Kodi mumadziwa bwanji za gulu la zida zamakina a CNC?

Gulu la zida zamakina a CNC zimatengera ntchito, kapangidwe kake ndi kugwiritsa ntchito.

Tsopano tiwona magulu osiyanasiyana:

Kutengera Ntchito

Makina osinthira:Makinawa amagwira ntchito makamaka potembenuza zigawo za cylindrical kapena conical.

Makinawa atha kugwiritsidwa ntchito mphero zafulati kapena zovuta.

Zotengera Kapangidwe

Horizontal Machining Centers:Spindle ndi workpiece zimayikidwa mopingasa patebulo.

Oyima Machining Center:Spindle ndi workpiece zimayikidwa molunjika patebulo.

Makina a Multi-axis:Makinawa ali ndi nkhwangwa zingapo (3 kapena kuposerapo), zomwe zimawalola kuti azigwira ntchito moyenera komanso movutikira.

Kutengera ndi Application

Makina obowola ndi makina omwe amagwira ntchito kwambiri pobowola.

Makina opukutira:Makinawa amatha kugwiritsidwa ntchito popera ndi kupukuta zitsulo.

Makina Odulira Laser:Ukadaulo wa laser umagwiritsidwa ntchito kudula zida zosiyanasiyana.

Makina Otulutsa Electro-Discharge (EDM):Makinawa amapanga ndikubowola zinthu zamagetsi zamagetsi.

Njira zogawira makina a CNC ndizosiyana. Pali mitundu yambiri ndi mafotokozedwe. Ikhoza kugawidwa pogwiritsa ntchito njira zamagulu pamwambapa, komanso mfundo zinayi za ntchito ndi kapangidwe.

1. Gulu la zida zamakina molingana ndi njira yawo yowongolera

1) Makina owongolera a CNC

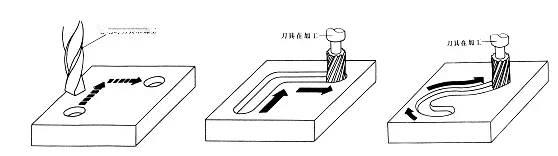

Chofunikira chokha pakuwongolera mfundo ndikuyika bwino magawo osuntha kuchokera ku chida china kupita ku china. Zofunikira za trajectory pakati pa mfundo zoyenda sizili zovuta kwambiri. Panthawi yosuntha, palibe kukonza komwe kumachitika. Sikofunikira momwe kayendetsedwe kake kakuchitikira pakati pa ogwirizanitsa aliyense. Kuti mukwaniritse malo olondola komanso ofulumira, ndikofunikira kuti muyambe kusuntha mtunda pakati pa mfundo ziwiri mwachangu, kenako pang'onopang'ono mufikire malowo kuti mutsimikizire kulondola. Njira yoyendetsera ikuwonetsedwa pansipa.

CNC makina mphero ndi CNC kukhomerera makina ndi zitsanzo za zida makina amene ali ndi mphamvu kulamulira mfundo. Machitidwe a CNC omwe amagwiritsidwa ntchito pongowongolera mfundo akhala osowa chifukwa cha kupita patsogolo kwaukadaulo wa CNC.

(2) Liniya ulamuliro CNC makina zida

Parallel control CNC makina amadziwikanso kuti makina owongolera a CNC. Lili ndi khalidwe lomwe silimangoyang'anira malo enieni pakati pa mfundo komanso kuthamanga kwa kuyenda ndi njira (trajectory), pakati pa mfundo ziwiri. Kuyenda kwake kumagwirizana kokha ndi zida zamakina zomwe zimagwirizanitsa nkhwangwa zikuyenda mofanana. Izi zikutanthauza kuti mgwirizano umodzi wokha umayang'aniridwa panthawi imodzi. Chidacho chingagwiritsidwe ntchito kudula pa mlingo wa chakudya chomwe chatchulidwa panthawi yosuntha. Itha kugwiritsidwa ntchito pokonza zigawo zamakona anayi komanso zopondapo.

Zithunzi za CNCndi ulamuliro liniya makamaka CNC mphero makina ndi CNC grinders. Makina a CNC a chida ichi amadziwikanso kuti makina owongolera a CNC. Momwemonso, makina a CNC omwe amagwiritsidwa ntchito poyang'anira mizere ndi osowa.

(3) Zipangizo zamakina a 3D CNC

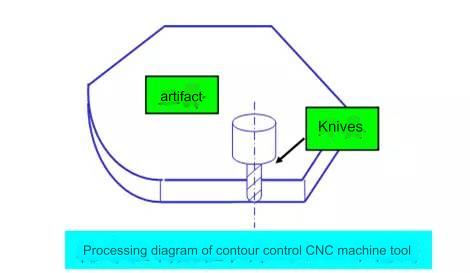

Kuwongolera mosalekeza makina a CNC amadziwikanso ngati makina owongolera a CNC. Chiwongolero cha makinawa ndikutha kuwongolera maulendo awiri kapena kuposerapo nthawi imodzi.

