N'chifukwa chiyani tiyenera kuchotsa zinthu zopangidwa?

Chitetezo:

Ma Burrs amatha kupanga m'mphepete mwakuthwa ndi zotuluka, zomwe zitha kukhala pachiwopsezo kwa ogwira ntchito komanso ogwiritsa ntchito kumapeto.

Ubwino:

Pochotsa ma burrs, mutha kusintha mawonekedwe ndi mawonekedwe azinthu zanu.

Kagwiritsidwe ntchito:

Burrs imatha kukhudza magwiridwe antchito ndi mawonekedwe awo ndi magawo ena.

Kutsata Malamulo

Mafakitale ena ali ndi malamulo okhwima okhudza kulekerera kwa burr kuti awonetsetse kuti zinthu zikuyenda bwino komanso chitetezo.

Kusonkhanitsa ndi Kusamalira

Zogulitsa zowonongeka zimapangitsa kuti zikhale zosavuta kusamalira ndi kusonkhanitsa, zomwe zimachepetsa chiopsezo cha kuwonongeka.

Burrs nthawi zambiri amapangidwa panthawi yodula zitsulo. Ma Burrs amatha kuchepetsa kulondola kwa kukonza komanso mawonekedwe apamwamba a workpiece. Zimakhudzanso magwiridwe antchito a chinthu ndipo, nthawi zina, zimayambitsa ngozi. Deburring nthawi zambiri amagwiritsidwa ntchito kuthetsa vuto la burr. Kuchotsa ndalama si njira yopindulitsa. Kuchotsa ndalama ndi njira yopanda phindu. Zimawonjezera ndalama, zimatalikitsa nthawi yopangira ndipo zimatha kuwononga katundu wonse.

Gulu la Anebon lasanthula ndikufotokozera zinthu zomwe zimakhudza mapangidwe a milling burrs. Akambirananso njira ndi matekinoloje omwe alipo kuti achepetse mphero za mphero ndikuwongolera, kuyambira gawo la mapangidwe apangidwe mpaka kupanga.

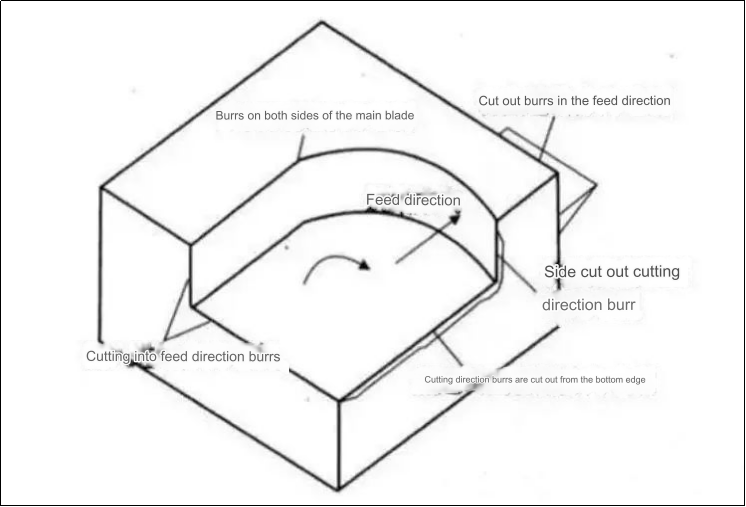

1. Mapeto mphero burrs: mitundu yaikulu

Malinga ndi dongosolo la gulu la ma burrs potengera kusuntha ndi zida zodulira m'mphepete, ma burrs akuluakulu omwe amapangidwa pakugaya komaliza amaphatikizanso ma burrs mbali zonse za pamwamba, ma burrs mbali imodzi polowera kudula, ma burrs pansi. mu njira kudula, ndi kudula mkati ndi kunja chakudya. Pali mitundu isanu ya ma burrs olunjika.

