Kodi chida cha CNC ndi chiyani?

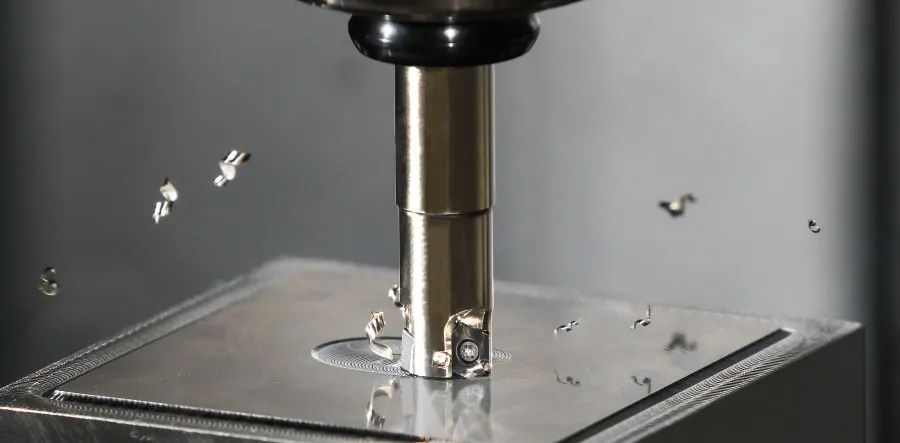

Kuphatikiza zida zapamwamba processing ndi mkulu-ntchito CNC kudula zida angapereke sewero lathunthu kwa ntchito yake chifukwa ndi kupeza ubwino wabwino zachuma. Ndi chitukuko chofulumira cha zida zodulira zida, zida zosiyanasiyana zatsopano zodulira zida zasintha kwambiri thupi lawo, zida zamakina ndi ntchito yodulira, komanso kugwiritsa ntchito kwawo kupitilirabe kukula.

Mapangidwe a zida za CNC?

Zida za CNC (Computer Numerical Control) ndi zida zamakina zomwe zimagwiritsidwa ntchito ndi malamulo okhazikika osungidwa pamalo osungira, monga kompyuta. Zida zimenezi zimagwiritsa ntchito makina oyendetsedwa ndi kompyuta pochita ntchito zolondola kwambiri, monga kudula, kubowola, mphero, ndi kuumba. Zidazi zimagwiritsidwa ntchito popanga, makamaka m'mafakitale monga mlengalenga, magalimoto, zamankhwala, ndi zitsulo.

Zida za CNC zimaphatikizapo makina osiyanasiyana, mongaKusintha kwa CNCmakina, CNCndondomeko ya lathe, CNC routers, CNC plasma cutters, ndi CNC laser cutters. Zida izi zimagwira ntchito posuntha chida chodulira kapena chogwirira ntchito mu nkhwangwa zitatu kapena kupitilira apo pogwiritsa ntchito kuwongolera manambala apakompyuta.

Zida za CNC zimadziwika chifukwa cha kulondola, kulondola, komanso kubwerezabwereza, zomwe zimawapangitsa kukhala abwino popanga magawo ovuta ndi zida zololera zolimba. Amathanso kupanga zinthu zapamwamba kwambiri mwachangu kuposa makina apamanja achikhalidwe, zomwe zimathandizira kukulitsa zokolola komanso zogwira mtima popanga.

Kodi zida za CNC ziyenera kukhala ndi zinthu ziti?

1. Kuuma: Zida za zida za CNC ziyenera kukhala zolimba mokwanira kuti zigonjetse ndi kung'ambika pakupanga makina.

2. Kulimba: Zida za CNC ziyenera kukhala zolimba kuti zisawonongeke komanso kugwedezeka.

3. Kutentha kwa kutentha: Zida za zida za CNC ziyenera kupirira kutentha kwakukulu komwe kumapangidwa panthawi ya makina osataya mphamvu kapena kulimba.

