HV, HB, ndi HRC zonse ndi miyeso ya kuuma yomwe imagwiritsidwa ntchito poyesa zida. Tiyeni tiwaphwanye:

1) Kuuma kwa HV (Vickers Kuuma): Kuuma kwa HV ndi muyeso wa kukana kwa chinthu ku indentation. Zimatsimikiziridwa ndikugwiritsa ntchito katundu wodziwika pamwamba pa zinthuzo pogwiritsa ntchito indenter ya diamondi ndikuyesa kukula kwa indentation yomwe imachokera. Kuuma kwa HV kumawonetsedwa m'mayunitsi a Vickers hardness (HV) ndipo nthawi zambiri amagwiritsidwa ntchito ngati zida zoonda, zokutira, ndi tizigawo tating'ono.

2) HB Kuuma (Brinell Hardness): Kuuma kwa HB ndi muyeso wina wa kukana kwa chinthu ku indentation. Zimaphatikizapo kuyika katundu wodziwika kuzinthuzo pogwiritsa ntchito cholembera chachitsulo cholimba chachitsulo ndikuyeza kukula kwa zomwe zimatsatira. Kuuma kwa HB kumawonetsedwa mumagulu a Brinell hardness (HB) ndipo nthawi zambiri amagwiritsidwa ntchito pazinthu zazikulu komanso zazikulu, kuphatikiza zitsulo ndi ma aloyi.

3) Kuuma kwa HRC (Kulimba kwa Rockwell): Kuuma kwa HRC ndi muyeso wa kukana kwazinthu kulowera kapena kulowa. Amagwiritsa ntchito masikelo osiyanasiyana (A, B, C, etc.) kutengera njira yoyesera komanso mtundu wa inndenter yomwe imagwiritsidwa ntchito (cone ya diamondi kapena mpira wachitsulo wowuma). Sikelo ya HRC imagwiritsidwa ntchito kwambiri kuyeza kuuma kwa zinthu zachitsulo. Mtengo wa kuuma umayimiridwa ngati nambala pamlingo wa HRC, monga HRC 50.

Gulu lofananiza la HV-HB-HRC lomwe limagwiritsidwa ntchito kwambiri:

| Gome lofananiza la ferrous chitsulo chofananira (pafupifupi kutembenuka kwamphamvu) | ||||

