Kodi ekseli yowonda yagalimoto ndi chiyani?

Axle yagalimoto yowonda ndi mtundu womwe umagwiritsidwa ntchito m'magalimoto ndikupangidwa kuti ukhale wopepuka. Ma axle ocheperako amakonda kugwiritsidwa ntchito m'magalimoto omwe amayang'ana kwambiri mafuta komanso mphamvu. Amachepetsa kulemera kwa galimoto pamene akuwongolera kachitidwe kake. Ma axles awa nthawi zambiri amapangidwa kuchokera ku zinthu zopepuka, zolimba monga aluminiyamu kapena chitsulo cholimba kwambiri. Ma axles awa amamangidwa kuti athe kuthana ndi mphamvu zoyendetsa, monga torque yopangidwa ndi injini, ndikusungabe mawonekedwe ophatikizika, owongolera. Ma axle ocheperako ndi ofunikira pakufalitsa mphamvu kuchokera ku injini kupita kumawilo.

Chifukwa chiyani ndikosavuta kupindika ndi kupunduka pokonza shaft yowonda yagalimoto?

Zingakhale zovuta kupindika kapena kupotoza mtengo womwe ndi woonda kwambiri. Zida zomwe zimagwiritsidwa ntchito popanga zitsulo zamagalimoto (zomwe zimadziwikanso kuti ma drive shaft kapena ma axles) nthawi zambiri zimakhala zamphamvu komanso zolimba, monga carbon fiber composite kapena chitsulo. Zida zomwe zimagwiritsidwa ntchito zimasankhidwa chifukwa cha mphamvu zawo zapamwamba, zomwe zimafunika kuti zithe kukana torque ndi mphamvu zomwe zimapangidwa ndi kufalitsa ndi injini ya galimoto.

Pakupanga, ma shafts amadutsa njira zosiyanasiyana, monga kupangira ndi kutentha kutentha, kuti akhalebe okhwima komanso amphamvu. Zidazi, pamodzi ndi njira zopangira, zimalepheretsa ma shafts kupindika pansi pazikhalidwe zabwino. Komabe, mphamvu zowopsa monga kugundana ndi ngozi zimatha kupindika kapena kusokoneza mbali iliyonse yagalimoto, kuphatikiza ma shafts. Ndikofunikira kukonza kapena kusintha zina zilizonse zomwe zawonongeka kuti galimoto yanu ikhale yotetezeka komanso yogwira ntchito.

Njira yopangira makina:

Zigawo zambiri za shaft zimakhala ndi chiŵerengero cha L / d> 25. Mzere wopingasa wowondayo umapindika mosavuta kapena ukhoza kutaya kukhazikika kwake mothandizidwa ndi mphamvu yokoka, kudula mphamvu ndi mphamvu zokhotakhota pamwamba. Vuto la kupsinjika pa shaft yowonda liyenera kuchepetsedwa potembenuza tsinde.

Njira yopangira:

Kutembenuza kwa chakudya chakumbuyo kumagwiritsidwa ntchito, ndi njira zingapo zogwirira ntchito, monga kusankha kwa zida za geometry, kuchuluka kwa kudula, zida zolimbitsa thupi, ndi zida zopumira.

