The zitsulo kutentha mankhwala ndi kutenthetsa zitsulo kapena aloyi workpiece ndi kutentha kwabwino mu sing'anga, ndipo pambuyo kusunga kutentha kwa nthawi inayake, utakhazikika mu TV zosiyanasiyana pa liwiro losiyana, kusintha pamwamba kapena mkati mwa chuma chachitsulo. Njira yopangira ma microstructural kuti aziwongolera magwiridwe ake.cnc Machining gawo

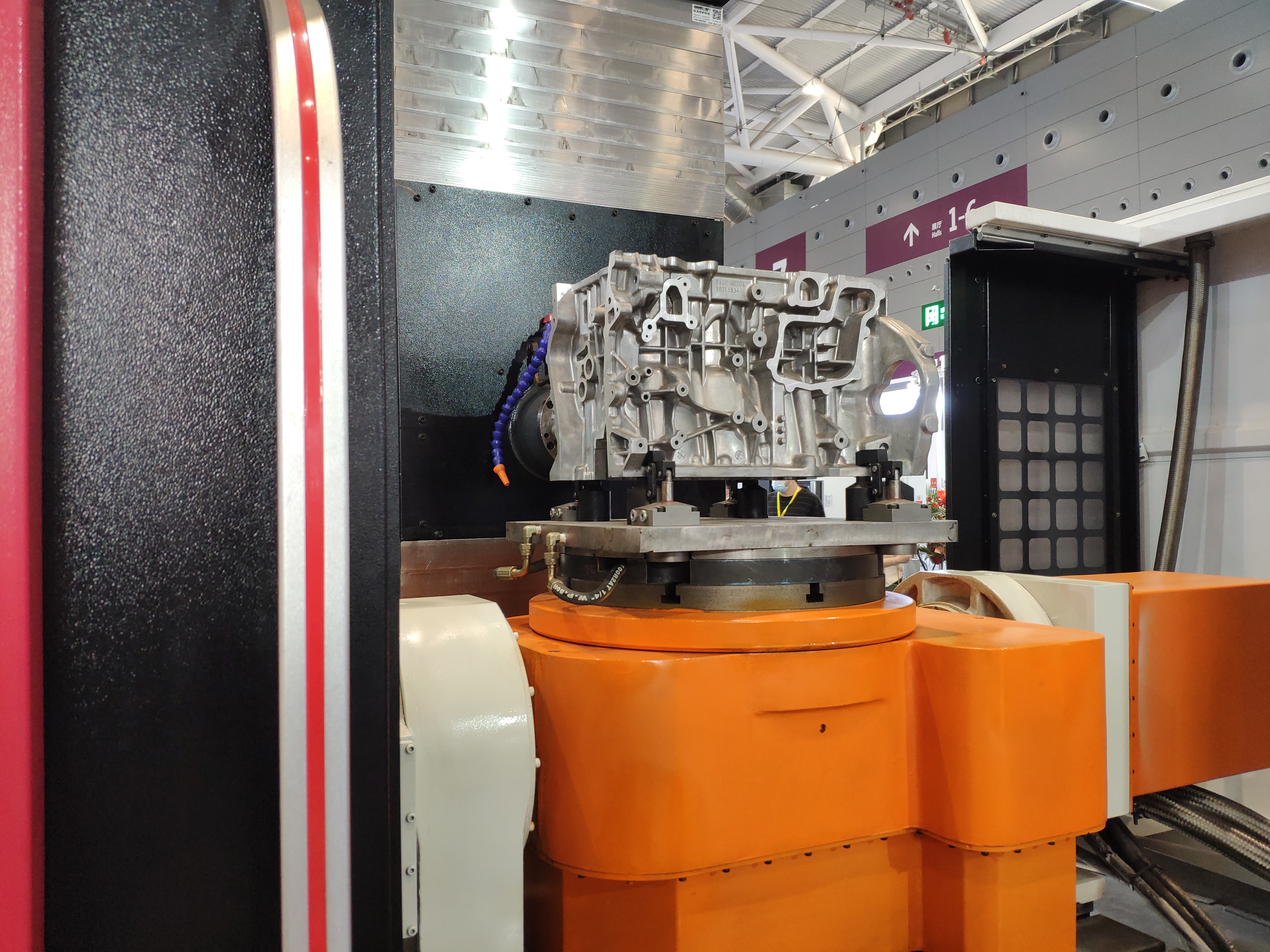

Gulu lalikulu

Njira zochizira kutentha kwachitsulo zitha kugawidwa m'magulu atatu: chithandizo cha kutentha kwathunthu, chithandizo cha kutentha pamwamba ndi chithandizo cha kutentha kwa mankhwala. Kutengera kutentha kwa sing'anga, kutentha kwa kutentha ndi njira yozizira, gulu lirilonse likhoza kugawidwa m'njira zingapo zosiyanasiyana zochizira kutentha. Chitsulo chomwecho chimagwiritsa ntchito njira zosiyanasiyana zochizira kutentha kuti zipeze ma microstructures osiyanasiyana komanso katundu wosiyana. Chitsulo ndicho chitsulo chomwe chimagwiritsidwa ntchito kwambiri pamakampani, ndipo microstructure yachitsulo ndizovuta kwambiri, kotero pali mitundu yambiri yazitsulo zopangira kutentha kwazitsulo.mkuwa cnc Machining gawo