4. Valani kukana: Zida za CNC ziyenera kukhala zosagwirizana ndi kuvala kwa abrasive chifukwa chokhudzana ndi workpiece.

5. Kukhazikika kwa Chemical: Zida za zida za CNC ziyenera kukhala zokhazikika kuti zipewe dzimbiri ndi mitundu ina ya kuwonongeka kwa mankhwala.

6. Kuthekera: Zida za zida za CNC ziyenera kukhala zosavuta kupanga makina ndi mawonekedwe omwe mukufuna.

7. Kutsika mtengo: Zida za zida za CNC ziyenera kukhala zotsika mtengo komanso zotsika mtengo, poganizira momwe zimagwirira ntchito komanso moyo wautali.

Mitundu, katundu, makhalidwe ndi ntchito kudula zida zida

Mtundu uliwonse wazinthu umakhala ndi mawonekedwe ake, mawonekedwe ake, komanso ntchito zake. Nawa zida zodulira wamba, pamodzi ndi katundu ndi ntchito:

1. Chitsulo Chothamanga Kwambiri (HSS):

HSS ndi chida chodulira chomwe chimagwiritsidwa ntchito kwambiri, chopangidwa kuchokera ku chitsulo, tungsten, molybdenum, ndi zinthu zina. Amadziwika chifukwa cha kuuma kwake kwakukulu, kukana kuvala, komanso kulimba, zomwe zimapangitsa kuti zikhale zoyenera kupanga zipangizo zosiyanasiyana, kuphatikizapo zitsulo, zitsulo zotayidwa, ndi mapulasitiki.

2. Carbide:

Carbide ndi chinthu chophatikizika chopangidwa kuchokera ku chisakanizo cha tungsten carbide particles ndi zitsulo zomangira zitsulo, monga cobalt. Amadziwika ndi kuuma kwake kwapadera, kukana kuvala, komanso kukana kutentha, zomwe zimapangitsa kuti zikhale zoyenera kupanga zida zolimba, monga chitsulo chosapanga dzimbiri, chitsulo chosungunuka, ndi ma alloys otentha kwambiri.

3. Ceramic:

Zida zodulira Ceramic zimapangidwa kuchokera kuzinthu zosiyanasiyana za ceramic, monga aluminium oxide, silicon nitride, ndi zirconia. Amadziwika chifukwa cha kuuma kwawo kwakukulu, kukana kuvala, komanso kukhazikika kwa mankhwala, kuwapangitsa kukhala oyenera kupanga zida zolimba komanso zonyezimira, monga zitsulo za ceramic, composites, ndi superalloys.

4. Kiyubiki Boron Nitride (CBN):

CBN ndi chinthu chopangidwa kuchokera ku makhiristo a boron nitride. Amadziwika ndi kuuma kwake kwapadera, kukana kuvala, ndi kukana kutentha, zomwe zimapangitsa kuti zikhale zoyenera kupanga zitsulo zolimba ndi zipangizo zina zomwe zimakhala zovuta kupanga makina pogwiritsa ntchito zida zina zodulira.

5. Daimondi:

Zida zodulira diamondi zimapangidwa kuchokera ku diamondi zachilengedwe kapena zopangidwa. Amadziwika ndi kuuma kwawo kwapadera, kukana kuvala, komanso kukana kutentha, kuwapangitsa kukhala oyenera kupanga zitsulo zopanda chitsulo, zophatikizika, ndi zida zina zolimba komanso zonyezimira.

Palinso chida chapadera chotchedwa chida chophimbidwa.

Nthawi zambiri, zida zomwe zili pamwambazi zimagwiritsidwa ntchito ngati zokutira, ndipo zimagwiritsidwa ntchito kwambiri pazida zamakina za CNC.