| Gulu la kuuma | Kulimba kwamakokedwe N/mm2 | |||

| Rockwell | Vickers | Brinell | ||

| Mtengo wa HRC | HRA | HV | HB | |

| 17 | - | 211 | 211 | 710 |

| 17.5 | - | 214 | 214 | 715 |

| 18 | - | 216 | 216 | 725 |

| 18.5 | - | 218 | 218 | 730 |

| 19 | - | 221 | 220 | 735 |

| 19.5 | - | 223 | 222 | 745 |

| 20 | - | 226 | 225 | 750 |

| 20.5 | - | 229 | 227 | 760 |

| 21 | - | 231 | 229 | 765 |

| 21.5 | - | 234 | 232 | 775 |

| 22 | - | 237 | 234 | 785 |

| 22.5 | - | 240 | 237 | 790 |

| 23 | - | 243 | 240 | 800 |

| 23.5 | - | 246 | 242 | 810 |

| 24 | - | 249 | 245 | 820 |

| 24.5 | - | 252 | 248 | 830 |

| 25 | - | 255 | 251 | 835 |

| 25.5 | - | 258 | 254 | 850 |

| 26 | - | 261 | 257 | 860 |

| 26.5 | - | 264 | 260 | 870 |

| 27 | - | 268 | 263 | 880 |

| 27.5 | - | 271 | 266 | 890 |

| 28 | - | 274 | 269 | 900 |

| 28.5 | - | 278 | 273 | 910 |

| 29 | - | 281 | 276 | 920 |

| 29.5 | - | 285 | 280 | 935 |

| 30 | - | 289 | 283 | 950 |

| 30.5 | - | 292 | 287 | 960 |

| 31 | - | 296 | 291 | 970 |

| 31.5 | - | 300 | 294 | 980 |

| 32 | - | 304 | 298 | 995 |

| 32.5 | - | 308 | 302 | 1010 |

| 33 | - | 312 | 306 | 1020 |

| 33.5 | - | 316 | 310 | 1035 |

| 34 | - | 320 | 314 | 1050 |

| 34.5 | - | 324 | 318 | 1065 |

| 35 | - | 329 | 323 | 1080 |

| 35.5 | - | 333 | 327 | 1095 |

| 36 | - | 338 | 332 | 1110 |

| 36.5 | - | 342 | 336 | 1125 |

| 37 | - | 347 | 341 | 1140 |

| 37.5 | - | 352 | 345 | 1160 |

| 38 | - | 357 | 350 | 1175 |

| 38.5 | - | 362 | 355 | 1190 |

| 39 | 70 | 367 | 360 | 1210 |

| 39.5 | 70.3 | 372 | 365 | 1225 |

| 40 | 70.8 | 382 | 375 | 1260 |

| 40.5 | 70.5 | 377 | 370 | 1245 |

| 41 | 71.1 | 388 | 380 | 1280 |

| 41.5 | 71.3 | 393 | 385 | 1300 |

| 42 | 71.6 | 399 | 391 | 1320 |

| 42.5 | 71.8 | 405 | 396 | 1340 |

| 43 | 72.1 | 411 | 401 | 1360 |

| 43.5 | 72.4 | 417 | 407 | 1385 |

| 44 | 72.6 | 423 | 413 | 1405 |

| 44.5 | 72.9 | 429 | 418 | 1430 |

| 45 | 73.2 | 436 | 424 | 1450 |

| 45.5 | 73.4 | 443 | 430 | 1475 |

| 46 | 73.7 | 449 | 436 | 1500 |

| 46.5 | 73.9 | 456 | 442 | 1525 |

| 47 | 74.2 | 463 | 449 | 1550 |

| 47.5 | 74.5 | 470 | 455 | 1575 |

| 48 | 74.7 | 478 | 461 | 1605 |

| 48.5 | 75 | 485 | 468 | 1630 |

| 49 | 75.3 | 493 | 474 | 1660 |

| 49.5 | 75.5 | 501 | 481 | 1690 |

| 50 | 75.8 | 509 | 488 | 1720 |

| 50.5 | 76.1 | 517 | 494 | 1750 |

| 51 | 76.3 | 525 | 501 | 1780 |

| 51.5 | 76.6 | 534 | - | 1815 |

| 52 | 76.9 | 543 | - | 1850 |

| 52.5 | 77.1 | 551 | - | 1885 |

| 53 | 77.4 | 561 | - | 1920 |

| 53.5 | 77.7 | 570 | - | 1955 |

| 54 | 77.9 | 579 | - | 1995 |

| 54.5 | 78.2 | 589 | - | 2035 |

| 55 | 78.5 | 599 | - | 2075 |

| 55.5 | 78.7 | 609 | - | 2115 |

| 56 | 79 | 620 | - | 2160 |

| 56.5 | 79.3 | 631 | - | 2205 |

| 57 | 79.5 | 642 | - | 2250 |

| 57.5 | 79.8 | 653 | - | 2295 |

| 58 | 80.1 | 664 | - | 2345 |

| 58.5 | 80.3 | 676 | - | 2395 |

| 59 | 80.6 | 688 | - | 2450 |

| 59.5 | 80.9 | 700 | - | 2500 |

| 60 | 81.2 | 713 | - | 2555 |

| 60.5 | 81.4 | 726 | - | - |

| 61 | 81.7 | 739 | - | - |

| 61.5 | 82 | 752 | - | - |

| 62 | 82.2 | 766 | - | - |

| 62.5 | 82.5 | 780 | - | - |

| 63 | 82.8 | 795 | - | - |

| 63.5 | 83.1 | 810 | - | - |

| 64 | 83.3 | 825 | - | - |

| 64.5 | 83.6 | 840 | - | - |

| 65 | 83.9 | 856 | - | - |

| 65.5 | 84.1 | 872 | - | - |

| 66 | 84.4 | 889 | - | - |

| 66.5 | 84.7 | 906 | - | - |

| 67 | 85 | 923 | - | - |

| 67.5 | 85.2 | 941 | - | - |

| 68 | 85.5 | 959 pa | - | - |

| 68.5 | 85.8 | 978 | - | - |

| 69 | 86.1 | 997 | - | - |

| 69.5 | 86.3 | 1017 | - | - |

| 70 | 86.6 | 1037 | - | - |

Maupangiri Oyandikira a HRC/HB

Kuuma kwake ndikwapamwamba kuposa 20HRC, 1HRC≈10HB,

Kuuma kwake ndikotsika kuposa 20HRC, 1HRC≈11.5HB.

