Bakeng sa lienjine, likaroloana tsa shaft joalo ka li-crankshaft, li-camshaft, le li-cylinder liner li sebelisa li-chucks ts'ebetsong e 'ngoe le e 'ngoe ea ho sebetsa. Nakong ea ts'ebetso, setsi sa li-chucks, se tiisa le ho khanna workpiece. Ho ea ka bokhoni ba chuck ho tšoara workpiece le ho boloka setsi, e arotsoe ka chuck e thata le chuck e phaphametseng. Sengoliloeng sena se bua haholo ka melao-motheo ea khetho ea li-chucks tsena tse peli le lintlha tsa tlhokomelo ea letsatsi le letsatsi.5aixs likarolo tsa mochini oa CNC

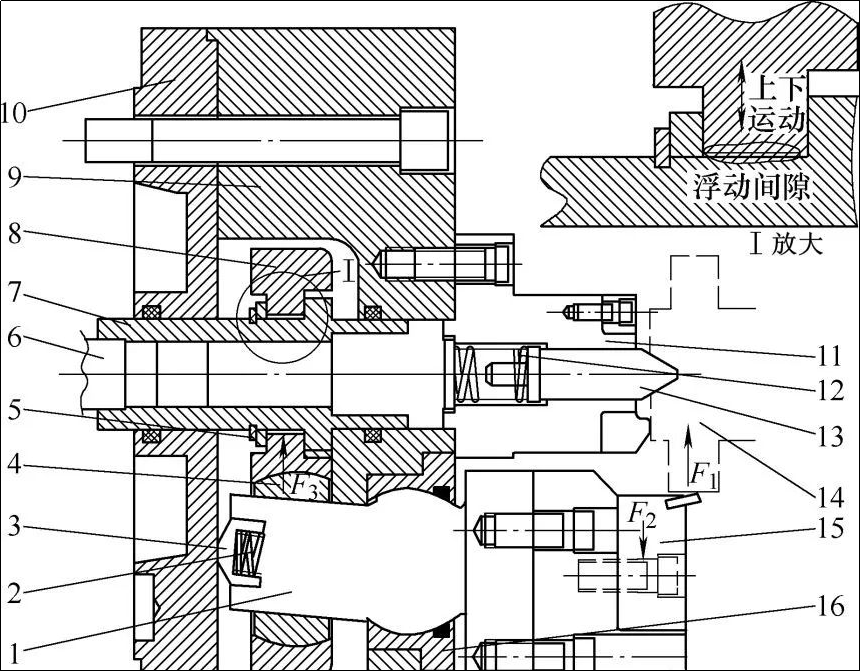

Li-chucks tse thata le li-chucks tse phaphametseng li fapane haholo ka sebopeho le mekhoa ea tokiso. Ho nka letoto la li-chucks tsa mofuta oa Majapane e le mohlala, Setšoantšo sa 1 se bonts'a ts'ebetso ea chuck e phaphametseng: sesebelisoa se tlas'a ts'ebetso ea sethala sa tšehetso sa boemo le holimo. Axial le radial positioning le clamping li etsoa. Ebe, silindara ea chuck e khanna molamu oa thae, poleiti ea ho lokisa lekhalo, poleiti ea letsoho la mohlahare, lenonyeletso le chitja, le letsoho la mohlahare ka har'a molamu oa thae, qetellong e hlokomela mohlahare oa chuck ho tiisa mosebetsi.

Ha ho na le ho kheloha ho hoholo ha coaxially pakeng tsa bohareng ba mehlahare e meraro ea chuck le bohareng ba workpiece, mohlahare oa chuck o kopanang le workpiece pele o tla kenngoa ka matla F2, e fetisetsoang mohlahareng. letlapa la ho tshehetsa letsoho ka letsoho la mohlahare le lenonyeletso le chitja. F3 e sebetsa holim'a poleiti e tšehetsang letsoho la claw. Bakeng sa chuck e phaphametseng, ho na le lekhalo pakeng tsa molamu o bohareng oa chuck le poleiti ea ho tšehetsa letsoho la claw. Tlas'a ts'ebetso ea matla a F3, poleiti e tšehetsang letsoho la claw e sebelisa sekheo se phaphametseng (poleiti ea ho lokisa lekhalo, Molamu o bohareng oa chuck, le poleiti ea tšehetso ea letsoho la mohlahare hammoho e theha mochini o phaphametseng oa chuck), tsamaea ka lehlakoreng la matla ho fihlela mehlahare e meraro e koala workpiece ka ho feletseng.

