Zofunikira za zida zamakina a CNC pazida zida

High kuuma ndi kuvala kukana

Kuuma kwa gawo lodula la chida kuyenera kukhala kokulirapo kuposa kuuma kwa zida zogwirira ntchito. Pamwamba kuuma kwa zida za chida, ndi bwino kukana kuvala kwake. Kuuma kwa zida za chipangizo kutentha kutentha kuzikhala pamwamba pa HRC62. Kuuma kumatha kukhala kokwera kuposa kwa wambaCNC Machining magawo.

Mphamvu zokwanira ndi kulimba

Chidacho chimanyamula kukakamizidwa kwambiri podula kwambiri. Nthawi zina, zimagwira ntchito pansi pa zovuta komanso kugwedezeka. Kuti chida chitha kusweka ndi kusweka, chidacho chiyenera kukhala ndi mphamvu zokwanira komanso zolimba. Nthawi zambiri, mphamvu yopindika imagwiritsidwa ntchito kuyimira mphamvu ya chidacho, ndipo mtengo wake umagwiritsidwa ntchito pofotokoza kulimba kwa chidacho.

kukana kutentha kwambiri

Kukana kutentha kumatanthawuza kugwira ntchito kwa zida zothandizira kuti zikhale zolimba, kukana kuvala, mphamvu, ndi kulimba pansi pa kutentha kwakukulu. Ndichizindikiro chotsogolera kuyesa ntchito yodula zida za zida. Ntchitoyi imatchedwanso kuuma kofiira kwa zida za zida.

Zabwino matenthedwe madutsidwe

Kuchuluka kwa matenthedwe a zida za chida, kutentha kwambiri kumasamutsidwa kuchokera ku chida, chomwe chimathandizira kuchepetsa kutentha kwa chida ndikuwongolera kukhazikika kwake.

Good processability

Kuti atsogolere chida processing ndi kupanga, zida zipangizo ayenera kukhala ndi katundu wabwino processing, monga forging, anagubuduza, kuwotcherera, kudula ndi grindability, katundu kutentha kutentha, ndi mkulu-kutentha pulasitiki mapindikidwe katundu zipangizo zida. Zida zomangira simenti ndi zida za ceramic zimafunikiranso zinthu zabwino zopangira sintering komanso kupanga mphamvu.

Mtundu wa zida zothandizira

zitsulo zothamanga kwambiri

Chitsulo chothamanga kwambiri ndi chitsulo cha alloy chopangidwa ndi W, Cr, Mo, ndi zinthu zina za alloy. Iwo ali mkulu matenthedwe bata, mphamvu, toughness, ndi mlingo wina wa kuuma ndi kuvala kukana, kotero ndi oyenera pokonza sanali ferrnonferrous ndi zipangizo zosiyanasiyana zitsulo. Komanso, chifukwa phokoso processing luso, ndi abwino kupanga zida zovuta kupanga, makamaka ufa zitsulo mkulu-liwiro zitsulo, amene ali anisotropic mawotchi katundu ndi kuchepetsa quenching mapindikidwe; ndizoyenera kupanga zida zolondola komanso zovuta kupanga.

Chitsulo cholimba

Carbide yokhala ndi simenti imakhala yolimba kwambiri komanso kukana kuvala. Pamene kudulaCNC kutembenuza magawo, ntchito yake ndi yabwino kuposa zitsulo zothamanga kwambiri. Kulimba kwake kumakhala kangapo mpaka kambirimbiri kuposa chitsulo chothamanga kwambiri, koma kulimba kwake ndikosavuta. Chifukwa cha ntchito yake yabwino yodula, imagwiritsidwa ntchito kwambiri ngati chida.

Kugawa ndi kuyika chizindikiro cha ma carbides opangidwa ndi simenti pazida zodulira

Chokutidwa ndi tsamba

1) Zida zokutira za njira ya CVD ndi TiC, zomwe zimawonjezera kulimba kwa zida za carbide zokhala ndi simenti nthawi 1-3. Makulidwe a zokutira: M'mphepete mwake ndi wosamveka komanso wothandiza kupititsa patsogolo moyo wothamanga.

2) Zida zokutira za njira ya PVD yoyika nthunzi ndi TiN, TiAlN, ndi Ti (C, N), zomwe zimathandizira kulimba kwa zida za carbide zokhala ndi simenti nthawi 2-10. Chophimba chochepa; Mphepete yakuthwa; Ndizothandiza kuchepetsa mphamvu yodulira.

★ makulidwe apamwamba a zokutira ≤ 16um

CBN ndi PCD

Cubic boron nitride (CBN) Kulimba ndi kutenthedwa kwa machubiki a boron nitride (CBN) ndizotsika poyerekeza ndi diamondi, ndipo zimakhala ndi kutentha kwakukulu komanso kukhazikika kwamankhwala. Choncho, ndi oyenera Machining zitsulo zolimba, chitsulo cholimba, superalloy, ndi simenti carbide.

