Khoele ke helix e sehiloeng ho sebetsa ka ntle kapa ka hare mme e sebeletsa mesebetsi e mengata ea bohlokoa. Ntlha ea pele, likhoele li theha khokahanyo ea mochine ka ho kopanya sehlahisoa se kentsoeng ka hare le sehlahisoa sa ka ntle. Khokahano ena e tiisa hore likarolo tse fapaneng tsa workpiece li ka hokahanngoa ka thata.

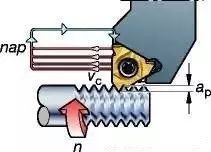

Ho feta moo, likhoele li phetha karolo ea bohlokoa ho fetiseng ho sisinyeha. Ba ka fetola motsamao oa rotary hore e be motsamao oa mola le ka tsela e fapaneng. Bokhoni bona bo bohlokoa haholo lits'ebetsong tse ngata, joalo ka mochining o hlokang ho sisinyeha ha mela ho etsa mesebetsi e itseng.

Ho feta moo, likhoele li fana ka melemo ea mochini. Ka ho sebelisa likhoele, ts'ebetso e phahameng ea mochini e ka fihlelleha maemong ohle. Sena se kenyeletsa ho eketseha ha matla a ho jara, matla a matlafalitsoeng a ho hanyetsa ho hlephisa kapa ho thothomela, le ho ntlafatsa bokhoni ba phetisetso ea matla.

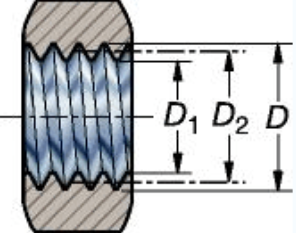

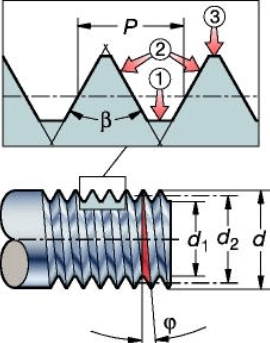

Ho na le mefuta e fapaneng ea likhoele, e 'ngoe le e' ngoe e khethollang geometry ea khoele. Karolo ea bohlokoa ea profil ea khoele ke bophara ba workpiece. Sena se kenyelletsa bophara bo boholo (bophara bo boholo ba khoele) le bophara ba sekontiri (bophara sebakeng se inahaneloang moo bophara ba khoele e leng zero). Litekanyo tsena li bohlokoa ho netefatsa hore likhoele li lumellana hantle le ho sebetsa hantle.

Ho utloisisa mantsoe a khoele ho bohlokoa ho sebelisa likhoele ka katleho. Mareo a mang a bohlokoa a kenyelletsa lead (sebaka sa axial seo khoele e se tsamaeang ka phetoho e le 'ngoe e felletseng) le sekontiri se matla (sebaka se pakeng tsa lintlha tse tsamaellanang holim'a likhoele tse haufi). Tekanyo e nepahetseng ea loto le sekontiri se bohlokoa ho netefatsa moralo o nepahetseng oa likhoele le ho lumellana.

Ka kakaretso, likhoele li sebetsa mesebetsi e mengata ea bohlokoa liindastering tse fapaneng. Li tsamaisa likhokahano tsa mochini, li fetisetsa motsamao le ho fana ka melemo ea mochini. Ho utloisisa litlaleho tsa likhoele le mantsoe a amanang le tsona ho bohlokoa ho sebelisa likhoele ka katleho le ho netefatsa ts'ebetso e nepahetseng.

Ho Rarolla Lekunutu la Pitch: Ho Fuputsa Moelelo oa Lona le Mokhoa oa ho Balla

Ho phahama ha likhoele ke ntlha ea bohlokoa lefapheng la tlhahiso le machining. Ho utloisisa seo e se bolelang le ho e bala ka nepo ho bohlokoa ho etsa likarolo tse entsoeng ka mochini oa boleng bo holimo. Sengoliloeng sena, re tla ikakhela ka setotsoana ho rarahaneng ha khoele ea molumo, geometry ea eona, le mokhoa oa ho e tseba ka nepo. Ho feta moo, re tla tsebisa Anebon, k'hamphani e sebetsanang le lits'ebeletso tsa mochini oa CNC tsa prototype le milling ea tloaelo ea CNC, e fanang ka mantsoe a qotsitsoeng a Marang-rang a potlakileng le a tšepahalang bakeng sa machining a CNC.