Setšoantšo sa 1 Sebopeho sa chuck se phaphametseng

1. Letsoho la manala

2. Rectangular selemo

3. Sekoahelo se ka holimo sa spherical

4. Lenonyeletso la spherical

5. Letlapa la phetoho ea ho hlakola

6. Molamu oa ho hula moqomo

7. Chuck setsi hula molamu

8. Letlapa le tšehetsang letsoho la claw

9. 'Mele oa Chuck 10. Sekoahelo sa ho qetela sa Chuck

10. Sebaka sa tšehetso sa boemo

12. Mosebetsi o tla sebetsoa

13. Chuck Jaws 16. Tšehetso ea bolo

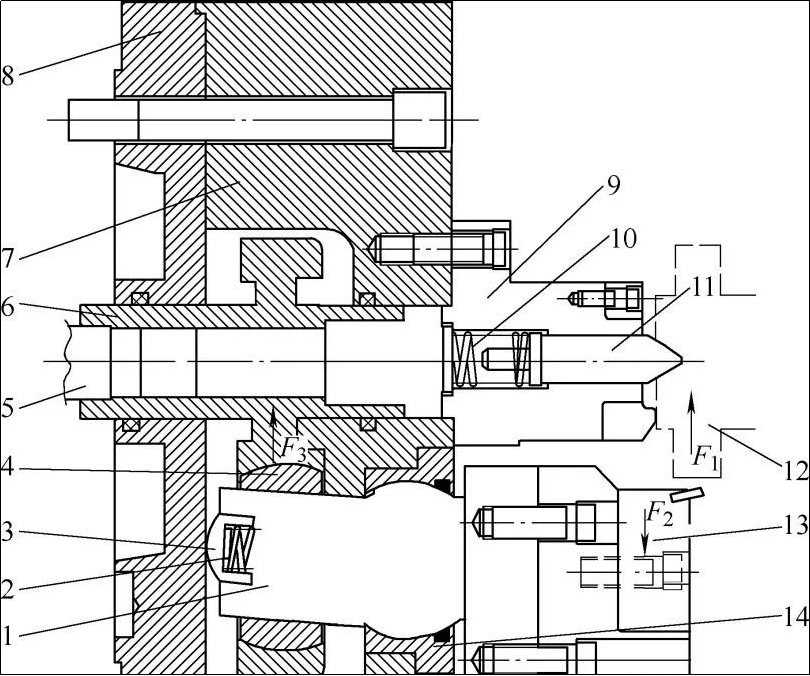

Setšoantšo sa 2 se bonts'a ts'ebetso ea ts'ebetso ea chuck e thata

Tlas'a ts'ebetso ea boloko ba ts'ehetso ea boemo le bokaholimo, workpiece e behiloe 'me e koaletsoe ka axially le radially, ebe moqomo oa oli oa chuck o khanna molamu o bohareng, motsoako o chitja le mohlahare oa chuck ka molamu oa ho hula. Letsoho lea sisinyeha, 'me qetellong, mehlahare ea chuck e tiisa mosebetsi. Kaha setsi se hula molamu oa chuck se kopantsoe ka thata le lenonyeletso le chitja le letsoho la mohlahare, ka mor'a hore mehlahare ea li-chuck (mehlahare e meraro) e koaletsoe, ho tla thehoa setsi sa clamping. Setsi sa clamping se entsoeng ka holimo ha se kopane, 'me workpiece e tla ba le deformation e hlakileng ea clamping ka mor'a hore chuck e koaletsoe. Pele chuck e sebelisoa, hoa hlokahala ho lokisa ho kopana pakeng tsa bohareng ba chuck le bohareng ba setsi ho etsa bonnete ba hore chuck e ke ke ea hlaha ka mor'a ho koala. Boemo ba clamped.