Kuwunika kwa Zinthu Zomwe Zimayambitsa Kupindika Kwa Kutembenuza Slender Shaft

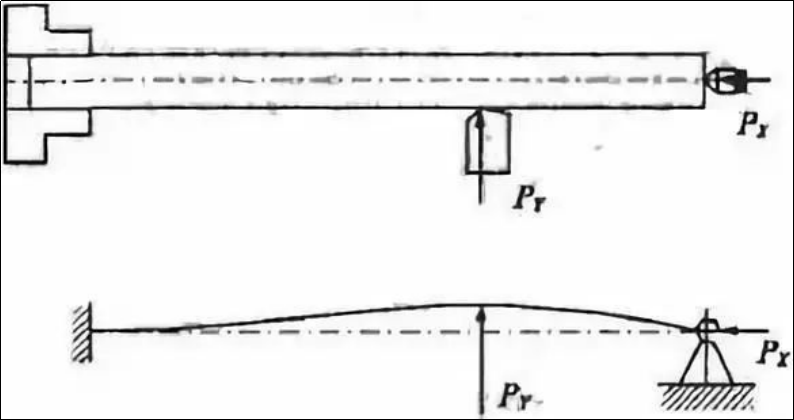

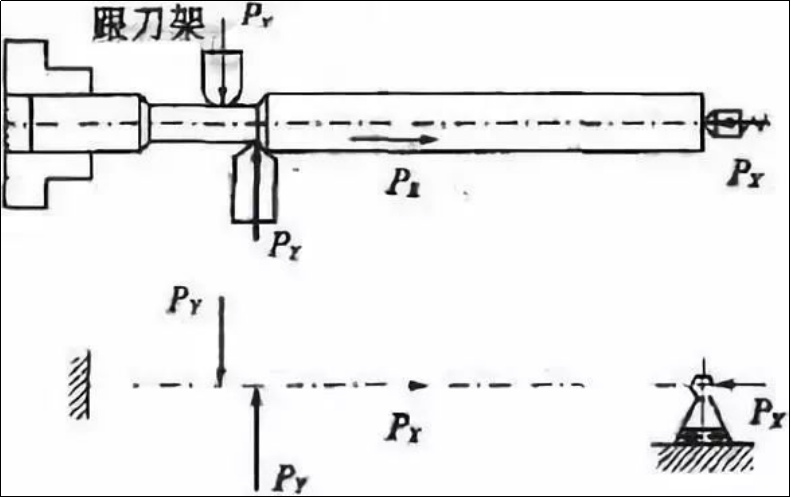

Njira ziwiri zachikhalidwe zokhomerera zimagwiritsidwa ntchito kutembenuza ma shafts ocheperako mu lathes. Njira imodzi imagwiritsa ntchito choletsa chimodzi chokhala ndi kuyika pamwamba kumodzi, ndipo ina ndi makhazikitsidwe awiri apamwamba. Tidzayang'ana makamaka pa njira yokhomerera ya clamp imodzi ndi pamwamba. Monga momwe chithunzi 1 chikusonyezera.

Chithunzi 1 Chingwe chimodzi ndi njira imodzi yokhomerera pamwamba ndikuwunika mphamvu

Zomwe zimayambitsa kupindika komwe kumachitika chifukwa chotembenuza shaft yowonda ndi:

(1) Kudula mphamvu kumayambitsa kusinthika

Mphamvu yodula imatha kugawidwa m'zigawo zitatu: axial force PX (axial force), radial force PY (radial force) ndi tangential force PZ. Mukatembenuza ma shafts opyapyala, mphamvu zodulira zosiyanasiyana zimatha kukhala ndi zotsatira zosiyanasiyana pakupindika.

1) Chikoka cha ma radial kudula mphamvu PY

Mphamvu ya radial imadula molunjika kupyola mu axis ya shaft. Mphamvu yodulira ma radial imapindika chingwe chowonda mu ndege yopingasa chifukwa cha kusakhazikika kwake. Chithunzi chikuwonetsa zotsatira za mphamvu yodulira pakupindika kwa shaft yowonda. 1.