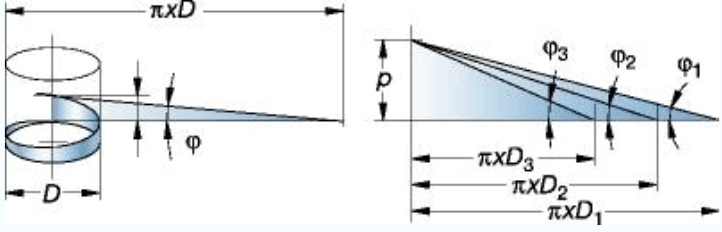

The geometry ea khoele e thehiloe ka khoele sekontiri se metsi bophara (d, D) le sekontiri se metsi (P): sebaka sa axial hammoho le khoele holim'a workpiece ho tloha ntlha e le 'ngoe profil ho ea ntlha e tšoanang e latelang. Nahana ka eona e le kgutlotharo e potolohang workpiece. Sebopeho sena sa khutlo-tharo se etsa qeto ea katleho le ts'ebetso ea likarolo tse khoele. Palo e nepahetseng ea sekhahla sa khoele e bohlokoa ho netefatsa ho lekana hantle, kabo e nepahetseng ea mojaro le ts'ebetso e ntle ea likarolo tse entsoeng ka mochini.

Bakeng sa ho tseba hantle hore na ho phahama hakae, moetsi o sebelisa theknoloji e tsoetseng pele ea mochini oa CNC. CNC machining, kapa machining a taolo ea linomoro tsa komporo, ke ts'ebetso ea tlhahiso e sebelisang lisebelisoa tsa mochini o laoloang ke komporo ho tlosa thepa ka nepo thepa e tala ho etsa likarolo tse entsoeng ka mochini. CNC Machining Online Quoting ke ts'ebeletso e fanoang ke lik'hamphani tse ngata tsa litsebi tse lumellang bareki ho fumana likhakanyo tsa litheko kapele le ha bonolo bakeng sa tloaelo ea bona.Likarolo tsa mochini oa CNC.

Anebon ke k'hamphani e etellang pele indastering ea lisebelisoa tsa thepa, e fanang ka lits'ebeletso tsa machining tsa CNC tsa boleng bo holimo le tloaelo ea ho sila ea CNC ho tloha ha e qala ka 2010. Ka sehlopha sa litsebi le lisebelisoa tsa morao-rao, Anebon e fana ka lihlahisoa tse sebetsang hantle, tsa boleng bo holimo. . Mechini e tloaelehileng e tsoang Japane. Li-mill tsa bona tsa CNC le li-lathe hammoho le li-grinders tse ka holim'a metsi li ba thusa ho fana ka lihlahisoa tse nepahetseng le boleng bo ikhethang. Ho feta moo, Anebon e netefalitsoe ke ISO 9001: 2015, e bontšang boitlamo ba bona ba ho boloka litekanyetso tse phahameng ka ho fetisisa tsa tlhahiso le khotsofalo ea bareki.

Ha ho baloa molumo oa lentsoe, hangata o hlahisoa ka likhoele ka inch (TPI) kapa limilimithara. Bakeng sa likhoele tsa metric, bophahamo bo hlalosoa e le sebaka sa limilimithara lipakeng tsa likhoele tse peli tse bapileng. Ka lehlakoreng le leng, bakeng sa litsamaiso tsa likhoele tse thehiloeng ho inch, TPI e emetse likhoele ka lisenthimithara tse lekanang. Ho lekanya khoele ka nepo ho bohlokoa ho etsa bonnete ba ho lumellana lipakeng tsa likarolo tse khoeleng le ho qoba mathata a ka bang teng joalo ka ho hlepha, ho brittleness kapa kabo e sa lekaneng ea mojaro.

Mechine ea CNCe phetha karolo ea bohlokoa ho fihlelleng tekanyo e nepahetseng ea molumo. Ka ho sebelisa mahlale a morao-rao le lisebelisoa tse nepahetseng, likarolo tsa mochini oa CNC li ka fihlela litlhoko le litlhaloso tse thata ka ho fetesisa. Mananeo a tsoetseng pele a software a nolofalletsa mechini ea CNC ho etsa lipalo tse rarahaneng tsa khoele, ho etsa bonnete ba hore molumo o nepahetseng oa khoele o finyelloa bakeng sa ts'ebeliso e 'ngoe le e' ngoe e ikhethang.