Ndemanga: Podulira, imatha kusinthidwa mofanana 1HRC≈10HB (kuuma kwa zinthu zogwirira ntchito kumakhala ndi kusinthasintha)

Kuuma kwa zinthu zachitsulo

Kuuma kumatanthauza kuthekera kwa chinthu kukana kupunduka kwanuko, makamaka kupunduka kwa pulasitiki, kulowa mkati kapena kukanda. Ndilolozera kuti muyese kufewa ndi kuuma kwa zinthu.

Malinga ndi njira zosiyanasiyana zoyesera, kuuma kumagawidwa m'mitundu itatu.

①Kukala kuuma. Amagwiritsidwa ntchito makamaka poyerekeza kufewa ndi kuuma kwa mchere wosiyanasiyana. Njirayi ndiyo kusankha ndodo yokhala ndi mapeto amodzi mwamphamvu ndipo mapeto enawo ndi ofewa, kupititsa zinthu zomwe zimayenera kuyesedwa pamodzi ndi ndodoyo, ndikudziwitsani kuuma kwa zinthu zomwe ziyenera kuyesedwa malinga ndi malo a scratch. Kunena zowona, zinthu zolimba zimapanga zikanda zazitali ndipo zofewa zimapanga zazifupi.

②Kulimba kwa indentation. Amagwiritsidwa ntchito makamaka pazinthu zachitsulo, njirayo ndikugwiritsa ntchito katundu wina kukanikiza inndenter yotchulidwa muzinthu zomwe zimayenera kuyesedwa, ndikuyerekeza kufewa ndi kuuma kwa zinthu zomwe ziyenera kuyesedwa ndi kukula kwa mapindikidwe apulasitiki apamtunda pamtunda wa zinthu. Chifukwa cha kusiyana kwa indenter, katundu ndi nthawi ya katundu, pali mitundu yambiri ya kuuma kwa indentation, makamaka kuphatikizapo Brinell hardness, Rockwell hardness, Vickers kuuma ndi microhardness.

③Rebound kuuma. Zomwe zimagwiritsidwa ntchito kwambiri pazitsulo zachitsulo, njirayo ndi kupanga nyundo yapadera yaing'ono kugwa momasuka kuchokera pamtunda wina kuti ikhudze chitsanzo cha zinthu zomwe zimayenera kuyesedwa, ndikugwiritsa ntchito kuchuluka kwa mphamvu yamagetsi yosungidwa (ndiyeno kumasulidwa) mu chitsanzo panthawi ya mphamvu (kudzera mu kubwerera kwa nyundo yaying'ono) kuyeza kutalika kwa kulumpha) kuti muwone kuuma kwa zinthuzo.

Kuuma kofala kwa Brinell, Rockwell hardness ndi Vickers kuuma kwazinthu zachitsulo ndizomwe zimakhala kuuma kwa indentation. Kuuma kwamtengo kumawonetsa kuthekera kwa zinthu zakuthupi kukana kupunduka kwa pulasitiki komwe kumayambitsidwa ndi chinthu china chomwe chikukanikizidwa; C) kuyeza kuuma, ndipo kuuma mtengo kumayimira kukula kwa zotanuka deformation ntchito yachitsulo.

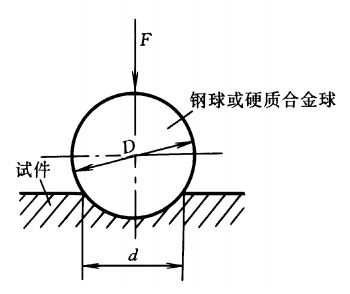

Brinell Kuuma

Gwiritsani ntchito mpira wachitsulo wozimitsidwa kapena mpira wolimba wa alloy ndi m'mimba mwake wa D monga cholembera, kanikizani pamwamba pa chidutswa choyesera ndi mphamvu yoyesera yofananira F, ndipo patatha nthawi yodziwika, chotsani mphamvu yoyesera kuti mupeze indentation ndi m'mimba mwa d. Gawani mphamvu yoyesera ndi malo a indentation, ndipo mtengo wake ndi Brinell hardness value, ndipo chizindikirocho chikuyimiridwa ndi HBS kapena HBW.

Kusiyana pakati pa HBS ndi HBW ndikusiyana kwa indenter. HBS imatanthawuza kuti indenter ndi mpira wachitsulo wowuma, womwe umagwiritsidwa ntchito poyeza zinthu zomwe zimakhala ndi mtengo wa Brinell kuuma pansi pa 450, monga chitsulo chochepa, chitsulo chotuwa ndi zitsulo zopanda chitsulo. HBW amatanthauza kuti inndenter ndi simenti carbide, amene ntchito kuyeza zipangizo ndi Brinell kuuma mtengo pansi 650.

