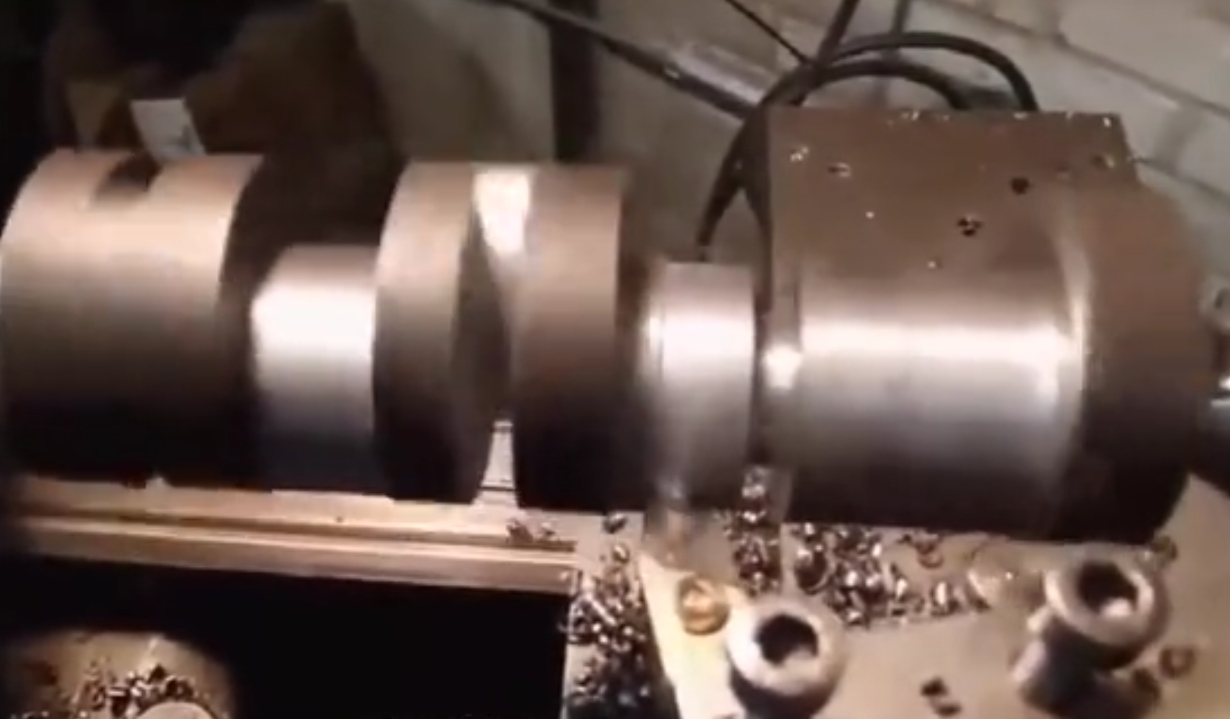

Zinthu zambiri zimathandizira kupotoza kwa zida za aluminiyamu panthawi yopanga, kuphatikiza zinthu zakuthupi, gawo la geometry, ndi magawo opanga.

Zinthu zazikuluzikulu zimaphatikizira kupsinjika kwamkati mkati mwazinthu zopangira, kupotoza komwe kumachitika chifukwa cha mphamvu zamakina ndi kutentha, komanso kupunduka komwe kumabwera chifukwa cha kukakamiza kwa clamping.

1. Njira zoyesera zochepetsera ma deformation

1. Chepetsani kupsinjika kwamkati komwe kulibe kanthu

Kukangana kwamkati mwazopangira kumatha kuchepetsedwa pang'onopang'ono kudzera mu ukalamba wachilengedwe kapena wochita kupanga komanso kugwedezeka. Kukonzekera koyambirira ndi njira yotheka. Pankhani ya zopangira zokhala ndi zopindika mowolowa manja komanso zotuluka zazikulu, kupotoza pambuyo pakukonza kumakhalanso kofunikira.

Kukonza gawo lotsala la zopangira zisanachitike ndikuchepetsa kuchulukira kwa gawo lililonse sikungangochepetse kupotoza kwa makonzedwewo m'njira zotsatila, komanso kulola kuti iziyikidwe kwa nthawi yayitali, zomwe zitha kuchepetsa kukangana kwamkati.