Ka bokhutšoanyane, ho utloisisa ho rarahana ha molumo oa molumo le ho o bala ka nepo ho bohlokoa ho etsa likarolo tse entsoeng ka mochini oa boleng bo holimo. Ka ho sebelisa litšebeletso tsa mochini oa CNC le ho sebelisa tloaeloCNC ho sila, bahlahisi ba ka finyella ho nepahala le boleng bo ikhethang lihlahisoa tsa bona. E ikemiselitse ho sebetsa hantle le ka lisebelisoa tsa morao-rao, lik'hamphani tse kang Anebon li etella pele ho fana ka lits'ebeletso tse tšepahalang, tse sebetsang hantle tsa CNC tsa ho qotsa marang-rang. Ka tsebo e nepahetseng ea molumo oa khoele, bahlahisi ba ka etsa likarolo tse nang le likhoele tse fihlelang litekanyetso tse phahameng ka ho fetisisa tsa ts'ebetso le ts'ebetso.

1. Palo le mamello ea khoele e ka ntle ea 60° e bōpehileng joaloka leino (tekanyetso ea naha GB197/196)

a.Calculation ea pitch diameter saese ya motheo

Boholo ba motheo ba bophara ba sekontiri ba khoele = bophara bo boholo ba khoele - pitch × coefficient value.

Kemelo ea foromo: d/DP×0.6495

Mohlala: Palo ea bophara ba sekontiri sa khoele ea M8 ea kantle

8-1.25×0.6495=8-0.8119≈7.188

b. Ka tloaelo ho sebelisoa 6h kantle ho khoele sekontiri se metsi mamello (e thehiloeng ho khoele sekontiri se metsi)

Boleng bo kaholimo ba moeli ke "0"

Moeli o ka tlase ke P0.8-0.095P1.00-0.112P1.25-0.118

P1.5-0.132P1.75-0.150P2.0-0.16

P2.5-0.17

Foromo e kaholimo ea lipalo ke saese ea mantlha, 'me moeli o tlase oa lipalo oa d2-hes-Td2 ke phallo e lumellehang ea boholo ba ho kheloha.

Boleng ba mamello ea 6h grade pitch bophara ba M8: boleng ba moeli o ka holimo 7.188 boleng bo tlaase ba moeli: 7.188-0.118 = 7.07.

C. Ka tloaelo ho sebelisoa 6g grade ea kantle ho khoele sekontiri sekontiri se khelohileng motheo: (ho ipapisitsoe le khoele ea molumo)

P0.80-0.024P1.00-0.026P1.25-0.028P1.5-0.032

P1.75-0.034P2-0.038P2.5-0.042

Foromo e kaholimo ea palo ea d2-ges ke phapang ea boholo ba mantlha

Foromo e tlase ea palo ea d2-ges-Td2 ke eona mamello ea boholo bo fapaneng

Ka mohlala, boleng ba mamello ea 6g grade pitch diameter ea M8: boleng bo phahameng ba moeli 7.188-0.028 = 7.16 boleng bo tlaase ba moeli: 7.188-0.028-0.118 = 7.042.

Hlokomela:

① Mamello ea likhoele tse kaholimo li thehiloe holim'a likhoele tse mahoashe, 'me likhoele tsa likhoele tse ntle li fetotsoe ka nepo, empa mamello e atolosoa feela, kahoo taolo e ke ke ea feta moeli o tloaelehileng, kahoo ha ba tšoauoa tafoleng. Bokaholimo bo ile ba tsoa.

② Tlhahisong ea 'nete, ho ea ka ho nepahala ho hlokehang ke moralo le matla a extrusion a lisebelisoa tsa ts'ebetso ea khoele, bophara ba molamu o pholisitsoeng o eketsoa ka 0.04-0.08 ha o bapisoa le bophara ba khoele e entsoeng, e leng bophara ba khoele e pholisitsoeng. thupa. Ka mohlala, bophara ba k'hamphani ea rona ea M8 e ka ntle ea khoele ea 6g ea khoele e bentšitsoeng ke 7.08-7.13, e ka hare ho mefuta ena.

③ Ha ho nahanoa ka litlhoko tsa ts'ebetso ea tlhahiso, moeli o tlase oa taolo oa bophara ba sekontiri sa khoele ea kantle ntle le kalafo ea mocheso le kalafo ea bokaholimo tlhahisong ea 'nete e lokela ho bolokoa maemong a 6h ka hohle kamoo ho ka khonehang.

