwa chilengedwe

Nthawi zambiri pamakhala tinthu tating'ono tating'ono tachitsulo pamalo opangira. Zitsulo zachitsulo izi zidzakhudza kulondola kwa makina a gawolo ngati ali pafupi ndi malo a dzenje kapena pamwamba pakutembenuza magawo. Tchipisi tachitsulo tating'ono kwambiri kuti sitingathe kuwona tidzakhala ndi chiwongola dzanja pakuwongolera molondola kwambiri. Ndizodziwika bwino kuti chikoka ichi chikhoza kukhala vuto, koma ndizovuta kuthetsa. Njira ya wogwiritsa ntchito ndiyonso chinthu chachikulu.

Cholinga chachikulu cha Anebon chikhala kukupatsirani ogula athu ubale wodalirika komanso wodalirika wamabizinesi, kupereka chisamaliro chaumwini kwa onse a New Fashion Design forOEM Shenzhen Precision Hardware Factory Custom Fabrication CNC milling process, kuponyera mwatsatanetsatane, ntchito yofananira. Mutha kupeza mtengo wotsika kwambiri pano. Komanso mupeza zinthu zabwino ndi mayankho ndi ntchito zabwino pano! Osazengereza kugwira Anebon!

Mapangidwe Atsopano Afashoni a China CNC Machining Service ndi MwamboCNC Machining Service, Anebon ili ndi nsanja zambiri zamalonda zakunja, zomwe ndi Alibaba,Globalsources,Global Market,Made-in-china. "XinGuangYang" mankhwala amtundu wa HID ndi mayankho amagulitsidwa bwino kwambiri ku Europe, America, Middle East ndi zigawo zina zoposa mayiko 30.

Ngati mukufuna kunena mawu opangidwa ndi makina, chonde omasuka kutumiza zojambula ku Anebon Email: info@anebon.com

Nthawi yotumiza: Dec-20-2023