1. Benchmark

Magawowa amakhala ndi malo angapo, iliyonse ili ndi kukula kwake komanso zofunikira zofananira. Zomwe zimafunikira pakati pa mawonekedwe a zigawozo zikuphatikizapo mbali ziwiri: mtunda wamtunda wolondola pakati pa malo ndi malo olondola (monga coaxiality, parallelism, perpendicularity ndi circular runout, etc.) zofunika. Kuphunzira kwa ubale wapamalo pakati pa malo a zigawozo sikungasiyanitsidwe ndi datum, ndipo malo a gawolo sangadziwike popanda datum yomveka bwino. M'lingaliro lake lonse, datum ndi mfundo, mzere, ndi pamwamba pa mbali yomwe imagwiritsidwa ntchito kudziwa malo a mfundo zina, mizere, ndi malo. Malinga ndi ntchito zawo zosiyanasiyana, benchmarks akhoza kugawidwa m'magulu awiri: benchmarks kapangidwe ndi ndondomeko benchmarks.

1. Kupanga maziko

Datum yomwe imagwiritsidwa ntchito pozindikira mfundo zina, mizere ndi mawonekedwe pagawo lojambulira imatchedwa design datum. Kwa pisitoni, mapangidwe apangidwe amatanthauza pakati pa pisitoni ndi pakati pa dzenje la pini.

2. Njira yoyezera

Datum yomwe imagwiritsidwa ntchito ndi magawo popanga makina ndi kusonkhanitsa amatchedwa process datum. Malinga ndi magwiritsidwe osiyanasiyana, ma benchmarks amagawidwa m'ma benchmarks, ma benchmarks ndi ma benchmarks.

1) Positioning Datum: Datum yomwe imagwiritsidwa ntchito kuti chogwirira ntchitocho chizikhala pamalo oyenera mu chida cha makina kapena chosinthira pakukonza chimatchedwa datum positioning. Malinga ndi magawo osiyanasiyana oyika, omwe amagwiritsidwa ntchito kwambiri ndi magulu awiri awa:

Kuyika pakati ndi malo: monga kuyika kwa nsagwada zitatu.

Kuyika kwa manja: Choyikapo chimapangidwa kukhala manja oyika, monga kuyimika kwa mbale yoyimitsa.

Zina zimaphatikizapo kuyika mu chimango chooneka ngati V, kuyika mu dzenje la semicircular, etc.

2) Datum yoyezera: Datum yomwe imagwiritsidwa ntchito kuyeza kukula ndi malo a malo opangidwa ndi makina panthawi yowunika imatchedwa kuyeza datum.

3) Datum ya Assembly: Datum yomwe imagwiritsidwa ntchito kudziwa malo a gawolo kapena chinthu panthawi ya msonkhano imatchedwa msonkhano datum.

Chachiwiri, njira unsembe wa workpiece

Pofuna kukonza malo omwe amakwaniritsa zofunikira zaumisiri pagawo linalake la workpiece, workpiece iyenera kukhala ndi malo oyenerera okhudzana ndi chida pa chida cha makina chisanayambe. Njirayi nthawi zambiri imatchedwa "kuyika" kwa workpiece. Pambuyo pa workpiece ndi pabwino, chifukwa cha zochita za kudula mphamvu, mphamvu yokoka, etc. pa processing, limagwirira ntchito ayenera kugwiritsidwa ntchito "clamp" workpiece kuti malo otsimikiza kukhalabe osasintha. Njira yopezera chogwirira ntchito pamalo oyenera pamakina ndikumangirira chogwirira ntchito chimatchedwa "kukhazikitsa".

Ubwino wa unsembe workpiece ndi nkhani yofunika kwambiri Machining. Izo osati mwachindunji zimakhudza kulondola Machining, liwiro ndi bata la workpiece unsembe, komanso zimakhudza mlingo wa zokolola. Pofuna kuwonetsetsa kulondola kwapakati pakati pa makina opangidwa ndi makina ake, chogwirira ntchito chiyenera kukhazikitsidwa kuti malo opangira makinawo akhale ndi malo oyenerera okhudzana ndi chida cha makina. Mwachitsanzo, pomaliza ma groove a mphete, kuti atsimikizire zofunikira za kuthamanga kozungulira kwapakati pamphepete mwa mphete ndi nkhwangwa ya siketi, chogwirira ntchito chiyenera kukhazikitsidwa kuti mapangidwe ake agwirizane ndi olamulira. wa spindle chida cha makina.