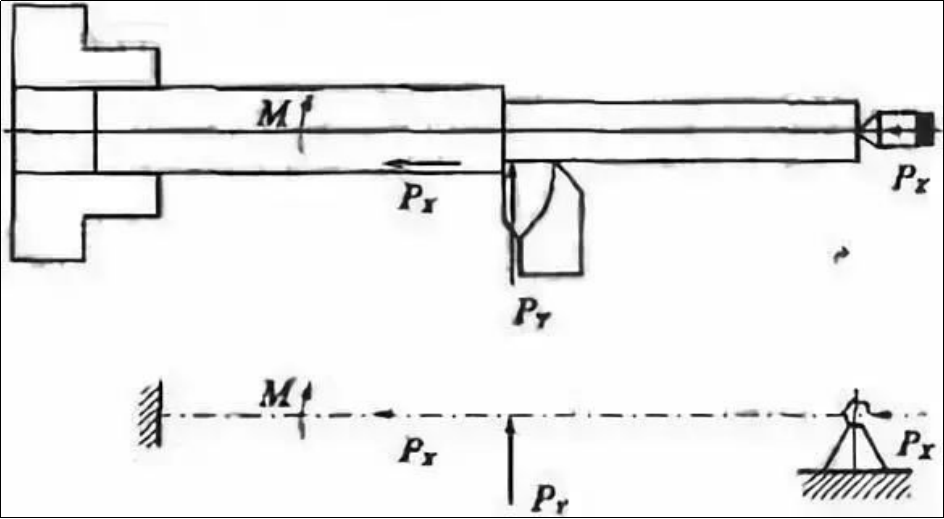

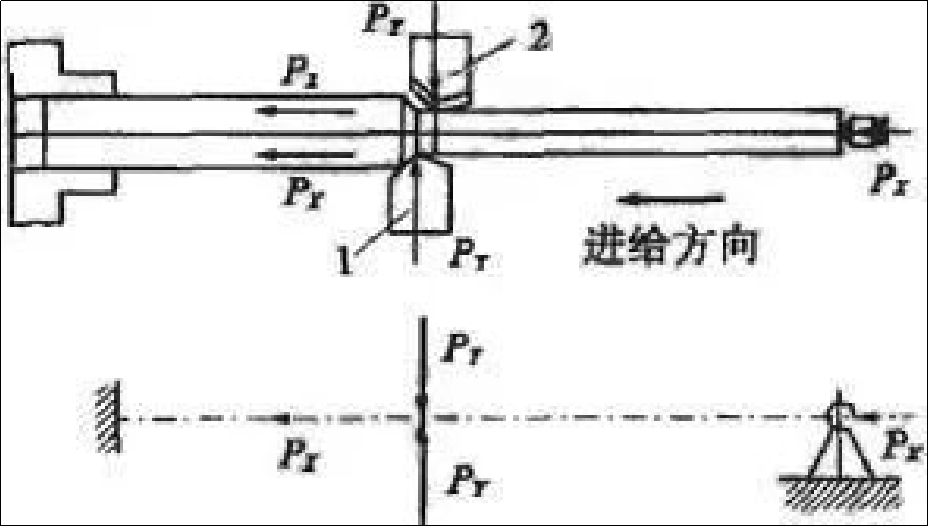

2) Mphamvu ya axial kudula mphamvu (PX)

Mphamvu ya axial imafanana ndi nsonga yomwe ili pamtunda wopyapyala ndipo imapanga mphindi yopindika muzogwirira ntchito. Mphamvu ya axial siili yofunikira pakutembenuka konse ndipo imatha kunyalanyazidwa. Chifukwa cha kusasunthika kwake, shaftyo imakhala yosakhazikika chifukwa cha kusakhazikika kwake. Mtsinje wowondayo umapindika pamene mphamvu ya axial ili yaikulu kuposa kuchuluka kwake. Monga momwe chithunzi 2 chikusonyezera.

Chithunzi 2: Mphamvu ya kudula mphamvu pa axial force

(2) Kudula kutentha

Kutentha kwa kutentha kwa workpiece kudzachitika chifukwa cha kutentha kwachangu komwe kumapangidwa ndi processing. Mtunda pakati pa chuck, pamwamba pa rearstock ndi workpiece amakhazikika chifukwa chuck ndi yokhazikika. Izi zimachepetsa kufalikira kwa axial kwa shaft, zomwe zimabweretsa kupindika kwa shaft chifukwa cha axial extrusion.

Zikuwonekeratu kuti kuwongolera kulondola kwa makina opyapyala ndi vuto lalikulu pakuwongolera kupsinjika ndi kusinthika kwamafuta munjira.

Njira Zothandizira Kulondola kwa Machining a Slender Shaft

Kuti muwongolere kulondola kwa makina ocheperako, ndikofunikira kuchitapo kanthu mosiyanasiyana malinga ndi momwe amapangira.

(1) Sankhani njira yoyenera yolumikizira

Kukhomerera kwapakati pawiri, imodzi mwa njira ziwiri zokhomerera zomwe nthawi zambiri zimagwiritsidwa ntchito potembenuza ma shafts ocheperako, zitha kugwiritsidwa ntchito kuyika chogwiriracho molondola ndikuwonetsetsa kuti pali coaxiality. Njira yokanikizira mkono wowondayo ndi wosakhazikika bwino, wopindika kwambiri, ndipo imatha kugwedezeka. Choncho ndi oyenera makhazikitsidwe ndi yaing'ono kutalika m'mimba mwake chiŵerengero, yaing'ono Machining chilolezo ndi mkulu zofunika coaxiality. Wamtalimwatsatanetsatane Machining zigawo zikuluzikulu.

