Sheet Metal Fabrication

Joalo ka sesebelisoa se felletseng le lebenkele la die, re na le litsebo libakeng tsohle tsa masela ho kenyelletsa fiber laser, CNC punching, CNC beng, CNC forming, welding, CNC machining, ho kenya hardware le kopano.

Re amohela lisebelisoa tse tala ka maqephe, lipoleiti, mekoallo kapa li-tubes 'me re na le phihlelo ea ho sebetsa ka lisebelisoa tse sa tšoaneng tse kang aluminium, koporo, tšepe e sa hloekang le litšepe tsa carbon. Litšebeletso tse ling li kenyelletsa ho kenya hardware, welding, grinding, machining, phethola le ho kopanya. Ha melumo ea hau e ntse e eketseha re boetse re na le khetho ea ho sebelisa likarolo tsa hau ka thata ho sebetsa lefapheng la rona la setempe sa tšepe. Likhetho tsa tlhahlobo li fapana ho tloha ho licheke tse bonolo ho tloha ho FAIR & PPAP.

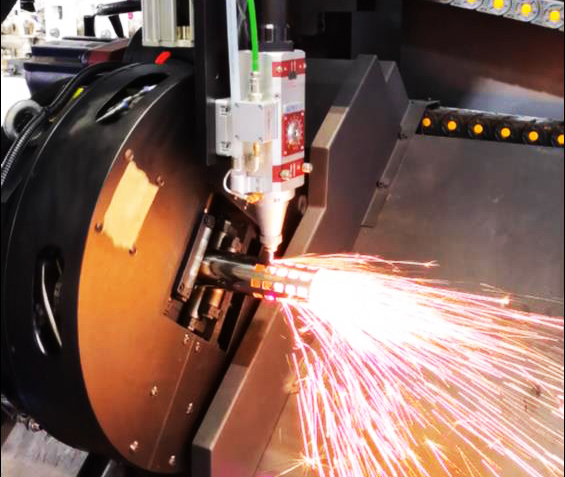

Ho khaola Laser

Ho Koba ka Tšepe

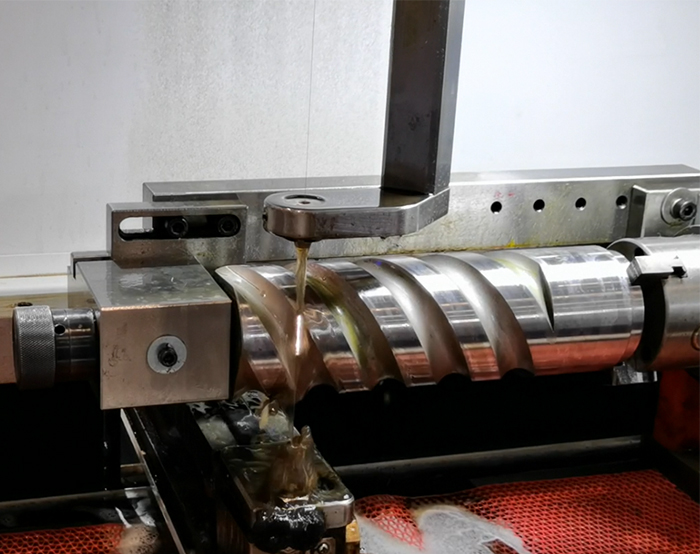

WEDM

Welding

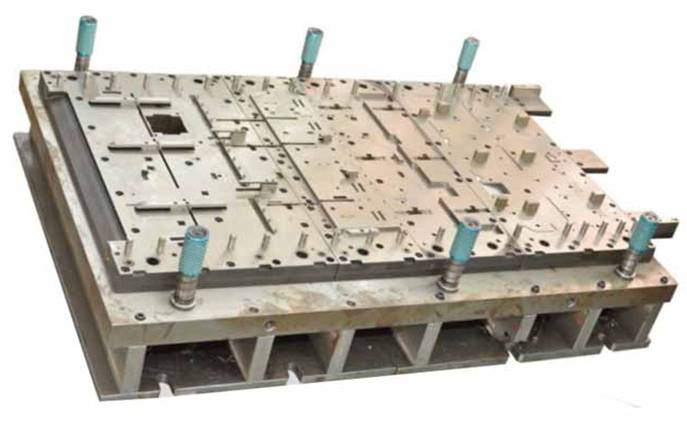