Kuwonetsetsa kuti kusuntha kwa chida pa contour ya workpiece kumagwirizana ndi makina opanga makina a workpiece, m'pofunika kugwirizanitsa molondola kusuntha ndi kuthamanga kwa kayendetsedwe kake kogwirizana malinga ndi mgwirizano wogwirizana.

Kuti mugwiritse ntchito njira yowongolera iyi, chipangizo cha CNC chiyenera kukhala ndi ntchito yomasulira. Kutanthauzira kumatanthawuza mawonekedwe a mzere wowongoka kapena arc pogwiritsa ntchito masamu opangidwa ndi omasulira mu CNC system. Izi zimachokera ku deta yoyambira yomwe yalowetsedwa ndi pulogalamuyo, monga ma coordinates a mapeto a mzere wowongoka, makonzedwe a mapeto a arc, kapena radius kapena center coordinate. Pamene mukuwerengera, perekani ma pulses kwa wolamulira aliyense wa coordinate axis malinga ndi zotsatira. Izi zimayang'anira kusamuka kwamalumikizidwe kwa kontrakitala iliyonse kuti igwirizane ndi mizere yomwe mukufuna. Pakusuntha, chidacho chimadula mosalekeza pamwamba pa chogwiriracho, chomwe chimalola kukonza kosiyanasiyana monga mizere yowongoka, ma curve, ndi ma arcs. Njira yoyendetsera makina ozungulira.

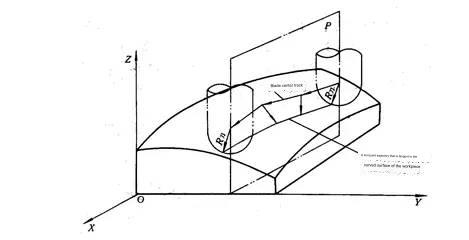

Zida zamakinazi zimaphatikizapo makina a CNC ndi mphero komanso makina odulira mawaya a CNC, malo opangira makina, ndi zina zambiri. Zida za CNC zomwe zimagwirizana nazo zimatchedwa makina owongolera ma contour. Itha kugawidwa m'mitundu itatu kutengera kuchuluka kwa nkhwangwa zomwe imawongolera: mawonekedwe

1 maulalo amitundu iwiri:ntchito makamaka CNC lathes kuti ndondomeko kasinthasintha pamalo, kapena CNC mphero makina kuti cylindrical pamalo yopindika.

2 Semi-linkage 2 nkhwangwa:Izi zimagwiritsidwa ntchito makamaka pakuwongolera zida zamakina zomwe zili ndi nkhwangwa zopitilira 3. Nkhwangwa ziwiri zitha kulumikizidwa ndipo olamulira achitatu amatha kudyetsa nthawi ndi nthawi.

3 Kulumikizana kwamagulu atatu:Izi ndi kugwirizana kuti kumaphatikizapo nkhwangwa atatu liniya kugwirizana, kawirikawiri X/Y/Z, ndipo amagwiritsidwa ntchito ndi CNC mphero makina, malo makina, etc. Mtundu wachiwiri amalola kulamulira awiri liniya zikugwirizana nthawi imodzi mu X/Y/Z, monga komanso mizere yolumikizira yomwe imazungulira mozungulira mizere yolumikizira.

Pamalo otembenuza makina, mwachitsanzo, kulumikizana pakati pa mizere iwiri yolumikizira mizere (X-axis ndi Z-axis mu utali wozungulira) kuyenera kuyendetsedwa nthawi imodzi ndi kulumikizana ndi spindle's (C-axis), yomwe imazungulira kuzungulira Z axis. .

4 Kulumikizana kwa Four-axis:Sinthani mizere itatu yolumikizira X, Y ndi Z nthawi imodzi kuti ilumikizidwe ndi m'mphepete umodzi wozungulira.

5 Kulumikizana kwa ma axis asanu:Izi zimakupatsani mwayi wowongolera kulumikizana kwa nkhwangwa zitatu nthawi imodzi, X/Y/Z. Chidachi chimawongoleranso nthawi imodzi ma AB ndi C amagwirizanitsa nkhwangwa zomwe zimazungulira ma nkhwangwawa. Izi zimapereka chiwerengero cha nkhwangwa zisanu. Chidachi tsopano chikhoza kukhazikitsidwa paliponse mumlengalenga.

Chidacho chikhoza kuyendetsedwa kuti chizizungulira mozungulira ma ax ndi y nthawi imodzi, kotero nthawi zonse chimadula mbali imodzi ya contour. Izi zimatsimikizira kusalala ndi kulondola kwa pamwamba. Pamwamba pamakina ndi osalala, ndikuwonjezera magwiridwe antchito.