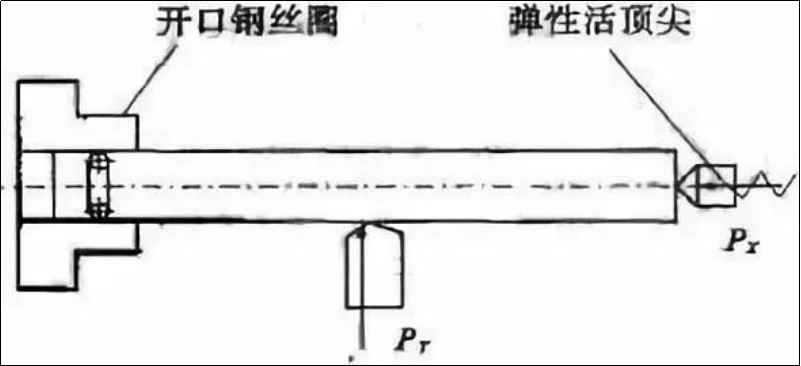

Nthawi zambiri, kupanga ma shafts opyapyala kumachitika pogwiritsa ntchito njira yokhotakhota yomwe imakhala ndi pamwamba imodzi ndi chingwe chimodzi. Komabe, munjira yokhomerera iyi, ngati muli ndi nsonga yothina kwambiri simangopindika tsindelo komanso kuti lisatalike pamene kutsinde likutembenuzika. Izi zitha kupangitsa kuti shaft ikanikidwe axially ndikupindika mopanda mawonekedwe. Malo otchinga sangagwirizane ndi dzenje la nsonga, zomwe zingayambitse shaft kupindika pambuyo pomangika.

Mukamagwiritsa ntchito clamping imodzi yokhala ndi pamwamba imodzi, pamwamba pake muyenera kugwiritsa ntchito malo okhala zotanuka. Mukatenthetsa mkono wowonda, ukhoza kukulitsidwa momasuka kuti uchepetse kupotoza kwake. Nthawi yomweyo chitsulo chotsegula chimayikidwa pakati pa nsagwada kupita ku dzanja laling'ono kuti achepetse kukhudzana kwa axial pakati pa nsagwada ndi mkono wowonda komanso kuthetsa kusakhazikika. Chithunzi 3 chikuwonetsa kukhazikitsa.

Chithunzi 3: Njira yowongolerera pogwiritsa ntchito chopachika chimodzi ndi chapamwamba

Kuchepetsa mphamvu ya deformation pochepetsa kutalika kwa shaft.

1) Gwiritsani ntchito chidendene ndi chimango chapakati

Chingwe chimodzi ndi chapamwamba chimodzi chimagwiritsidwa ntchito kutembenuza tsinde lowonda. Kuti muchepetse mphamvu ya ma radial pakupindika komwe kumachitika chifukwa cha shaft yowonda, chida chachikhalidwe ndi chimango chapakati chimagwiritsidwa ntchito. Izi ndizofanana ndi kuwonjezera chithandizo. Izi zimawonjezera kulimba ndipo zimatha kuchepetsa mphamvu ya radial pamtengowo.

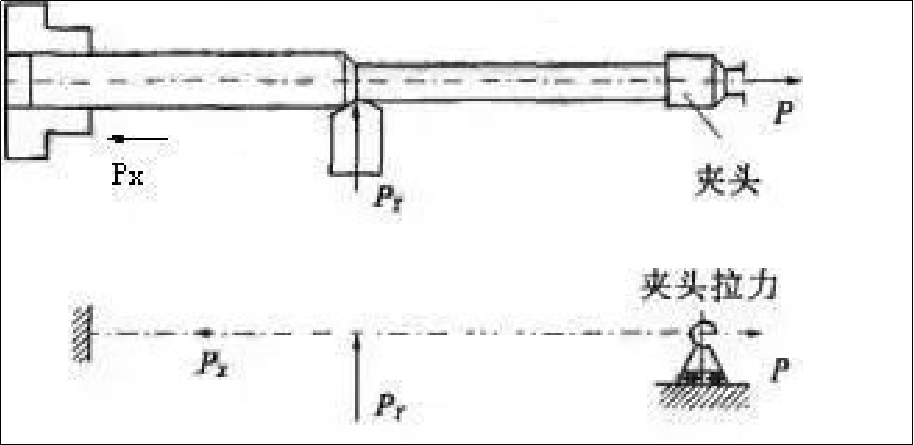

2) Manja owonda amazunguliridwa ndi njira ya axial clamping

N'zotheka kuonjezera kukhwima ndi kuthetsa zotsatira za mphamvu ya radial pa workpiece pogwiritsa ntchito mpumulo wa chida kapena chimango chapakati. Sizingathetsebe vuto la mphamvu ya axial yopinda chogwirira ntchito. Izi ndizowona makamaka kwa shaft yowondayo yokhala ndi mainchesi aatali. Chifukwa chake shaft yocheperako imatha kutembenuzidwa pogwiritsa ntchito njira ya axial clamping. Axial clamping imatanthawuza kuti, kuti mutembenuzire shaft yopyapyala, mbali imodzi ya shaft imangiriridwa ndi chuck ndipo mapeto ake ena ndi mutu wokhotakhota wopangidwa mwapadera. Mutu wokhomerera umagwiritsa ntchito mphamvu ya axial ku shaft. Chithunzi 4 chikuwonetsa mutu wa clamping.

