Aluminiyamu ndizomwe zimagwiritsidwa ntchito kwambiri zitsulo zopanda chitsulo, ndipo mawonekedwe ake akukulirakulirabe. Mitundu yopitilira 700,000 ya aluminiyamu imapangidwa pogwiritsa ntchito zida za aluminiyamu. Malinga ndi ziwerengero, pali mitundu yopitilira 700,000 ya zinthu za aluminiyamu, ndipo mafakitale osiyanasiyana, monga zomangamanga ndi zokongoletsa, zoyendera, zamlengalenga, ndi zina zambiri, zimakhala ndi zosowa zosiyanasiyana. Masiku ano, Xiaobian ayambitsa ukadaulo wokonza zinthu za aluminiyamu komanso momwe angapewere kusinthika.CNC Machining gawo

Ubwino ndi mawonekedwe a aluminiyamu ndi awa:

1. Kutsika kochepa. Kuchuluka kwa aluminiyumu ndi pafupifupi 2.7 g/cm3. Kuchulukana kwake ndi 1/3 yokha yachitsulo kapena mkuwa.

2. Mapulasitiki apamwamba. Aluminiyamu imasinthasintha ndipo imatha kupangidwa kukhala zinthu zosiyanasiyana pogwiritsa ntchito njira zopopera monga kutulutsa ndi kutambasula.

3. Kukana dzimbiri. Aluminiyamu ndi chitsulo chosawonongeka kwambiri, ndipo filimu yoteteza oxide idzapangidwa pamtunda pansi pa chilengedwe kapena anodizing. Ili ndi kukana bwino kwa dzimbiri kuposa chitsulo.

4, yosavuta kulimbitsa. Aluminiyamu yoyera si yamphamvu kwambiri, koma imatha kuwonjezeredwa ndi anodizing.

5. Easy pamwamba mankhwala. Chithandizo chapamwamba chimatha kupititsa patsogolo kapena kusintha mawonekedwe a aluminiyamu. Njira yopangira aluminium anodizing ndi yokhwima komanso yokhazikika ndipo imagwiritsidwa ntchito kwambiri pokonza zinthu za aluminiyamu.

6. Good conductivity ndi zosavuta zobwezeretsanso.

Ukadaulo wokonza zinthu za aluminiyamu

Kukomedwa kwa zinthu za aluminiyamu

1. Kuzizira kozizira

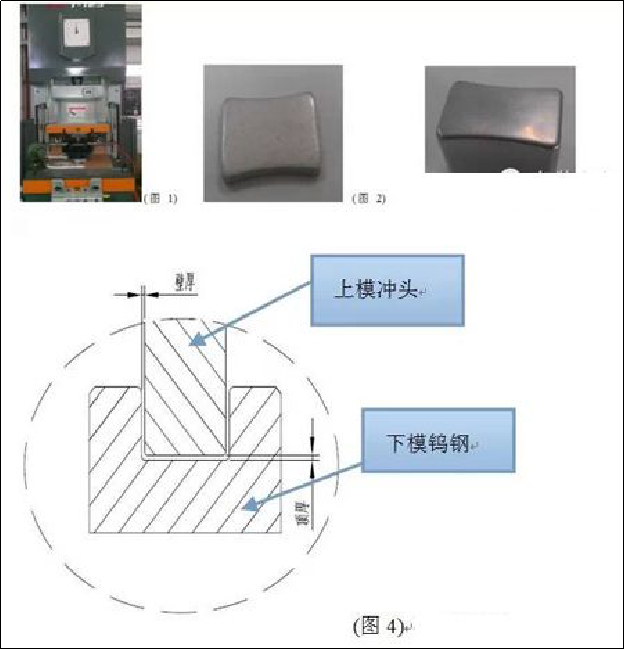

Gwiritsani ntchito ma pellets a aluminiyamu. makina extrusion ndi kufa ntchito akamaumba kamodzi ndi oyenera mankhwala cylindrical kapena akalumikidzidwa mankhwala zovuta kukwaniritsa ndi njira kutambasula, monga chowulungika, lalikulu, ndi mankhwala amakona anayi.