Chida chophimbidwa ndi chida chokhala ndi chinthu chochepa kwambiri chomwe chimagwiritsidwa ntchito pamwamba pake kuti chiwongolere ntchito yake ndikuwonjezera moyo wake. Zida zokutira zimasankhidwa kutengera momwe chidacho chimagwiritsidwira ntchito, ndipo zida zokutira wamba zimaphatikizapo titanium nitride (TiN), titanium carboni (TiCN), ndi carbon-ngati diamondi (DLC).

Zopaka zimatha kupititsa patsogolo ntchito ya chida m'njira zosiyanasiyana, monga kuchepetsa kukangana ndi kuvala, kukulitsa kuuma ndi kulimba, komanso kuwongolera kukana dzimbiri ndi kuwonongeka kwa mankhwala. Mwachitsanzo, chobowola chokhala ndi TiN-chokutidwa ndi TiN chimatha kuwirikiza katatu kuposa Chopanda chotchinga, ndipo mphero yotchinga ndi TiCN imatha kudula zida zolimba ndi kuvala pang'ono.

Zida zokutira zimagwiritsidwa ntchito kwambiri m'mafakitale monga kupanga, zakuthambo, magalimoto, ndi zida zamankhwala. Atha kugwiritsidwa ntchito podula, kubowola, mphero, kugaya, ndi ntchito zina zamakina.

Mfundo zosankhidwa za zida za CNC

Kusankhidwa kwa zida za CNC ndizofunikira kwambiri popanga ndi kupanga molondolakutembenuza magawo. Kusankhidwa kwa chida kumatengera zinthu zingapo, kuphatikiza mtundu wazinthu zomwe zimapangidwira, makina opangira, komanso kumaliza komwe akufuna.

Nazi zina mwazosankha za zida za CNC:

1. Kuuma:Zida za chida ziyenera kukhala zolimba kuti zithe kupirira mphamvu ndi kutentha komwe kumapangidwa panthawi ya makina. Kuuma kumayesedwa pa sikelo ya Rockwell C kapena Vickers.

2. Kulimba:Chidacho chiyeneranso kukhala cholimba kuti chisaphwanyeke ndi kusweka. Kulimba kumayesedwa ndi mphamvu yamphamvu kapena kulimba kwa fracture.

3. Kukana kuvala:Chidacho chiyenera kukhala ndi kukana kwabwino kuti chikhalebe chodula komanso kupewa kulephera kwa zida. Kukana kuvala kwa chinthu nthawi zambiri kumayesedwa ndi kuchuluka kwa zinthu zomwe zimachotsedwa ku chida panthawi yopangira makina.

4. Thermal conductivity: Zida zopangira zida ziyenera kukhala ndi matenthedwe abwino otenthetsera kutentha komwe kumapangidwa panthawi yopanga makina. Izi zimathandiza kupewa kulephera kwa zida ndikusunga zolondola kwambiri.

5. Kukhazikika kwa Chemical:Chida chakuthupi chiyenera kukhala chokhazikika kuti chisasunthike ndi zinthu za workpiece.

6. Mtengo:Mtengo wa zida zogwiritsira ntchito ndizofunikanso kuziganizira, makamaka pakupanga kwapamwamba kwambiri.

Zida zomwe zimagwiritsidwa ntchito pazida za CNC zimaphatikizapo carbide, chitsulo chothamanga kwambiri, ceramic, ndi diamondi. Kusankhidwa kwa zida zopangira zida kumadalira momwe makinawo amagwirira ntchito komanso kumaliza komwe akufuna, komanso zida zomwe zimapangidwira komanso zida zomwe zilipo.

1) Zida zodulira zimagwirizana ndi makina a chinthu chopangidwa ndi makina

Kufananiza zida zodulira ndi zida zamakina a chinthu chopangidwa ndi makina ndizofunikira kwambiri pakukonza makina a CNC. Makina a chinthu chopangidwa ndi makina amaphatikiza kuuma kwake, kulimba, ndi ductility, pakati pa ena. Kusankha chida chodulira chomwe chikufanana kapena chogwirizana ndi makina a chinthu chopangidwa ndi makina kumatha kupititsa patsogolo magwiridwe antchito ndi magwiridwe antchito, kuchepetsa kuvala kwa zida, ndikuwongolera gawo lomalizidwa.