2. Kupititsa patsogolo luso lodula la chida

Kudula mphamvu ndi kudula kutentha pa Machining amakhudzidwa kwambiri ndi zinthu zikuchokera ndi mawonekedwe enieni a chida. Kusankha chida choyenera ndikofunikira kuti muchepetse kupotoza panthawi yokonza gawo.

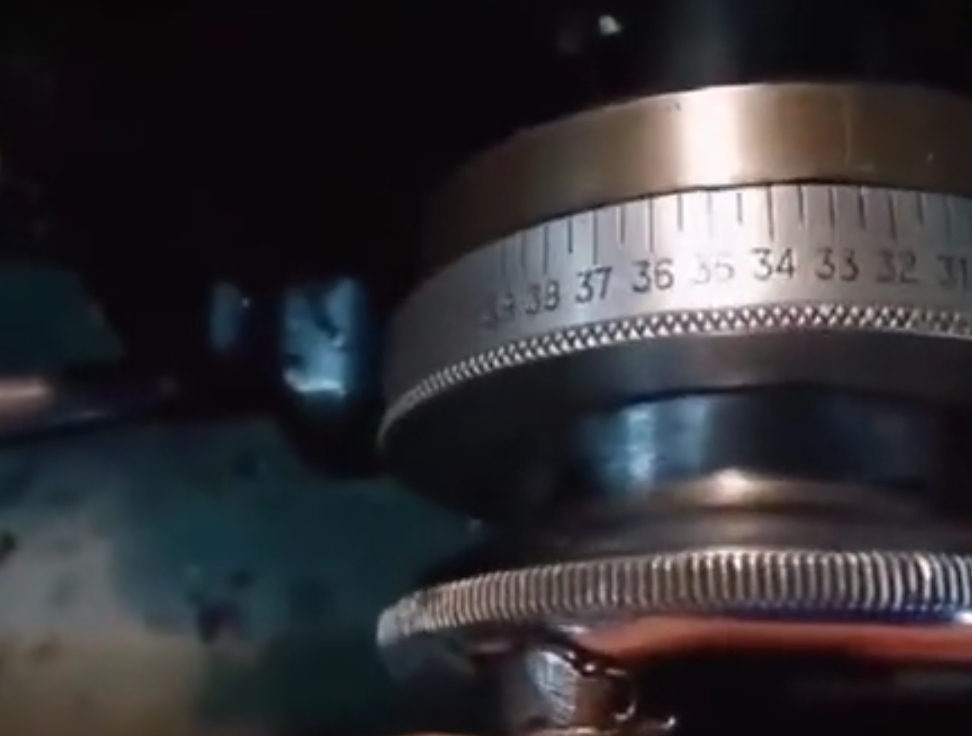

1) Sankhani moyenerera zida za geometric.

①Ngodya ya Rake imagwira ntchito yofunika kwambiri pakudula. Ndikofunika kusankha mosamala mbali yokulirapo ndikuwonetsetsa kuti mphamvu ya tsambayo ikusungidwa. Kudulira kokulirapo sikumangothandiza kuti pakhale kutsetsereka kokulirapo komanso kumachepetsa kupotoza komanso kumathandizira kuchotsa bwino tchipisi, zomwe zimapangitsa kuchepetsa mphamvu ndi kutentha. Zida zokhala ndi ma angles olakwika ziyenera kupewedwa zivute zitani.

②Ngodya yothandizira: Kukula kwa mbali yopumula kumakhudza kwambiri kuvala kumbali ndi mtundu wa malo opangidwa ndi makina. Kusankhidwa kwa mbali yothandizira kumadalira makulidwe a odulidwa. Pogaya mphero, pomwe pali chakudya chochuluka, kudula kwambiri, komanso kutentha kwakukulu, ndikofunikira kuwonetsetsa kuti chidacho chikutha kutentha kwambiri. Chifukwa chake, mbali yaing'ono yothandizira iyenera kusankhidwa. Mosiyana ndi zimenezi, pa mphero yabwino, mphero yakuthwa ndiyofunikira kuti muchepetse mikangano pakati pa mbali ndi malo opangidwa ndi makina komanso kuti muchepetse kupunduka. Chifukwa chake, mbali yokulirapo yololeza tikulimbikitsidwa.

③Ngodya ya Helix: Kuti mphero ikhale yosalala komanso kuchepetsa mphamvu ya mphero, ngodya ya helix iyenera kukhala yayikulu momwe mungathere.