Chithunzi 4 Axial clamping ndi kupsinjika maganizo

Manja ocheperako amakhala ndi kugwedezeka kosalekeza kwa axial panthawi yotembenuka. Izi zimathetsa vuto la axial kudula mphamvu yopindika kutsinde. Mphamvu ya axial imachepetsa kupindika kopindika komwe kumayambitsidwa ndi mphamvu zodulira ma radial. Imalipiritsanso kutalika kwa axial chifukwa cha kutentha kwapakati. kulondola.

3) Bwezerani kudula kutsinde kuti mutembenuzire

Monga momwe chithunzi 5 chikusonyezera, njira yodulira m'mbuyo ndi pamene chidacho chimadyetsedwa kudzera pa spindle kupita ku tailstock panthawi yotembenuza shaft yopyapyala.

Chithunzi cha 5 Kusanthula kwa Mphamvu Zamagetsi ndi Kusinthana ndi Njira Yodulira Reverse

Mphamvu ya axial yomwe imapangidwa panthawi yakukonza imalimbitsa tsinde, ndikulepheretsa kupindika. The zotanuka tailstock amathanso kubweza matenthedwe elongation ndi compression deformation chifukwa cha workpiece pamene akuyenda kuchokera chida kupita tailstock. Izi zimalepheretsa deformation.

Monga momwe chithunzi cha 6 chikusonyezera, mbale ya slide yapakati imasinthidwa ndikuwonjezera chosungira chakumbuyo ndikutembenuza zida zonse zakutsogolo ndi zakumbuyo nthawi imodzi.

Chithunzi 6 Limbikitsani kusanthula ndi kupanga mipeni iwiri

Chida chakutsogolo chimayikidwa mowongoka, pomwe chida chakumbuyo chimayikidwa mobwerera. Mphamvu zodulira zomwe zidapangidwa ndi zida ziwirizi zimathetsana pakutembenuka. Chogwirira ntchito sichimapunduka kapena kugwedezeka, ndipo kulondola kwadongosolo ndikokwera kwambiri. Izi ndizoyenera kupanga zambiri.

4) Njira yodulira maginito potembenuza tsinde lopyapyala

Mfundo ya maginito kudula ndi ofanana ndi reverse kudula. Mphamvu ya maginito imagwiritsidwa ntchito kutambasula shaft, kuchepetsa mapindikidwe panthawi yokonza.

(3) Chepetsani kuchuluka kwa kudula

Kuchuluka kwa kutentha komwe kumapangidwa ndi ndondomeko yodula kudzatsimikizira kuyenera kwa chiwerengero chodulidwa. Kusinthika komwe kumachitika chifukwa chozungulira tsinde lopyapyala kudzakhalanso kosiyana.

1) Kuzama kwa Dulani (t)

Malinga ndi lingaliro lakuti kukhwima kumatsimikiziridwa ndi ndondomeko ya ndondomeko, pamene kuya kwa kudula kumawonjezeka, momwemonso mphamvu yodulira, ndi kutentha komwe kumapangidwa potembenuka. Izi zimapangitsa kuti kupsinjika ndi kupotoza kwa kutentha kwa shaft yopyapyala kuchuluke. Potembenuza mitsinje yopyapyala, ndikofunikira kuchepetsa kuya kwa kudula.

2) Kuchuluka kwa chakudya (f).

Kuchuluka kwa chakudya kumawonjezera mphamvu yodulira komanso makulidwe. Mphamvu yodula imawonjezeka, koma osati molingana. Zotsatira zake, mphamvu yosinthira mphamvu ya shaft yopyapyala imachepetsedwa. Pankhani yowonjezereka yocheka, ndi bwino kuonjezera mlingo wa chakudya kusiyana ndi kuonjezera kudula kwakuya.

3) Kudula liwiro (v).