Polycrystalline diamondi (PCD) PCD ikagwiritsidwa ntchito ngati chida chodulira, imayikidwa pa simenti ya carbide. Itha kutsiriza kusamva kuvala, kuuma kwakukulu, zopanda zitsulo, komanso zopanda chitsulo monga carbide yoyimitsidwa, zoumba, ndi aloyi wapamwamba wa silicon aluminium.

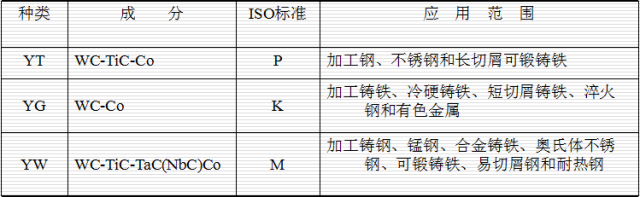

★ ISO machine clamp blade material classification ★

Zigawo zachitsulo: P05 P25 P40

Chitsulo chosapanga dzimbiri: M05 M25 M40

Chitsulo chachitsulo: K05 K25 K30

★ Nambala yaying'ono imakhala yovuta kwambiri, tsambalo limakhala lovuta kwambiri, ndi bwino kukana kuvala kwa chidacho, ndipo kukana kwamphamvu kumakhala koipitsitsa.

★ Nambala ikakulirakulira, mpeniwo umakhala wofewa, ndiye kuti chidacho chimagwira ntchito bwino komanso kuti chisamavale bwino.

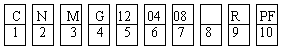

Imasinthidwa kukhala blade model ndi malamulo oyimira ISO

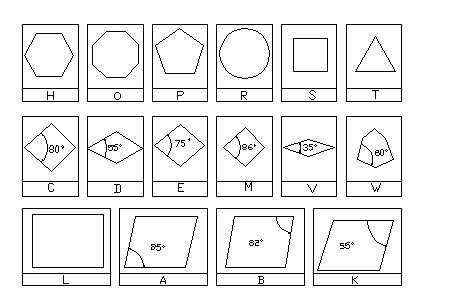

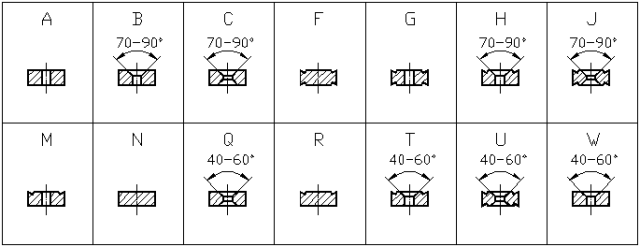

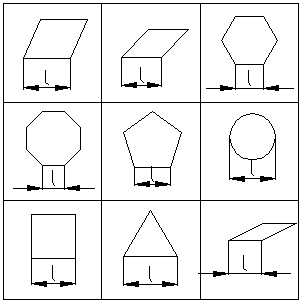

1. Khodi yoyimira mawonekedwe a tsamba

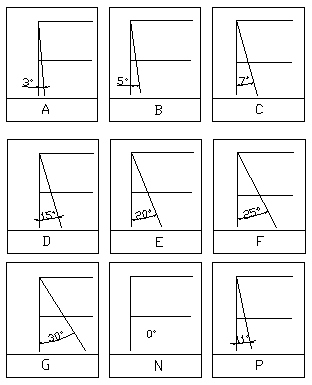

2. Khodi yoyimira mbali yakumbuyo ya tsogolo lodulira

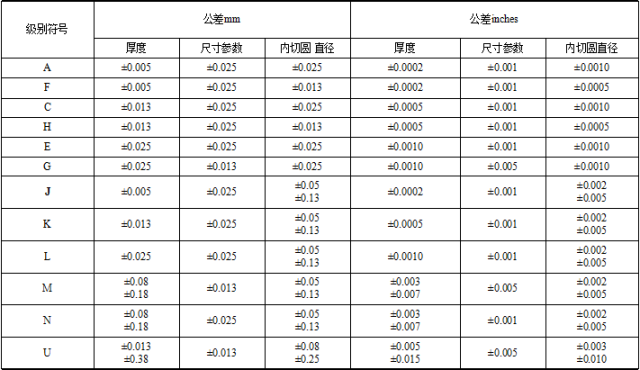

3. Code yoyimira kulolerana kwamtundu wa tsamba

4. Khodi yoyimira kuthyoka kwa chip ndi kutsekereza mawonekedwe a tsamba

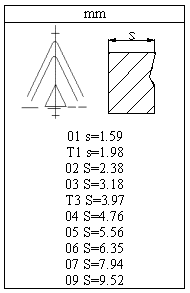

5. Kuyimiridwa ndi kutalika kwa kudula

6. Khodi yoyimira makulidwe a tsamba

7. Khodi yoyimira m'mphepete mwa kupukuta ndi ngodya ya R

Tanthauzo la ziwerengero zina

Eyiti imatanthawuza chikalata chosonyeza zosowa zapadera;