Makhalidwe

Kuchiza kutentha kwazitsulo ndi imodzi mwazinthu zofunika kwambiri pakupanga makina. Poyerekeza ndi njira zina processing, kutentha mankhwala zambiri sasintha mawonekedwe ndi lonse mankhwala zikuchokera workpiece, koma amasintha microstructure mkati workpiece kapena kusintha mankhwala zikuchokera pamwamba pa workpiece. , kupereka kapena kupititsa patsogolo ntchito ya workpiece. Imadziwika ndi kusinthika kwamkati kwa chogwirira ntchito, chomwe nthawi zambiri sichimawoneka ndi maso. Choncho, ndi njira yapadera yopangira makina komanso gawo lofunikira la kayendetsedwe ka khalidwe.

Kuti zitsulo zopangira zitsulo zikhale ndi zofunikira zamakina, katundu wakuthupi ndi mankhwala, kuphatikizapo kusankha koyenera kwa zipangizo ndi njira zosiyanasiyana zopangira, njira zothandizira kutentha nthawi zambiri zimakhala zofunikira. Chitsulo ndiye chinthu chomwe chimagwiritsidwa ntchito kwambiri pamakampani opanga makina. The microstructure yachitsulo ndi yovuta ndipo imatha kuwongoleredwa ndi chithandizo cha kutentha. Choncho, chithandizo cha kutentha kwazitsulo ndizofunika kwambiri pazitsulo zachitsulo. Kuphatikiza apo, aluminiyamu, mkuwa, magnesium, titaniyamu, ndi zina zotero zimathanso kusinthidwa ndi chithandizo cha kutentha kuti mupeze makina osiyanasiyana, katundu wakuthupi, ndi mankhwala.

Basic ndondomeko

Chithandizo chonse cha kutentha ndi njira yachitsulo yochizira kutentha yomwe imatenthetsa ntchito yonseyo kenako ndikuyizizira pa liwiro loyenera kuti isinthe mawonekedwe ake onse. Onse kutentha mankhwala zitsulo ali njira zinayi zofunika: annealing, normalizing, quenching ndi tempering.pulasitiki gawo

Annealing ndi kutenthetsa workpiece kutentha koyenera, pogwiritsa ntchito nthawi zosiyanasiyana malinga ndi zinthu ndi kukula kwa workpiece, ndiyeno kuzizira pang'onopang'ono, kuti abweretse mkati mwa chitsulo kapena pafupi ndi mgwirizano, kapena kumasula kupsinjika kwamkati komwe kumapangidwa ndi njira yapitayi. Pezani magwiridwe antchito abwino ndi magwiridwe antchito, kapena konzekerani kuzimitsa kwina.

Normalizing kapena normalizing ndi kuziziritsa workpiece ndi kutentha koyenera ndiyeno kuziziziritsa mu mpweya. Zotsatira za normalizing ndizofanana ndi annealing, koma mapangidwe ake ndi abwino, omwe nthawi zambiri amagwiritsidwa ntchito kuti apititse patsogolo kudula kwa zipangizo, ndipo nthawi zina amagwiritsidwa ntchito pazinthu zina. Zigawo zomwe sizili zapamwamba zimagwiritsidwa ntchito ngati chithandizo chomaliza cha kutentha.

Kuzimitsa ndi kuziziritsa mofulumira workpiece pambuyo Kutenthetsa ndi kuchisunga mu sing'anga kuzimitsira monga madzi, mafuta kapena ma inorganic mchere njira kapena organic amadzimadzi njira. Pambuyo kuzimitsa, chitsulo chimakhala cholimba koma chimakhala chophwanyika nthawi yomweyo.

Pofuna kuchepetsa kuphulika kwachitsulo, chitsulo chozimitsidwa chimatsekedwa kwa nthawi yaitali pa kutentha koyenera pamwamba pa kutentha kwa chipinda ndi pansi pa 650 ° C, ndiyeno utakhazikika. Njira imeneyi imatchedwa tempering. Annealing, normalizing, quenching ndi tempering ndi "moto zinayi" mu wonse kutentha mankhwala. Pakati pawo, kuzimitsa ndi kutentha ndizogwirizana kwambiri, ndipo nthawi zambiri zimagwiritsidwa ntchito palimodzi, ndizofunikira.

Anebon Metal Products Limited ikhoza kupereka CNC Machining, Die Casting, Sheet Metal Fabrication service, chonde omasuka kulankhula nafe.

Tel: +86-769-89802722 E-mail: info@anebon.com URL: www.anebon.com

Nthawi yotumiza: Aug-31-2019