Matani a makina omwe amagwiritsidwa ntchito amagwirizana ndi gawo lazogulitsa. Kukhuthala kwa khoma la chinthucho ndi kusiyana pakati pa nkhonya yakumtunda ndi chitsulo chotsika cha tungsten. Pamene nkhonya yapamwamba yakufa ndi chitsulo chapansi cha tungsten chakufa chikanikizidwa palimodzi, kusiyana koyang'ana pansi pakatikati pakufa ndi Kwa makulidwe apamwamba a mankhwala.gawo la aluminiyamu

Ubwino: Kutsegula kwa nkhungu kumakhala kochepa, ndipo mtengo wa chitukuko ndi wotsika kuposa wa nkhungu yojambula.

Zoipa: Ntchito yopanga ndi yayitali, kukula kwake kumasinthasintha kwambiri, ndipo mtengo wa ntchito ndi wokwera.

2. Kutambasula

Gwiritsani ntchito khungu la aluminiyamu. Ndioyenera kupundutsa matupi omwe si a cylindrical (mankhwala a aluminiyamu okhala ndi zinthu zokhotakhota), nthawi zambiri amagwiritsa ntchito makina opitilira kufa ndi nkhungu kuti akwaniritse zofunikira za mawonekedwe.

Ubwino: zinthu zovuta kwambiri komanso zingapo zopindika zimakhala ndi mawonekedwe okhazikika popanga, ndipo mawonekedwe ake amakhala osalala.

kuipa: mkulu nkhungu mtengo, mkombero yaitali ndi chitukuko, ndi mkulu makina kusankha ndi zofunika mwatsatanetsatane.

Chithandizo chapamwamba cha zinthu za aluminiyamu

1. Kuwombera mchenga (kuwomberedwa)

Njira yoyeretsera ndi roughening zitsulo pamalo ntchito mphamvu ya mkulu-liwiro mchenga otaya.

The pamwamba mankhwala a aluminiyamu mbali mu njira imeneyi akhoza kupeza mlingo wina wa ukhondo ndi roughness osiyana pamwamba pa workpiece kuti makina katundu pamwamba pa workpiece ndi bwino, motero kusintha kutopa kukana workpiece ndi kuonjezera kusiyana pakati pa izo ndi zokutira. Kumamatira kwa zokutira kumatalikitsa kukhazikika kwa filimu yophimba komanso kumathandizira kuti pakhale kukwera ndi kukongoletsa kwa zokutira. Tikuwona munjira iyi kuti zinthu za Apple ndi o2. Kupukutira

Amagwiritsa ntchito makina, mankhwala, kapena ma electrochemical zochita kuti achepetse kuuma kwa malo ogwirira ntchito ndikupeza njira yowala, yosalala pamwamba. Njira yopukuta imagawidwa kukhala makina, mankhwala, ndi electrolytic kupukuta. Pambuyo pakupukuta kwamakina + kupukuta kwa electrolytic, mbali za aluminiyamu zimatha kukhala pafupi ndi galasi lachitsulo chosapanga dzimbiri. Njirayi imapatsa anthu malingaliro osavuta apamwamba komanso tsogolo labwino.

3. Kujambula

Kujambula kwawaya wazitsulo ndi njira yopangira kukanda mobwerezabwereza pepala la aluminiyamu kuchokera pamizere ndi sandpaper. Kujambula kumatha kugawidwa molunjika, mwachisawawa, mozungulira, ndi ulusi. Njira yojambulira waya wachitsulo imatha kuwonetsa bwino kachidindo kakang'ono kalikonse ka silika, kotero kuti tsitsi loyengedwa bwino limawonekera muzitsulo zachitsulo, ndipo mankhwalawa ali ndi malingaliro a mafashoni ndi zamakono.

4. Kudula kwambiri kwa gloss

Pogwiritsa ntchito makina ojambulira, mpeni wa diamondi umalimbikitsidwa pamtengo waukulu wa makina ojambulira, ozungulira pa liwiro lalikulu (nthawi zambiri 20,000 rpm) kuti adule mbalizo, ndipo malo owonetserako amapangidwa pamwamba pa mankhwala. Kuwala kwa mfundo zodulira kumakhudzidwa ndi liwiro la kubowola mphero. Kuthamanga kwa liwiro la kubowola, kumawonekeranso kowoneka bwino, komanso mosiyana, kumakhala mdima komanso wosavuta kupanga mizere yodulira. Kudula kwapamwamba komanso kowala kwambiri kumagwiritsidwa ntchito makamaka pama foni am'manja monga ma iPhones. Mafelemu ena apamwamba kwambiri azitsulo za TV posachedwapa atenga njira yopukuta kwambiri. Kuphatikiza apo, anodizing ndi njira zojambulira waya zimapangitsa TV kukhala yodzaza ndi mafashoni ndiukadaulo.