Setšoantšo sa 2 Sebopeho se thata sa chuck

1. Letsoho la manala

2. 10. Seliba sa Rectangular

3. Sekoahelo se ka holimo sa spherical

4. Lenonyeletso la spherical

5. Molamu oa cylinder tie

6. Chuck setsi sa thae molamu

7. 'Mele oa Chuck

8. Sekoahelo se ka morao sa Chuck

9. Sebaka sa tšehetso sa boemo

10. Holimo

11. Mosebetsi o tla sebetsoa

12. Mehlahare ea Chuck

13. Tšehetso e chitja

Ho tsoa tlhahlobong ea mochini oa chuck ho Setšoantšo sa 1 le Setšoantšo sa 2, chuck e phaphametseng le chuck e thata li na le phapang e latelang.

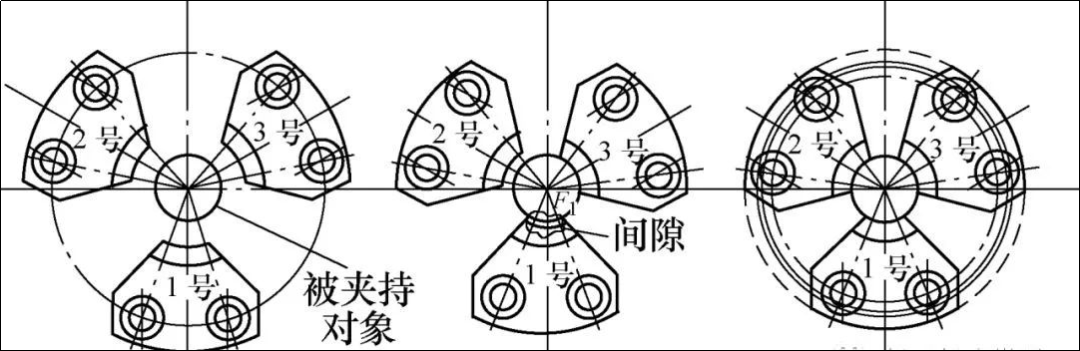

Floating chuck: Joalokaha ho bontšitsoe Figure 3, ka tshebetso ya ho clamping workpiece, ka lebaka la ho bophahamo bo fapaneng ba workpiece e se nang letho holim'a metsi kapa e khōlō roundness mamello ea sekheo, ea No. 3 mohlahare tla kopana le workpiece holim'a metsi le. ho tla hlaha mehlahare ea No. 1 le No. 2. Haeba workpiece e e-s'o angoa leha ho le joalo, ka nako ena, mochine o phaphametseng oa chuck o phaphametseng o sebetsa, o sebelisa bokaholimo ba workpiece e le tšehetso ea ho phaphametsa mohlahare oa No. Hafeela palo e phaphametseng e lekane, mehlahare ea No. 1 le No. 2 e tla qetella e koaletsoe. Sebaka sa mosebetsi se na le phello e fokolang bohareng ba mosebetsi.