Ndikopindulitsa kuonjezera liwiro la kudula kuti muchepetse mphamvu. Pamene liwiro lodulira limawonjezera kutentha kwa chida chodulira, kukangana pakati pa chida, chogwirira ntchito, ndi shaft kumachepa. Ngati liwiro lodula ndilokwera kwambiri, ndiye kuti shaft imatha kupindika mosavuta chifukwa cha mphamvu za centrifugal. Izi zidzawononga kukhazikika kwa ndondomekoyi. Kuthamanga kwa zida zogwirira ntchito zomwe ndi zazikulu m'litali ndi m'mimba mwake ziyenera kuchepetsedwa.

(4) Sankhani ngodya yoyenera ya chida

Kuti muchepetse kupindika kopindika komwe kumachitika chifukwa chotembenuza tsinde lopyapyala, mphamvu yodulira panthawi yotembenuka iyenera kukhala yotsika momwe mungathere. Makona olowera, otsogola ndi m'mphepete amakhudza kwambiri mphamvu yodulira pakati pa ma angle a geometric a zida.

1) Mbali yakutsogolo (g)

Kukula kwa ngodya (g) kumakhudza mwachindunji mphamvu yodulira, kutentha ndi mphamvu. Mphamvu yodulira imatha kuchepetsedwa kwambiri powonjezera ma angles a rake. Izi zimachepetsa kupindika kwa pulasitiki komanso kumachepetsanso kuchuluka kwazitsulo zomwe zimadulidwa. Kuti muchepetse mphamvu zodulira, kuwonjezera ma angles okwera kutha kuchitika. Ma angles ake nthawi zambiri amakhala pakati pa 13deg ndi 17deg.

2) Lead angle (kr)

Kupatuka kwakukulu (kr), komwe ndiko mbali yayikulu kwambiri, kumakhudza kufanana ndi kukula kwa zigawo zonse zitatu zamphamvu yodula. Mphamvu ya radial imachepetsedwa pamene ngodya yolowera ikuwonjezeka, pamene mphamvu ya tangential imawonjezeka pakati pa 60deg ndi 90deg. Ubale wofananira pakati pa zigawo zitatu za mphamvu yodulira ndizabwinoko mumtundu wa 60deg75deg. Mbali yotsogola yayikulu 60deg nthawi zambiri imagwiritsidwa ntchito potembenuza ma shafts oonda.

3) Kupendekera kwa tsamba

Kupendekera kwa tsamba (ls), kumakhudza kuyenda kwa tchipisi ndi mphamvu ya nsonga ya chida, komanso mgwirizano wolingana pakati pa atatuwo.anatembenuza zigawokudula panthawi yokhotakhota. Mphamvu ya radial yodula imachepa pamene kupendekera kumawonjezeka. Komabe, mphamvu za axial ndi tangential zimawonjezeka. Ubale wofanana pakati pa zigawo zitatu za mphamvu yodula ndizomveka pamene kupendekera kwa tsamba kuli mkati mwa -10deg + 10deg. Kuti tchipisi tiyendere pamwamba pa shaft potembenuza tsinde lopyapyala, ndizofala kugwiritsa ntchito mbali yabwino pakati pa 0deg ndi +10deg.

Zimakhala zovuta kukwaniritsa miyezo yamtengo wapatali ya shaft yowonda chifukwa cha kusakhazikika kwake. Ubwino wokonza shaft wocheperako ungakhale wotsimikizika potengera njira zapamwamba zowongolera ndi njira zokhomerera, komanso kusankha ma angles oyenera ndi magawo.

Ntchito ya Anebon ndikuzindikira zolakwika zopanga ndikupanga ntchito yabwino kwambiri kwa makasitomala athu apakhomo ndi akunja kwathunthu kwa 2022 Aluminiyamu Akuluakulu Akuluakulu Akuluakulu a CNC Otembenuza Makina a Aerospace kuti akulitse msika wathu padziko lonse lapansi, Anebon imapatsa makasitomala athu akunja. ndi makina apamwamba kwambiri, zidutswa za milled ndiCNC kutembenuza ntchito.

China yogulitsa China Machinery Parts ndi CNC Machining Service, Anebon amasunga mzimu wa "zatsopano ndi mgwirizano, mgwirizano, kugawana, njira, patsogolo zothandiza". Mukatipatsa mwayi, tidzawonetsa kuthekera kwathu. Ndi thandizo lanu, Anebon akukhulupirira kuti titha kumanga tsogolo labwino kwa inu ndi banja lanu.

Nthawi yotumiza: Aug-28-2023