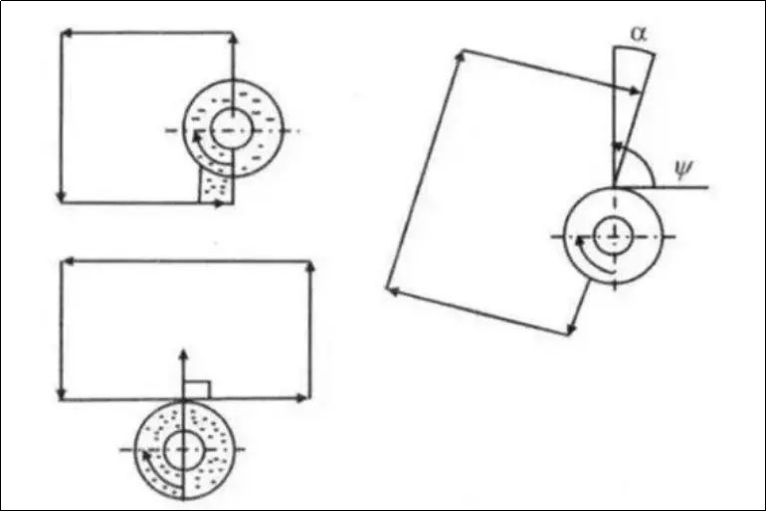

Chithunzi 1 Mabomba opangidwa ndi mphero yomaliza

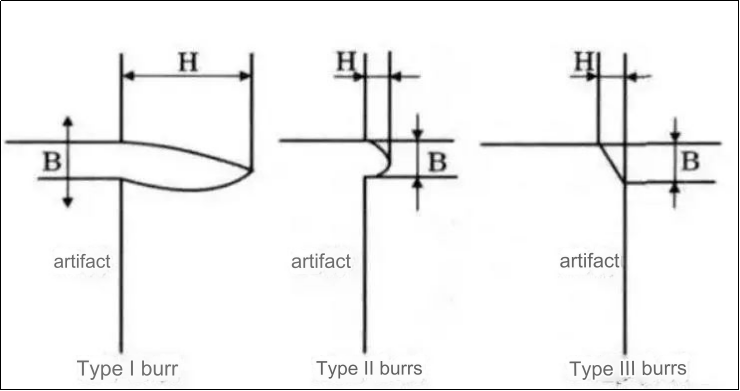

Kawirikawiri, kukula kwa ma burrs omwe ali mu njira yodulira pansi pamphepete ndi yaikulu komanso yovuta kuchotsa. Pepalali limayang'ana pa ma burrs apansi omwe ali m'njira zodulira. Kukula ndi mawonekedwe akhoza m'gulu la mitundu itatu yosiyanasiyana ya burrs amene amapezeka kumapeto mphero kudula malangizo. Mitundu yamtundu wa I imatha kukhala yovuta kuchotsa komanso yokwera mtengo, ma burrs a Type II amatha kuchotsedwa mosavuta, ndipo mtundu wa III ukhoza kukhala woyipa (monga momwe tawonetsera pa chithunzi 2).

Chithunzi 2 Mitundu ya Burrs mumayendedwe amphero.

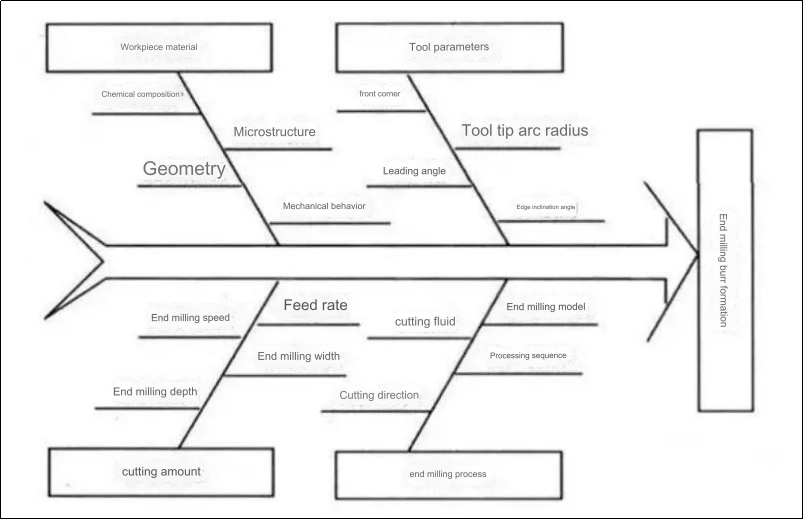

2. Zinthu zazikulu zomwe zimakhudza mapangidwe a burrs pamakina omaliza a mphero

Burr mapangidwe ndi njira yovuta ya zinthu deformation. Mapangidwe a burrs amakhudzidwa ndi zinthu zingapo, kuphatikizapo zinthu zakuthupi za workpiece, geometry yake, chithandizo chapamwamba, zida za geometry ndi njira yodulira, kuvala zida, kudula magawo, kugwiritsa ntchito kozizira, ndi zina zotero. zikuwonetsa zinthu zomwe zimakhudza mapeto a milling burrs. Maonekedwe ndi kukula mapeto millings burrs zimadalira kuchuluka zotsatira zosiyanasiyana chikoka zinthu pansi enieni mphero. Komabe, zinthu zosiyanasiyana zimakhala ndi zotsatira zosiyana pakupanga burr.