Setšoantšo sa 3 Ho koala mehlahare ea chuck e phaphametseng

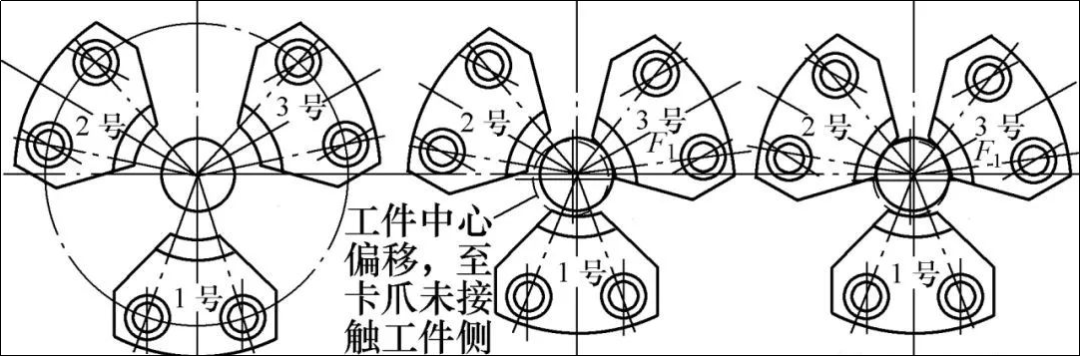

Rigid chuck: Joalokaha ho bontšitsoe setšoantšong sa 4, nakong ea ts'ebetso ea clamping, haeba concentricity pakeng tsa chuck le workpiece e sa lokisoe hantle, mohlahare oa No. 3 o tla ikopanya le workpiece, 'me No. 1 le No. ho kopana le workpiece. , ebe chuck clamping force F1 e tla sebetsa ho workpiece. Haeba matla a lekaneng a lekana, mosebetsi o tla tlosoa ho tloha setsing se reriloeng esale pele, ho qobella workpiece ho fallela bohareng ba chuck; ha matla a clamping a chuck a le nyane, linyeoe tse ling li tla etsahala. Ha mehlahare e sa khone ho ikopanya ka botlalo le workpiece, ho sisinyeha ho etsahala nakong ea machining.sehokelo sa cnc milling

Setšoantšo sa 4 Ho koala mehlahare e thata ea chuck

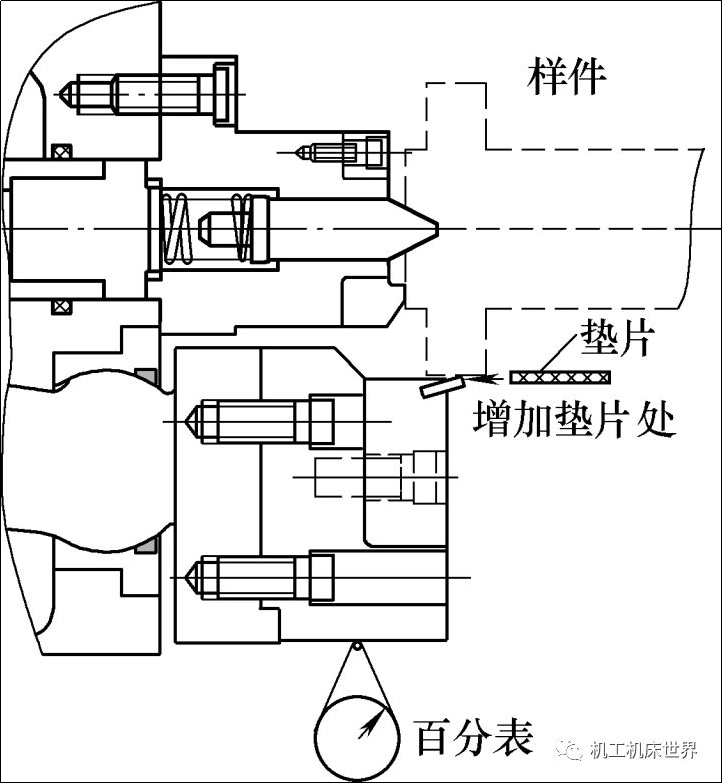

Litlhoko tsa ho fetola pele chuck e sebelisoa: The chuck e thata e tla theha setsi sa clamping ea chuck ka boeona ka mor'a ho koala. Ha u sebelisa chuck e thata, hoa hlokahala ho lokisa setsi sa clamping sa chuck hore se tsamaisane le setsi sa ho koala le ho beha sebaka sa mosebetsi, joalo ka ha ho bonts'itsoe setšoantšong sa 5.cnc machining aluminium karolo