Kwa chipika choyesera chofanana, pamene mayesero ena ali ofanana ndendende, zotsatira za mayesero awiriwa zimakhala zosiyana, ndipo mtengo wa HBW nthawi zambiri umakhala waukulu kuposa mtengo wa HBS, ndipo palibe lamulo lachiwerengero loyenera kutsatira.

Pambuyo pa 2003, dziko langa lidatengeranso miyezo yapadziko lonse lapansi, kuletsa zotsekera mpira wachitsulo, ndi mitu yonse ya mpira wa carbide. Chifukwa chake, HBS imasiyidwa, ndipo HBW imagwiritsidwa ntchito kuyimira chizindikiro cha Brinell kuuma. Nthawi zambiri, kuuma kwa Brinell kumangowonetsedwa mu HB, kutanthauza HBW. Komabe, HBS imawonedwabe nthawi ndi nthawi m'mapepala a mabuku.

Njira yoyezera kuuma kwa Brinell ndi yoyenera chitsulo choponyedwa, ma aloyi osagwiritsa ntchito chitsulo, zitsulo zosiyanasiyana zozimitsidwa komanso zozimitsidwa, ndipo sizoyenera kuyesa zitsanzo kapenacnc kutembenuza magawozolimba kwambiri, zazing'ono, zoonda kwambiri, kapena zomwe sizilola kuloza kwakukulu pamtunda.

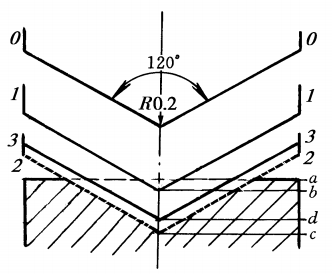

Rockwell Hardness

Gwiritsani ntchito cone ya diamondi yokhala ndi ngodya ya 120 ° kapena Ø1.588mm ndi Ø3.176mm mipira yachitsulo yozimitsidwa ngati indenter ndi katundu kuti mugwirizane nayo. Katundu woyambirira ndi 10kgf ndipo katundu wonse ndi 60, 100 kapena 150kgf (ndiko kuti, katundu woyamba kuphatikiza katundu wamkulu). Kuuma kumasonyezedwa ndi kusiyana pakati pa kuya kwa indentation pamene katundu wamkulu akuchotsedwa ndi kuya kwa indentation pamene katundu wamkulu amasungidwa ndi kuya kwa indentation pansi pa katundu woyamba pambuyo pa katundu wonse.

Mayeso a Rockwell hardness amagwiritsa ntchito mphamvu zitatu zoyesera ndi ma indenters atatu. Pali zophatikizira 9, zofananira ndi masikelo 9 a kuuma kwa Rockwell. Kugwiritsa ntchito olamulira awa 9 kumakwirira pafupifupi zida zonse zomwe zimagwiritsidwa ntchito kwambiri. Pali atatu omwe amagwiritsidwa ntchito kwambiri HRA, HRB ndi HRC, omwe HRC ndi omwe amagwiritsidwa ntchito kwambiri.

Zomwe zimagwiritsidwa ntchito pafupipafupi pa Rockwell hardness test table table:

| Kuuma | | | Kuuma | |

| | | | | Carbide, carbide, |

| | | | | Chitsulo chokhazikika, chokhazikika, aluminiyamu aloyi |

| | | | | chitsulo cholimba, chozimitsidwa ndi chitsulo chosungunuka, chakuya |

Mitundu yogwiritsira ntchito sikelo ya HRC ndi 20 ~ 70HRC. Pamene kuuma mtengo ndi zosakwana 20HRC, chifukwa conicalaluminium cnc Machining gawoya indenter imapanikizidwa kwambiri, kukhudzika kumachepa, ndipo sikelo ya HRB iyenera kugwiritsidwa ntchito m'malo mwake; pamene kuuma kwa chitsanzo kuli kwakukulu kuposa 67HRC, kupanikizika pansonga ya indenter ndi yaikulu kwambiri, ndipo diamondi imawonongeka mosavuta. Moyo wa inndenter udzafupikitsidwa kwambiri, kotero sikelo ya HRA iyenera kugwiritsidwa ntchito m'malo mwake.