2. Palo le mamello ea bophahamo ba molumo oa khoele ea ka hare ea 60° (GB197/196)

a.6H boemo ba khoele ea sekontiri se bophahamo ba mamello (e thehiloeng holim'a khoele ea khoele)

moeli o ka holimo:

P0.8+0.125P1.00+0.150P1.25+0.16P1.5+0.180

P1.25+0.00P2.0+0.212P2.5+0.224

Boleng bo tlase ba moeli ke "0",

Foromo e kaholimo ea palo ea 2+TD2 ke boholo ba motheo + mamello.

Ka mohlala, bophara ba molumo oa khoele ea ka hare ea M8-6H ke: 7.188 + 0.160 = 7.348 moeli o ka holimo: 7.188 ke moeli o ka tlaase.

b. Mokhoa oa ho bala bophara ba sekontiri sa khoele e ka hare o tšoana le oa khoele e ka ntle

Ke hore, D2 = DP × 0.6495, ke hore, bophara ba sekontiri sa khoele ea ka hare bo lekana le bophara ba sekontiri × boleng ba coefficient.

c.6G sehlopha sa khoele sekontiri se metsi kheloha ea motheo E1 (e thehiloeng holim'a khoele ea khoele)

P0.8+0.024P1.00+0.026P1.25+0.028P1.5+0.032

P1.75+0.034P1.00+0.026P2.5+0.042

Mohlala: Moeli o ka holimo oa bophara ba molumo oa khoele ea ka hare ea M86G: 7.188+0.026+0.16 = 7.374

Moeli o ka tlaase: 7.188+0.026 = 7.214

Foromo e kaholimo ea moeli 2+GE1+TD2 ke boholo ba mantlha ba bophara ba sekontiri+ho kheloha+ho mamellana.

Foromo e tlase ea boleng ba 2+GE1 ke saese ea pitch diameter+deviation

3. Palo le mamello ea bophara bo boholo ba khoele e ka ntle (GB197/196)

a.Moeli o ka holimo oa 6h bophara bo boholo ba khoele e ka ntle

Ke hore, mohlala oa boleng ba khoele M8 ke φ8.00, 'me moeli o ka holimo oa mamello ke "0".

b. Mamello ea moeli o ka tlase oa bophara bo boholo ba sehlopha sa 6h sa khoele ea kantle (e ipapisitseng le molumo oa khoele)

P0.8-0.15P1.00-0.18P1.25-0.212P1.5-0.236P1.75-0.265

P2.0-0.28P2.5-0.335

Foromo ea lipalo bakeng sa moeli o ka tlase oa bophara bo boholo: d-Td ke mamello ea motheo ea boholo ba bophara ba khoele.

Mohlala: Khoele ea ka ntle ea M8 6h boholo ba bophara bo boholo: moeli o ka holimo ke φ8, moeli o ka tlaase ke φ8-0.212=φ7.788

c.Palo le Mamello ea Diameter e kholo 6g ea Khoele e Ntle

6g kheloha ea khoele ea kantle (e ipapisitse le molumo oa khoele)

P0.8-0.024P1.00-0.026P1.25-0.028P1.5-0.032P1.25-0.024P1.75–0.034

P2.0-0.038P2.5-0.042

Foromo e kaholimo ea palo ea d-ges ke tekanyo ea mantlha ea khoele e khelohileng ea referense e kholo.

Foromo e tlase ea palo ea d-ges-Td ke tekanyo ea mantlha ea khoele e kholo ea li-diameter-baseline deviation-tolerance.

Mohlala: M8 thread ea ka ntle 6g sehlopha sa bophara bo boholo moeli o ka holimo φ8-0.028 = φ7.972.

Moeli o ka tlaase φ8-0.028-0.212 = φ7.76

Tlhokomeliso: ① Bophara bo boholo ba khoele bo khethoa ke bophara ba khoele e bentšitsoeng le tekanyo ea ho khathala ha khoele e kolobang/rolara ea leino, 'me boleng ba eona bo fapana ho lekana le bophara bo ka holimo le bo bohareng ba khoele. Motheong oa sesebelisoa se tšoanang se se nang letho le sa khoele, bophara ba bohareng bo nyane, bophara bo boholo bo boholo, 'me ka tsela e fapaneng, bophara bo bohareng bo boholo, bophara bo boholo bo nyane.