9 imayimira ndondomeko ya chakudya; mwachitsanzo, kachidindo R kakuyimira chakudya choyenera, kachidindo L amaimira chakudya chakumanzere, ndipo code N imayimira chakudya chapakati;

10 imayimira mtundu wa chip breaking groove;

11 imayimira ma code a kampani ya zida;

kudula liwiro

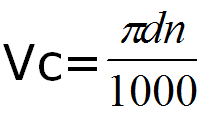

Kuwerengera kwa liwiro la Vc:

Mu formula:

D - kuzungulira kozungulira kwa workpiece kapena chida, unit: mm

N - liwiro lozungulira la chogwirira ntchito kapena chida, gawo: r/min

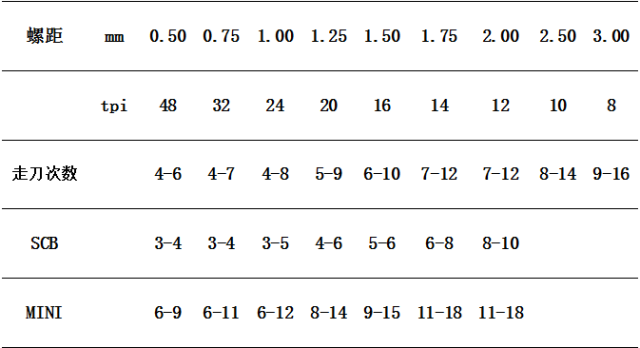

Kuthamanga kwa Machining Thread ndi Ordinary Lathe

Liwiro la spindle n potembenuza ulusi. Podula ulusi, liwiro la spindle la lathe limakhudzidwa ndi zinthu zambiri, monga kukula kwa ulusi (kapena lead) wa chogwirira ntchito, kukweza ndi kutsitsa kwa injini yoyendetsa, komanso kuthamanga kwa kumasulira kwa ulusi. Choncho, kusiyana kwapadera kulipo pa liwiro la spindle la ulusi wokhotakhota pamakina osiyanasiyana a CNC. Zotsatirazi ndi njira yowerengera liwiro la spindle potembenuza ulusi pazitsulo za CNC:

Mu formula:

P - phula kapena ulusi wa ulusi wa workpiece, unit: mm.

K - inshuwaransi coefficient, nthawi zambiri 80.

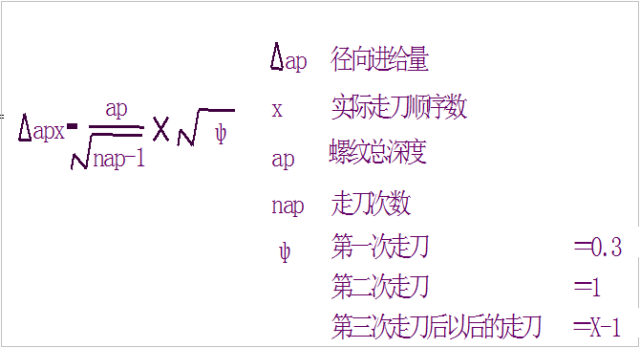

Kuwerengera kwa kuya kwa chakudya chilichonse pakupanga ulusi

Chiwerengero cha njira zopangira ulusi

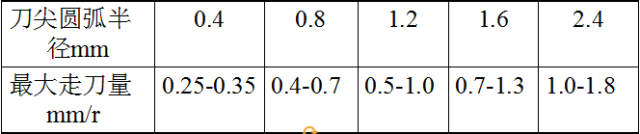

1) Makina osavuta

Njira yowerengetsera yamphamvu ya chakudya chamakina ovuta: f rough=0.5 R

Kumene: R ------ nsonga ya chida arc radius mm

F ------ akhama Machining chida chakudya mm

2) Kumaliza

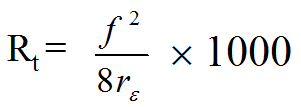

Mu chilinganizo: Rt ------ kuya kwa contour µ m

F ------ Mulingo wa chakudya mm/r

r ε ------ Radius ya tooltip arc mm

Siyanitsani kutembenuka kwaukali ndi komaliza molingana ndi kuchuluka kwa chakudya ndi chip-breaking groove

F ≥ 0,36 makina ovuta

0.36 > f ≥ 0.17 theka-kumaliza

F < 0.17 kumaliza kukonza

Sizinthu za tsamba koma chip-breaking groove chomwe chimakhudza makina okhwima ndi omaliza a tsamba. Mphepete mwake ndi yakuthwa ngati chamfer ndi yosakwana 40um.

Nthawi yotumiza: Nov-29-2022