Setšoantšo sa 5 Tokiso ea setsi se thata sa chuck

Ho ea ka tlhahlobo e ka holimo ea sebopeho, ho kgothaletswa ho latela melao-motheo e latelang ho lokisong le tlhokomelong ea chuck: Li-lubrication le mafura a likarolo tse tsamaeang ka hare ho chuck li lula li nkeloa sebaka. Ho tsamaea pakeng tsa likarolo tse tsamaeang ka hare ho chuck ha e le hantle ke ho ferekana ho thellang. Hoa hlokahala ho eketsa le ho khutlisa sehlopha se boletsoeng sa oli / mafura ho latela litlhoko tsa tlhokomelo ea chuck. Ha u eketsa mafura, ho hlokahala hore u pepese mafura 'ohle a sebelisitsoeng nakong e fetileng, ebe o thibela koung ea ho ntša oli ka mor'a ho koala chuck ho thibela lehare la ka hare la chuck hore le se ke la ts'oaroa.

Ho hlahloba khafetsa le ho lokisoa ha setsi sa "clamping" sa chuck e thata le setsi sa mosebetsi: Chuck e thata e hloka ho lekanya nako le nako hore na bohare ba chuck le bohareng ba "workpiece spindle" boa ts'oana. Lekanya ho fela ha disc. Haeba e feta tekanyo e hlokahalang, eketsa li-spacers ka mokhoa o nepahetseng mohlahare o le mong kapa tse peli tse lumellanang le ntlha e phahameng, 'me u phete mehato e ka holimo ho fihlela litlhoko li finyelloa.