5. Anodizing

Anodic makutidwe ndi okosijeni amatanthauza electrochemical makutidwe ndi okosijeni wa zitsulo kapena aloyi. Pansi pa electrolyte yofananira ndi zochitika zinazake, aluminiyamu ndi ma aloyi ake amapanga filimu ya okusayidi pazitsulo za aluminiyamu (anode) chifukwa cha ntchito yapano. Anodizing sikungothetsa zovuta za aluminiyumu kuuma pamwamba ndi kukana kuvala komanso kutalikitsa moyo wautumiki wa aluminiyumu ndikuwonjezera kukongola. Yakhala gawo lofunika kwambiri pazamankhwala a aluminiyamu ndipo pakali pano ndiyomwe imagwiritsidwa ntchito kwambiri komanso yopambana kwambiri. ntchito

6. Anode yamitundu iwiri

Mitundu iwiri ya anodizing ikutanthauza anodizing pa chinthu chimodzi ndikupereka mitundu yosiyanasiyana kumadera ena. Njira ya anodizing yamitundu iwiri siigwiritsidwa ntchito kawirikawiri m'makampani a TV chifukwa ndondomekoyi ndi yovuta komanso yokwera mtengo. Komabe, kusiyana pakati pa mitundu iwiri kungathe

amawonetsa bwino mawonekedwe apamwamba komanso apadera a mankhwalawa.

Njira zoyezera ndi luso lantchito kuti muchepetse kusinthika kwa aluminiyumu processing

Pali zifukwa zambiri zomwe zimapangidwira mbali za aluminiyamu, zomwe zimagwirizana ndi zinthu, mawonekedwe a gawolo, ndi kupanga zinthu. Pali makamaka mbali izi: mapindikidwe chifukwa cha kupsyinjika kwamkati kwa chopanda kanthu, kupunduka chifukwa cha kudula mphamvu ndi kudula kutentha, ndi mapindikidwe chifukwa clamping mphamvu.

Njira zoyeserera zochepetsera ma deformation

1. Kuchepetsa kupsinjika kwamkati kwa chikhalidwe cha tsitsi

Kukalamba kwachilengedwe kapena kochita kupanga ndi chithandizo cha kugwedezeka kungathe kuthetsa pang'ono kupsinjika kwamkati komwe kulibe kanthu. Pre-processing ndi njira yothandiza kwambiri. Chifukwa cha chiwongola dzanja chachikulu, kupindika pambuyo pokonza ndikofunikanso kwa chopanda kanthu ndi mutu wonenepa komanso makutu akulu. Tiyerekeze kuti gawo lowonjezera la chopanda kanthu lidakonzedwa kale, ndipo gawo lililonse limachepetsedwa. Zikatero, zimatha kuchepetsa kusinthika kwa njira yotsatila ndikumasula kupsinjika kwamkati mutatha kukonza kwa nthawi yayitali.

2. Kupititsa patsogolo luso lodula la chida

Zida ndi mawonekedwe a geometric a chidacho zimakhudza kwambiri mphamvu yodulira ndi kudula kutentha. Kusankhidwa kolondola kwa chida ndikofunikira kuti muchepetse mapindikidwe a makina a gawolo.

1) Kusankha koyenera kwa zida za geometric.

①Ngodya ya Rake: Pansi pakukhalabe ndi mphamvu ya tsamba, mbali yakeyo imasankhidwa moyenerera kuti ikhale yayikulu; mbali imodzi, imatha kupukuta nsonga, ndipo kumbali ina, imatha kuchepetsa kudulidwa, kupanga kuchotsa chip chosalala, ndiyeno kuchepetsa mphamvu yodulira ndi kudula kutentha. Osagwiritsa ntchito zida zokhala ndi ngodya yolakwika.