④ Ngodya yayikulu yokhotakhota: Kuchepetsa bwino mbali yayikulu yokhotakhota kumatha kusintha kutentha ndikuchepetsa kutentha kwa malo opangirako.

2) Sinthani mawonekedwe a zida.

①Kupititsa patsogolo kutuluka kwa chip, ndikofunikira kuchepetsa kuchuluka kwa mano pa chodulira ndikukulitsa malo a chip. Chifukwa cha mapulasitiki ochulukirapo a aluminiyamu, pamakhala mapindikidwe odulira panthawi yokonza, zomwe zimafunikira danga lalikulu la chip. Zotsatira zake, tikulimbikitsidwa kuti pakhale utali wokulirapo wa pansi wa chip groove ndi kuchepetsa kuchuluka kwa mano odula mphero.

②Kukukuta ndendende mano a tsamba, kuwonetsetsa kuti makulidwe a m'mphepete mwake ndi pansi pa Ra=0.4um. Mukamagwiritsa ntchito mpeni watsopano, ndi bwino kukukuta kutsogolo ndi kumbuyo kwa mano pang'onopang'ono pogwiritsa ntchito mwala wonyezimira wamafuta kuti muchotse ziboliboli ndi zolakwika zing'onozing'ono zomwe zingakhalepo chifukwa chakunola. Njirayi sikuti imangochepetsa kutentha komanso imachepetsanso kudula.

③Ndikofunikira kuyang'anitsitsa miyezo yovala ya zida zodulira. Chidacho chikatha, kuuma kwamphamvu kwa chogwiriracho kumakwera, kutentha kumawonjezeka, ndipo kusinthika kwa workpiece kumawonekera kwambiri. Kuphatikiza pa kusankha zida zodulira zokhala ndi kukana kovala bwino, ndikofunikira kumamatira ku malire ovala zida za 0.2mm kuti mupewe kupezeka kwa m'mphepete mwake. Pa ntchito yodula, tikulimbikitsidwa kusunga kutentha kwa workpiece pansi pa 100 ° C kuti tipewe kuwonongeka.

3. Kupititsa patsogolo njira ya clamping ya workpieces

Pazitsulo zopyapyala zokhala ndi mipanda ya aluminiyamu yosakhazikika bwino, njira zotsatirazi zokhomerera zingagwiritsidwe ntchito kuchepetsa mapindikidwe:

①Mukamagwira ntchito ndi tchire zokhala ndi mipanda yopyapyala, kugwiritsa ntchito chuck ya nsagwada zitatu kapena chuck ya kasupe kuti mumangirire magawowo mozungulira kumatha kupangitsa kuti ntchitoyo iwonongeke ikamasulidwa mukatha kukonza. Zikatero, m'pofunika kugwiritsa ntchito njira yamphamvu ya axial kumapeto kwa nkhope. Yambani ndikupeza dzenje lamkati la gawolo, ndikupanga mandrel opangidwa ndi mwambo, ndikulowetsa mu dzenje lamkati. Gwiritsani ntchito chivundikirocho kuti mugwiritse ntchito kumapeto kwa nkhope, ndiyeno mutetezeni ndi mtedza. Pogwiritsa ntchito njirayi, mutha kupewa kupunduka kwa clamping panthawi yokonza bwalo lakunja, zomwe zimapangitsa kuwongolera kulondola.

②Mukagwira ntchito ndi zida zachitsulo zokhala ndi mipanda yopyapyala, ndikofunikira kugwiritsa ntchito ukadaulo wa maginito kuti mukwaniritse mphamvu yolimba yofananira, kuphatikiza magawo odula bwino. Njirayi imachepetsa bwino chiopsezo cha kuwonongeka kwa workpiece panthawi ya processing.Monga njira ina, chithandizo chamkati chikhoza kukhazikitsidwa kuti chikhale chokhazikika cha zigawo zoonda kwambiri.

Mwa kuphatikizira chogwirira ntchito ndi sing'anga yothandizira, monga yankho la urea lomwe lili ndi 3% mpaka 6% potaziyamu nitrate, kuthekera kwa kupunduka panthawi ya clamping ndi kudula kumatha kuchepetsedwa. Chodzaza ichi chitha kusungunuka ndikuchotsedwa ndikumiza chogwirira ntchito m'madzi kapena mowa pambuyo pokonza.