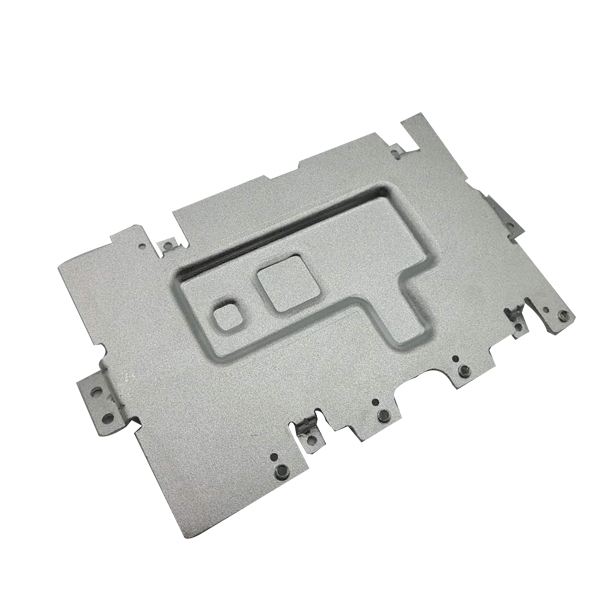

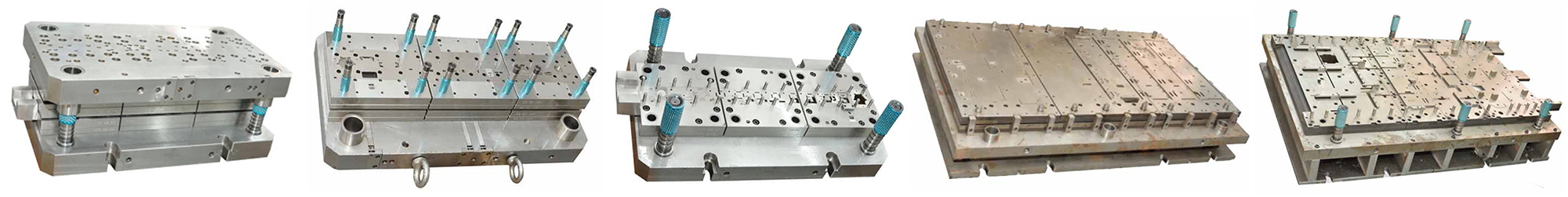

Tšebeletso ea Setempe

Re tla sebelisa lisebelisoa tsa rona tse tsoetseng pele le sehlopha se nang le boiphihlelo ho etsa lihlahisoa tseo u li nahanang, 'me re lumela hore re ka fihlela litlhoko tsa hau ho latela theko le boleng.

Stamping ke eng?

Letlapa la tšepe le entsoe ka likarolo tse fapaneng tse kang lakane le likhetla, li-workpieces tse kang setshelo mochining oa khatiso ka hlobo, kapa likotoana tsa li-tube li entsoe ka li-workpieces tse fapaneng tsa tubula. Mokhoa ona oa ho bopa sebakeng se batang o bitsoa serame sa serame, se bitsoang ho hatakela.

Ho sebetsa ka setempe ke theknoloji ea tlhahiso ea likarolo tsa lihlahisoa tse nang le sebōpeho se itseng, boholo le ts'ebetso ka matla a lisebelisoa tse tloaelehileng kapa tse khethehileng tsa litempe, tse senyang ka ho toba le ho senya lakane ka hlobo. Lipampiri, hlobo le lisebelisoa ke lintlha tse tharo tsa ho hatakela.