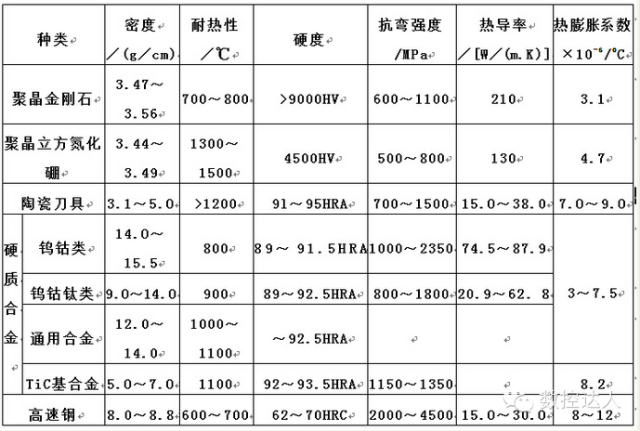

① Dongosolo la kuuma kwa zida ndi: chida cha diamondi> chida cha cubic boron nitride> chida cha ceramic> tungsten carbide>chitsulo chothamanga kwambiri.

② Dongosolo la mphamvu yopindika ya zida za zida ndi: chitsulo chothamanga kwambiri> carbide ya simenti> zida za ceramic> zida za diamondi ndi cubic boron nitride.

③ Dongosolo la kulimba kwa zida za zida ndi: chitsulo chothamanga kwambiri> carbide simenti> kiyubiki boron nitride, diamondi ndi zida za ceramic.

Mwachitsanzo, ngati chinthu chopangidwa ndi makina chimapangidwa ndi zinthu zolimba komanso zowonongeka monga chitsulo cholimba kapena chitsulo, chida chodulira chopangidwa ndi zinthu zolimba komanso zosavala ngati carbide kapena ceramic zingakhale zabwino kwambiri. Zidazi zimatha kupirira mphamvu zodula kwambiri komanso kutentha komwe kumapangidwa popanga makina ndikusunga m'mphepete mwawo lakuthwa kwa nthawi yayitali.

Kumbali ina, ngati chinthu chopangidwa ndi makina chimapangidwa ndi zinthu zofewa komanso zowonjezereka monga aluminiyamu kapena mkuwa, chida chodulira chopangidwa ndi zinthu zolimba monga chitsulo chothamanga kwambiri chingakhale choyenera. Chitsulo chothamanga kwambiri chimatha kuyamwa bwino komanso kugwedezeka pakupanga makina, kuchepetsa chiopsezo cha kusweka kwa zida ndikuwongolera moyo wa zida.

2) Kufananiza zida zodulira ndi mawonekedwe a chinthu chopangidwa ndi makina

Kufananiza zida zodulira ndi zinthu zakuthupi za chinthu chopangidwa ndi makina ndizofunikiranso pakukonza makina a CNC. Mawonekedwe a chinthu chopangidwa ndi makina amaphatikiza matenthedwe ake, kuchuluka kwa matenthedwe, ndi zofunika kumaliza pamwamba, pakati pa ena. Kusankha chida chodulira chomwe chimafanana kapena chogwirizana ndi mawonekedwe a chinthu chopangidwa ndi makina kumatha kusintha magwiridwe antchito, kuchepetsa kuvala kwa zida, ndikuwongolera gawo lomwe lamalizidwa.

① Kutentha kosagwira kutentha kwa zida zosiyanasiyana: 700-8000C pazida za diamondi, 13000-15000C zida za PCBN, 1100-12000C pazida za ceramic, 900-11000C ya TiC(N) yopangidwa ndi simenti ya carbide, ndi 11000C-WC1000C - mbewu za ultrafine Carbide ya simenti ndi 800 ~ 9000C, HSS ndi 600 ~ 7000C.