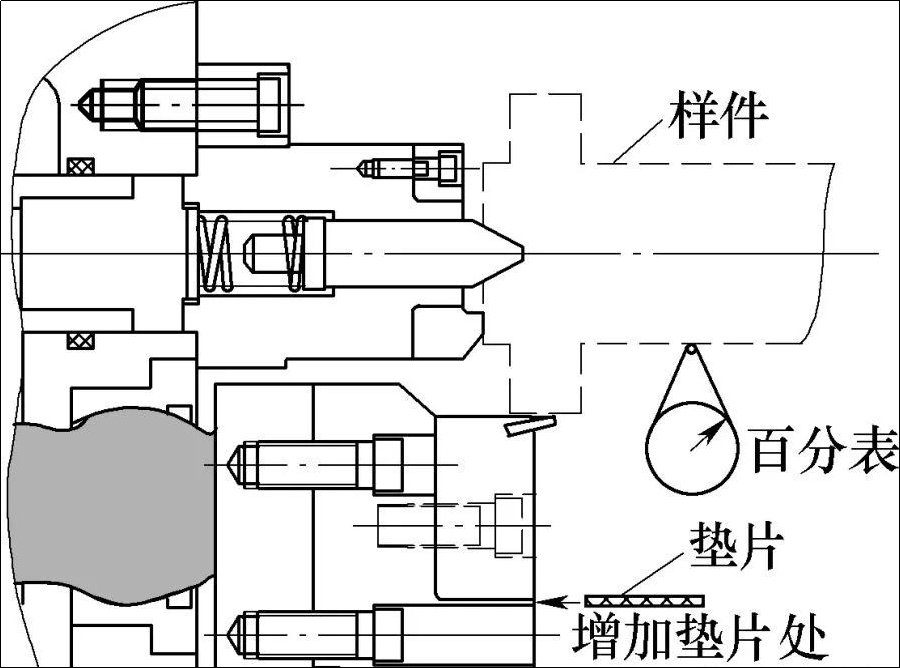

Tlhahlobo ea nako le nako ea palo e phaphametseng ea chuck e phaphametseng (sheba setšoantšo sa 6). Tlhokomelong ea letsatsi le letsatsi ea chuck, hoa hlokahala ho lekanya khafetsa palo e phaphametseng le ho nepahala ho phaphametseng ha chuck e phaphametseng, le ho fana ka tataiso bakeng sa tlhokomelo ea kahare ea chuck nakong ea morao. Mokhoa oa ho lekanya oa ho phaphamala ka nepo: ka mor'a hore chuck e hatelle sampole, beha chuck hore e lekanngoe. Fetolela manala sebakeng se loketseng sa ho metha, lekanya letšoao la ho daela (tlhoko ea ho hokela botlaaseng ba methara ea makenete ho shaft e tsamaeang), 'me u tšoaee ntlha ea ho metha joalo ka ntlha ea noto. Ebe u laola servo axis ho tsamaisa lets'oao la ho daela, bula chuck, beha gasket e nang le botenya ba Amm lipakeng tsa mehlahare e lokelang ho lekanyetsoa le sampole, tiisa sampole ho chuck, tsamaisa letšoao la ho daela sebakeng sa zero, mme o netefatse hore na data e hatisitsweng ke sesupa sa ho daela e mabapi le Amm. Haeba ho joalo, ho bolela hore ho nepahala ho phaphametseng ho molemo. Haeba data e fapane haholo, ho bolela hore ho na le bothata ka mochine o phaphametseng oa chuck. Tekanyo ea mehlahare e meng e tšoana le e ka holimo.

Setšoantšo sa 6 Ho hlahloba palo e phaphametseng ea chuck e phaphametseng

Ho nkeloa sebaka khafetsa ha likarolo tse kang liqibi, li-gaskets le liliba ka har'a chuck: liliba tse mahlakore a mabeli, 'mele oa chuck, sekoaelo se ka morao sa chuck, liliba tse mahlakore a mabeli, litiiso le liliba tse nang le litšehetso tse chitja li tlameha ho etsoa ho latela makhetlo a tšebeliso le tse kaholimo. liphetho tsa liteko. Fetola sebaka kamehla. Ho seng joalo, mokhathala o tla e senya, e leng se tla fella ka palo e phaphametseng le ho phalla ho thata ha chuck.

Ka tlhahlobo e kaholimo ea lintlha tsa bohlokoa tsa tokiso le tlhokomelo ea sebopeho sa chuck, ela hloko melao-motheo e latelang khethong ea li-chucks: haeba karolo ea chuck clamping ea karolo e sebelitsoeng ke sebaka se se nang letho, chuck e phaphametseng e ea khethoa, le chuck e thata. e sebelisoa sebakeng sa mosebetsi. The chuck clamping holim'a karolo e entsoeng ka mochine ke bokaholimo ka mor'a ho hlaka, ho qeta halofo / ho qeta. Ka mor'a ho latela melao ea motheo e ka holimo, ho etsa khetho e nepahetseng ho latela maemo a fapaneng a mosebetsi hoa hlokahala.

Khetho ea chuck e thata:

①Maemo a machining a hloka palo e kholo ea ho itšeha le matla a maholo a ho itšeha. Ka mor'a hore clamped ke workpiece ho sebetswa le ho tšehetsoa ke setsi foreime, e mesifa workpiece rigidity, 'me e khōlō workpiece rotational matla a ho khanna ho hlokahala.

②Ha ho se na mochine oa nako e le 'ngoe, joalo ka holimo, moralo oa chuck centering oa hlokahala.

Khetho ea li-chuck tse phaphametseng:

① Litlhoko tse phahameng bakeng sa ho theha setsi sa spindle sa workpiece. Kamora hore chuck e tiisetsoe, ho phaphamala ha eona ho ke ke ha sitisa setsi sa mantlha sa spindle ea workpiece.

② Chelete ea ho itšeha ha e kholo, 'me ho hlokahala feela ho khanna spindle ea workpiece ho potoloha le ho eketsa ho tiea ha mosebetsi.

Lintlha tse ka holimo li hlalosa liphapang tsa sebopeho le litlhoko tsa tlhokomelo le khetho ea li-chucks tse phaphametseng le tse thata, tse thusang bakeng sa tšebeliso le tlhokomelo. U hloka kutloisiso e tebileng le tšebeliso e tenyetsehang; o hloka ho lula o akaretsa boiphihlelo ba ts'ebeliso le tlhokomelo ea setšeng.

Anebon Metal Products Limited e ka fana ka CNC Machining, Die Casting、Sheet Metal Fabrication service, ka kopo ikutloe u lokolohile ho ikopanya le rona.

Tel: +86-769-89802722 E-mail: info@anebon.com URL: www.anebon.com

Nako ea poso: Mar-31-2022