②Njira yopumula: Kukula kwa mbali yopumula kumakhudza kwambiri mavalidwe a m'mbali mwake komanso mawonekedwe ake. Kudula makulidwe ndi chinthu chofunikira posankha ngodya ya chilolezo. Chidacho chimafuna kutentha kwabwino panthawi ya mphero chifukwa cha kuchuluka kwa chakudya, katundu wodula kwambiri, komanso kutentha kwakukulu. Choncho, mbali ya chilolezo iyenera kusankhidwa kuti ikhale yaying'ono. Pamene mphero yabwino, m'mphepete mwake iyenera kukhala yakuthwa, kukangana pakati pa nkhope ya m'mbali ndi malo opangidwa ndi makina kumachepetsedwa, ndipo zotanuka zimachepetsedwa. Chifukwa chake, mbali ya chilolezo iyenera kukhala yofunika kwambiri.

③ Ngodya ya Helix: Ngodya ya helix iyenera kukhala yayikulu momwe ingathere kuti ikhale yosalala komanso kuchepetsa mphamvu yamphero.

④Main declination angle: Kuchepetsa bwino mbali yapakati yochepetsera kumatha kusintha kutentha ndikuchepetsa kutentha kwa malo opangirako.

2) Sinthani mawonekedwe a zida.

①Chepetsani kuchuluka kwa mano a mphero ndikuwonjezera malo a chip. Chifukwa cha kuchulukitsitsa kwa aluminiyumu komanso kupindika kwakukulu pakukonza, malo okwanira a chip amafunikira, kotero utali wapansi wa chip groove uyenera kukhala wofunikira, ndipo kuchuluka kwa mano odula mphero kuyenera kukhala kochepa.

② Kukukuta bwino mano. Mtengo wa roughness wa m'mphepete mwa mano ocheka uyenera kukhala wocheperapo Ra = 0.4um. Musanagwiritse ntchito mpeni watsopano, muyenera kugwiritsa ntchito mwala wonyezimira bwino wamafuta kuti muwongole kutsogolo ndi kumbuyo kwa mano a mpeni kangapo kuti muchotse ma burrs ndi ma serrations ang'onoang'ono omwe amatsalira pakunola mano. Mwanjira iyi, kutentha kwadulira kumatha kuchepetsedwa, ndipo mawonekedwe odulira ndi ochepa.

③ Yang'anirani mwamphamvu kavalidwe ka chida. Chidacho chitavala, kuchuluka kwa roughness kwa workpiece kumawonjezeka, kutentha kwa kudula kumakwera, ndipo kusinthika kwa workpiece kumawonjezeka. Chifukwa chake, kuwonjezera pa kusankha zida zokhala ndi kukana kwabwino kovala, zida zovalira siziyenera kukhala zabwino kwambiri kuposa 0.2mm. Apo ayi, n'zosavuta kupanga m'mphepete mwake. Podula, kutentha kwa workpiece sayenera kupitirira 100 ℃ kuteteza mapindikidwe.

3. Kupititsa patsogolo njira ya clamping ya workpiece

Pazitsulo zopyapyala zokhala ndi mipanda ya aluminiyamu yosakhazikika bwino, njira zotsatirazi zokhomerera zingagwiritsidwe ntchito kuchepetsa mapindikidwe:

①Pazigawo zopyapyala zokhala ndi mipanda yopyapyala, ngati chuck ya nsagwada zitatu yodziyimira payokha kapena kasupe ikagwiritsidwa ntchito poboola ma radial, chogwiriracho chimapunduka chikatulutsidwa. Njira yolimbikitsira nkhope yomaliza ya axial ndi kukhazikika bwino iyenera kugwiritsidwa ntchito. Ikani dzenje lamkati la gawolo, pangani ulusi wa mandrel, mulowetse mu dzenje lamkati, kanikizani kumapeto kwake ndi mbale yophimba, ndiyeno kumangitsa ndi nati. Kupindika kwa clamping kumatha kupewedwa pokonza bwalo lakunja kuti mupeze kulondola kokwanira.

② Mukakonza zogwirira ntchito zokhala ndi mipanda yopyapyala komanso yopyapyala, ndi bwino kugwiritsa ntchito makapu akuyamwa vacuum kuti mupeze mphamvu yogawira yogawanika ndikuyidula pang'ono, yomwe ingalepheretse kupunduka kwa workpiece.