Mayeso a Rockwell hardness ndi osavuta, othamanga, komanso olowera pang'ono, ndipo amatha kuyesa zinthu zomalizidwa komanso zolimba komanso zoonda. Chifukwa cha indentation yaying'ono, pazida zokhala ndi mawonekedwe osagwirizana ndi kuuma, mtengo wowuma umasinthasintha kwambiri, ndipo kulondola sikuli kokwera ngati Brinell kuuma. Kuuma kwa Rockwell kumagwiritsidwa ntchito kudziwa kuuma kwachitsulo, zitsulo zopanda chitsulo, ma aloyi olimba, ndi zina zambiri.

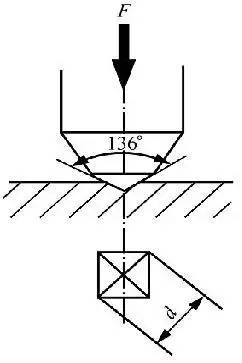

Vickers Kuuma kwa Vickers Kuuma

Mfundo yoyezera kuuma kwa Vickers ndi yofanana ndi ya Brinell kuuma. Gwiritsani ntchito cholozera cha diamondi lalikulu la piramidi yokhala ndi ngodya yophatikizidwa ya 136 ° kukanikiza pamwamba pa zinthuzo ndi mphamvu yoyesera F, ndikuchotsa mphamvu yoyeserera mutasunga nthawi yodziwika. Kuuma kumawonetsedwa ndi kukakamiza kwapakati pagawo lagawo la piramidi yayikulu. Mtengo, chizindikiro cha HV.

Muyeso wa kuuma kwa Vickers ndi waukulu, ndipo umatha kuyeza zida zolimba kuyambira 10 mpaka 1000HV. Malo olowera ndi ang'onoang'ono, ndipo nthawi zambiri amagwiritsidwa ntchito kuyeza zida zoonda komanso zolimba zolimba monga carburizing ndi nitriding.

Leeb Kuuma Leeb Kulimba

Gwiritsani ntchito thupi lokhudzidwa lomwe lili ndi mutu wina wa mpira wa tungsten carbide kuti mukhudze pamwamba pa gawo loyeserera pochitapo kanthu ndi mphamvu inayake, kenako ndikubwereranso. Chifukwa cha kuuma kosiyanasiyana kwa zida, liwiro la rebound pambuyo pamphamvu limakhalanso losiyana. Maginito okhazikika amaikidwa pa chipangizo chokhudzidwa. Thupi lachiwombankhanga likamayenda m'mwamba ndi pansi, koyilo yake yozungulira imapangitsa kuti chizindikiro cha electromagnetic chifanane ndi liwiro, kenako ndikuchisintha kukhala mtengo wa Leeb kuuma kudzera pamagetsi. Chizindikirocho chimalembedwa kuti HL.

Choyesa cholimba cha Leeb sichikusowa chogwiritsira ntchito, ndipo chowunikira chake chimakhala chochepa ngati cholembera, chomwe chimagwiritsidwa ntchito mwachindunji ndi manja, ndipo chikhoza kudziwika mosavuta ngati ndi lalikulu, lolemera kwambiri kapena ntchito yokhala ndi miyeso yovuta ya geometric.

Ubwino wina wa kuuma kwa Leeb ndikuti uli ndi zowonongeka pang'ono pamwamba pa mankhwala, ndipo nthawi zina zingagwiritsidwe ntchito ngati mayeso osawononga; ndizopadera pakuyesa kuuma kumbali zonse, malo opapatiza komanso apaderazigawo za aluminiyamu.

Anebon amatsatira mfundo yakuti "Woona mtima, wolimbikira, wochita chidwi, wanzeru" kuti apeze mayankho atsopano mosalekeza. Anebon amawona ziyembekezo, kupambana ngati kupambana kwake. Lolani Anebon amange tsogolo labwino m'manja pazigawo zamakina zamkuwa ndi zida za Complex titanium cnc / zida zopondaponda. Anebon tsopano ili ndi katundu wokwanira komanso mtengo wogulitsa ndi mwayi wathu. Takulandilani kuti mufunse za malonda a Anebon.

Zomwe Zili Padziko Lapansi China CNC Machinging Part ndi Precision Part, ngati chilichonse mwazinthuzi chingakusangalatseni, chonde tidziwitseni. Anebon adzakondwera kukupatsani mawu oti mutenge mwatsatanetsatane. Anebon ali ndi akatswiri athu a R&D akatswiri kuti akwaniritse zofunikira zilizonse. Anebon akuyembekezera kulandira zofunsa zanu posachedwa ndipo ndikuyembekeza kukhala ndi mwayi wogwira ntchito limodzi nanu mtsogolo. Takulandilani kuti muwone bungwe la Anebon.

Nthawi yotumiza: May-18-2023