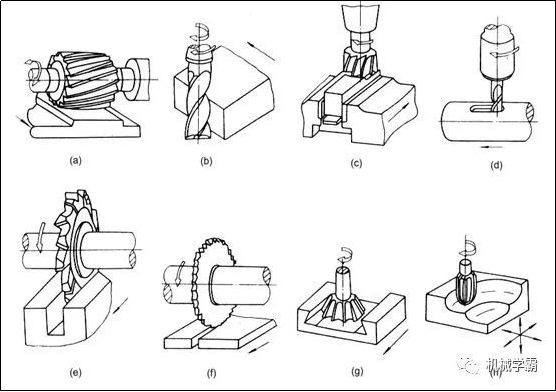

Mukamapanga magawo pazida zosiyanasiyana zamakina, pali njira zingapo zoyikapo. Njira zoyikamo zitha kugawidwa m'mitundu itatu: njira yolumikizirana mwachindunji, njira yolumikizira alembi ndi njira yokhazikitsira.

1) Njira yolumikizira mwachindunji Mukamagwiritsa ntchito njirayi, malo olondola omwe chogwiriracho chimayenera kukhala pa chida cha makina chimapezeka kudzera muzoyeserera zingapo. Njira yeniyeni ndiyo kugwiritsa ntchito chizindikiro choyimba kapena singano yolembera pa scribing mbale kukonza malo olondola a workpiece poyang'ana zowoneka pambuyo poti workpiece imayikidwa mwachindunji pa chida cha makina, mpaka ikwaniritse zofunikira.

Kulondola kwa malo ndi liwiro la njira yolunjika kumadalira kulondola kwa kulondola, njira yoyendetsera, zida zogwirizanitsa ndi luso la ogwira ntchito. Choyipa chake ndi chakuti zimatengera nthawi yochuluka, zokolola zochepa, ndipo zimafunika kuti zizigwiritsidwa ntchito ndi zochitika, ndipo zimafuna luso lapamwamba kwa ogwira ntchito, choncho zimangogwiritsidwa ntchito popanga chidutswa chimodzi komanso chochepa. Mwachitsanzo, kudalira kutsanzira kutengera thupi ndi njira yolunjika.

2) Njira yolumikizirana yolembera Njira iyi ndikugwiritsa ntchito singano yolembera pamakina kuti agwirizane ndi chogwirira ntchito molingana ndi mzere womwe umajambulidwa pachopanda kanthu kapena chomaliza, kuti chipeze malo oyenera. Mwachiwonekere, njirayi imafuna njira ina yolembera. Mzere wokokedwawo umakhala ndi m'lifupi mwake, ndipo pali cholakwika cholembera polemba, ndipo pali cholakwika chowonera pokonza malo a workpiece. Chifukwa chake, njirayi imagwiritsidwa ntchito kwambiri pamagulu ang'onoang'ono opanga, olondola opanda kanthu, ndi zida zazikulu zogwirira ntchito. Sikoyenera kugwiritsa ntchito zomangira. mu makina ovuta. Mwachitsanzo, malo a dzenje la pini la mankhwala a sitiroko awiri amatsimikiziridwa pogwiritsa ntchito njira yolembera mutu.

3) Kugwiritsa ntchito njira yokhazikitsira: zida zamakina zomwe zimagwiritsidwa ntchito kukakamiza chogwirira ntchito ndikuchipangitsa kukhala pamalo oyenera chimatchedwa chida cha makina. Chidacho ndi chida chowonjezera cha chida cha makina. udindo wake wachibale ndi chida pa chida makina wakhala kusinthidwa pasadakhale workpiece pamaso anaika, kotero si koyenera kuti agwirizane ndi udindo mmodzi ndi mmodzi pokonza mtanda wa workpieces, amene angathe kuonetsetsa luso zofunika processing. Ndi njira yabwino yokhazikitsira yomwe imapulumutsa ntchito ndi mavuto, ndipo imagwiritsidwa ntchito kwambiri mumagulu ndi kupanga zochuluka. Makina athu amakono a piston ndi njira yokhazikitsira zida zomwe zimagwiritsidwa ntchito.

①. Pambuyo poyika chogwirira ntchito, ntchito yosunga malo osasinthika panthawi yopanga makina imatchedwa clamping. Chipangizo chomwe chili muzitsulo chomwe chimasunga chogwirira ntchito pamalo omwewo panthawi yokonza chimatchedwa chipangizo cha clamping.

②. Chipangizo cha clamping chiyenera kukwaniritsa zofunikira izi: pamene clamping, malo a workpiece sayenera kuonongeka; pambuyo clamping, malo workpiece pa processing sayenera kusintha, ndi clamping ayenera kukhala olondola, otetezeka ndi odalirika; clamping Ntchitoyo ndi yachangu, ntchitoyo ndi yabwino komanso yopulumutsa ntchito; kapangidwe kake ndi kosavuta ndipo kupanga ndikosavuta.