Mefuta e ka sehloohong ea ts'ebetso: ho otla, ho kobeha, ho kuta, ho taka, ho phunya, ho ohla, ho lokisa.

Lisebelisoa: Bofofisi, sesole, mechini, mechini ea temo, lisebelisoa tsa elektroniki, tlhahisoleseling, literene, poso le likhokahano tsa mehala, lipalangoang, lik'hemik'hale, lisebelisoa tsa bongaka, lisebelisoa tsa lapeng le indasteri e bobebe.

Litšobotsi

Re sebelisa liforomo tse nepahetseng, ho nepahala ha mosebetsi ho ka fihla boemong ba micron, 'me ho pheta-pheta ho nepahetseng ho phahame, litlhaloso li tšoana,' me masoba le baokameli ba ka phunngoa.

1 Palo ea lichapo tsa mochine o tloaelehileng oa khatiso e fihla ho makhetlo a mashome a 'maloa ka motsotso,' me khatello e phahameng e ka ba makhetlo a makholo kapa a likete ka motsotso, 'me ho ka fumanoa punch bakeng sa setoro se seng le se seng sa khatiso.

(2) Kaha lefu le tiisa boholo le sebōpeho sa ho nepahala ha karolo ea setempe nakong ea ho hatakela, 'me ka kakaretso ha e senye boleng ba bokaholimo ba karolo ea setempe,' me bophelo ba lefu ka kakaretso bo bolelele, boleng ba setempe bo tsitsitse, ho fapanyetsana ho molemo, 'me ho na le "tšoana". Litšobotsi.

(3) Re ka tobetsa le ho sebetsana le likarolo tse nang le boholo bo boholo le libopeho tse rarahaneng, joalo ka li-stopwatches tse nyane joalo ka lioache, ho ea fihla maballong a longitudinal ea koloi, likarolo tse koahelang, joalo-joalo, hammoho le phello e batang ea deformation e thata ea thepa ea setempe, matla a ho otla le ho satalla. li phahame.

(4) Ho hatakela ka kakaretso ha ho na likhechana tsa chip, tšebeliso e fokolang ea thepa, 'me ha ho hlokahale lisebelisoa tse ling tsa ho futhumatsa. Ka hona, ke mokhoa oa ho boloka thepa le ho boloka matla, 'me litšenyehelo tsa likarolo tsa setempe li tlaase.

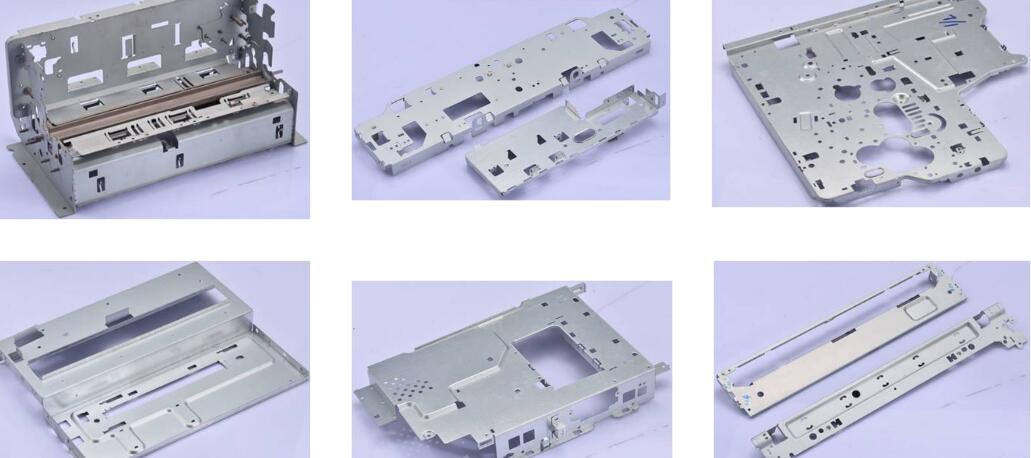

Lihlahisoa