Kuphatikiza apo, njira yolongedza ingagwiritsidwenso ntchito. Kuonjezera processing rigidity wa workpieces woonda-mipanda, sing'anga akhoza kudzazidwa mkati workpiece kuchepetsa mapindikidwe workpiece pa clamping ndi kudula. Mwachitsanzo, urea kusungunuka wokhala ndi 3% mpaka 6% potaziyamu nitrate amatsanuliridwa mu workpiece. Pambuyo pokonza, workpiece imatha kumizidwa m'madzi kapena mowa, ndipo chodzazacho chikhoza kusungunuka ndikutsanulidwa.

4. Kukonzekera koyenera kwa njira

Pa kudula-liwiro, chifukwa chachikulu Machining chilolezo ndi kudula anasokonekera, ndondomeko mphero zambiri amapanga kugwedera, zomwe zimakhudza kulondola Machining ndi pamwamba roughness. Choncho, CNC mkulu-liwiro kudula ndondomeko akhoza zambiri kugawidwa mu roughing-semi-kumaliza-ngodya kuyeretsa-kumaliza ndi njira zina. Nthawi zina zimakhala zofunikira kuti magawo omwe ali ndi zofunikira kwambiri kuti azitha kumaliza ndi kumaliza. Pambuyo pokonza movutikira, zigawozo zimatha kukhazikika mwachilengedwe, ndikuchotsa kupsinjika kwamkati komwe kumachitika chifukwa cha makina olimba komanso kuchepetsa mapindikidwe. Chilolezo chomwe chimasiyidwa pambuyo pokonza movutikira chiyenera kukhala chachikulu kuposa mapindikidwe, nthawi zambiri 1 mpaka 2 mm. Pamapeto, kutsirizitsa pamwamba pa mbali ayenera kukhala yunifolomu Machining chilolezo, zambiri 0.2 ~ 0.5mm, kuti chida ndi khola pa ndondomeko Machining, amene kwambiri kuchepetsa kudula mapindikidwe, kupeza wabwino pamwamba Machining khalidwe ndi kuonetsetsa Product zolondola.

Maluso ogwirira ntchito kuchepetsa kupotoza kwa makina

Kuphatikiza pazifukwa zomwe zili pamwambazi, zigawo za aluminiyamu zimapunduka panthawi yokonza. Njira yogwiritsira ntchito ndiyofunikanso pakugwira ntchito kwenikweni.

1. Kwa magawo omwe ali ndi chilolezo chachikulu cha makina, kuti awapatse kutentha kwabwinoko panthawi yopangira makina ndikupewa kutentha kwa kutentha, makina osakanikirana ayenera kutengedwa panthawi ya makina. Ngati pepala lakuda la 90mm liyenera kukonzedwa mpaka 60mm ngati mbali imodzi ikuphwanyidwa ndipo mbali inayo ikuphwanyidwa nthawi yomweyo, ndipo kukula komaliza kumakonzedwa nthawi imodzi, flatness idzafika 5mm; ngati imakonzedwa mofananira ndi kudyetsa mobwerezabwereza, mbali iliyonse imakonzedwa kawiri mpaka Kukula komaliza kumatha kutsimikizira kusalala kwa 0.3mm.kupondaponda gawo

2. Ngati pali mikwingwirima yambiri pazigawo za mbale, sikuli koyenera kugwiritsa ntchito njira yotsatizana yazitsulo imodzi ndi patsekeke imodzi panthawi yokonza, zomwe zidzachititsa kuti ziwalozo zikhale zopunduka chifukwa cha kupsinjika kosagwirizana. Mipikisano wosanjikiza processing amatengedwa, ndipo wosanjikiza aliyense kukonzedwa ku cavities onse pa nthawi yomweyo, ndiyeno wosanjikiza wotsatira kukonzedwa kuti zigawo wogawana anatsindika ndi kuchepetsa mapindikidwe.