③. Chenjezo pomanga: mphamvu yothirira iyenera kukhala yoyenera. Ngati ndi yayikulu kwambiri, chogwirira ntchito chimakhala chopunduka. Ngati ndi yaying'ono kwambiri, chogwiritsira ntchito chidzachotsedwa panthawi yokonza ndipo chidzawononga malo a workpiece.

3. Chidziwitso choyambirira cha kudula zitsulo

1. Kutembenuza kusuntha ndi kupanga pamwamba

Kutembenuka: Podula, kuti muchotse zitsulo zochulukirapo, ndikofunikira kupanga chogwirira ntchito ndi chida kuchitapo kanthu. Kuyenda kochotsa chitsulo chowonjezera pa chogwirira ntchito ndi chida chotembenuza pa lathe kumatchedwa kutembenuka, komwe kungathe kugawidwa kukhala kusuntha kwakukulu ndi kayendedwe ka chakudya. perekani masewera olimbitsa thupi.

Kusuntha kwakukulu: Kudulira kodulira pa workpiece kumadulidwa mwachindunji kuti ikhale tchipisi, potero kupanga kayendedwe ka malo atsopano a workpiece, omwe amatchedwa gulu lalikulu. Podula, kusuntha kozungulira kwa workpiece ndiko kuyenda kwakukulu. Kawirikawiri, liwiro la kayendetsedwe kake ndilokwera kwambiri, ndipo mphamvu yodula yomwe imagwiritsidwa ntchito ndipamwamba.

Kudyetsa kadyedwe: kayendedwe ka kupanga latsopano kudula wosanjikiza mosalekeza kuika mu kudula, kayendedwe chakudya ndi kayendedwe pamodzi padziko workpiece kupangidwa, amene angakhale mosalekeza kusuntha kapena wapakatikati kayendedwe. Mwachitsanzo, kusuntha kwa chida chotembenuza pa lathe yopingasa kumakhala kosalekeza, ndipo kayendetsedwe ka chakudya cha workpiece pa planer ndi kayendedwe kapakati.

Zomwe zimapangidwira pa workpiece: Panthawi yodula, malo opangidwa ndi makina, malo opangidwa ndi makina, ndi malo oti apangidwe amapangidwa pa workpiece. Fanished surface imatanthauza malo atsopano omwe achotsedwa pazitsulo zowonjezera. Malo oti apangidwe amatanthauza malo omwe zitsulo ziyenera kudulidwa. Malo opangidwa ndi makina amatanthawuza pamwamba pomwe tsinde lodulira la chida chotembenuza chikuzungulira.

2. Zinthu zitatu za kuchuluka kwa kudula zikunena za kudula kuya, kuchuluka kwa chakudya ndi liwiro locheka.

1) Kudula kwakuya: ap=(dw-dm)/2(mm) dw=diameter of unmachined workpiece dm=diameter of machined workpiece,kuzama kodula ndizomwe timakonda kuzitcha kuchuluka kwa kudula.

Kusankhidwa kwa kuya kwa kudula: Kuzama kwa αp kuyenera kutsimikiziridwa molingana ndi chilolezo cha makina. Pamene roughing, kuwonjezera kusiya finishing allowance, onse roughing allowance ayenera kuchotsedwa mu chiphaso chimodzi momwe angathere. Izi sizingangopangitsa kuti mankhwala a kudula kuya, mlingo wa chakudya ƒ ndi kudula liwiro V lalikulu pansi pa maziko a kuonetsetsa mlingo winawake durability, komanso kuchepetsa chiwerengero cha zidutsa. Pamene machining allowance ndi aakulu kwambiri kapena kukhazikika kwa dongosolo la ndondomeko sikukwanira kapena mphamvu ya tsamba ndi yosakwanira, iyenera kugawidwa m'madutsa oposa awiri. Panthawiyi, kudula kwakuya kwa chiphaso choyamba kuyenera kukhala kwakukulu, komwe kungathe kuwerengera 2/3 mpaka 3/4 ya malipiro onse; ndipo kudula kwakuya kwachiwiri kwachiwiri kuyenera kukhala kochepa, kuti njira yomaliza ipezeke. Zing'onozing'ono pamwamba makulidwe chizindikiro mtengo ndi apamwamba Machining molondola.