② Bakeng sa likarolo tse hlokang phekolo ea mocheso le phekolo ea holim'a metsi, ho nahanoa ka kamano pakeng tsa theknoloji ea ho sebetsa le tlhahiso ea sebele, bophara bo boholo ba khoele bo lokela ho laoloa moeling o ka tlaase oa sehlopha sa 6h hammoho le 0.04mm kapa ho feta. Ka mohlala, bakeng sa khoele e ka ntle ea M8, bophara bo boholo ba khoele ea ho roala (rolling) e lokela ho tiisetsoa hore e ka holimo ho 7.83 le ka tlase ho 7.95.

4. Palo le mamello ea bophara bo nyane ba khoele ea ka hare

a.Palo ea boholo ba motheo ba bophara bo bonyenyane ba khoele e ka hare (D1)

Boholo ba motheo ba khoele e nyenyane ea bophara = boholo ba motheo ba khoele ea ka hare - pitch × coefficient

Mohlala: Boholo ba motheo ba bophara bo bonyenyane ba khoele ea ka hare M8 ke 8-1.25 × 1.0825 = 6.646875≈6.647

b. Palo ea khoele ea ka hare 6H mamello e nyenyane ea bophara (e thehiloeng holim'a khoele ea khoele) le boleng bo fokolang ba bophara

P0.8+0.2P1.0+0.236P1.25+0.265P1.5+0.3P1.75+0.335

P2.0+0.375P2.5+0.48

Moeli o ka tlase oa ho kheloha foromo D1 + HE1 ea khoele ea ka hare ea 6H sehlopha ke boholo ba motheo ba khoele e ka hare bophara bo nyane + kheloha.

Tlhokomeliso: Boleng ba leeme ke "0" boemong ba 6H

Foromo ea lipalo bakeng sa moeli o ka holimo oa 6H boemo ba khoele ea ka hare=D1+HE1+TD1, ke hore, boholo ba motheo ba bophara bo bonyenyane ba khoele ea ka hare + kheloha + mamello.

Mohlala: Moeli o ka holimo oa bophara bo bonyenyane ba khoele ea ka hare ea 6H grade M8 ke 6.647+0 = 6.647

Moeli o ka tlase oa bophara bo bonyenyane ba khoele ea ka hare ea 6H grade M8 ke 6.647 + 0 + 0.265 = 6.912

c.Palo ea ho kheloha ha motheo oa bophara bo bonyenyane ba khoele ea ka hare ea 6G (e thehiloeng ho molumo) le boleng ba bophara bo bonyenyane.

P0.8+0.024P1.0+0.026P1.25+0.028P1.5+0.032P1.75+0.034

P2.0+0.038P2.5+0.042

Mokhoa oa ho bala bakeng sa moeli o ka tlaase oa bophara bo nyenyane ba khoele ea ka hare 6G = D1 + GE1 ke boholo ba motheo ba khoele ea ka hare + ho kheloha.

Mohlala: Moeli o ka tlase oa bophara bo bonyenyane ba khoele ea ka hare ea 6G grade M8 ke 6.647 + 0.028 = 6.675

Foromo ea D1 + GE1 + TD1 bakeng sa tekanyo e ka holimo ea moeli oa bophara bo nyenyane ba khoele ea ka hare ea 6G grade M8 ke boholo ba motheo oa khoele ea ka hare + ho kheloha + ho mamellana.

Mohlala: Moeli o ka holimo oa bophara bo bonyenyane ba khoele ea ka hare ea 6G grade M8 ke 6.647 + 0.028 + 0.265 = 6.94

Hlokomela:

①Bophahamo ba leino la khoele ea ka hare bo amana ka ho toba le nako ea ho beha khoele ea ka hare, kahoo sekheo se lokela ho ba ka har'a moeli o ka holimo oa sehlopha sa 6H ka hohle kamoo ho ka khonehang.

②Nakong ea machining ea likhoele tse ka hare, ha bophara bo nyane ba khoele e ka hare bo le nyane, bo theola ts'ebetso ea sesebelisoa sa ho lokisa - pompo. Ho ea ka pono ea ts'ebeliso, bophara bo nyane bo nyane, bo molemo, empa bo nahannoe ka botlalo, bophara bo nyane hangata bo sebelisoa lipakeng tsa moeli o bohareng le moeli o kaholimo, haeba e entsoe ka tšepe kapa aluminium, e lokela ho sebelisoa lipakeng tsa moeli o tlase le moeli o bohareng oa bophara bo bonyenyane.