3. Kuchepetsa mphamvu yodula ndi kudula kutentha mwa kusintha kuchuluka kwa kudula. Pakati pa zinthu zitatu za kudula kuchuluka, kuchuluka kwa kubwereranso kumakhudza kwambiri mphamvu yodula. Ngati machining allowance ndi aakulu kwambiri, mphamvu yodulira ya chiphaso chimodzi ndi yaikulu kwambiri, zomwe sizidzangowononga mbali zake zokha komanso zimakhudza kulimba kwa nsonga ya makina opota ndi kuchepetsa kulimba kwa chidacho—chiŵerengero cha mipeni yoti idyedwe. Ngati msana wafupika, kupanga kwachangu kumachepetsedwa kwambiri. Komabe, mphero yothamanga kwambiri imagwiritsidwa ntchito mu CNC Machining, yomwe imatha kuthana ndi vutoli. Pamene kuchepetsa kuchuluka kwa kudulidwa kumbuyo, malinga ngati chakudya chikuwonjezeka moyenerera ndipo liwiro la chida cha makina likuwonjezeka, mphamvu yodulira imatha kuchepetsedwa, ndipo kugwiritsira ntchito bwino kungathe kutsimikiziridwa panthawi imodzi.

4. Dongosolo la kusuntha kwa mpeni liyenera kuperekedwanso chidwi. Kupanga makina movutikira kumagogomezera kuwongolera magwiridwe antchito ndikutsata kuchuluka kwa kuchotsa pagawo lililonse la nthawi. Nthawi zambiri, mphero yodulidwa imatha kugwiritsidwa ntchito. Ndiko kuti, zinthu zowonjezera zomwe zili pamwamba pa chopanda kanthu zimachotsedwa mofulumira kwambiri komanso nthawi yochepa kwambiri, ndipo mawonekedwe a geometric omwe amafunikira kuti amalize amapangidwa. Ngakhale kutsirizitsa kumatsindika kulondola kwambiri komanso khalidwe lapamwamba, ndibwino kugwiritsa ntchito mphero. Chifukwa makulidwe odula a mano odula pang'onopang'ono amachepa kuchokera pamlingo wokulirapo mpaka zero panthawi ya mphero, kuchuluka kwa kuuma kwa ntchito kumachepetsedwa kwambiri, ndipo kuchuluka kwa gawolo kumachepetsedwanso.

5. Mipanda yopyapyala yokhala ndi mipanda imapunduka chifukwa chomangirira panthawi yokonza; ngakhale kumaliza sikungalephereke. Kuchepetsa mapindikidwe a workpiece kuti achepetse, mutha kumasula kachidutswa kokanikizira musanamalize kukula komaliza kuti chogwiriracho chibwerere momasuka ku chikhalidwe chake choyambirira ndikuchisindikiza pang'ono, bola ngati chogwiriracho chikhoza kutsekedwa (konse) . Malinga ndi kumverera kwa dzanja), njira yabwino yopangira ntchito imatha kupezeka motere. Mwa kuyankhula kwina, malo ogwirira ntchito a clamping force makamaka amakhala pamtunda wothandizira, ndipo mphamvu yokhotakhota iyenera kugwiritsidwa ntchito potsata kukhazikika kwa workpiece. Kuonetsetsa kuti workpiece si lotayirira, ang'onoang'ono clamping mphamvu, ndi bwino.

6. Pamene mukukonza mbali zokhala ndi kabowo, yesetsani kuti wodula mphero asalowe mwachindunji mu gawolo ngati kubowola pobowola pobowola, zomwe zimapangitsa kuti malo osakwanira odula mphero agwirizane ndi tchipisi ndi kuchotsa bwino tchipisi, zomwe zimapangitsa kutentha kwambiri, kukulitsa. , ndi kugwa kwa ziwalo—mipeni, kusweka, ndi zochitika zina zoipa. Choyamba, kubowola dzenje ndi galimoto yofanana ndi chodulira mphero kapena kukula kumodzi kofunikira, kenako mphero ndi chodula mphero. Kapenanso, mapulogalamu a CAM angagwiritsidwe ntchito kupanga mapulogalamu ozungulira.

Anebon Metal Products Limited ikhoza kupereka CNC Machining, Die Casting, Sheet Metal Fabrication service, chonde omasuka kulankhula nafe.

Tel: +86-769-89802722 E-mail: info@anebon.com URL: www.anebon.com

Nthawi yotumiza: Jun-16-2022