2. Gulu la machitidwe olamulidwa ndi servo

1) Zida zamakina otsegula a CNC

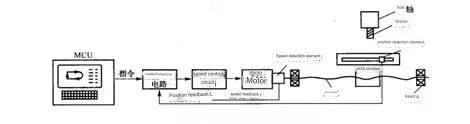

Chida chamtundu woterechi chimakhala ndi servo yotseguka, zomwe zikutanthauza kuti palibe chida chowunikira mayankho. Makina ake oyendetsa nthawi zambiri amakhala stepper. Chofunikira chachikulu cha mota ya stepper ndikuti imazungulira gawo lonse nthawi iliyonse pomwe makina owongolera amasintha ma pulse. Galimoto ili ndi chinthu chodzitsekera chokha ndipo chingagwiritsidwe ntchito kusintha mtunda wautali.

Wogawa ma pulse amawongolera mayendedwe oyendetsa pogwiritsa ntchito chizindikiro cha chakudya chochokera ku CNC system. Chiwerengero cha ma pulses ndi ma pulse frequency amatha kusinthidwa kuti athe kuwongolera kusamutsidwa, kuthamanga kwakusamuka, kapena kusamuka. malangizo.

Mbali yaikulu ya njirayi ndi yosavuta, yosavuta kugwiritsa ntchito, komanso yotsika mtengo. Palibe vuto losakhazikika ndi dongosolo lolamulira chifukwa dongosolo la CNC limangotumiza zizindikiro za njira imodzi. Kulondola kwa kusamukako kumakhala kochepa, komabe, chifukwa cholakwika cha makina opatsirana sichikukonzedwa kudzera mu ndemanga.

Njira yowongolerayi idagwiritsidwa ntchito ndi makina onse oyambirira a CNC, koma inali ndi kulephera kwakukulu. Ngakhale kusintha kwa mabwalo oyendetsa galimoto, njira yoyendetserayi imagwiritsidwabe ntchito kwambiri masiku ano. Njira yowongolera iyi, makamaka m'dziko lathu imagwiritsidwa ntchito pamakina onse a CNC omwe ndi azachuma komanso kusintha zida zakale pogwiritsa ntchito CNC. Njira yowongolera iyi imalolanso kompyuta yachip imodzi kapena kompyuta imodzi yokha kukhazikitsidwa ngati makina a CNC, omwe amachepetsa mtengo wadongosolo.

Zida zamakina zokhala ndi zowongolera zotsekeka

Mtundu uwu wa CNC makina chida amagwiritsa ntchito chatsekedwa- kuzungulira. Magalimoto agalimoto amatha kukhala DC kapena AC ndipo amayenera kukhala ndi mayankho komanso kuthamanga kwamayendedwe kuti azindikire kusuntha kulikonse kwa gawo lomwe likusuntha nthawi iliyonse pakukonza. Dongosolo la CNC limadyetsa ndalamazo mu nthawi yeniyeni kwa wofananira. Chizindikiro cholamula chimapezeka kudzera mukutanthauzira ndikuyerekeza ndi kuchuluka kwake. Kusiyanaku kumagwiritsidwa ntchito kuwongolera servodrive, yomwe imayendetsa gawo losamuka kuti lithetse cholakwikacho.

Kutengera malo ndi chipangizo choyankha cha chojambulira chaposachedwa, pali mitundu iwiri: loop yotsekedwa (yodzaza) ndi loop yotsekedwa (yotsekeka).

1 Kuwongolera kotseka kotseka

Chida chofotokozera malo, monga momwe chikuwonetsedwera pachithunzichi chimagwiritsa ntchito chinthu chodziwira mtunda wa mzere. (Pakadali pano, lamulo la grating limagwiritsidwa ntchito kwambiri) Izi zimayikidwa pa chishalo cha chida cha makina. Imazindikira mwachindunji kusamutsidwa kwa mzere muzogwirizanitsa zida zamakina. Chizindikiro chochokera ku mota chimatha kuthetsedwa kudzera mu ndemanga. Zolakwika zopatsirana zimachepetsedwa pamakina otengera makina, zomwe zimapangitsa kuti makinawo azikhala olondola kwambiri poyimitsa makinawo.

Kuyankha kwamphamvu kwa makina otumizirana mawotchi onse ndiatali kwambiri kuposa kuyankha kwamagetsi. Dongosolo lonse lotsekeka lotsekeka ndizovuta kwambiri kukhazikika, ndipo mapangidwe ake ndikusintha kwake ndizovuta kwambiri. Izi zotsekedwa- kuzungulira njira ya ulamuliro ntchito makamaka kwa CNC kugwirizanitsa makina, CNC mwatsatanetsatane akupera makina, etc. Amene amafuna mwatsatanetsatane mkulu.