Chithunzi 3: Choyambitsa ndi Zotsatira za Kupanga kwa Milling Burr

1. Kulowa/kutuluka kwa chida

Ma burrs omwe amapangidwa pamene chidacho chikuzungulira kutali ndi chogwirira ntchito chimakhala chokulirapo kuposa chomwe chimapangidwa chikazungulira mkati.

2. Chotsani ngodya mu ndege

Ma angles odulidwa a ndege ali ndi chikoka chachikulu pa mapangidwe a burrs m'mphepete mwa pansi. Pamene kudula m'mphepete amazungulira kutali otsiriza padziko workpiece mu ndege, kudutsa mfundo perpendicular mphero wodula axis pa mfundo imeneyi, ndi vekitala kuphatikiza toolpeed ndi feedspeed ndi wofanana ndi ngodya pakati pa malangizo a mapeto a nkhope za iye. workpiece. Nkhope yomaliza ya workpiece imachokera ku screw screw mpaka kumalo opangira chida. Mu chithunzi 5, kuchuluka kwa Ps, mbali yomwe imadulidwa mu ndege ndi 0degPs = 180deg.

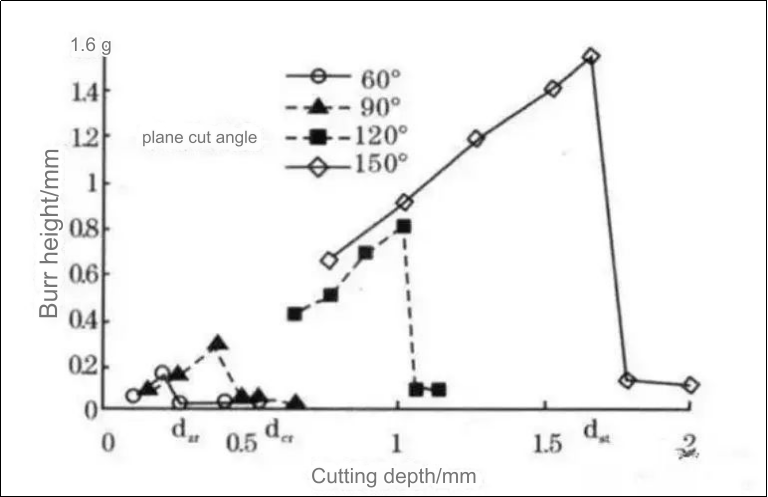

Zotsatira zoyesa zikuwonetsa kuti kuzama kwa kudula kumawonjezera kusintha kwa ma burrs kuchokera ku mtundu I kupita ku mtundu II. Nthawi zambiri, kuya kocheperako komwe kumafunikira kuti apange mtundu wa II burrs (womwe umatchedwanso limit cutting deep kapena dcr) umatchedwa kuzama kocheperako. Chithunzi 6 chikuwonetsa momwe ma angles odulira ndege amakhudzidwira ndikudula mozama pamtunda wa ma burr panthawi yakupanga ma aluminiyamu aloyi.

Chithunzi 6 Ndege kudula ngodya, burr mawonekedwe ndi kudula kuya

Chithunzi 6 chikuwonetsa kuti, pamene mbali yodula ndege imakhala yaikulu kuti 120deg mtundu wa I burrs ndi waukulu ndipo kuya komwe amasinthira ku mtundu wa II burrs kumawonjezeka. Njira yaying'ono yodulira ndege imalimbikitsa mapangidwe amtundu wa II burrs. Chifukwa chake ndikuti kutsika kwa Ps, kumapangitsanso kuuma kwa pamwamba pa terminal. Izi zimapangitsa kukhala kosavuta kwa ma burrs.

Kuthamanga kwa chakudya ndi mayendedwe ake kudzakhudza kuthamanga ndi mbali ya kudula kwa ndege ndi mapangidwe a ma burrs. Kukula kwakukulu kwa chakudya ndi kuchepetsa m'mphepete mwa kutuluka, a, ndi ang'onoang'ono a Ps, kumakhala kothandiza kwambiri popondereza mapangidwe akuluakulu a burrs.