③Ha bophara bo bonyenyane ba khoele e ka hare e le 6G, e ka bonoa e le 6H. Boemo ba ho nepahala haholo-holo bo nahana ka ho roala ha bophara ba sekontiri sa khoele. Ka hona, feela bophara ba sekontiri sa pompong bo nahanoa nakong ea ts'ebetso ea khoele, 'me bophara bo bonyenyane ha bo nahane. Bophara ba lesoba le khanyang.

5. Mokhoa oa lipalo oa mokhoa oa ho arola hlooho e le 'ngoe

Mokhoa oa ho bala oa karolo e le 'ngoe: n=40/Z

n: palo ya didikadikwe tseo hlooho e arolang e tlamehang ho di fetola

Z: karolo e lekanang ea workpiece

40: nomoro ea hlooho ea indexing e tsitsitseng

Mohlala: Palo ea ho sila hexagon

Kenyelletsa foromo: n=40/6

Palo: ① Nolofatsa likaroloana: fumana karolo e nyane haholo ea 2 'me u arole ka, ke hore, arola palo le denominator ka 2 ka nako e le 'ngoe ho fumana 20/3. Ha a ntse a fokotsa lintlha, karohano ea eona e lekanang e ntse e tšoana.

② Palo ea likaroloana: Mothating ona, ho ipapisitsoe le boleng ba lipalo le denominator; haeba palo le denominator li le kholo, joale palo e etsoa.

20÷3=6(2/3) ke boleng ba n, ke hore, hlooho e arolang e lokela ho fetola li-circles tse 6(2/3). Nakong ena, karoloana e fetohile karoloana; karolo e felletseng ea decimal 6 ke hlooho ea karohano e lokela ho fetola selikalikoe tse 6 tse felletseng. Karolo ea 2/3 e nang le karoloana e ka ba 2/3 feela ea selikalikoe 'me e tlameha ho baloa bocha ntlheng ena.

③ Khetho le palo ea poleiti ea indexing: lipalo tse ka tlase ho selikalikoe se le seng li tlameha ho phethahala ka thuso ea poleiti ea indexing ea hlooho ea indexing. Mohato oa pele oa lipalo ke ho atolosa ka nako e le 'ngoe karoloana ka 2/3. Mohlala: haeba lintlha li holisitsoe ka makhetlo a 14 ka nako e le 'ngoe, ke 28/42; haeba e holisitsoe ka makhetlo a 10 ka nako e le 'ngoe, lintlha ke 20/30; haeba e holisitsoe ka makhetlo a 13 ka nako e le 'ngoe, lintlha ke 26/39…Sekala se atolositsoeng se lokela ho latela daele Khetha palo ea masoba ho eona.

Tabeng ena, o lokela ho ela hloko:

①Palo ea masoba a indexing plate e khethiloeng e tlameha ho aroloa ke denominator 3. Mohlala, mohlaleng o ka holimo, masoba a 42 ke makhetlo a 14 a 3, masoba a 30 ke makhetlo a 10 ho 3, 'me masoba a 39 ke makhetlo a 13 ho 3. .

②Katoloso ea likaroloana e tlameha ho ba hore palo le denominator li atolosoa ka nako e le 'ngoe,' me karohano e lekanang e lula e sa fetohe, mohlala.

28/42=2/3×14=(2×14)/(3×14); 20/30=2/3×10=(2×10)/(3×10);

26/39=2/3×13=(2×13)/(3×13)

28/42 Denominator 42 ke ho sebelisa masoba a 42 a index index bakeng sa indexing; Numerator 28 e ea pele ka lesoba la boemo ba lebili le ka holimo, ebe e phethola lesoba le 28, ke hore, lesoba la 29 ke lesoba la boemo ba lebili la hona joale, 20/30 ke masoba a 10 pele sebakeng se potolohang sa 30-hole index plate, 'me lesoba la 11 ke hantle feela lesoba la lebili lena. 26/39 ke lesoba la boemo ba lebili lena holim'a poleiti ea likoti tse 39, 'me masoba a 26 a masoba a 27 a potoloha pele.

Ha ho siloa hexagon (botšelela), masoba joalo ka masoba a 42, masoba a 30, le masoba a 39 a ka arohang ka 3 a sebelisoa e le sekala: ts'ebetso ke ho potoloha mofeng ka makhetlo a 6, ebe o tsoela pele ka lesoba la boemo ho ea pele. e be lebili le ka holimo ka ho latellana. Fetola 28+1/10+1/26+ hape! Lesoba le ka holimo ho 29/11/27 lesoba le sebelisoa e le lesoba le behang lebili.