②Kapangidwe ka matenthedwe a zida zosiyanasiyana: PCD>PCBN>WC-based cemented carbide>TiC(N)-based cemented carbide>HSS>Si3N4-based ceramics>A1203-based ceramics.

③ Dongosolo la kuchuluka kwa matenthedwe a zida zosiyanasiyana ndi: HSS>WC-based cemented carbide>TiC(N)>A1203-based ceramics>PCBN>Si3N4-based ceramics>PCD.

④Kukonzekera kwa kutentha kwamphamvu kwa zida zosiyanasiyana ndi: HSS>WC-based cemented carbide>Si3N4-based ceramics>PCBN>PCD>TiC(N)-based cemented carbide>A1203-based ceramics.

Mwachitsanzo, ngati chinthu chopangidwa ndi makina chimakhala ndi matenthedwe apamwamba, monga mkuwa kapena aluminiyamu, chida chodulira chokhala ndi matenthedwe apamwamba komanso chochepa chochepa cha kuwonjezeka kwa kutentha chingakhale chisankho chabwino kwambiri. Izi zimathandiza kuti chidacho chiwononge kutentha bwino panthawi yopangira makina komanso kuchepetsa chiopsezo cha kuwonongeka kwa kutentha kwa chida ndi chinthu chopangidwa ndi makina.

Mofananamo, ngati chinthu chopangidwa ndi makina chili ndi zofunikira zomaliza pamwamba, chida chodulira chokhala ndi kukana kovala kwambiri komanso kocheperako kocheperako kungakhale chisankho chabwino kwambiri. Izi zitha kuthandiza kukwaniritsa zomwe mukufuna kumaliza popanda kugwiritsa ntchito zida zambiri kapena kuwonongeka kwa chinthu chopangidwa ndi makina.

3) Kufananiza zida zodulira ndi mankhwala a chinthu chopangidwa ndi makina

Kufananiza zida zodulira ndi zida zamakina a chinthu chopangidwa ndi makina ndizofunikiranso pakukonza makina a CNC. Zomwe zimapangidwa ndi chinthu chopangidwa ndi makina zimaphatikizanso kuchitapo kanthu, kukana kwa corrosion, komanso kapangidwe kake, pakati pa ena. Kusankha chida chodulira chomwe chimafanana kapena chogwirizana ndi mankhwala a chinthu chopangidwa ndi makina kumatha kusintha magwiridwe antchito, kuchepetsa kuvala kwa zida, ndikuwongolera gawo lomwe lamalizidwa.

Mwachitsanzo, ngati chinthu chopangidwa ndi makina chimapangidwa ndi zinthu zowonongeka kapena zowonongeka monga titaniyamu kapena chitsulo chosapanga dzimbiri, chida chodulira chopangidwa ndi zinthu zosagwira dzimbiri monga diamondi kapena PCD (polycrystalline diamondi) chingakhale chisankho chabwino kwambiri. Zidazi zimatha kupirira malo owononga kapena otakasuka ndikusunga nsonga zake zakuthwa kwa nthawi yayitali.

Mofananamo, ngati chinthu chopangidwa ndi makina chimakhala ndi mankhwala ovuta, chida chodula chopangidwa ndi zinthu zomwe zimakhala zokhazikika komanso zopanda mphamvu, monga diamondi kapena cubic boron nitride (CBN), zingakhale zabwino kwambiri. Zida izi zimatha kupewa kukhudzidwa kwa mankhwala ndi zida zogwirira ntchito ndikusunga magwiridwe antchito awo pakapita nthawi.

① Kutentha kwa anti-bonding kwa zida zosiyanasiyana (ndi chitsulo) ndi: PCBN>ceramic>hard alloy>HSS.