4. Konzani ndondomeko moyenera

M'kati mwa kudula kothamanga kwambiri, mpheroyo imakonda kugwedezeka chifukwa cha mwayi wochuluka wa makina ndi kudula kwapakatikati, zomwe zimapangitsa kuti pakhale zovuta pakulondola kwa makina ndi kuuma kwa pamwamba. Chifukwa chake, njira yodulira yothamanga kwambiri ya CNC imakhala ndi magawo osiyanasiyana, monga kukonza movutikira, kumaliza pang'ono, kuyeretsa pamakona, ndikumaliza, ndi zina.

Nthawi zina zigawo zimafuna kulondola kwambiri, pangakhale kofunikira kumaliza semi-finishing kenako ndikumaliza. Pambuyo popanga makina ovuta, ndizopindulitsa kulola kuti ziwalozo ziziziziritsa mwachilengedwe kuti muchepetse kupsinjika kwamkati komwe kumabwera chifukwa cha makina ovuta komanso kuchepetsa kupunduka. Mphepete mwa njira yotsalira pambuyo pokonza movutikira iyenera kupitirira mlingo wa mapindikidwe, nthawi zambiri kuyambira 1 mpaka 2 mm.

Kuphatikiza apo, pomaliza kumaliza, ndikofunikira kukhalabe ndi gawo lokhazikika la makina pagawo lomalizidwa, kuyambira 0.2 mpaka 0.5mm. Mchitidwewu umatsimikizira kuti chidacho chikhalabe chokhazikika panthawi yokonza, potero kuchepetsa kudulira mapindikidwe, kukwaniritsa khalidwe lapamwamba la processing, ndi kusunga kulondola kwa mankhwala.

2. Maluso ogwirira ntchito kuti achepetse kusinthika kwa kukonza

Magawo opangidwa ndicnc makina a aluminiyamu zigawoamapunduka panthawi yokonza. Kuphatikiza pazifukwa zomwe zili pamwambazi, njira yogwiritsira ntchito ndi yofunika kwambiri pa ntchito yeniyeni.

1. Pazigawo zomwe zili ndi chilolezo chochulukira cha makina, ndikofunikira kugwiritsa ntchito njira zofananira kuti zithandizire kutulutsa kutentha panthawi yopanga ndikupewa kutentha. Monga fanizo, pochepetsa 90mm wandiweyani pepala kukhala 60mm, mphero mbali imodzi ndiyeno nthawi yomweyo mphero ina, kutsatiridwa ndi njira imodzi yomaliza yomaliza kumapangitsa kuti ikhale yosalala ya 5mm. Mosiyana, kugwiritsa ntchito mobwerezabwereza symmetrical processing, ndi mbali iliyonse milled mu magawo awiri, zimatsimikizira kukula komaliza ndi flatness 0.3mm.

2. Ngati pali ma indentation angapo pagawo la mbale, sizikulimbikitsidwa kuti mugwiritse ntchito njira yopangira pang'onopang'ono pamtundu uliwonse. Izi zitha kupangitsa kugawanika kwapang'onopang'ono kosakhazikika komanso kusinthika kotsatira kwa gawolo. M'malo mwake, lingalirani kugwiritsa ntchito kusanjikiza kosanjikiza kumakina ma indentation onse nthawi imodzi pagawo lililonse, musanapitirire ku gawo lina. Izi zidzathandiza kuonetsetsa ngakhale kugawanika kwa nkhawa komanso kuchepetsa ma deformation.

3. Kuchepetsa mphamvu yodula ndi kutentha, kuchuluka kwa kudula kumatha kusinthidwa. Pakati pa zinthu zitatu zodula, kuchuluka kwa kudula kumbuyo kumakhudza kwambiri mphamvu yodula. Kuloledwa kochulukira kwa makina ndi mphamvu yodulira kumatha kupangitsa kuti pakhale kupindika, kusokoneza kulimba kwa chida cha makina, ndikuchepetsa kulimba kwa chida. Kuchepa kwa kuchuluka kwa kudula kumbuyo kungachepetse kwambiri kupanga bwino. Komabe, mphero yothamanga kwambiri mu makina a CNC imatha kuthana ndi vutoli. Pakuchepetsanso kuchuluka kwa kudula ndikuwonjezera liwiro la chakudya ndi zida zamakina, mphamvu yodulira imatha kuchepetsedwa ndikusunga magwiridwe antchito.