Pamene pamwamba pa odulidwa zigawo ndi olimba khungu castings, forgings kapena zitsulo zosapanga dzimbiri ndi zinthu zina ozizira kwambiri ozizira, kuya kwa odulidwa ayenera kupitirira kuuma kapena ozizira wosanjikiza kupewa kudula m'mphepete kudula pa zolimba kapena ozizira wosanjikiza.

2) Kusankhidwa kwa kuchuluka kwa chakudya: kusamutsidwa kwachibale kwa chogwirira ntchito ndi chida cholozera kayendedwe ka chakudya nthawi iliyonse pomwe chogwirira ntchito kapena chida chimazungulira kapena kubweza kamodzi, gawolo ndi mm. Pambuyo pakusankhidwa kwa kuya kwa kudula, chakudya chokulirapo chiyenera kusankhidwa momwe zingathere. Kusankhidwa kwa mtengo wokwanira wa chakudya kuyenera kuonetsetsa kuti chida cha makina ndi chida sichidzawonongeka chifukwa cha mphamvu yodula kwambiri, kupotoza kwa workpiece chifukwa cha mphamvu yodulira sikudzapitirira mtengo wololeka wa kulondola kwa workpiece, ndipo pamwamba pa roughness parameter mtengo sidzakhala waukulu kwambiri. Pamene roughing, malire chachikulu cha chakudya ndi kudula mphamvu, ndipo mu theka kumaliza ndi kumaliza, malire a chakudya ndi roughness pamwamba.

3) Kusankhidwa kwa kudula liwiro: Panthawi yodula, kuthamanga kwanthawi yomweyo kwa mfundo inayake pamphepete mwa chida chokhudzana ndi pamwamba kuti chipangidwe mumayendedwe akuluakulu, unit ndi m / min. Pamene kuya kwa odulidwa αp ndi mlingo wa chakudya ƒ amasankhidwa, pazipita kudula liwiro amasankhidwa pa maziko awa, ndi chitukuko malangizo kudula processing ndi mkulu-liwiro kudula.kupondaponda gawo

Chachinayi, lingaliro lamakina la roughness

M'makanika, kukhwimitsa kumatanthauza mawonekedwe owoneka bwino a geometric okhala ndi timipata tating'onoting'ono ndi nsonga ndi zigwa pamalo opangidwa ndi makina. Ndi limodzi mwamavuto a kafukufuku wosinthika. Kuuma kwapamwamba kumapangidwa ndi njira yopangira ntchito ndi zinthu zina, monga kukangana pakati pa chida ndi pamwamba pa gawo panthawi yokonza, kupindika kwa pulasitiki pamwamba pazitsulo pamene tchipisi talekanitsidwa, ndi kugwedezeka kwakukulu mu ndondomeko ya ndondomeko. Chifukwa cha njira zosiyanasiyana zogwirira ntchito ndi zipangizo zogwirira ntchito, kuya, kachulukidwe, mawonekedwe ndi mawonekedwe a zizindikiro zomwe zatsala pamtunda wopangidwa ndi makina ndizosiyana. Ukali wapamtunda umagwirizana kwambiri ndi mawonekedwe ofananira, kukana kuvala, mphamvu ya kutopa, kuuma kwa kukhudzana, kugwedezeka ndi phokoso la magawo amakina, ndipo zimakhudza kwambiri moyo wautumiki komanso kudalirika kwazinthu zamakina.aluminium kuponyera gawo

Kuyimilira roughness

Pambuyo pa kukonzedwa pamwamba pa gawolo, kumawoneka kosalala, koma kumakhala kosagwirizana pambuyo pa kukulitsa. Ukali wapamtunda umatanthawuza mawonekedwe ang'onoang'ono a geometric opangidwa ndi mtunda waung'ono ndi nsonga zazing'ono ndi zigwa pamtunda wa gawo lokonzedwa, lomwe nthawi zambiri limapangidwa ndi njira yopangira ndi (kapena) zinthu zina. Ntchito ya pamwamba pa gawoli ndi yosiyana, ndipo kufunika kokhala ndi roughness parameter mtengo kumasiyananso. Khodi ya roughness ya pamwamba (chizindikiro) iyenera kulembedwa pagawo lojambula kuti lifotokoze makhalidwe omwe ayenera kukwaniritsidwa pambuyo pake. Pali mitundu itatu ya kutalika kwa makulidwe:

1. Masamu a contour amatanthauza kupatuka Ra

Kutanthauza masamu a mtengo wokwanira wa mtunda pakati pa mfundo pa mzere wa mizere yoyezera (Y mayendedwe) ndi mzere wolozera mkati mwautali wa zitsanzo.