Chithunzi 7 Zotsatira za njira ya chakudya pakupanga burr

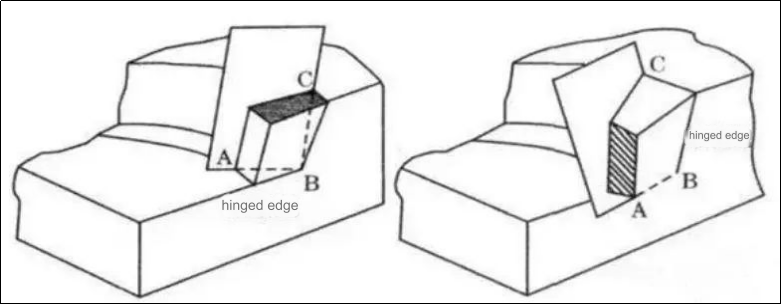

3. Chida nsonga EOS kutuluka motsatizana

Kukula kwa burr kumatsimikiziridwa ndi dongosolo lomwe nsonga ya chida imatuluka kumapeto kwa mphero. Pachithunzi 8, mfundo A ikuyimira pang'ono kudula. Mfundo C imayimira mbali zazikulu zodula. Ndipo nsonga B imayimira nsonga yapamwamba. Chida cha nsonga yozungulira sichinyalanyazidwa chifukwa chimaganiziridwa kuti ndi chakuthwa. Tchipisi zidzalumikizidwa pamwamba pa chogwirira ntchito ngati m'mphepete AB wasiya chogwiriracho patsogolo pa BC. Pamene mphero ikupitilira, tchipisi timakankhidwa kuchokera ku chogwirira ntchito ndikupanga burr yayikulu yodula pansi. Ngati m'mphepete AB wasiya workpiece pamaso m'mphepete BC, tchipisi adzakhala wodalira pa kusintha pamwamba. Kenako amadulidwa kuchokera ku workpiece kupita kukadula.

Kuyesera kukuwonetsa:

①Kutuluka kwachida ABC/BAC/ACB/BCA/CAB/CBA komwe kumawonjezera kukula kwa burr motsatizana.

②Zotsatira za EOS ndizofanana, kupatulapo kuti kukula kwa burr komwe kumapangidwa muzinthu zapulasitiki pansi pa ndondomeko yotuluka mofanana ndi yaikulu kuposa yomwe imapangidwa muzinthu zowonongeka. Kutuluka kwa nsonga ya chida sikungokhudzana ndi zida za geometry komanso zinthu monga kuchuluka kwa chakudya, mphero yakuya, geometry ya workpiece, ndi kudula. Burrs amapangidwa ndi kuphatikiza angapo zinthu.

Chithunzi 8 Chida nsonga yopangira burr ndikutsatizana kotuluka

4. Mphamvu ya Zinthu Zina

① Milling parameters (kutentha, malo odula, etc.). Mapangidwe a burrs adzakhudzidwanso ndi zinthu zina. Chikoka cha zinthu zazikulu monga chakudya liwiro, mphero mtunda, etc. Ndege kudula ngodya ndi chida nsonga kutuluka zinayendera mfundo EOS zikuonekera mu chiphunzitso cha ngodya kudula ndege. Sindifotokoza mwatsatanetsatane apa;

② The pulasitiki kwambiri zinthu zacnc kutembenuza magawo, kudzakhala kosavuta kupanga I type ma burrs. Mukamaliza mphero, kuchuluka kwa chakudya kapena ngodya zazikulu zodulira ndege kumatha kubweretsa zolakwika zamtundu wa III.

③ Kuwuma kowonjezereka kwa pamwamba kumatha kupondereza mapangidwe a ma burrs pamene ngodya pakati pa mapeto ndi ndege yopangidwa ndi makina imadutsa mbali yakumanja.

④ Kugwiritsa ntchito madzi amphero ndikopindulitsa kukulitsa moyo wa zida, kuchepetsa kutha ndi kung'ambika, kupaka mafuta pogaya ndikuchepetsa kukula kwa ma burr;

⑤ Kuvala kwa chida kumakhudza kwambiri mapangidwe a burr. Arc ya nsonga imawonjezeka pamene chida chavala pamlingo wina. Kukula kwa burr kumawonjezeka potuluka njira ya chida, komanso njira yodulira. Kuphunzira kwina kumafunika kuti mumvetsetse makinawo. Kumba mozama.