4. Chidwi chiyeneranso kuperekedwa ku ndondomeko yodula. M'makina ovuta, cholinga chake ndi kukulitsa magwiridwe antchito ndikuyesetsa kuchotsa zinthu zambiri panthawi imodzi. Kawirikawiri, mphero ndi yabwino. Izi zikutanthauza kuti zinthu zowonjezera pamwamba pa workpiece zimachotsedwa pa liwiro lapamwamba kwambiri ndipo mu nthawi yaifupi zotheka kukhazikitsa ndondomeko ya geometric yofunikira kuti amalize. Kumbali inayi, kutsirizitsa kumayika patsogolo kulondola kwapamwamba komanso khalidwe lapamwamba, choncho mphero yotsika imalimbikitsidwa. Pamene makulidwe odula a chidawo amachepa pang'onopang'ono kuchokera pamlingo wokulirapo mpaka ziro panthawi ya mphero, amachepetsa kuuma kwa ntchito ndikuchepetsa kupunduka kwa mbali.

5. Matembenuzidwe a workpieces woonda-mipanda chifukwa cha clamping pa processing ndi nkhani yosapeŵeka, ngakhale atatha. Kuti muchepetse kusinthika kwa workpiece, tikulimbikitsidwa kuti mutulutse kupanikizika musanamalize kukwaniritsa miyeso yomaliza. Izi zimathandiza workpiece kubwerera mwachibadwa mawonekedwe ake oyambirira. Pambuyo pake, kukakamiza kumatha kuimitsidwa mosamala mpaka chogwiriracho chikatsekeredwa, kukwaniritsa zomwe mukufuna kukonza. Momwemo, mphamvu yokhotakhota iyenera kugwiritsidwa ntchito pamtunda wothandizira, kugwirizanitsa ndi kulimba kwa workpiece. Ngakhale kuwonetsetsa kuti chogwiriracho chikhalabe chotetezeka, ndibwino kugwiritsa ntchito mphamvu yocheperako.

6. Mukamapanga zida zokhala ndi dzenje, ndikofunikira kupewa chodulira mphero kulowa mwachindunji mu gawo lofanana ndi kubowola panthawiyi. Izi zitha kupangitsa kuti chip chikhale chocheperako chodulira mphero, kulepheretsa kuthamangitsidwa kwa chip, komanso kutenthedwa, kukulitsa, ndi kuwonongeka kwa magawowo. Zochitika zosafunikira monga kupotoza ndi kusweka kwa zida zitha kuchitika. Ndikoyenera kuti poyamba mugwiritse ntchito kubowola kofananako kapena kukulirapo pang'ono kuposa chodulira mphero kuti kubowola dzenjelo ndikugwiritsanso ntchito chodulira mphero pokonza. Kapenanso, pulogalamu yodula mozungulira imatha kupangidwa pogwiritsa ntchito pulogalamu ya CAM.

Vuto lalikulu lomwe limakhudza kulondola kwa mapangidwe a aluminiyumu komanso kukhazikika kwake kwapamwamba ndikuti magawowa asokonezeke panthawi yokonza. Izi zimafuna kuti wogwiritsa ntchitoyo akhale ndi luso linalake la ntchito ndi luso.

Anebon imadalira mphamvu yolimba yaukadaulo ndikupanga matekinoloje apamwamba kwambiri kuti akwaniritse zofunikira za makina achitsulo a cnc,5 olamulira cnc mpherondi kuyendetsa galimoto. Malingaliro onse ndi malingaliro adzayamikiridwa kwambiri! Mgwirizano wabwino ukhoza kupititsa patsogolo tonsefe kukhala chitukuko chabwino!

ODM Manufacturer ChinaMakonda Aluminiyamu CNC Magawondi mbali makina kupanga, Pakali pano, zinthu Anebon wakhala zimagulitsidwa ku mayiko oposa sikisite ndi zigawo zosiyanasiyana, monga Southeast Asia, America, Africa, Eastern Europe, Russia, Canada etc. Anebon ndi mtima wonse akuyembekeza kukhazikitsa kukhudzana lonse ndi makasitomala angathe. ku China komanso kumadera ena a dziko lapansi.

Ngati mukufuna kudziwa zambiri za ife kapena mukufuna kufunsa, chonde tumizani imelo kwainfo@anebon.com

Nthawi yotumiza: Feb-02-2024