Mohlala 2: Palo ea ho sila lisebelisoa tsa meno a 15.

Kenyelletsa foromo: n=40/15

Bala n=2(2/3)

Ke ho fetola li-circles tse 2 tse felletseng, ebe u khetha masoba a indexing a ka arohang ka 3, joalo ka 24, 30, 39, 42.51. Eketsa lesoba le le leng, e leng 17, 21, 27, 29, 35, 37, 39, 45 masoba, e le lesoba la boemo ba lebili lena.

Mohlala 3: Palo ea indexing bakeng sa ho sila meno a 82.

Kenyelletsa foromo: n=40/82

Bala n=20/41

Ke hore: ha feela poleiti ea index e nang le masoba a 41 e khethiloe, fetola 20+1 ka lesoba la boemo ba lebili le ka holimo, ke hore, likoti tse 21 li sebelisoa e le lesoba la boemo ba lebili la hona joale.

Mohlala 4: Palo ea indexing bakeng sa ho sila meno a 51

Ho fetola foromo n = 40/51, kaha lintlha ha li khone ho baloa ka nako ena, o ka khetha feela sekoti ka ho toba, ke hore, khetha poleiti ea index e nang le masoba a 51, ebe o fetola lebili le ka holimo la 51 + 1 sebakeng sa boemo. lesoba, ke hore, likoti tse 52, joalo ka lebili la hona joale. Ho beha masoba e leng.

Mohlala 5: Palo ea indexing bakeng sa ho sila meno a 100.

Kenyelletsa foromo ea n=40/100

Bala n=4/10=12/30

Khetha poleiti ea index ea masoba a 30 ka nako, 'me u behe masoba a 12+1 kapa a 13 holim'a lesoba le ka holimo la lebili e le lesoba la hona joale la ho beha lebili.

Haeba li-disc tsohle tsa indexing li sa fihle ho palo ea likoti tse hlokahalang bakeng sa lipalo, mokhoa oa indexing oa motsoako o lokela ho sebelisoa bakeng sa ho bala, o sa kenyelletsoeng mokhoa ona oa ho bala. Tlhahisong ea 'nete, ho sebelisoa li-gear hobbing, hobane ts'ebetso ea 'nete ka mor'a lipalo tsa indexing ea kompone ha e bonolo haholo.

6. Foromo ea lipalo bakeng sa hexagon e ngotsoeng ka selikalikoe

① Fumana lehlakore le fapaneng la hexagon (S bokaholimo) la selikalikoe sa D

S=0.866D ke bophara×0.866 (coefficient)

② Bala bophara (D) ba selikalikoe ho tloha ka lehlakoreng le leng la hexagon (S surface)

D=1.1547S lehlakore le shebaneng×1.1547 (coefficient)

7. Foromo ea lipalo ea lehlakore le fapaneng le mola o diagonal oa hexagon ka mokhoa o batang oa sehlooho

① Fumana angle e fapaneng ea lehlakore le fapaneng (S) la hexagon e kantle

e=1.13s Lehlakore le hanyetsanang×1.13

② Fumana angle e fapaneng (e) ho tloha lehlakoreng le fapaneng (ma) la hexagon e ka hare

e=1.14s Lehlakore le fapaneng×1.14 (coefficient)

③ Fumana bophara ba thepa ea hlooho e tšekaletseng (D) ho tsoa mahlakoreng a fapaneng a hexagon e kantle.

Bophara (D) ba selikalikoe bo lokela ho baloa ho ea ka lehlakore le fapaneng (sefofane sa s) sa hexagon (formula ea bobeli ho 6), 'me boleng ba setsi sa offset bo lokela ho eketseha ka mokhoa o nepahetseng, ke hore, D≥1.1547s. Chelete ea ho fokotsa ho tloha bohareng e ka hakanngoa feela.