⑥ Zinthu zina, monga zida, zimathanso kukhudza mapangidwe a burr. Zida za diamondi zimapondereza ma burrs bwino kuposa zida zina pansi pamikhalidwe yomweyi.

3. Kuwongolera mapangidwe a milling burrs ndikosavuta.

Zinthu zambiri zimakhudza mapangidwe a milling burrs. Mphero ndi chinthu chimodzi chokha chomwe chimakhudza mapangidwe a mapeto mphero burrs. Zinthu zina zikuphatikizapo geometry ya chida, kapangidwe ndi kukula workpiece, etc. Pofuna kuchepetsa chiwerengero cha mapeto mphero burrs opangidwa, m'pofunika kulamulira ndi kuchepetsa burr m'badwo kuchokera ngodya angapo.

1. Mapangidwe omveka bwino

Mapangidwe a workpiece ndi chinthu chofunika kwambiri pakupanga burrs. Maonekedwe ndi kukula pambuyo pokonza ma burrs m'mphepete nawonso amasiyana malinga ndi kapangidwe ka workpiece. Pamene zinthu ndi pamwamba mankhwala amagawo a cncamadziwika, geometry ndi m'mphepete zimagwira ntchito yaikulu pakupanga burrs.

2. Mndandanda wa processing

Dongosolo lomwe makonzedwewo amapangidwira amathanso kukhudza kukula ndi mawonekedwe a burr. Deburring imakhudzidwa ndi mawonekedwe ndi kukula kwake, komanso kubweza katundu ndi ndalama. Kubweza ndalama kumatha kuchepetsedwa posankha ndondomeko yoyenera yokonza.

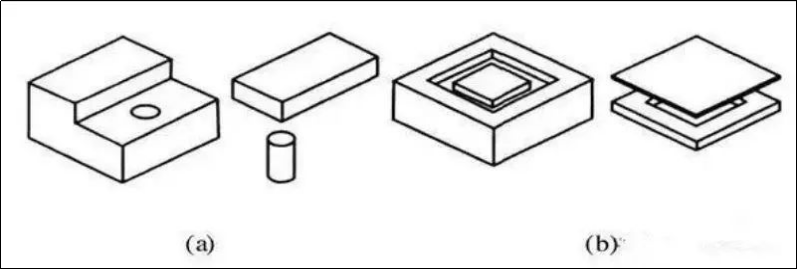

Chithunzi 9 Kusankha njira yoyendetsera ndondomeko

Ngati ndege yomwe ili pa Chithunzi 10a idabowoledwa koyamba kenako ndikugaya, ndiye kuti padzakhala mphero zazikulu kuzungulira dzenjelo. Komabe, ngati agayidwa koyamba ndikubowoleredwa, ndiye kuti tinthu tating'onoting'ono tobowola timawoneka. Pachithunzi 10b, mphero yaying'ono imapangidwa pamene malo opindika ayamba kuphwanyidwa, kutsatiridwa ndi mphero kumtunda.

3. Pewani Kutuluka kwa Chida

Ndikofunikira kupewa kuchotsedwa kwa zida, chifukwa ichi ndiye chifukwa chachikulu cha ma burrs kupanga podulira. Ma burrs omwe amapangidwa pamene chida chogaya chikuzunguliridwa kutali ndi chogwirira ntchito chimakhala chokulirapo kuposa chomwe chimapangidwa chikakulungidwa. Chodula mphero chiyenera kupewedwa panthawi yokonza momwe zingathere. Chithunzi 4 chikuwonetsa kuti burr yomwe idapangidwa pogwiritsa ntchito Chithunzi 4b inali yaying'ono kuposa yomwe idapangidwa ndi Chithunzi 4.