2. Ten-point height Rz of microscopic inevenness

Zimatanthawuza kuchuluka kwa nsonga 5 zazitali zazitali kwambiri komanso 5 zakuya zazitali zazitali kwambiri muzachitsanzozo.

3. Kutalika kwakukulu kwa contour Ry

Mtunda pakati pa mzere wa nsonga yapamwamba kwambiri ndi mzere wa chigwa chotsika kwambiri cha mbiri mkati mwa kutalika kwa zitsanzo.

Pakali pano, Ra. amagwiritsidwa ntchito makamaka m'makampani opanga makina.

chithunzi

4. Njira Yoyimilira Mwankhaza

5. Zotsatira za roughness pa ntchito ya ziwalo

Ubwino wa pamwamba wa workpiece pambuyo processing mwachindunji zimakhudza thupi, mankhwala, ndi makina katundu. Ntchito yogwira ntchito, kudalirika ndi moyo wa mankhwalawa zimadalira kwambiri pamtundu wapamwamba wa zigawo zikuluzikulu. Nthawi zambiri, zofunikira zapamtunda zamagulu ofunikira kapena ofunikira ndizokwera kuposa magawo wamba chifukwa magawo omwe ali ndi mawonekedwe abwino amawongolera kwambiri kukana kwawo kuvala, kukana dzimbiri, komanso kukana kuwonongeka kwa kutopa.CNC Machining aluminium gawo

6. Kudula madzimadzi

1) Ntchito yodula madzimadzi

Kuzizira kwenikweni: Kutentha kwa kutentha kumatha kuchotsa kutentha kwakukulu, kukonza kutentha kwa kutentha, kuchepetsa kutentha kwa chida ndi workpiece, potero kumatalikitsa moyo wautumiki wa chida ndikuletsa kulakwitsa kwakukulu kwa workpiece chifukwa cha ntchito. matenthedwe matenthedwe.

Kupaka mafuta: Madzi odulira amatha kulowa pakati pa chogwiritsira ntchito ndi chida, kotero kuti filimu yowonda kwambiri ya adsorption imapangidwa mumpata wawung'ono pakati pa chip ndi chida, zomwe zimachepetsa mikangano yamagetsi, kotero imatha kuchepetsa mikangano pakati pa chida. chip ndi workpiece , kuchepetsa mphamvu yodulira ndi kudula kutentha, kuchepetsa kuvala kwa chida ndikuwongolera pamwamba pa workpiece. Pomaliza, kudzoza ndikofunikira kwambiri.

Kuyeretsa: Titchipisi tating'onoting'ono timene timapangidwa panthawi yoyeretsa ndizosavuta kumamatira ku workpiece ndi chida, makamaka pobowola mabowo akuya ndi mabowo obwezeretsanso, tchipisi timatsekeka mosavuta mu chitoliro cha chip, chomwe chimakhudza roughness ya workpiece ndi moyo wautumiki wa chida. . Kugwiritsa ntchito madzi odulira kumatha kutsuka tchipisi mwachangu, kuti kudula kuchitidwe bwino.

2) Mtundu: Pali mitundu iwiri yamadzi odula omwe amagwiritsidwa ntchito kwambiri

Emulsion: Imagwira ntchito yoziziritsa. The emulsion amapangidwa ndi diluting mafuta emulsified ndi 15-20 nthawi madzi. Kudulira kwamtunduwu kumakhala ndi kutentha kwakukulu kwapadera, kukhuthala pang'ono komanso madzi abwino, ndipo kumatha kuyamwa kutentha kwambiri. Kudula madzimadzi makamaka ntchito kuziziritsa chida ndi workpiece, kusintha moyo chida ndi kuchepetsa mapindikidwe matenthedwe. Emulsion imakhala ndi madzi ochulukirapo, ndipo ntchito zoteteza mafuta ndi dzimbiri ndizosauka.

Kudula mafuta: Chigawo chachikulu cha kudula mafuta ndi mafuta amchere. Mtundu uwu wamadzimadzi odulira umakhala ndi kutentha pang'ono, kukhuthala kwakukulu komanso kusayenda bwino. Zimagwira ntchito yopaka mafuta. Mafuta amchere okhala ndi mamasukidwe otsika amagwiritsidwa ntchito, monga mafuta agalimoto, mafuta a dizilo opepuka, Palafini etc.

Anebon Metal Products Limited ikhoza kupereka CNC Machining, Die Casting, Sheet Metal Fabrication service, chonde omasuka kulankhula nafe.

Tel: +86-769-89802722 E-mail: info@anebon.com URL: www.anebon.com

Nthawi yotumiza: Jun-24-2022