② The makutidwe ndi okosijeni kukana kutentha kwa zipangizo zosiyanasiyana zida ndi motere: ceramic> PCBN> tungsten carbide> diamondi> HSS.

③Kuphatikizika kwamphamvu kwa zida (zachitsulo) ndi: diamondi>Si3N4-based ceramics>PCBN>A1203-based ceramics. Kuchuluka kwamphamvu (kwa titaniyamu) ndi: A1203-based ceramics>PCBN>SiC>Si3N4>diamondi.

4) Kusankhidwa koyenera kwa zida zodulira za CNC

Kusankhidwa kwa zida zodulira za CNC kumadalira zinthu zosiyanasiyana monga zida zogwirira ntchito, makina opangira makina, ndi geometry ya zida. Komabe, malangizo ena onse posankha zida zodulira makina a CNC ndi monga:

1. Zakuthupi za workpiece: Ganizirani za makina, thupi, ndi mankhwala a workpiece posankha chida chodulira. Gwirizanitsani zida zodulira ndi zida zogwirira ntchito kuti mukwaniritse makina abwino komanso apamwamba kwambiri.

2. Makina opangira makina: Ganizirani za mtundu wa makina omwe akuchitidwa, monga kutembenuza, mphero, kubowola, kapena kugaya. Zosiyanasiyana Machining ntchito amafuna osiyana kudula zida geometries ndi zipangizo.

3. Chida cha geometry: Ganizirani chida chodulira geometry posankha chida. Sankhani zinthu zomwe zimatha kukhalabe lakuthwa lakuthwa ndikupirira mphamvu zodulira zomwe zimapangidwa panthawi yopangira makina.

4. Kuvala kwa zida: Ganizirani kuchuluka kwa mavalidwe a zida posankha zida zodulira. Sankhani zinthu zomwe zimatha kupirira mphamvu zodulira ndikukhalabe lakuthwa kwake kwanthawi yayitali kuti muchepetse kusintha kwa chida ndikuwongolera magwiridwe antchito.

5. Mtengo: Ganizirani mtengo wa zida zodulira posankha chida. Sankhani zinthu zomwe zimapereka njira yabwino kwambiri yochepetsera ntchito komanso mtengo wake.

Zida zina zodulira zomwe zimagwiritsidwa ntchito muCNC makinazikuphatikizapo mkulu-liwiro zitsulo, carbide, ceramic, diamondi, ndi CBN. Chilichonse chili ndi ubwino ndi zovuta zake, ndipo kusankha kwa chidacho chiyenera kukhazikitsidwa pa kumvetsetsa bwino kwa makina opangira makina ndi zida zogwirira ntchito.

Zofuna zamuyaya za Anebon ndi malingaliro a "msika, samalani mwambo, samalani sayansi" ndi chiphunzitso cha "khalidwe loyambira, khulupirirani woyamba ndikuyang'anira zotsogola" zogulitsa zotentha za Factory OEM Service High Precision CNC Machining magawo a automation. mafakitale, mawu a Anebon pakufunsa kwanu. Kuti mumve zambiri, chonde lemberani, Anebon adzakuyankhani ASAP!

Hot zogulitsa Factory China 5 olamulira cnc Machining mbali, CNC anatembenuza mbali ndi mphero mkuwa mbali. Takulandilani kudzayendera kampani yathu, fakitale ndi chipinda chathu chowonetsera komwe kumawonetsa malonda osiyanasiyana atsitsi omwe angakwaniritse zomwe mukuyembekezera. Pakadali pano, ndikosavuta kukaona tsamba la Anebon, ndipo ogulitsa ku Anebon ayesetsa momwe angathere kuti akupatseni ntchito yabwino kwambiri. Chonde lemberani Anebon ngati mukufuna kudziwa zambiri. Cholinga cha Anebon ndikuthandiza makasitomala kuzindikira zolinga zawo. Anebon akhala akuyesetsa kwambiri kuti akwaniritse izi.

Nthawi yotumiza: Mar-08-2023