2 Semi-otsekedwa loop control

Ndemanga za malo zimatengera magawo omwe amazindikira ma angle, omwe pakadali pano amakhala ma encoder. Ma servo motors kapena zomangira zimakhala ndi zida zozindikira ma angle (makamaka ma encoder). Makhalidwe olamulira a dongosololi ndi okhazikika chifukwa maulalo ambiri otengera makinawa sali munjira yotsekedwa. Kulipiridwa kwa mtengo wokhazikika wa pulogalamu kumatha kuwongolera zolakwika zamakina, monga zolakwika za screw. Makina ambiri a CNC amagwiritsa ntchito njira yotsekeka yotsekeka.

3 Dimensional hybrid control CNC makina

Kuti mupange dongosolo lowongolera la haibridi, mawonekedwe a njira iliyonse yowongolera amatha kukhazikika mwa kusankha. Pofuna kukwaniritsa zofunikira za zida zina zamakina ndikulipira kusiyana pakati pa njira ziwirizi, tikulimbikitsidwa kuti pakhale ndondomeko yolamulira yosakanizidwa. Njira ziwiri zodziwika bwino ndi mtundu wamalipiro wotseguka-lupu ndi mtundu wolipiritsa wotsekeka.

3. CNC Systems mgulu malinga ndi ntchito mlingo wawo

Machitidwe a CNC amagawidwa m'magulu atatu kutengera momwe amagwirira ntchito: otsika, apakati, ndi apamwamba. Njira iyi yamagulu imagwiritsidwa ntchito kwambiri m'dziko lathu. Miyezo yamagulu ndi yosiyana kuchokera ku nthawi imodzi kupita ku ina. Malingana ndi msinkhu wamakono wa chitukuko, mitundu yosiyanasiyana ya machitidwe a CNC amagawidwa m'magulu atatu kutengera ntchito zina ndi zizindikiro. Sing'anga ndi mkulu-mapeto kachitidwe CNC nthawi zambiri amatchedwa zonse ntchito kapena muyezo CNC.

(1) Kudula Zitsulo

Amatanthauza makina a CNC omwe amagwira ntchito zosiyanasiyana zodula mongacnc kutembenuka & mphero. Izi zikhoza kugawidwa m'magulu awiri akuluakulu.

CNC makina monga lathes ndi makina mphero.

Mbali yaikulu ya malo opangira makina ndi laibulale yake ya zida, yomwe ili ndi makina osinthira zida. Imangodutsa chogwirira ntchito pamakina kamodzi. Pambuyo clamping workpiece, zida kudula m'malo basi. Njira zosiyanasiyana, kuphatikizapo mphero (kutembenuka), makiyi, kubwezeretsa (kubowola), ndi kujambula kwa ulusi kumachitidwa mosalekeza pamtunda uliwonse wa chidutswa pamakina omwewo, mwachitsanzo, (kumanga / mphero). Center, potembenukira pakati, pobowola, etc.

(2) Chitsulo Forming

Amatanthauza makina CNC kuti ntchito extrusion, kukhomerera ndi kukanikiza, komanso kujambula, ndi zina kupanga ntchito. Ena mwa makina ambiri ntchito CNC monga CNC osindikizira ndi CNC chitoliro benders.

(3) Gulu la Special Processing

CNC waya EDM makina ndi ambiri, kutsatiridwa ndicnc kudula zitsulomakina ndi CNC laser processing makina.

(4) Kuyeza ndi kujambula

Zomwe zili m'gululi ndi zida zoyezera zamitundu itatu, zoseta zida za CNC, zopanga za CNC, ndi zina zambiri.

Cholinga chachikulu cha Anebon chikhala kukupatsirani ogula athu ubale wamphamvu komanso wodalirika wamabizinesi, kupereka chisamaliro chaumwini kwa onse a New Fashion Design forOEM Shenzhen Precision Hardware Factory Custom Fabrication.Kusintha kwa CNCndondomeko, kuponya mwatsatanetsatane, ntchito ya prototyping. Mutha kupeza mtengo wotsika kwambiri pano. Komanso mupeza zinthu zabwino ndi mayankho ndi ntchito zabwino pano! Osazengereza kugwira Anebon!

Mapangidwe Atsopano Amakono a China CNC Machining Service ndi Custom CNC Machining Service, Anebon ili ndi nsanja zingapo zamalonda zakunja, zomwe ndi Alibaba,Globalsources,Global Market,Made-in-china. "XinGuangYang" mankhwala amtundu wa HID ndi mayankho amagulitsidwa bwino kwambiri ku Europe, America, Middle East ndi zigawo zina zopitilira 30.

Nthawi yotumiza: Oct-06-2023