8. Mokhoa oa ho bala oa lisekoere tse ngotsoeng ka selikalikoe

① Etsa selikalikoe (D) ho fumana lehlakore le fapaneng la lisekoere (S surface)

S=0.7071D ke bophara×0.7071

② Fumana selikalikoe (D) ho tloha ka lehlakoreng le leng la sekoere (S surface)

D=1.414S lehlakoreng le fapaneng×1.414

9. Liforomo tsa lipalo bakeng sa mahlakore a fapaneng a lisekoere le li-angles tse fapaneng ka mokhoa o batang oa lihlooho

① Fumana angle e fapaneng (e) ho tloha lehlakoreng le leng (S) la lisekoere tse kantle

e=1.4s ke lehlakore le fapaneng (ma)×1.4 paramethara

② Fumana lehlakore le fapaneng (e) la lehlakore le fapaneng (ma) la lisekoere tse ka hare

e=1.45s ke lehlakore le fapaneng (ma)×1.45 coefficient

10. Foromo ea ho bala molumo oa Hexagon

s20.866×H/m/k e bolela lehlakore le fapaneng×lehlakoreng le fapaneng×0.866× bophahamo kapa botenya.

11. Foromo ea lipalo bakeng sa molumo o fokolitsoeng (cone).

0.262H (D2+d2+D×d) ke 0.262×bophahamo×(bophahamo ba hlooho e kgolo×bophahamo ba hlooho e kgolo+boalo bo bosesane ba hlooho e nyenyane+botenya ba hlooho e kgolo×boalo ba hlooho e nyenyane).

12. Foromo ea lipalo bakeng sa bophahamo ba sekhahla (joalo ka hlooho ea semicircular)

3.1416h2(Rh/3) ke 3.1416×bophahamo×bophahamo×(radius-height÷3).

13. Foromo ea lipalo bakeng sa litekanyo tsa machining tsa lipompo tsa khoele tse ka hare

1. Palo ea pompo e kholo bophara ba D0

D0=D+(0.866025P/8)×(0.5~1.3) ke boholo ba motheo ba khoele e kholo ea bophara ba pompo + 0.866025 pitch÷8×0.5~1.3.

Tlhokomeliso: Khetho ea 0.5 ~ 1.3 e lokela ho khethoa ho latela boholo ba molumo. Ha boleng ba molumo bo le boholo, coefficient e nyane e lokela ho sebelisoa. Ka lehlakoreng le leng, ha boleng ba molumo bo le nyane, coefficient e tsamaellanang e lokela ho ba kholoanyane.

2. Palo ea bophara ba pompo ea molumo (D2)

D2=(3×0.866025P)/8, ke hore, tap diameter=3×0.866025×pitch÷8

3. Palo ea bophara ba pompo (D1)

D1=(5×0.866025P)/8 ke bophara ba theipi=5×0.866025×pitch÷8

leshome le metso e mene,

Palo ea palo ea bolelele ba thepa bakeng sa sebopeho sa lihlooho tse batang tsa libopeho tse fapaneng

Foromo ea molumo oa selikalikoe se tsebahalang ke bophara× bophara×0.7854× bolelele kapa radius×radius×3.1416× bolelele. Ke hore, d2×0.7854×L kapa R2×3.1416×L

Ha u bala, molumo oa X÷diameter÷diameter÷0.7854 kapa X÷radius÷radius÷3.1416 ea thepa e hlokahalang ke bolelele ba boitsebiso.

Foromo ea kholomo = X/(3.1416R2) kapa X/0.7854d2

Ka foromo, X e emela boleng ba molumo oa thepa e hlokahalang;

L e emela bolelele ba boleng ba phepo ea sebele;

R/d e emela radius ea phepelo ea 'nete kapa bophara.

Sepheo sa Anebon ke ho utloisisa ho senyeha ho hoholo ho tloha indastering le ho fana ka tšehetso e holimo ho bareki ba malapeng le ba linaheng tse ling ka pelo eohle bakeng sa 2022 High Stainless Steel Aluminium High Precision Custom Made CNC Turning Milling Machining Spare Part for Aerospace, E le ho atolosa 'maraka oa rona oa machaba, Anebon. haholo-holo fana ka bareki ba rona mose ho maoatle Top quality tshebetso likarolo mechine, likarolo milled le cnc phethola tšebeletso.

China wholesale China Machinery Parts and CNC Machining Service, Anebon e ts'ehetsa moea oa "boqapi, kutloano, mosebetsi oa sehlopha le ho arolelana, litsela, tsoelo-pele ea pragmatic". Re fe monyetla 'me re tla be re tla paka bokhoni ba rona. Ka thuso ea hau e mosa, Anebon e lumela hore re ka theha bokamoso bo khanyang le uena hammoho.

Nako ea poso: Jul-10-2023