4. Sankhani njira yoyenera yodulira

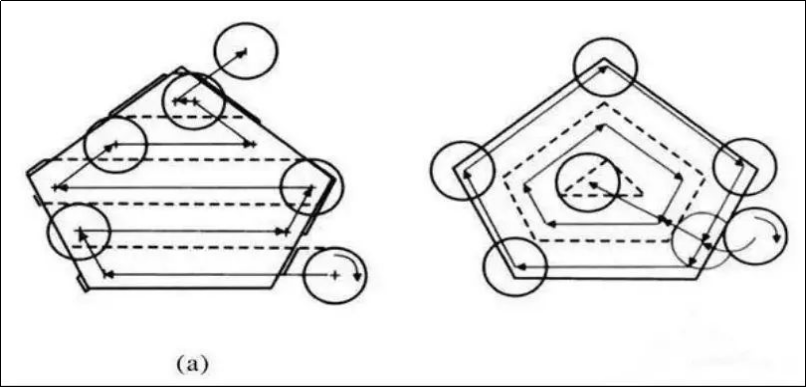

Kusanthula kwam'mbuyomu kukuwonetsa kuti kukula kwa burr ndi kocheperako pamene mbali yodula ndege ndi yotsika kuposa nambala inayake. Kusintha kwa mphero m'lifupi, kuthamanga kwa kasinthasintha ndi liwiro la chakudya kumatha kusintha mbali yodulira ndege. Posankha njira yoyenera yothandizira, ndizotheka kupewa kupanga ma burrs amtundu wa I (onani Chithunzi 11).

Chithunzi 10: Njira yowongolera zida

Chithunzi 10a chikuwonetsa njira ya zida zachikhalidwe. Dera lamthunzi la chithunzichi limasonyeza malo omwe angatheke pamene ma burrs angakhoze kuchitika mu njira yodula. Chithunzi 10b chikuwonetsa njira yowongolera chida chomwe chingachepetse mapangidwe a ma burrs.

Njira yachida yomwe ikuwonetsedwa pa chithunzi 11b ingakhale yotalikirapo pang'ono ndipo imatenga mphero yochulukirapo, koma sifunika kubweza kwina kulikonse. Chithunzi 10a, kumbali ina, imafuna kutaya kwambiri (ngakhale kulibe ma burrs ambiri m'derali, kwenikweni, muyenera kuchotsa ma burrs onse m'mphepete). Mwachidule, njira ya chida cha Chithunzi 10b ndiyothandiza kwambiri pakuwongolera ma burrs kuposa a Chithunzi 10a.

5. Sankhani magawo oyenera a mphero

Magawo a mphero (monga kudyetsa-pa-dzino, kutalika kwa mphero, kuya, ndi ngodya ya geometric) zitha kukhudza kwambiri mapangidwe a ma burrs. Burrs amakhudzidwa ndi magawo ena.

Zinthu zambiri zimakhudza mapangidwe a milling swarfs. Zinthu zazikuluzikulu zikuphatikizapo: zida zolowera / kutuluka, ngodya zodulira ndege, nsonga zotsatizana, magawo a mphero etc. Maonekedwe ndi kukula kwa mapeto a mphero burr ndi zotsatira za zinthu zambiri.

Nkhaniyi imayamba ndi mapangidwe apangidwe a workpiece, njira yopangira makina, kuchuluka kwa mphero ndi chida chosankhidwa. Imasanthula ndikukambirana zinthu zomwe zimakhudza ma mphero ndikupereka njira zowongolera njira zodulira mphero, kusankha njira zoyenera ndikuwongolera kapangidwe kake. Ukadaulo, njira, ndi njira zomwe zimagwiritsidwa ntchito kupondereza kapena kuchepetsa ma burrs amphero zimapereka mayankho aukadaulo omwe angagwiritsidwe ntchito pokonza mphero kuti azitha kuwongolera kukula ndi mtundu wa burr, kuchepetsa mtengo, komanso kufupikitsa kupanga.

Khalani ndi "Kasitomala woyamba, Wapamwamba Kwambiri" m'maganizo, Anebon imagwira ntchito bwino ndi makasitomala athu ndikuwapatsa chithandizo chaukadaulo komanso chaukadaulo ku Factory For.CNC mphero zing'onozing'ono, cnczida za aluminiyamu zopangidwa ndi makinandi Zigawo za kufa. Chifukwa Anebon nthawi zonse amakhala ndi mzerewu zaka zopitilira 12. Anebon ili ndi othandizira othandizira kwambiri pazabwino komanso zotsika mtengo. Ndipo Anebon anali ndi ogulitsa udzu omwe anali otsika kwambiri. Tsopano mafakitale angapo a OEM adagwirizana nafenso.

Factory For China Aluminium Section and Aluminium, Anebon imatha kukwaniritsa zosowa zosiyanasiyana za makasitomala kunyumba ndi kunja. Tikulandira makasitomala atsopano ndi akale kuti abwere kudzakambirana & kukambirana nafe. Kukhutitsidwa kwanu ndiye chilimbikitso chathu! Lolani Anebon agwire ntchito limodzi kuti alembe mutu watsopano wabwino kwambiri!

Ngati mukufuna kudziwa zambiri kapena kupeza mawu, chonde lemberaniinfo@anebon.com

Nthawi yotumiza: Dec-06-2023